The term “Nanotechnology” describes a large field of scientific and technical activities dealing with objects and technical components with small dimensions. Typically, bodies that are in–at least–two dimensions smaller than 0.1 µm are regarded as “nanobjects”. By this definition, a lot of advanced materials, as well as the advanced electronic devices, are objects of nanotechnology. In addition, many aspects of molecular biotechnology as well as macromolecular and supermolecular chemistry and nanoparticle techniques are summarized under “nanotechnology”. Despite this size-oriented definition, nanotechnology is dealing with physics and chemistry as well as with the realization of technical functions in the area between very small bodies and single particles and molecules. This includes the shift from classical physics into the quantum world of small molecules and low numbers or single elementary particles. Besides the already established fields of nanotechnology, there is a big expectation about technical progress and solution to essential economic, medical, and ecological problems by means of nanotechnology. Nanotechnology can only meet these expectations if fundamental progress behind the recent state of the art can be achieved. Therefore, very important challenges for nanotechnology are discussed here.

- limits of nanotechnology

- nanofacility shrinking

- modularity

- sustainability

- hierarchical organiza-tion

- entropy export

- time scales

- life cycles

- Introduction

About half a century ago, nanotechnology was not much more than a vision [1]. However, during the last decades, it has developed quickly, and there are many branches of science and technology which are related to nanotechnology [2]. From the point of application, two fields are particularly far developed: on the one hand, the creation and production of nanomaterials [3] and, on the other hand, the production of electronic chip elements, which play a crucial role in nearly every recent field of advanced technology due to their key role for computer and communication technology, for machine control, sensing, and for many other technical devices.

Highly integrated electronic solid-state devices are built up by billions of single nanostructures, recently. This ultimate degree of integration is based on a very high level of circuit design, micro, and nanolithography, and a lot of special preparation and measurement technologies and sophisticated materials are needed [4]. The enormous power of recent computers is a direct consequence of stepwise downscaling of the minimal structures in microlithography and the continuous improvement of all related technological steps and the equipment for manufacturing over the past five decades. These result in critical structure sizes below about 20 nm in production and below 10 nm in advanced development, which is not very far from the dimension of small molecules [5], and are in the order of magnitude of 1 nm. The basis for this successful development is the general convention of planar technology and a consequent down-scaling of functional structures in the frame of this proved concept.

The opposite development was inspired by the vision of realizing a bottom-up approach instead of a downscaling of microtechniques into the nanometer range. This approach is motivated by the insight into the ability of nature to form very complex functional structures by arranging small molecular units in living cells. The understanding of the chemical structure of complex biomolecules and the causing nature of chemical bonds behind–as it was explained by L. Pauling, F. Crick, J. Watson, and others–gave hope to constructing complex molecular machinery and to build complex functional systems from ultimate small modules artificially [6]. Supermolecular chemistry and strategies of controlled molecular self-assembling [7] are the main approaches for realizing molecular machines [8]. Indeed, these ideas led to a lot of interesting investigations and inventions during the last decades. However, it must be said that the dream of bottom-up nanotechnical manufacturing was not fulfilled, up to now. Thus, very important challenges remain, and some of the important ones will be discussed in the following.

- Overcoming the Limitations of Planar Technology

Planar technology is a technical convention that allows the efficient production of high and extremely high integrated chip devices. The convention ensures to achieve the required exact positioning of large numbers of smallest functional structures on macroscopic carriers, for example, silicon wafers. By the conventions of planar technology, it becomes possible to develop extremely complex architectures of integrated circuits containing billions of single semiconductor elements and ensure their reliable function over trillions of electronics operations. This concept was very successful for more than a half-century. Its fundament is the connection of the macroscopic and microscopic scale in two dimensions, but a strict restriction of the third dimension to the microscopic scale. The complete industry of integrated semiconductors–that means nearly all communication and computer technology–is based on this concept.

The restriction on two lateral dimensions is important for device fabrication and thin-film and lithographic techniques. Technological tools as projection photolithography, lithography with focused or shaped electron and ion beams, and, in particular, the lithographic alignments between subsequent lithographic layers in functional multilayer systems are reliant on the strict application of the planar technological conventions. Planarization steps in the multilayer technology support a high homogeneity and reproducibility in film thicknesses and in the related electronic and other physical properties of micro and nano-patterned structures.

Besides the manufacturing, the planar architectures of semiconductor chip devices are also crucial for operating them. The high surface-to-volume ratio ensures, for example, a sufficiently high heat exchange. In addition, the planar structure supports the integration of sensing components, optical arrays, and other interface components.

The restriction on two dimensions means a restriction in the topology of interconnections, too. On the one hand, a very large and hierarchically structured network of connections is realized in two dimensions. In the third dimension, it is impossible to realize a high number of connections or complex structures because only a few layers can be used for designing them. The restriction to two dimensions means a low degree of connectivity. This is, probably, the most important difference between the architectures of computer chips and brains. The wirings of chips are mainly marked by series connections, which means strongly limited connectivity of logical elements. In contrast, the three-dimensional network of synapses in the brain represents high connectivity and allows huge numbers of parallelized operations.

It has to be remarked, that the electronic switches in integrated circuits are operated in the sub-nanosecond range. They are very fast in comparison to the electrical processes in synapses which are marked by the release and transport of ions and result in a time scale in the order of magnitude of milliseconds. Thus, semiconductor switches are operated about a million times faster than nervous connections. It is a fascinating vision to combine the advantages of both systems: the fast electron transport in technical nanodevices and the enormous parallelization in the three-dimensional brain-like networks.

The extension of micro and nanofabrication from planar technology into the third dimension demands an extension of production methods into the third dimension, on the one hand. On the other hand, the third dimension of devices needs architectures allowing a fast transfer of power, heat, signals, and–probably–masses, too. The thermodynamic power density has to be lowered drastically in comparison with recent electronic standard devices. Architectures with a strongly enhanced degree of connectivity via three-dimensional networks have to be developed. The thin-film technology and the plane-related lithography have to be substituted by three-dimensional patterning and assembling strategies.

There is no convincing concept of how these challenging developments could be initiated, up to now.

- Shrinking of Production Facilities

A second important problem is a blatant disproportion between the sizes of production facilities and functional nanodevices. Integrated solid-state devices are produced, recently, in large cleanroom facilities. In general, the size of facilities and their investment volumes increased with the decrease of the size of lithographic structures during the last decades. This trend must be inverted.

New strategies are needed which allow for creating production facilities for nanodevices which can be downscaled to small dimensions. Future nanotechnology should not only produce nano-scaled objects but also have to use nano-scaled production tools. There are required concepts on how the size of manufacturing systems can be limited to nearly the same order of magnitude as the operated objects and the generated products.

At the moment, it seems to be a crazy illusion to shrink nanofabrication facilities into the nanometer range. However, an important step in this direction is the size reduction from large industrial buildings to table-top machines. The next step leads into the matchbox scale, hopefully, followed by steps into milli and micro-manufacturing systems. It is clear that such a development demands a revolution in production strategies and in the designing of production facilities.

It is very probable that these steps cannot be continued with the keeping of all traditional architectures for devices and facilities and for using identical materials. However, the need for miniaturization of production tools is not the only reason for changing materials and technologies. At least from the point of view of sustainability (see below) a strong re-thinking about the character of the recent industry is required, too. The challenges from the point of view of shrinking of nanotechnical production systems and the requirement of environment-adapted production procedures point in the same direction.

- Completed Sustainability

During the last decades, a lot of discussions and demands concerned the conversion of traditional industrial energy production into sustainable energy management. In the beginning, this discussion was mainly devoted to saving fossil resources. Meanwhile, the need for atmosphere protection became so urgent that the limitation of fossil resources such as coal, gas, and oil stepped into the background. The arguments for closing all power plants which use fossil energy resources as a substitution for fuel-driven machines and cars by electrically driven are coming mainly from the insight into the non-reversible changes in earth climate due to continuous burning of fossil resources. The insight into rising danger for human life on earth, climate change-induced desertification, human miseries, and misery-driven migration are strong arguments for re-enforcing nuclear power despite its non-sustainable character and all unsolved safety and waste-deposition problems.

Sustainable energy production is related to the choice of exploiting spot-concentrated resources or using large surface areas. The classical energy production using coal, oil, gas, and uranium–and to a certain extent, the use of waterpower, too–are spot related. The concentration of energy carrying matter on small spots made energy production comparatively cheap, convenient, and profitable. However, it is connected with deep artificial impacts into the local natural situations and into the global natural material cycles.

Sustainable energy production by solar-thermal, photovoltaic, and wind energy is related to the earth's surface. Larger areas have to be involved in energy production. This aspect moves these technologies close to the basis of photosynthesis by plants and photosynthetic microorganisms. Here, nanotechnology is obviously required to contribute to sustainable energy production by the use of the sunlight illuminating the earth's surface. The question is if using giant windmills and large semiconductor arrays for photovoltaics is the right way for the future.

With a closer look at the arising global problems, the problem of sustainable production of energy is recognized as only the tip of the iceberg. For the future, the rearrangement of all production and consumption processes for achieving complete sustainability is on the agenda. In the future, we have to close the mines and quarries, we have to substitute many plastics and inorganic semiconductors and metals as far as possible, and we have to construct closed-loop strategies for all needs in industry and in everyday life [9]. This demand concerns all devices and production facilities and also concerns the materials used for the construction of windmills and photovoltaic cells. Finally, all human activities have to become adapted to the natural material cycles and their intrinsic time scales [10].

For solving the connected problems and to find new solutions, important hopes are directed to smart technologies, among them nanotechnology [11]. In principle, the problems should be solvable by nanodevices. Living nature shows that biomolecular nanomachines can be based on completely recyclable components. They are able to synthesize a large spectrum of substances, food for many different organisms, and technically usable materials. This type of machinery is able to collect energy and convert it into the energetically charged matter and molecular building blocks by photosynthesis. The sustainability of these processes is kept stable as long as all human activities are part of the natural material cycles, known from traditional agriculture and use of forests, but it gets lost in the case of the most recent types of industrial use.

Recently, there is no clear picture of how nanotechnology can offer the right perspectives for the development of sustainability for industrial production. Nanotechnical devices as well as the majority of applied nanomaterials are made by production concepts that are very far from sustainability including the use of non-renewable resources and the distribution of toxic side products and wastes. For a fundamental change, the most inorganic components have to be substituted by organic–or better–biological materials which can easily be recycled by natural environmental processes. A simple picture might illustrate how far we are from this goal: Imagine a car, an airplane, or even a computer that can be composted in forest soil or in a garden's compost heap!

This strange picture also gives a spotlight on the state of the bottom-up strategy of nanotechnology. The basic idea includes the possibility to substitute classical machines with molecule-scale devices, inorganic macroscopic bodies by organic by filigree nanoscaled molecular architectures. Macroscopic shaping and assembly by macroscopic tools should be substituted by highly specific molecular interaction and self-assembling. The vision of a transition from top-down strategies with its inorganic basis and harsh operations to the soft materials and self-controlled careful processes in the frame of the bottom-up concept is more than three decades old. However, a real change in system designs and industrial production concepts is not recognizable, up to now.

An honest look into the recent state of nanotechnology discloses a disillusioning picture: On the one side stands the top-down strategy which is technically and economically successful but far away from sustainability. On the other side stands the bottom-up strategy which has created a lot of fascinating research projects for more than three decades but brought no breakthrough for sustainable production in any important direction.

- Learning from Nature

5.1. The Bottom-Up Approach

The idea of constructing complex nanomachines by chemical techniques, macromolecular, supermolecular, and biomolecular chemistry, was pushed forward in the frame of the nanotechnical “bottom-up approach” [12]. The main stimulation for the bottom-up concept has deviated from the fascinating model of functional nanostructures in living nature. Biomacromolecules, microorganisms, and highly specialized cells of different tissues are motivated to search for the realization of analog or similar nanosystems by technical means. The fascinating world of natural nanosystems was opened by a deep insight into the chemical structure of molecules and a detailed understanding of molecular biological and biochemical mechanisms. The most important message from living nature is that we can learn a lot about nanotechnology [7].

This learning starts with insight into the mechanisms of natural sustainability. All technologies with the claim of sustainability have to respect the natural cycles of matter and their time scales. Life on earth can be protected, and the future of mankind can be ensured if we work with and not against the natural material and life cycles. Future material management has to be integrated completely into the natural cycles of matter. Future technologies including nanotechnology have to be based on this integration into this natural network of matter flows.

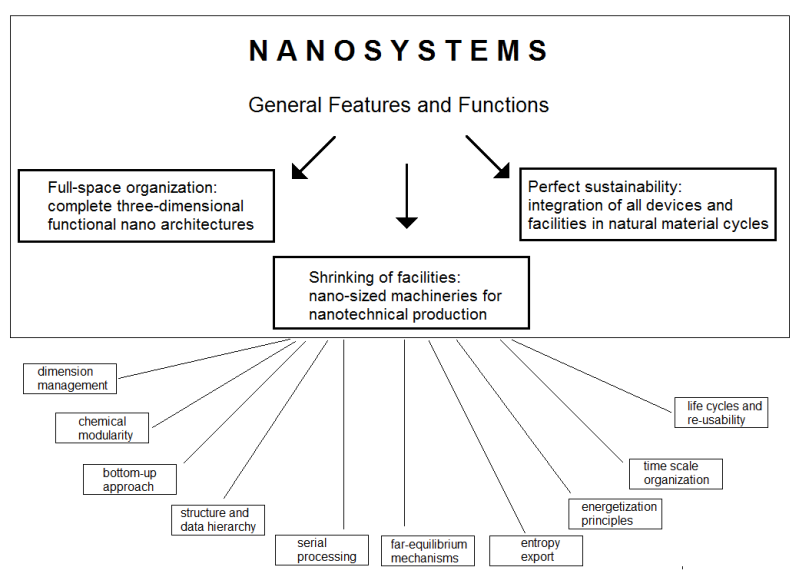

The most amazing aspect of natural nanoworld is the realization of reliable and reproducible processes of molecular self-organization under conditions of strong thermal fluctuations resulting in bridging the level of molecular building blocks with the micrometer-scaled size of cells containing billions of these smallest units. Meanwhile, many details of the molecular processes are well understood and can be modified in the frame of advanced biochemistry, molecular and cell biology, and molecular biotechnology [13]. However, despite this impressive scientific state of the art [14], there is no new creation of comparable systems by technical means. Therefore, the question remains, what makes natural nanosystems so unique and efficient (Figure 1).

Figure 1. Fundamental requirements for future nanosystems.

Figure 1. Fundamental requirements for future nanosystems.

5.2. Chemical Modularity–Syntheses Using Molecular Standard Building Blocks

From a chemical point of view, biological cells are extremely complex. Despite this enormous complexity it is fascinating to see, that nature is able to organize cellular activities, metabolic networks, responsivity against changes in environmental conditions, and steering the cell cycle by highly parallelized biochemical reactions with high efficiency and reliability. The fundament is the fact that key molecules and their processing–synthesis, application, and decomposition–follow very clear rules and mechanisms. The restriction on certain classes of key molecules and reactions is still more important than the high number of different chemical species.

The molecular processes are strictly based on standardization and modularity. The conventions for this molecular standardization are not only fixed for one organism or for one species but for the complete system of life–from the simplest bacteria up to highly developed plants and animals. This standardization is perfectly represented by nucleic acids and proteins. All DNA molecules are constructed by four different standard modules, only–the four different nucleotides. Single molecular strands of DNA present a linear arrangement of these few standard building units. The simple construction principle, the availability of enzymes as natural tools for processing of DNA fragments, and the principle of molecular recognition by base-pairing allowing for the synthesized manipulation of DNA in the artificial molecular construction is an impressive example for the realization of a bottom-up approach [15,16].

Besides nucleic acids, proteins are built by a modular chemical principle, too. All proteins are primarily synthesized from a set of 20 alpha-amino acids. The huge variability in structures and functions of proteins is made from this standardized set with only slight post-translational modifications. It is very astonishing what an incredibly large spectrum of biochemical activities and cellular functions is implemented by the arrangement of these 20 amino acids in the right linear chain, only. Meanwhile, the structure and properties of natural proteins can not only be enlightened but modified in the frame of molecular engineering [17].

The limitations of these few standard modules have less to do with the unique and expedient properties of the amino acids as substance class but must be specially explained by the ultimate need of limitation. Probably, other of the millions and billions of different chemical substances could be suited for the creation of a powerful modular system. The deciding trick is the restriction to one special molecular system which was optimized in the early biomolecular evolution.

5.3. Management of Geometric Dimensions

Molecular tools are demanded special structures, recognition, and binding sites, for special chemical functionalities and combinations of stiff and mobile molecular components. It is clear, that these requirements can only be met by three-dimensional molecular architectures. Natural chain molecules as nuclei acids and peptides are primarily synthesized as linear objects. These constitutional elements form a chain that can be described by a sequence of characters. However, despite functioning as linear information-carrying molecules, both substance classes are able to form complex three-dimensional structures, spontaneously [18]. The folded proteins–and also catalytic nucleic acid molecules folded by internal base-pairing–represent, indeed well-defined and functional three-dimensional geometries.

Although the three-dimensional character is very important for the biomolecular function of most proteins, they are not synthesized by the three-dimensional molecular mounting of the basic modules. In opposite, they are formed as linear objects, primary, and only folded secondary in secondary and tertiary structures. The mastery of three-dimensional space is based on a primary restriction to one dimension. Later only, this linear structure is self-organizing into a three-dimensional architecture by a program encoded in the order of building units inside the original linear chain.

Recently, technical systems are available to build such molecular chains by automated syntheses. They are well suited for the generation of DNA libraries which can be used for many purposes, for example for DNA nanotechnology and DNA origami arrangements [16]. DNA can also be used for molecular labeling and for the creation of DNA-encoded chemical libraries [19,20]. In principle, oligopeptides and–to a certain length- polypeptides can be generated by automated solid-phase syntheses in a similar way. However, besides these biologically created substance classes of sequence molecules like nucleic acids and proteins, no other substance systems for molecular construction by folding (one-dimensional) molecular sequences into a large spectrum of there-dimensional molecular architectures are available. The usual synthetic polymers, copolymers, block copolymers, and related systems are far away from intelligent dimension management and self-optimized three-dimensional folding.

It is an urgent challenge to evaluate which artificial modular chemical systems could be of interest for technical purposes and fulfill the following requirements:

- simple chemical building units

- automatable free synthesis of sequence molecules (sequence generation)

- high variability of chemical, mechanical and electronic properties with a small set of different building units

- self-organized folding into well-determined three-dimensional functional structures

- accessibility of characterization by automated sequencing (sequence read-out)

- transferability of sequence information into other classes of sequence molecules

- replicability of sequence molecules

5.4. Serial Processing

The crucial advantage of sequence molecules is their one-dimensional character. It ensures the possibility of direct transfer of chains of commands or characters into linear spatial arrangements and vice versa. This linear principle is of central importance in technical processes and found, for example, in the linear character of production in assembly lines, in the sequence of characters, words, and sentences in texts as in the linear structure of computer programs. It is also essential for the biological synthesis and replication of key molecules like DNA, RNA, polysaccharides, and proteins. All these biomolecules are generated or copied in a linear process, by stepwise addition of building units.

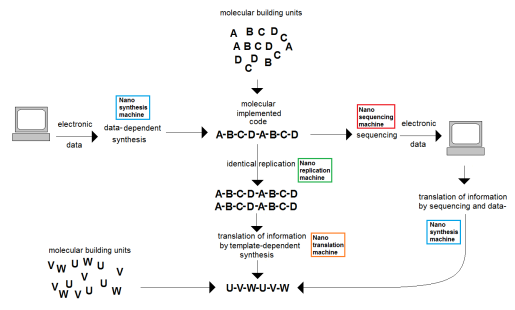

In future molecular nanotechnology, systems for serial processing are required, too. There have to be developed micro or nanomachines for molecular manufacturing and conversion (Figure 2). This includes the following functions:

Figure 2. Basic processes for conversion of data and molecular-encoded information and realization and modification of molecular functionality.

Figure 2. Basic processes for conversion of data and molecular-encoded information and realization and modification of molecular functionality.

- copying of sequence molecules:

There is a nanotechnical system required which is able to recognize a certain type of sequence molecules formed by–at least–two classes of molecular building units, to use it as a template, and to catalyze the synthesis of an identical molecule, which means, with the identical order of molecular building units inside the molecular chain.

(In analogy to replication of nucleic acids, for example [21,22]).

- readout of molecular sequence information:

There is required a nanotechnical system that is able to recognize a sequence of molecules, distinguish different molecular building units inside the molecular chain of this sequence molecule, and transfer this sequence information into a physical signal readable by technical standard systems like an optical or an electronic sensor.

(Miniaturized sequencing machine).

- synthesis of sequence molecules by program-controlled stepwise addition of building units:

There is a nanotechnical system required that is able to receive a sequential data set from a technical standard data system like optical or electronic devices, and to translate, this information into a synthesis program for chemical coupling of molecular building units into a molecular chain with a sequence of building units exactly corresponding to the input data set [23].

(Miniaturized synthesis machine).

- translation of the information content of one sequence molecule to another type of sequence molecule:

There is a nanotechnical system required that is able to recognize a certain type of sequence molecules formed by – at least – two classes of molecular building units and to use it as a template for the catalytic synthesis of sequence molecules of another type of sequence molecules.

(In analogy to transcription or translation process in molecular biology).

5.5. Hierarchy of Molecular Structures and Information Units

It is a trivial fact that the required complex nanotechnical machinery consists of large numbers of atoms and building units. It is impossible to control a large number of components without having an ordering mechanism. Therefore, a hierarchical structure is required. Such a hierarchy has to involve two simple main aspects: (1) Lower levels of objects (or sub-systems) in the hierarchy are used as components for the construction of higher levels. (2) The knot strength in the hierarchy–which means the number of elements belonging to one common parent unit–should not be too large and in the same order of magnitude for all organization levels, which means within the complete hierarchy.

The English language is a nice example of a hierarchical organization of information-carrying units: The first level is formed by the letters (characters). The second level is formed by words, the third level by sentences, the fourth level by paragraphs, the fifth level by chapters, and the sixth level by books, typically. The whole system is forming a one-dimensional data set, meaning a structured line of characters that can be sequentially written and read. Synthetic molecular systems should be one-dimensionally constructed in the same way: Nature shows that nucleic acids are structured similarly to language using the nucleotides as letters forming triplets (like words), genes (like sentences or paragraphs), gen clusters (like chapters), chromosomes (like books) and complete genomes (like a library).

Artificial systems for molecular information storage and processing should be structured in a hierarchical order, too: At the first level, building units have to be defined, for example by limited sets of different monomers which can be used for creating sequence molecules by them. At the second level, modules consisting of several monomers should get a certain meaning, and finally, macromolecules representing large data sets have to be synthesized.

The natural organization of proteins impressively shows how such a hierarchy can work in the nano cosmos [24]: each proteinogenic amino acid consists of four groups of a low number of atoms: three constant groups (carboxyl group COOH, amino group NH2, and central methin group CH) and one variable group. Twenty different amino acids are used for coding all information and chemical functions which are required for the three-dimensional self-organized construction of the folded protein, the so-called tertiary structure. In dependence on the type of protein, one or two further organization levels exist between the level of single amino acids and the complete protein. The first is the formation of secondary structure elements like betasheets and alpha-helices. The second is the formation of domains in the case of proteins which are organized in domains–typically between 2 and about a dozen of these subunits. Finally, two or several proteins are assembled into supermolecules forming the quarternary structure of proteins.

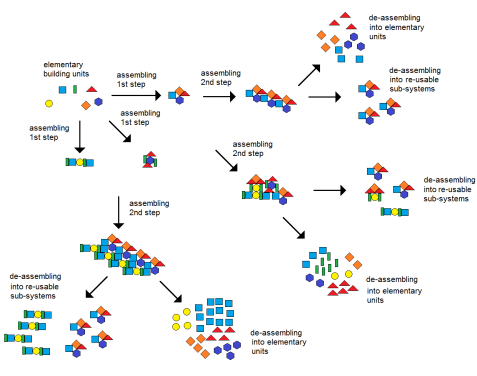

The combination of modularity and hierarchical organization is also an important precondition for consequent sustainability. It supports the organization of life cycles, the de-assembling of systems to different levels of integration, and the re-use of elementary building units as well as of larger modules and sub-systems (Figure 3).

Figure 3. Nested assembling and de-assembling of modular and hierarchical constructed systems for a sustainable circular economy (schematically).

Figure 3. Nested assembling and de-assembling of modular and hierarchical constructed systems for a sustainable circular economy (schematically).

5.6. Hierarchy of Bond Strengths and Coupling of Near-and Far-Equilibrium Processes

Despite the fact that the processes of creation, read-out, and processing of information-carrying molecules are under the control of supermolecular nanomachinery, molecular self-organization is crucial for well-determined molecular processes [25]. All elementary processes proceed with the background of Brownian motion and thermal fluctuation of chemical reactions. Surprisingly, complex directed development processes are based on chemical reactions and can be controlled in spite of the unpredictable single motions in the noise of thermal fluctuations.

How can such a system work? The solution is found by the combination of reactions with more and less distance to the thermal equilibrium. Highly reversible elementary processes are combined with strictly non-reversible procedures. On the one hand, there are reactions marked by low activation thresholds, which permanently run for the adaption of chemical equilibria. On the other hand, there are thermodynamically more demanding reactions marked by higher activation thresholds and are running into a preferential direction as far as the chemical system is kept at a certain distance to the related chemical equilibrium.

These thermodynamic differences present a fundamental condition for controlling complex biochemical reaction networks in living cells. The thermodynamic boundary conditions determine the kinetics of the ongoing chemical processes. They are responsible for the realization of typical time constants in biochemical reactions and in response time to perturbations from outside.

The molecular basis for these different time constants is given by the differences in the bond strengths. Biomolecular processes are using systems of stepwise-structured bond strength. Living nature has realized a complementary system of a hierarchy of structures, a hierarchy of (bio)-chemical time constants, and a hierarchy of molecular bond strengths. The example of proteins impressively shows the connection between the hierarchical molecular structure and the hierarchy of bond stability. Non-polar covalent bonds dominate the lowest structural level, the single amino acids. The internal bonds of the single amino acids are very stable and cannot be split by hydrolyzation. At the next level, connections between single amino acids are formed by peptide bonds, which present a polar covalent bond. They are forming the primary structure of oligo and polypeptides, which can be split by hydrolyzation again into amino acids. At the third level of bond strength hierarchy, dense regular polyvalent structures of hydrogen bridges (“H-bridges”) are responsible for the formation of comparative stable secondary structures as helices and leaflets. Finally, a combination of second-order interactions as dipole interactions, H-bridges, and non-polar interactions contribute to the formation of tertiary and quarternary protein structures.

Despite the fact that, meanwhile, the principal molecular structures and mechanisms of proteins and protein biochemistry are well known, there is no comparable new artificial molecular system that is comparable with peptides and proteins. The translation of the recognized principles of protein structure, protein synthesis, and protein chemistry to other types of molecules is a still-unsolved problem.

5.7. Time-Scale Management

The hierarchical organization of bond strength and bond sensitivity is strongly connected to time-scale management. The chemical strategy of controlling time scales is the control of reaction rates. In principle, the rate of a chemical reaction can be controlled by temperature. However, it has to be reconsidered, that the degree of freedom for varying temperatures is not very compatible with living systems should be achieved, on the one hand. On the other hand, a temperature shift would accelerate or delay all chemical reactions in a complex reaction network. However, a possibility for independent control of individual reaction rates are needed.

Living nature has developed a very subtle instrument for the individual adaptation of reaction rates. The trick consists of the fine-tuning of activation energy. This fine-tuning is achieved by small differences in the efficiency of the biocatalysts. Small variations in the sequence and structure of enzymes result in more or less strong changes in the catalyzed reactions.

For molecular nanotechnology, analogous instruments are required. Efficient catalysts must be constructed in such a way that small variations in their structure can be used for tuning catalytic activity. It is hard to imagine that this challenge can be met simply by inorganic solid-state catalysts as they are recently mainly used in technical heterogeneous catalysis. Instead, enzyme-analog technical catalysts have to be developed. They could help to realize nanotechnical time-scale management in analogy to biochemical reaction networks.

5.8. Active Drive by A Universal Energy Conversion System

Future nanosystems cannot only work by passive chemical or bio-analogous catalytic processes alone. In addition, driven partial processes are required, which allows to elongate reaction systems in controlled directions from the thermodynamic equilibrium.

All living beings are such driven far-equilibrium systems. Working machines as well as working computers, for example, are far-equilibrium systems, as long as they are running. Machines as well as living beings convert input energy in order to build and to maintain a far-equilibrium state.

The introduction of well-controlled driven far-equilibrium processes demands a reliable energy supply. In technical environments, electrical power is used, therefore, mainly for a standardized energy supply. The energy flow of technical systems is, normally, adapted, to the supply and consumption of electrical energy. In contrast, organisms and cells are using chemical energy for maintaining far-equilibrium states. However, these systems need a standardized power supply too. The central role of adenosine triphosphate (ATP) in living cells represents such an important standardized chemical power supply. A high number of driven enzymatic processes are based on the activation of ATP. Cells are producing ATP as a universal energy source enabling them to drive a lot of essential processes against the general thermodynamic time arrow.

Artificial nanosystems need an energy supply too. An electrical power supply by a permanent wire connection is not suited if the nanosystems should be mobile. The advantage of the chemical energizing as it is realized by the ATP system is that the power-carrying molecule itself is not permanently integrated into the nanotechnical systems, but is picked up from the environment. Cells are “charging” their internal system by the “power molecules” and the bionanomachines make a self-service of them. Similar approaches are needed for artificial nanosystems, too. The feeding can be realized by chemical energizing, but also by physical energizing from outside, for example by light or by electricity. In the last-mentioned cases, the outside energy source could be combined with a small nanosystem-internal storage for temporal accumulation of small amounts of energy like a “nano battery system”.

5.9. Entropy Export Management

Energizing, mechanisms with driven processes, and energy conversion are key features of a living or a working system. Each process of energy conversion is connected with the production of entropy. From a thermodynamic point of view, each living being and each working machine produces entropy [26]. These systems have to be open in a thermodynamical sense. They have to be supplied by convertible energy and they have to have the ability to export the produced entropy. The transfer of entropy from the living system to the environment is absolutely required for keeping the system alive and to realize a further development, for accumulation of information and increasing complexity. Active machines, as well as living beings, are “Entropy-exporting” systems.

Without entropy export, running systems would lose their driving forces and could be destroying themselves. Therefore, active nanosystems–like all working machines–have to be equipped with an entropy export mechanism. Typically, this entropy export is marked by the input of “high-value” energy like electrical or chemical energy and output of low-value” energy as heat.

Besides energy conversion, the entropy export can also be realized by chemical reactions or by the distribution of substances. Light-driven systems are producing exporting entropy by uptake of short-wavelength photons and a release of heat or long-wavelength photons.

A key issue is the coupling of all driven nanosystem activities with the entropy export mechanism. Most desirable is a standard entropy management and export strategy which can be connected with different forms of nanosystem activities including information processing, chemical conversion, and synthesis, as well as active mobility and directed motion.

5.10. Local Information Processing, Communication, and Controlled Functional Autonomy

An efficient entropy export management is also the precondition for constructing nanosystems with individual mobility and functional autonomy. Besides the mechanical drive, energy is needed for an internal signal and information processing, too.

Functional autonomy of nanosystems [27] demands internal data storage [28] and information processing. Such nanosystems must be able to receive signals from the environment to convert the primary signals, evaluate them, make a decision about the response to a signal from the outside, and initiate the response activity. The most simply “nano-brain” activity would consist of the realization of case-sensitive activity programs. A higher level of “technical intelligence” could be achieved if autonomous nanosystems have implemented learning mechanisms, for example by algorithms of artificial intelligence.

Technical nanosystems should not operate completely independent of the control from outside. Technical systems are built and released with a certain purpose. Therefore, activity control from outside is necessary. Thus, these functional nanosystems must include communication competence. The data exchange between the nanosystem and a master system would allow for the use of all advantages of operational autonomy of the nanosystem with safe control of its activities. This ability for communication can also be used for decentralized cooperation of several or many partial autonomous nanosystems in the form of swarm activities.

These functions likely cannot be realized by the typical tools of classical construction of technical systems or by the usual strategies of solid-state electronics. It could be rather realized by functional bio-analogous super-molecular assemblies. Obviously, we are at the very beginning of the development of such molecular-based systems.

5.11. Establishing Life Cycles by Controlled Self-Assembling, Dissembling, and Re-Use

One of the most challenging points for future nanosystem development is the absolute need for sustainability. A short look into what the components of recent computer, optical communication, and sensor systems teach us is that the recent material use, as well as the structures of our nano-sized devices, is far away from sustainability. We need special mineral resources for their production, and their recycling is energy-demanding and incomplete. Lost or released components are often a danger for animals, plants, and soils.

It has to be expected, that we cannot completely dispense with solid-state devices, metals, semiconductors, and lithographic technologies. However, future constructions of nanosystems must solve their difficult recycling problems.

The best solution would consist of a complete substitution of inorganic metals and semiconductors, compound semiconductors, as well as doped silicon–by functional organic materials. Therefore, new types of synthetic macromolecules, supermolecules, and functional self-assembling systems are required. A very promising field is the development of new devices based on functional derivatives of graphene and carbon nanotubes. Probably, metals cannot be completely excluded because they are needed for special electronic, optical, and catalytic properties. However, their content in devices should be reduced drastically down to a level comparable with the absolutely required metal ion content in metalloenzymes, for example, enabling them as highly efficient biocatalytic tools.

In addition, and meanwhile, we have to think about nanosystem designs including strategies for easy dissembling in a recycling operation. Still, better would be nanosystems with self-dissembling mechanisms. Such mechanisms could directly supply the raw material for new production processes. Dissembling and production would be realized in one integrated factory. The automated splitting of complex devices in their components and the separation of all different materials would include the possibility to re-use them also in case of completely new designed products. Therefore, conceptual modularity in all devices is required, which includes the construction of state-of-the-art systems and then disassembly of these systems after use to the elementary modules and pure materials for the next generation of use.

The recent “life cycles” of technical devices are determined by their reliable operability and by their level in the process of technological innovation. These criteria have to be completed by the criterion of “recycling lifetime”. This means, that future nanosystems have to be constructed for becoming systematically recycled after a reasonable time of use.

- Outlook: Integrability of Technical Matter in Natural Material Cycles

Recently, the term “recycling” stands for an improvement of material use and protection of natural resources. However, for many technical and everyday applications, only a small number of cycles can be realized. The disaster of overusing the earth’s natural resources can be delayed by the recent strategies of “recycling”, but it cannot be avoided. Therefore, a completely new approach is demanded.

Above everything stands the problem of keeping the earth's biosphere viable. This includes the global cycles of organic and inorganic materials by the non-biological transport and conversion processes and by the entirety of metabolic activities in the biosphere. These natural cycling processes must become the ultimate scale for a sustainable economy.

A real sustainable solution means the complete integration of all production and consumption processes into natural life cycles. Therefore, the type of objects, the applied materials, the combination of materials, and the placing and distribution of all materials, devices, and all residual technical or personal waste must fulfill the criterion of integrability into natural material cycles. This integration is related to the qualities as well as to the quantities of matters and has to further reconsider the very different process rates and environmental conditions in different parts of the earth.

We have to adapt our technical products and product application to the conversion processes in living nature. We have to reconsider the converted materials, their conversion paths, transport mechanisms, and their feedback on the development of living nature in the concerned regions and places. Resource management, material use, and recycling are directly coupled with all aspects of species protection and maintenance of biocenoses. Therefore, we need new thinking about interfaces between the technical and natural world.

Nanotechnology is particularly asked for the development of these new interfaces. It could supply keys for the adaptation of advanced technical solutions to ecological requirements. The future progress in nanotechnology should lead this technical field closer to the conditions and relations of living and ecological systems.

This future convergence between technology and nature will probably become a process in which most technologies have to respect and support the original natural mechanisms. However, in a further future, we will learn how much we can modulate the natural cycles of life and matter without risking the natural global viability. It is to be assumed, that the fusion of nanotechnology with biotechnology and supermolecular chemistry will be a deciding step in this direction.