Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Dean Liu and Version 1 by Jhon Diaz.

Reverse osmosis is the leading technology for desalination of brackish water and seawater, important for solving the growing problems of fresh water supply.

- seawater

- reverse osmosis

- renewable energy

- specific energy consumption

- integration

- hybridization

1. Introduction

Although about 70% of the Earth’s surface is covered by water, just 2.5% is fresh water [1], and it is estimated that only 1% of this is easily accessible [2]. 40% of the world population currently lives in arid areas or islands where fresh water is scarce [3]. Additionally, an increase of droughts worldwide, resilience reduction to climate change from conventional water resources, and overexploitation have increased dependence on desalination technologies, whose implementation is affected by economic, environmental, technical, social, and political factors [4]. Recent inclusion of water in the stock market is an example of the challenges to be faced in the 21st century. It is estimated that by 2025 two thirds of the world population will face shortages of this resource [5], for which governments must establish functional policies addressing social concerns on water access by the poorest communities [6], while guaranteeing the resource for industrial and household purposes.

The 2030 agenda of the United Nations seeks to: “guarantee availability and sustainable management of water and sanitation for all” [7]. Different water management strategies, along with decarbonized desalination and improvement of irrigation systems, are key elements to achieving this goal of sustainable development [8]. There is a wide diversity of technologies for desalination and treatment operations for distinct water types. Energy consumption is shown in Table 1 according to the used type of source. Reducing energy consumption is one of the focuses of researchers [9].

Table 1. Energy consumption for different water sources.

| Water Supply Alternative | Technology | Energy Use (kWh/m3) | Reference |

|---|---|---|---|

| Conventional treatment of surface water | Physical treatments; coagulation | 0.2–0.4 | [10] |

| Water reclamation | -- | 0.5–1.0 | [10] |

| Wastewater treatment | Filtration, coagulation and / or biological treatments | 0.2–0.67 | [11] |

| Indirect potable reuse | -- | 1.5–2.0 | [10] |

| Brackish water desalination | BWRO | 0.8–2.5 | [12] |

| Water Desalination of Pacific Ocean Water | SWRO | 2.5–4.0 | [10] |

| Seawater | SWRO | 2.58–8.5 | [13] |

Seawater and brackish water desalination is one of the most promising processes to solve the world’s water shortages. Its use has increased 6.8% per year in the last decade, equivalent to an annual addition in fresh water production of 4.6 million m3/day and, although plants with the highest capacity are scarce, they contribute to most of the installed capacity [14]. According to the International Desalination Association (IDA), desalination plant capacity in the world reached 99.8 million m3/day in 2017, with some 18,500 plants installed in 150 countries [15]. In China alone, some 142 plants operating with seawater were installed during 2018 [16]. Between January 2019 to February 2020, some 155 new plants were put in operation, increasing the installed capacity by up to 5.2 million m3/day [14].

A total of 61% of the world’s installed desalination capacity corresponds to seawater, while 30% to brackish water. Moreover, 62.25% is used for municipal purposes and 30.2% for industrial use. The Middle East and North Africa contribute 47.5 % to the installed capacity, while East Asia and the Pacific add up to 18.4%, and North America, 11.9% [17,18][17][18]. It is estimated that the world desalination market will grow at a speed of 9% in the coming years. 74% of this growth will come from Europe, the Middle East, and Africa [19].

Currently, more than 20 different technologies are used for seawater desalination [20]. Nonetheless, only a handful of these dominate global water production. Commercial desalination processes are grouped into three broad categories: thermal processes, membrane separations, and emerging technologies. Within thermal processes, multi-effect distillation (MED) and multi-stage flash distillation (MSF) stand out. Reverse osmosis (RO) is the dominant technology [16] in membrane processes, while multi-effect desalination (MED) covers 7% of the installed capacity, and multistage flash systems (MSF) cover 18%, being the most used technology in large-scale dual-purpose desalination plants (water and electricity). On the other hand, RO technologies are more used at the middle and small scale in single process plants (fresh water production) [9], being the ones with the highest participation with 69% of the installed capacity in the world. Other membrane technologies such as nano filtration (NF) contribute 3% to desalination, while electrodialysis (ED) 2%, and reverse electrodialysis (EDR) 1% [18]. In the Middle East, thermal desalination technologies continue to be overriding, due to their integration with power plants and useful life of more than 30 years [21]. Hybridization of thermal desalination technologies with renewable energy sources is one of the trends in research and development that seeks to improve the sustainability of these processes [22].

Other emerging technologies such as capacitive deionization, freezing, humidification-dehumidification, and desalination with gel hydrates are in the preliminary stages of research and development, and have not reached enough maturity for extensive use. Ultrafiltration, nanofiltration, and ionic filtration are often used as technologies for pre- and post-treatment processes [10[10][14],14], being used in small-scale plants and providing less than 2% of the installed capacity in about 940 plants around the world, mainly of electrodialysis and reverse electrodialysis [17]. Electrodialysis is used in industrial applications for selective removal of ions and for brackish water desalination [23]. Desalination through carbon nanopores, inspired by biological aquaporins, is found in a laboratory phase and is a promising technology for desalination [24].

2. Reverse Osmosis (RO)

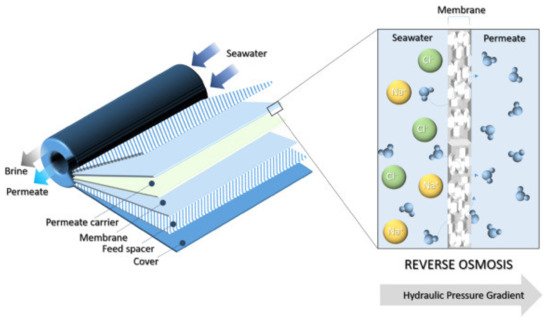

The first RO desalination process was marketed by Loeb & Sourirajan in 1964 [21]. Since then, it has had important advances that have positioned it as the leading technology in desalination operations. It is versatile, thanks to the fact that water evaporation is not necessary for its separation. It has a relatively low energy consumption compared to thermal technologies [67,68][25][26], has high flexibility to work under different salinity conditions, takes up little space, and is easy to operate and automate [69,70][27][28]. Installed capacity in RO plants is currently more than 60 Mt/day, with an annual growth between 10% and 15%, and a combined energy consumption of 100 TWh/year [71][29]. RO units are commercially available in varied sizes, from household applications with capacities of 0.1 m3/day, to sizes for industrial and municipal use with capacities of up to 900,000 m3/day [26][30]. Figure 3 shows a representation of the rolled membranes in common use for seawater desalination processes.

This is currently the most reliable technology for seawater desalination at the lowest capital costs [68][26] and lower energy consumption; however, it has significant maintenance costs associated with pretreatment operations and membrane replacement that, combined, contribute 25% of the total operational cost [3]. According to the water quality to be processed, RO operations can be classified into brackish water plants (BWRO), with salinities between 500 and 10,000 mg/L and seawater plants (SWRO), with salt contents close to 30,000 mg/L. The efficiency of these plants depends on multiple factors such as operating parameters, membrane type, configuration, and feedwater characteristics [69][27].

Osmotic pressure is a trait linked to the colligative properties of mixtures and has important impacts on RO systems. High salinities cause increases in osmotic pressure requiring higher operating pressures. Seawater (35,000 mg/L of salts dissolved) have an osmotic pressure of 2413 kPa. For the system to operate correctly, 10,342 kPa will be needed to overcome both the osmotic pressure and pressure drop across the membrane [69][27]. Therefore, rises in salinity produce higher costs associated with the pumps’ operation and increase the concentration of polarization and fouling of the membranes, reducing their useful life [65,67][31][25].

The first asymmetric cellulose acetate (CA) membrane for RO systems was developed by Loeb and Sourirajan [72][32] in the 1960s. Then, in the 1970s, Cadotte et al. [73][33] developed a new membrane, composed of a thin film composite (TFC), which monopolized the market for many years. Nowadays, and with nanotechnology development, a new type of composite membrane called the thin film nanocomposite membrane (TFN) has been consolidated [74][34]. Normally, there are two techniques that can be used to synthesize TFN membranes. The first technique, also the most popular, is based on the interfacial polymerization (IP) technique in which nanofillers are embedded within the polyamide (PA) layer during the IP process. The second technique is based on the coating or deposition of the surface in which nanofillers are introduced on the existing PA layer. Lately, a combination of these two techniques has been used for the manufacture of nanofillers of TFN membranes [75][35].

The obtained water quality by RO is relatively lower (400 TDS) compared to thermal technologies (25 TDS) [3], however, it is considered acceptable for most agricultural, industrial, and human consumption applications. RO can remove all colloidal material and dissolved solids with a size greater than 1.0 nm from a liquid solution. The process normally consists of three stages: pretreatment, RO operation, and post-treatment [27][36].

The specific energy consumption is also associated with the temperature and water source quality, operating conditions, process scale and energy source, varying between 1.5 kWh/m3 to 15 kWh/m3, while the cost of fresh water can vary between 0.26 US $/m3 up to 1.72 US $/m3 [26,69][30][27]. According to thermodynamic theory, the minimum consumption for desalination of seawater with 33,500 mg/L of salt and 25 °C (Pacific Ocean conditions), and assuming 50% recoveries, is 1.1 kWh/m3. The company Affordable Desalination Collaboration (ADC) achieved consumption of 1.58 kWh/m3, with recoveries of 42% and flows of 10.2 L/m2h [10]. However, when pre-treatment, distribution, and post-treatment consumptions are included, the consumptions of large-scale plants can increase to values between 3.5 and 4.5 kWh /m3 [76][37].

Voutchkov and his team [10] estimated the costs of water production and energy consumption of 20 SWRO plants built in the United States. Table 3 shows results for medium and large-scale plants, (a medium plant is considered to have a capacity of 40,000 m3/day of fresh water production). Energy consumption contributes between 25 to 40% of the fresh water cost. The RO system consumes 71% of the energy of the entire plant, so these values must be included in the pre-treatment energy consumption (10.8% of consumption), feedwater pumping (5.3%), fresh water distribution (5%), and the consumption of other storage facilities, maintenance, and disposal of brine (7.6%).

Table 1.

| Classification | Cost of Water (US $/m3) | Energy Use (kWh/m3) |

|---|---|---|

| Low-end bracket | 0.5–0.8 | 2.5–2.8 |

| Medium range | 0.9–1.5 | 2.9–3.2 |

| High-end bracket | 1.6–3.0 | 3.3–4.0 |

| Average | 1.1 | 3.1 |

The SWRO specific energy consumption was reduced from 20 kWh/m3 in the 1970s to 2.5 kWh/m3 by 2010 [77], all thanks to improvements in the efficiency of the high-pressure pumps, inclusion and advance in energy recovery of devices, continuous improvement of high-performance membranes, and in the design of the membrane module to reduce the pressure drop through it. However, there is still room for maneuvering to implement improvements [78], hybridization with other desalination technologies, multipurpose plants, and coupling with renewable energy are fields of growing interest that can take this technology along increasing paths of sustainability and resilience.

Seawater desalination costs in the large capacity plants currently installed in the world vary between 0.35 and 1.87 US $/m3, and in the case of brackish water it is between 0.35 and 1.53 US $/m3 [14]. In an average SWRO plant, 44% of the costs are associated with energy use [6]. Efficiency of the older plants can only be 10% while the more modern ones reach values of 50%. Motors, pumps and separation systems are the units that contribute the most to system inefficiency [79][38]. Furthermore, RO membranes have made important advances in the last two decades, achieving water production from seawater and other water at reasonable costs [80][39]. Since the operating pressures for SWRO are between 49.34 and 67.11 atm [81][40], the high-pressure pump is responsible for up to 68% of the desalination energy consumption by RO [82][41]. Advanced exergy analyzes performed on a BWRO desalination plant in the Canary Islands, Spain, found exergy destructions (usable energy), 92.94% in the feed pump, 70.61% in the high-pressure pump, and 7.83% in the RO system. About 198.78 kW of exergy is inevitably lost [83][42].

Use of Energy Recovery Devices (ERD) has allowed a significant reduction in energy consumption of the RO thanks to the transfer of hydraulic energy from the brine to the feed, reducing consumption of high-pressure pumps. Francis turbines were the first to be used followed by Pelton turbines. Efficiency of these devices is reduced by the conversion of hydraulic energy from the brine to mechanical energy in the device and the new conversion to hydraulic energy in the water [76][37]. In the 1980s, the development of positive displacement devices, known as isobaric chambers, achieved a considerable increase in the energy transfer efficiency. The DWEER TM from Calder, SalTec DT from KSB company, OSMOREC, and RO-KINETIC are some examples of ERDs based on positive displacement, while the Pressure Exchanger (PX) from Energy Recovery Inc., and the iSave ERD from Danfoss are examples of commercial isobaric chambers based on rotary displacement technologies used in large-scale plants [84][43]. PX devices have been reported to have energy efficiencies greater than 95% [76][37]. There is little research on the development of ERD devices for small-scale plants (production less than 50 m3/day). A study carried out with a new HPP-ERD device showed that with an additional investment of 6.3% in this type of device, it is possible to reduce the fresh water cost produced between 17.8 and 21.9%, as well as reduce the capital recovery period by 12.3%, using ERD devices designed for these low fresh water productions [85][44].

(References would be added automatically after the entry is online)

References

- Chen, C.; Jiang, Y.; Ye, Z.; Yang, Y.; Hou, L. Sustainably integrating desalination with solar power to overcome future freshwater scarcity in China. Glob. Energy Interconnect. 2019, 2, 98–113.

- Schmidt, J.M.; Gude, V.G. Nuclear Cogeneration for Cleaner Desalination and Power Production—A Feasibility Study. Clean. Eng. Technol. 2021, 2, 100044.

- Harby, K.; Ali, E.S.; Almohammadi, K.M. A novel combined reverse osmosis and hybrid absorption desalination-cooling system to increase overall water recovery and energy efficiency. J. Clean. Prod. 2021, 287, 125014.

- Ibrahim, Y.; Ismail, R.A.; Ogungbenro, A.; Pankratz, T.; Banat, F.; Arafat, H.A. The sociopolitical factors impacting the adoption and proliferation of desalination: A critical review. Desalination 2021, 498, 114798.

- Tappe, A. Investors Can Now Trade Water Futures—CNN. Available online: (accessed on 12 December 2020).

- Zetland, D. The role of prices in managing water scarcity. Water Secur. 2021, 12, 100081.

- Leijon, J.; Boström, C. Freshwater production from the motion of ocean waves—A review. Desalination 2018, 435, 161–171.

- Caldera, U.; Breyer, C. Strengthening the global water supply through a decarbonised global desalination sector and improved irrigation systems. Energy 2020, 200, 117507.

- Soliman, M.N.; Guen, F.Z.; Ahmed, S.A.; Saleem, H.; Khalil, M.J.; Zaidi, S.J. Energy consumption and environmental impact assessment of desalination plants and brine disposal strategies. Process Saf. Environ. Prot. 2021, 147, 589–608.

- Voutchkov, N. Energy use for membrane seawater desalination—current status and trends. Desalination 2018, 431, 2–14.

- Yang, J.; Chen, B. Energy efficiency evaluation of wastewater treatment plants (WWTPs) based on data envelopment analysis. Appl. Energy 2021, 289, 116680.

- Pan, S.Y.; Haddad, A.Z.; Kumar, A.; Wang, S.W. Brackish water desalination using reverse osmosis and capacitive deionization at the water-energy nexus. Water Res. 2020, 183, 116064.

- Nassrullah, H.; Anis, S.F.; Hashaikeh, R.; Hilal, N. Energy for desalination: A state-of-the-art review. Desalination 2020, 491, 114569.

- Eke, J.; Yusuf, A.; Giwa, A.; Sodiq, A. The global status of desalination: An assessment of current desalination technologies, plants and capacity. Desalination 2020, 495, 114633.

- Virgili, F.; Brown, H.; Pankratz, T. IDA Desalination Yearbook 2017–2018; Media Analytics Ltd.: Oxford, UK, 2018; pp. 5–15.

- Lin, S.; Zhao, H.; Zhu, L.; He, T.; Chen, S.; Gao, C.; Zhang, L. Seawater desalination technology and engineering in China: A review. Desalination 2021, 498, 114728.

- Elsaid, K.; Kamil, M.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A. Environmental impact of desalination technologies: A review. Sci. Total Environ. 2020, 748, 141528.

- Jones, E.; Qadir, M.; van Vliet, M.T.H.; Smakhtin, V.; Kang, S. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019, 657, 1343–1356.

- Ahmed, F.E.; Hashaikeh, R.; Hilal, N. Solar powered desalination—Technology, energy and future outlook. Desalination 2019, 453, 54–76.

- Liu, S.; Wang, Z.; Han, M.; Zhang, J. Embodied Water Consumption between Typical Desalination Projects: Reverse Osmosis versus Low-temperature Multi-effect Distillation. J. Clean. Prod. 2021, 295, 126340.

- Ahmed, F.E.; Hashaikeh, R.; Diabat, A.; Hilal, N. Mathematical and optimization modelling in desalination: State-of-the-art and future direction. Desalination 2019, 469, 114092.

- Feria-Díaz, J.J.; López-Méndez, M.C.; Rodríguez-Miranda, J.P.; Sandoval-Herazo, L.C.; Correa-Mahecha, F. Commercial Thermal Technologies for Desalination of Water from Renewable Energies: A State of the Art Review. Processes 2021, 9, 262.

- Doornbusch, G.; van der Wal, M.; Tedesco, M.; Post, J.; Nijmeijer, K.; Borneman, Z. Multistage electrodialysis for desalination of natural seawater. Desalination 2021, 505, 114973.

- Kurupath, V.P.; Kannam, S.K.; Hartkamp, R.; Sathian, S.P. Highly efficient water desalination through hourglass shaped carbon nanopores. Desalination 2021, 505, 114978.

- Alsarayreh, A.A.; Al-Obaidi, M.A.; Farag, S.K.; Patel, R.; Mujtaba, I.M. Performance evaluation of a medium-scale industrial reverse osmosis brackish water desalination plant with different brands of membranes. A simulation study. Desalination 2021, 503, 114927.

- Goh, P.S.; Lau, W.J.; Othman, M.H.D.; Ismail, A.F. Membrane fouling in desalination and its mitigation strategies. Desalination 2018, 425, 130–155.

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse osmosis desalination: A state-of-the-art review. Desalination 2019, 459, 59–104.

- Zhao, S.; Liao, Z.; Fane, A.; Li, J.; Tang, C.; Zheng, C.; Lin, J.; Kong, L. Engineering antifouling reverse osmosis membranes: A review. Desalination 2021, 499, 114857.

- Fane, A.G. (Tony) A grand challenge for membrane desalination: More water, less carbon. Desalination 2018, 426, 155–163.

- Anand, B.; Shankar, R.; Murugavelh, S.; Rivera, W.; Midhun Prasad, K.; Nagarajan, R. A review on solar photovoltaic thermal integrated desalination technologies. Renew. Sustain. Energy Rev. 2021, 141, 110787.

- Tedesco, M.; Cipollina, A.; Tamburini, A.; Micale, G. Towards 1kW power production in a reverse electrodialysis pilot plant with saline waters and concentrated brines. J. Memb. Sci. 2017, 522, 226–236.

- Loeb, S.; Sourirajan, S. Sea water demineralization by means of osmotic membrane. Adv. Chem. Ser. 1963, 38, 117–132.

- Cadotte, J.E.; Petersen, R.J.; Larson, R.E.; Erickson, E.E. A new thin-film composite seawater reverse osmosis membrane. Desalination 1980, 32, 25–31.

- Saleem, H.; Zaidi, S.J. Nanoparticles in reverse osmosis membranes for desalination: A state of the art review. Desalination 2020, 475, 114171.

- Ng, Z.C.; Lau, W.J.; Matsuura, T.; Ismail, A.F. Thin film nanocomposite RO membranes: Review on fabrication techniques and impacts of nanofiller characteristics on membrane properties. Chem. Eng. Res. Des. 2021, 165, 81–105.

- Skuse, C.; Gallego-Schmid, A.; Azapagic, A.; Gorgojo, P. Can emerging membrane-based desalination technologies replace reverse osmosis? Desalination 2021, 500, 114844.

- Kim, J.; Park, K.; Yang, D.R.; Hong, S. A comprehensive review of energy consumption of seawater reverse osmosis desalination plants. Appl. Energy 2019, 254, 113652.

- Gude, V.G. Desalination and sustainability—An appraisal and current perspective. Water Res. 2016, 89, 87–106.

- Park, K.; Kim, J.; Yang, D.R.; Hong, S. Towards a low-energy seawater reverse osmosis desalination plant: A review and theoretical analysis for future directions. J. Memb. Sci. 2020, 595, 117607.

- Cañas-Kurz, E.E.; Figoli, A.; Hoinkis, J. Membrane-based power generation from seawater treatment and desalination processes. In Current Trends and Future Developments on (Bio-) Membranes; Figoli, A., Li, Y., Basile, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 239–261. ISBN 978-0-12-816778-6.

- Bhojwani, S.; Topolski, K.; Mukherjee, R.; Sengupta, D.; El-Halwagi, M.M. Technology review and data analysis for cost assessment of water treatment systems. Sci. Total Environ. 2019, 651, 2749–2761.

- Al-hotmani, O.M.A.; Al-Obaidi, M.A.; Patel, R.; Mujtaba, I.M. Performance analysis of a hybrid system of multi effect distillation and permeate reprocessing reverse osmosis processes for seawater desalination. Desalination 2019, 470, 114066.

- Alhathal Alanezi, A.; Altaee, A.; Sharif, A.O. The effect of energy recovery device and feed flow rate on the energy efficiency of reverse osmosis process. Chem. Eng. Res. Des. 2020, 158, 12–23.

- Fellaou, S.; Ruiz-Garcia, A.; Gourich, B. Enhanced exergy analysis of a full-scale brackish water reverse osmosis desalination plant. Desalination 2021, 506, 114999.

- Arenas-Urrea, S.; Díaz-Reyes, F.; Peñate-Suárez, B.; de la Fuente Bencomo, J.A. Technical review, evaluation and efficiency of energy recovery devices installed in the Canary Islands desalination plants. Desalination 2019, 450, 54–63.

- Song, D.; Zhang, Y.; Wang, H.; Jiang, L.; Wang, C.; Wang, S.; Jiang, Z.; Li, H. Demonstration of a piston type integrated high pressure pump-energy recovery device for reverse osmosis desalination system. Desalination 2021, 507, 115033.

More