The fresh fruit chain has been recognized as a very important and strategic part of the economic development of many countries. The planning framework for production and distribution is highly complex as a result. Mathematical models have been developed over the decades to deal with this complexity. This review focuses on the recent progress in mathematically based decision making to account for uncertainties in the fresh fruit supply chain

- fresh fruit

- supply chain

- mathematical model

- agricultural supply chain

- literature review

1. Introduction

1.1. Constraints and Challenges

-

The traditional practice of trade is still dominant. With many intermediary stages as well as complex local rules, the food supply chain is longer and logistically more complex than in developed countries.

-

Storage after harvesting and transportation is quite expensive due to a climate with high temperature and humidity.

-

Although the growth of the formal agro-industrial sector has been rapid, the practice of using low paid labor is widespread. Though labor is cheap (and often unskilled), there is a high turnaround. Companies/farms must deal with workforce shortages during busy periods at the beginning and the end of the season when planting and harvesting take place, offering opportunities for workers to quickly change employers for better pay.

-

Communication and the exchange of information between value chain partners in harvesting, preliminary processing, packing, labelling, preserving and transportation is often very poor, as is consumer awareness and the usage of agricultural products.

-

Farmers are the most important factor in the food supply chain. However, most of them cannot set a good price for their products, due to these complex elements and their lack of market information and experience. The price for their products is often determined by traders, although cooperatives and fair trade have emerged through the last 50 years.

1.2. Influencing Elements

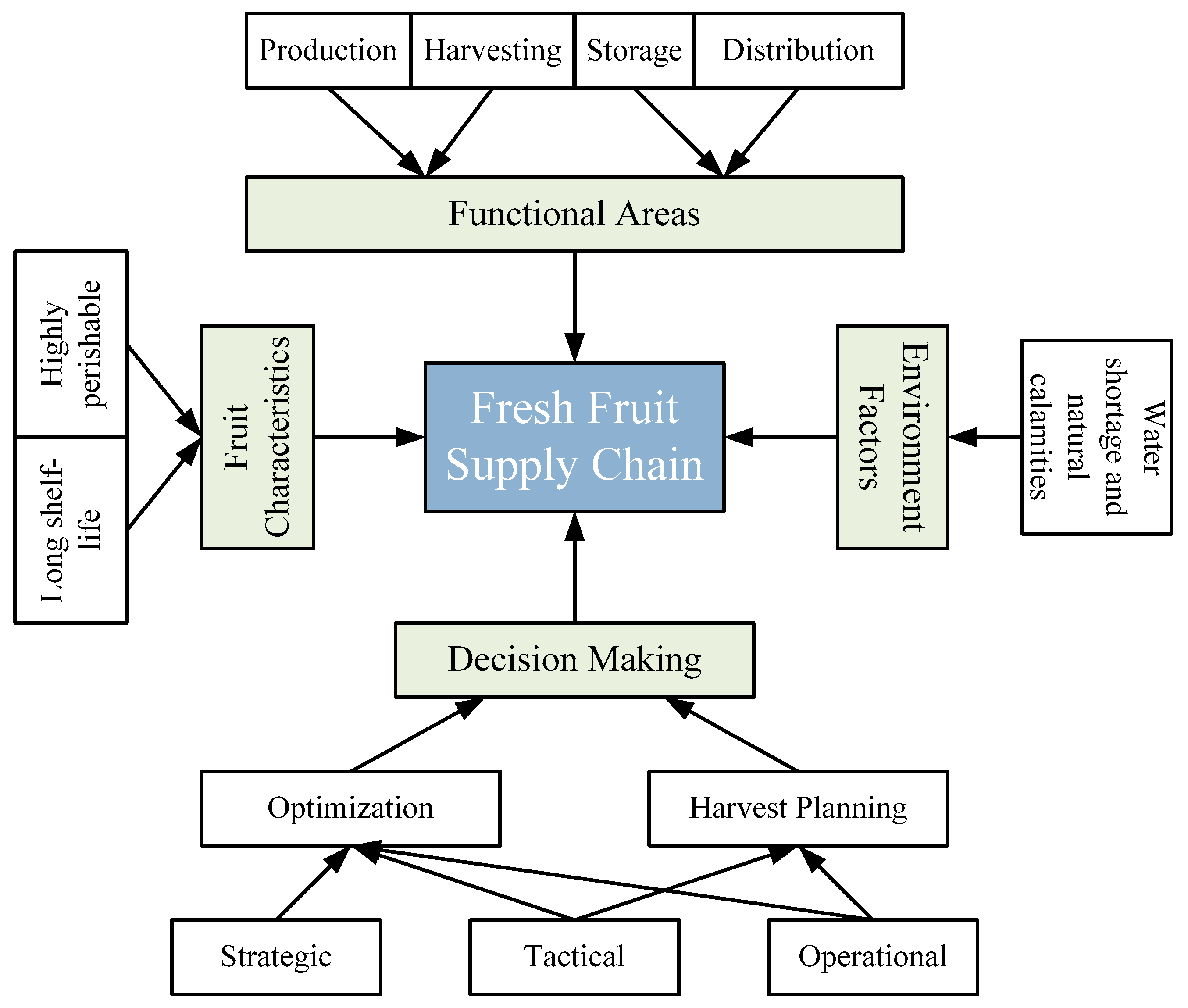

Figure 1. Constraints, challenges and influencing elements on the fresh fruit supply chain.

Figure 1. Constraints, challenges and influencing elements on the fresh fruit supply chain.-

Functional areas: this category comprises production, harvest, storage and distribution

-

Purpose of the chain: this category includes the scope of the decisions made: such as harvest planning and optimization.

-

Environmental factors: these include the planting environment with uncertainties and risks (countries with water shortage or natural calamities).

-

Fruit characteristics, such as (1) highly perishable and (2) long shelf life.

1.3. Common Concepts and Dominant Approaches

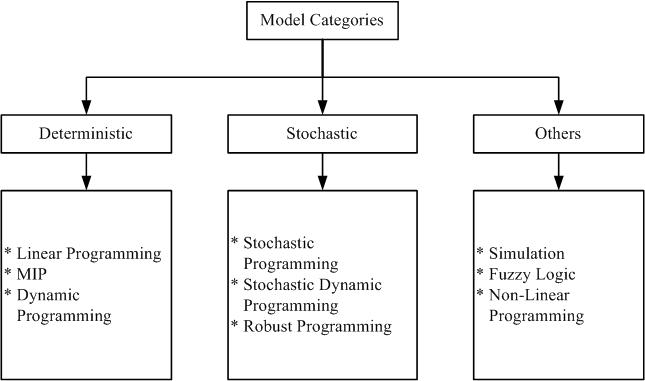

Several modeling approaches for the fresh fruit supply chain were conceived based on various settings, constraints, challenges and influencing elements (shown in Figure 2):.

Figure 2. Model classification framework for fresh fruit supply chains.

Most papers dealing with FFSC in a deterministic context implement LP or MIP formulations to make tactical and/or operational decisions. Additionally, the agricultural activities such as planting, harvesting and storing are covered more than the others. Besides, almost all authors only consider one kind of fruit as a case study to evaluate their model. Diverse decision-making levels and stages of the FFSC need to be considered more. Monoculture is known to be detrimental to soil health. Thus, future models should deal with polyculture farming and its SC implications.

Traditional deterministic models using linear programming or MIP are generally unable to deal with problems that involve uncertainties or give solutions with a high level of risk. This is particularly true in agricultural with several uncertain factors starting with weather conditions. Stochastic programming and robust programming (both extensions of linear programming) can address uncertainties in the parameters of linear or MIP optimization models for production and logistics planning in agri-food industries.

The L-shaped method is considered an effective tool to solve the stochastic problem. In addition, most of the authors believed that the two-stage stochastic model was a good choice for making tactical and operational decisions. Hence, two-stage stochastic models will still be used to deal with risks and uncertainties in the FFSC. However, new developments in robustness should be considered and applied to support decision making under uncertainty.

In many fresh fruit supply chains, uncertain elements include the time to harvest, quantity for packing, cost for shortage, etc. Such uncertainties can be modelled in ways other than stochastic programming as Fuzzy programming, Simulation and Non-linear programming.

2. Robustness and Limitations of Existing Models

In the general view, the following are the main criteria on which researchers conceive and structure their models for the planning and logistics of the fresh fruit supply chain:-

Relationship between price and demand

-

Environmental constraints

-

Planting/harvesting times and shipping/transporting factors

-

Operational decision-making styles

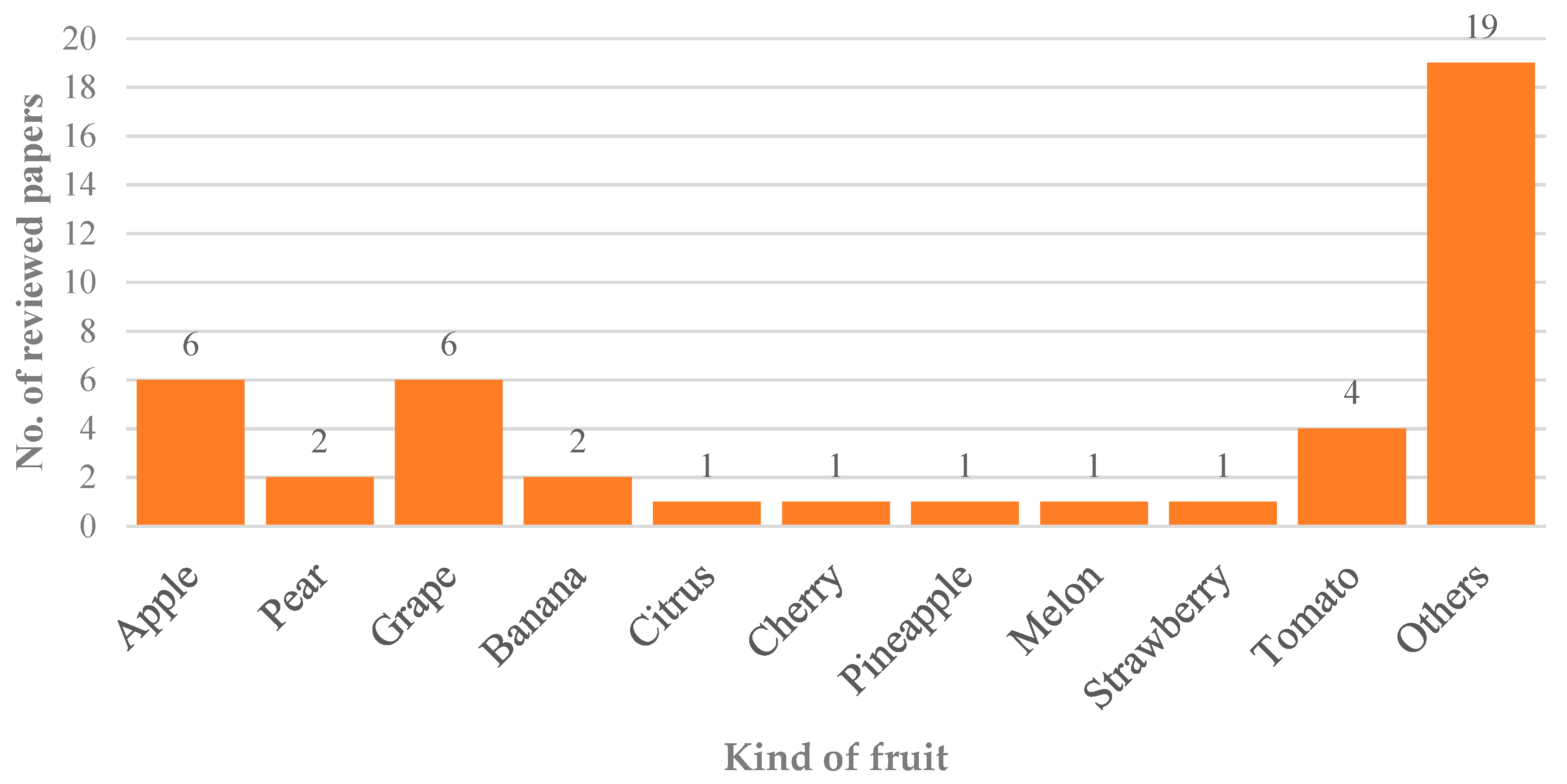

Figure 3. Statistics related to the fresh fruit supply chain research in term of fruit species from 1978–2017.

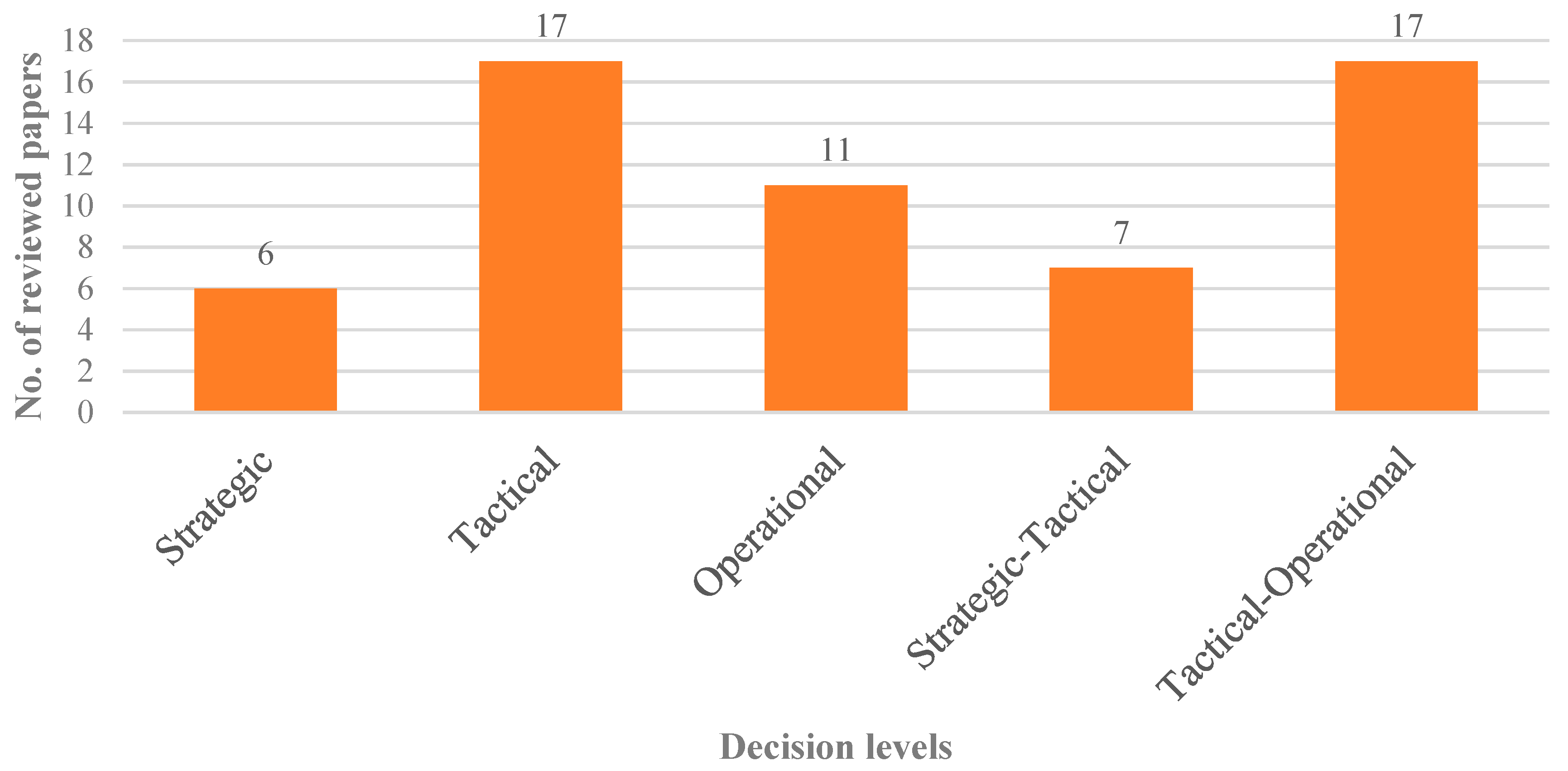

Figure 3. Statistics related to the fresh fruit supply chain research in term of fruit species from 1978–2017. Figure 4. Number of model categories in fresh fruit supply chain optimization.

Figure 4. Number of model categories in fresh fruit supply chain optimization.3. Conclusions and Research Perspectives for Future Models

References

- Soto-Silva, W.E.; Nadal-Roig, E.; González-Araya, M.C.; Pla-Aragones, L.M. Operational research models applied to the fresh fruit supply chain. Eur. J. Oper. Res. 2016, 251, 345–355.

- Karp, D. Most of America’s Fruit Is Now Imported. Is That a Bad Thing? The New York Times. 18 March 2018. Available online: (accessed on 15 November 2019).

- Monostori, J. Supply chains robustness: Challenges and opportunities. Procedia CIRP 2018, 67, 110–115.

- Hamer, P.J. A decision support system for the provision of planting plans for Brussels sprouts. Comput. Electron. Agric. 1994, 11, 97–115.

- Gigler, J.K.; Hendrix, E.M.; Heesen, R.A.; van den Hazelkamp, V.G.; Meerdink, G. On optimisation of agri chains by dynamic programming. Eur. J. Oper. Res. 2002, 139, 613–625.

- Ampatzidis, Y.G.; Vougioukas, S.G.; Whiting, M.D.; Zhang, Q. Applying the machine repair model to improve efficiency of harvesting fruit. Biosyst. Eng. 2014, 120, 25–33.

- Munhoz, J.R.; Morabito, R. Optimization approaches to support decision making in the production planning of a citrus company: A Brazilian case study. Comput. Electron. Agric. 2014, 107, 45–57.

- Bezat-Jarzębowska, A.; Rembisz, W. Efficiency-focused economic modeling of competitiveness in the agri-food sector. Procedia Soc. Behav. Sci. 2013, 81, 359–365.

- Ahumada, O.; Villalobos, J.R.; Mason, A.N. Tactical planning of the production and distribution of fresh agricultural products under uncertainty. Agric. Syst. 2012, 112, 17–26.

- Foong, S.Z.; Goh, C.K.; Supramaniam, C.V.; Ng, D.K. Input–output optimisation model for sustainable oil palm plantation development. Sustain. Prod. Consum. 2019, 17, 31–46.

- Van Der Vorst, J.G.; Tromp, S.O.; van der Zee, D.J. Simulation modelling for food supply chain redesign; integrated decision making on product quality, sustainability and logistics. Int. J. Prod. Res. 2009, 47, 6611–6631.

- Cittadini, E.D.; Lubbers, M.; de Ridder, N.; Van Keulen, H.; Claassen, G. Exploring options for farm-level strategic and tactical decision-making in fruit production systems of South Patagonia, Argentina. Agric. Syst. 2008, 98, 189–198.

- Soto-Silva, W.E.; González-Araya, M.C.; Oliva-Fernández, M.A.; Plà-Aragonés, L.M. Optimizing fresh food logistics for processing: Application for a large Chilean apple supply chain. Comput. Electron. Agric. 2017, 136, 42–57.

- Darby-Dowman, K.; Barker, S.; Audsley, E.; Parsons, D. A two-stage stochastic programming with recourse model for determining robust planting plans in horticulture. J. Oper. Res. Soc. 2000, 51, 83–89.

- Trivedi, A.; Sohal, A.; Joshi, S.; Sharma, M. A two-stage optimization model for tactical planning in fresh fruit supply chains: A case study of Kullu, India. Int. J. Supply Oper. Manag. 2021, 8, 18–28.

- Broekmeulen, R.A. Operations management of distribution centers for vegetables and fruits. Int. Trans. Oper. Res. 1998, 5, 501–508.

- Verdouw, C.; Beulens, A.; Trienekens, J.; Wolfert, J. Process modelling in demand-driven supply chains: A reference model for the fruit industry. Comput. Electron. Agric. 2010, 73, 174–187.