Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Vivi Li and Version 1 by Moritz Berneis.

The most successful applications of Blockchain Technology are still in the area of crypto-currencies, although both scientists and practitioners have discovered the potential of Blockchain Technology in Supply Chain Management. There is a significant theoretical literature on Blockchain Technology, but there exists a lack of published case studies and concrete examples.

- Blockchain Technology

- Smart Contracts

- logistics

- Supply Chain Management

1. Introduction

In 2008, an individual using the pseudonym Satoshi Nakamoto published the basic concept of the first crypto-currency, Bitcoin [1]. Bitcoin is a cryptocurrency, which does not require a central institution such as a central bank or a trusted third party, like PayPal. The Bitcoin network is based on Blockchain Technology (BCT) [2] (p. 22). The Blockchain (BC) is a distributed peer-to-peer database that consists of a network of equal nodes [3] (p. 1). Because the data is tamperproof and firmly integrated into the BC, the BC can reduce human intermediaries. Currently, BCT is mainly used in the field of crypto-currencies, but researchers and companies have recognized the potential of BCT for other areas, such as logistics [4] (p. 263).

2. Blockchain Technology in Supply Chain Management

2.1. Functionalities of the Blockchain Technology in Supply Chain Management

The possible applications of BCT are very diverse. However, for a meaningful economic use, this technology must solve existing problems of SCs or lead to process improvements. From the analyzed literature of the first cluster “Overview of BCT in SCM,” two fundamental functionalities of the BCT have been identified which may be beneficial for SCM. The two identified functionalities of the BCT that have a high potential for the SCM are its functionality as a transparent database and the application of Smart Contracts written on the BC.

2.1.1. BCT with the Functionality of a Database

For the first functionality, the BC acts as a database, whereby the data must be stored permanently and without contradiction along the SC. In this way, a complete, cross-company data and information flow along the entire SC can be ensured. Thus, the SC can be strengthened, since functional problems of the SC can be found or searched for in a targeted manner. Because nowadays it is not only individual companies that compete with each other, but entire SCs, a SC can generate or secure a competitive advantage over other SCs by increasing its efficiency. Since the data in the BC cannot be manipulated by the participants at a later time, the individual companies along the SC can gain an advantage because cooperation is more transparent and therefore fairer [25][5] (p. 5). When acting as a database in SCM, there are two possible advantages that BCT can provide: on the one hand, BCT can provide process improvements and, on the other hand, BCT can offer added value to the customer [26][6]. In the first case, competitive advantages arise from lower costs and in the second case, customers are willing to pay a higher price.

With regard to process improvements, it can be stated that a database based on BCT differs from a conventional database in that each participant in the network may have a complete copy of the database. In this way, everyone can copy the current changes to his database and check if it is consistent with the previous blocks [25][5] (p. 2). BCT is a suitable solution when trust is required and transparency needs to be created. According to Giungato and colleagues (2017), this may be the most important advantage of BCT in SCM and could be applied in many areas of SCM [27][7] (p. 8). Tijan and colleagues (2019) point out that the developments around Industry 4.0 already offer many possibilities to improve processes that can be supported or enabled by BCT. The goods remain traceable along the entire SC for all participants. Applying Big Data is a necessity for Industry 4.0. Big Data and BCT can benefit each other, because with BCT the data can be collected along the SC, which generates deeper insights through Big Data. This includes a large amount of structured, but also unstructured, data that are often only collected in order to obtain more data. The amount of this data is growing exponentially [7][8] (p. 6).

Traceability of processes or goods can be of great interest for SCs. Traceability can be implemented on the basis of BCT, which is why Business Process Management conducts research in the area of BCT. Due to the high degree of specialization of companies, SCs are becoming more and more complex and contain more participants, which can lead to trust problems in certain processes within an SC. This is especially problematic if critical goods, such as pharmaceuticals, are part of the SC; regulations and laws require full traceability of origin and processing for some critical goods [28][9] (p. 56). BCT in SCM could also prevent time delays and significantly reduce human error. Every transport within the SC can be documented reliably with BCT. In the best case, this traceability starts with the mining of the respective raw materials and ends with the purchase by the end customer [7][8] (p. 6).

The second possibility of BCT generating a competitive advantage in SCM is to offer the customer added value. The increase in transparency does not only provide an advantage for the SC companies, but can also create more trust in the product among final customers [29][10] (p. 2125). This increased trust could lead to higher customer satisfaction [4] (p. 264) and greater willingness to pay, especially for critical products such as food or pharmaceuticals [30][11] (p. 36505).

2.1.2. BCT with the Functionality of Smart Contracts

Smart Contracts have been identified in the literature as a second way in which BCT could provide advantages in SCM. In Section 2.4, Smart Contracts were presented theoretically. In summary, Smart Contracts are automated, secure contracts that are written to the BC and only trigger a transaction under previously known conditions. No support of a centralized execution authority is necessary. Smart Contracts enable the automation of complex multi-step processes [12] (p. 2301). For these reasons, the functions of Smart Contracts are very relevant to SCM. Traditional contracts often require a central, trusted third party. This trusted third party often charges high transaction fees and can become a weak point in the process; failure of this party can lead to security problems and a cancellation of the transaction. Furthermore, the decision of a trusted third party is not always objective and understandable for all the parties involved. Smart Contracts are different in that they function as autonomous actors and their behavior is completely predictable [12] (p. 2297).

Smart Contracts come with many problems, which is one reasons why there are hardly any real applications of Smart Contracts in SCM in the literature. The problems can be divided into four categories, which are described in more detail in the next section: programming, security, data protection and performance problems [18][13] (p. 94).

2.2. Implementation of Blockchain Technology in Supply Chain Management—Barriers and Weaknesses

To implement a BC in an SC, it is important that all parties involved agree on a BC and that everyone is involved in the process of implementation. As the average number of participants in a SC has increased, reaching an agreement is becoming more and more important, but also more complex and difficult. Some companies gain a greater advantage from the implementation of BCT than others. Therefore, many decisions have to be taken together by the participants. A public BC is the most secure and has the highest transparency and can therefore offer the end customers the best and most trustworthy information. With a public BC, sensitive company data also becomes public. This extensive disadvantage overrides the advantages of a public BC for most companies. In most cases, a private, permissioned BC is used to which only certain parties have access. Only a small part of the data is subsequently released to the final customer [15][14] (p. 6).

One problem with Smart Contracts is that the legal enforceability is still limited. The problem is made worse by the fact that Smart Contracts in SCM are supposed to be valid across national borders. Efforts are being made to make the technical rules of smart contracts legally enforceable and binding for all parties. As an interim solution until these problems are globally solved, a so-called “Dual Integration” is proposed (See: https://erisindustries.com/components/erislegal/ (Last accessed on 7 June 2021)). This involves drawing up two contracts between companies that refer to each other. On the one hand, a real contract is drawn up that is legally binding for all parties. On the other hand, a Smart Contract is drawn up which refers to the real contract between the companies.

If a function of the Smart Contract contains errors (logical or content-related), the decisions made in the Smart Contract cannot be reversed, which is problematic. For example, a Smart Contract in its simplest form can function as a lockbox. It may happen that depositing money into this safe deposit box is possible without any problems, but there is an error in the code for the payment of the funds or the “withdrawal function” (See: https://solidity.readthedocs.io/en/latest/introduction-to-smart-contracts.html (Last accessed on 7 June 2021)). This means that the deposited crypto-currencies are irrecoverably lost and cannot be recovered by any party [12] (p. 2300).

The problems of Smart Contracts can be classified into the following four categories: programming, security, data protection and performance problems. Programming Smart Contracts requires accurate contracts, but programming them is a challenge, because the contracts cannot be changed or cancelled. Another challenge is the complex programming language. Smart contracts should be more secure than traditional contracts that are monitored by third parties. Unfortunately, there are still conceptual problems that might affect security. There is a dependency on time stamps; at Ethereum, for example, the execution of the contract may depend on Miner if two dependent transactions update the same Smart Contract in the same block. Other problems include transaction dependency, criminal activities and untrusted data feeds [18][13] (p. 94).

Smart Contracts, due to their transparency, give away more information than traditional contracts. The problem becomes more manageable through private BCs, but it still remains. If transparency becomes limited for the protection of company data, the security and trustworthiness of the data is simultaneously reduced. With BCT, the number of executable transactions or Smart Contracts is limited. This can be particularly problematic when executing Smart Contracts sequentially, since with BCT one contract is executed after another. The BCT is only limited and can be scaled at high expense, which can lead to performance problems if the number of contracts to be executed is very high [31][15] (p. 183).

In summary, BCT is a secure, transparent and decentralized database for monitoring the product flow. The increased transparency can either offer added value to the end customer, or it can help to comply with regulations and laws and provide the companies along the SC with opportunities to increase the efficiency of the SC. The greatest economic potential results from the tracking of critical goods, such as food or pharmaceuticals. In order to make tracking easier for Smart Contracts and to automate the processes, sensors can be used to document the transport of the goods. Due to sensible company data, private, permissioned BCs are better suited than more secure, and more transparent, public BCs.

3. Applications of Blockchain Technology in Supply Chain Management

This paper aims to present real applications of BCT in SCM. First, a logistic process is described and then two use cases are presented, where BCT is already in use. The specific added value of the BCT for the respective use cases will be shown. In order to achieve this goal, the second cluster “Possible applications of BCT in SCM” will be analyzed. This consists of 17 publications in which the authors deal with the practical applications of this technology in SCM, and whose evaluation resulted in a multitude of different applications. The majority of the publications in the second cluster examine an application of BCT in the food SC (six publications) and an implementation in the SC of the healthcare sector (five publications). For these two major clusters, a concrete use case, where BCT is already in service, will be given. BCT is already used in many areas (e.g., financial engineering and crypto-currencies), but virtually no financially self-sustaining applications exist in the real world [32][16] (p. 10).3.1. An Examplary Logistics Process in Detail—Inside the Luxury Supply Chain

In the literature, there are various ways that BCT can support a so-called Luxury SC. A current application is the authentication and certification of diamonds, on the one hand to prevent the acquisition of so-called “blood diamonds.” On the other hand, conventional certificates can be faked, or a real certificate can be used for a fake diamond, since BC certificates are permanent [33][17] (p. 17).

Platforms like Everledger offer a unique digital thumbprint for high value and hard- to-replace goods, such as diamonds and fine wine [15][14] (p. 9). This thumbprint is made by using the BCT that is unalterably stored in the BC; the thumbprint consists “of 40 metadata points, the laser inscription on the girdle, and the stone’s four Cs—color, clarity, cut, and carat weight.” (See: https://www.altoros.com/blog/a-close-look-at-everledger-how-blockchain-secures-luxury-goods/ (Last accessed on 7 June 2021); Primary source: https://youtu.be/GAdjL-nultI?t=202 (Everledger, Last accessed on 7 June 2021)).

In addition to the already existing BC-certificates [33][17] (p. 27), the transport of the diamond could be documented completely by means of the BCT (tracked and traced). The TrustChain™ from IBM can already track and authenticate diamonds [34][18] (p. 587) (Source: https://www.trustchainjewelry.com (Last accessed on 7 June 2021)). Transports usually involve several transshipments (processes in which the mean of transport is changed). The diamond is transported by different transport service providers. Ideally, the diamond would have to be checked for its digital thumbprint at each transfer point and the result would have to be stored in the BC. For one thing, checking the diamond takes time and for another, special measuring technology is required.

One way to speed up the process is to mandate that only the final receiver checks the digital thumbprint. The seller and the sender are responsible for the quality of the diamond, and can authenticate and certify it using the BCT. The shipper seals a transport box and is responsible for the fact that the diamond matching the digital thumbprint is in the box. Inside the box, there is an RFID chip beside the diamond, and a barcode is attached to the outside of the box. Inside the box, further sensors can be installed, which can be connected (e.g., via Bluetooth), such as temperature sensors or acceleration sensors, which might be able to detect shocks [34][18] (p. 587). The shipment could be refused on the basis of the sensor data.

In this example, the diamond is transported as follows: from the shipping point, the diamond is transported by truck to the freight port by a forwarding agent. There the diamond is transshipped into a cargo ship; at the final port, the diamond changes the means of transport (from the ship to the truck) and the responsible party. The truck then transports the diamond directly to the recipient. During the actual transport, the diamond can be shipped in a properly sealed package (e.g., a hard-plastic box). Opening the box is thus visible to the person next in the transport chain. The condition of the package is documented with each handling and saved in a block of the BC. For this purpose, the following transfer protocol could be processed for each transfer:

-

Is the package intact and in a flawless condition?

-

Is the seal undamaged?

-

Do the barcode and RFID match the shipping note?

-

Confirmation that the package has been passed.

As soon as the recipient of the package confirms that the package has been delivered, a transaction can be triggered by means of a Smart Contract. One advantage of BCT is that it can be used across different companies, which means that the transportation means of different companies can be used, as long as they agree to use the same BC. No one can change the data in the BC retrospectively. As the BC is law, the currently responsible party for the diamond is always visible to all parties; this currently responsible party is liable for any damage or loss. The responsible persons can individually insure themselves. In the case of a public block certificate, there is a risk that criminals could gain access to the current location of the valuable diamond, which makes a private, permissioned BC suitable [15][14] (p. 6). However, a residual risk remains because all companies along the SC have access to the BC.

3.2. Food Supply Chains

Although the literature analysis found quite a number of publications in the field of food SCs, no case was found in which a company actively used the BCT to earn money and gain a competitive advantage. Many feasibility studies have been found, but only few have tested the prototypes in the real world; this finding matches the findings of Hinckeldeyn (2019) [16][19] (p. 32). In the following section, several projects are briefly mentioned as examples, followed by a more detailed description of one application.

First, there is the cooperation of Walmart and Hyperledger Fabric, a BC platform for companies, which is intensively supported by IBM [16][19] (p. 24) and has been found referenced numerous times (See: https://fortune.com/2017/08/22/walmart-blockchain-ibm-food-nestle-unilever-tyson-dole/ (Last accessed on 7 June 2021)). In a field test, Walmart and IBM were able to demonstrate that the origin of mangoes and pork could be determined via BC within a short time [16][19] (p. 32). The IBM Trustchain can track tomatoes from the farm to the pot, to the jar, to the table, but is not yet in use, although a working prototype is (Source: https://www.trustchainjewelry.com (Last accessed on 7 June 2021)). Bumble Bee Foods cooperates with SAP to document tuna fish products from Indonesia. The size of the fish, fishing location and time, freshness during its processing and the company’s certificate of production are stored within a BC (See: https://cointelegraph.com/news/north-american-seafood-firm-to-use-blockchain-tech-in-supply-chain/amp (Last accessed on 7 June 2021)). Other examples deal with the traceability and certification of Extra Virgin Olive Oil [35][20] (p. 173) or describe how eggs can be traced in the USA using BCT [36][21] (p. 1).

On the one hand, these examples demonstrate the increased interest of food manufacturers in the trustworthy documentation of their products in a BC [37][22]. Many companies are already trying to gain the trust of consumers with the help of seals, such as the Fairtrade label, which is given by a Fairtrade organization under certain conditions. On the other hand, the examples also show the interest of the large IT groups. Whether the interest comes from the Research and Development department or the Marketing department is not always identifiable. Food scandals have led to manufacturers generating competitive advantages by providing reliable proof of the origin and processing of goods. The BCT might be able to strengthen the confidence of the consumer [16][19] (p. 32).

In the following section, a prototype that has been tested in the field will be discussed. Zhang and colleagues (2020) have developed a new system architecture along the entire Grain SC based on BCT. Compared to traditional methods of the SCM, their system is characterized by high data security, real-time exchange of relevant information (such as hazardous material information) and trustworthy grain tracing along the entire SC [38][23] (p. 36398).

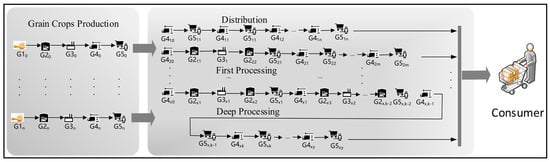

The Grain SC starts with grain cultivation and production, primary grain processing, grain product cycles, and deep grain processing and ends with transport to the consumer (see Figure 41). Zhang and colleagues (2020) have identified five typical links in the traditional Grain SC (see Figure 41): the link of grain production (G1), the link of grain storage (G2), the link of grain processing (G3), the link of grain logistics and transport (G4) and the link of grain marketing (G5) [38][23] (p. 36400).

Smart Contracts define the conditions for the execution of the transactions in advance. The system collects data about the grain, which is then stored within the BC. The data are collected mainly by electronic tags and various sensors such as code-scan guns, cameras, smoke detectors, humidity sensors, light sensors, etc. When the parameters of the grain meet the requirements and all other requirements are met, the transaction is automatically triggered [38][23] (p. 36404).

A special use case was applied to validate the proposed system. An Information Management System for the Grain SC was established with grain companies in the province of Shandong. This field test was conducted on the BC platform of Hyperledger Fabric with the cloud database MySQL. The system was able to provide reliable information in the SC for participants, consumers and third parties, and the data provided a good basis for assessing, predicting and early warning of hazards [38][23] (p. 36407).

5.3. Supply Chains in Healthcare

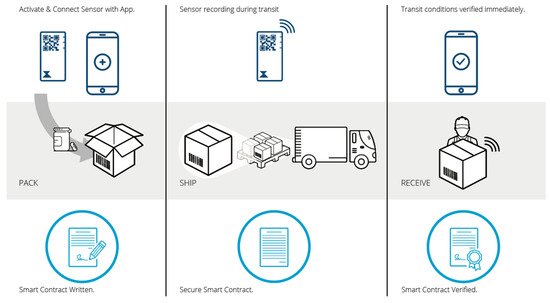

The company Modum, a Swiss start-up, is to be shown as an example for SCs in Healthcare. Modum has initiated several studies and has developed and tested prototypes and offers its services in the field of BCT in SCM. The goal of the company is the secure tracking and tracing of pharmaceutical products. To this end, the company relies on the public Ethereum BC. For tracking, IoT sensor devices (IoT = Internet of things), QR codes and barcodes are used to clearly identify the items handled.

The Good Distribution Practice Regulation (GDP 2013/C 343/01) requires proof that the transport conditions (in particular the temperature) could not have affected the quality of the pharmaceutical products transported [39][24]. The company Modum.io enables other companies to meet the GDP requirements with the help of BCT. At the same time, it should be possible to generate significant cost savings for the transport of pharmaceuticals that do not require active cooling [40][25] (p. 5). The system is based on the components shown in Figure 52.

To monitor the temperature during the transport of medicines, a calibrated temperature sensor in the package stores a measured value every 10 min. When receiving the package, the customer can scan the ID number on the package and then request the temperature data via Bluetooth, without having to open the package [40][25] (p. 5). The customer then sends the data to the Smart Contract (see Figure 63). The data are stored in PostgreSQL because the collected data is too large or too sensitive to be stored in the Ethereum BC [34][18] (p. 588).

References

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. 2009, p. 9. Available online: (accessed on 21 June 2021).

- Dujak, D.; Sajter, D. Blockchain Applications in Supply Chain. In SMART Supply Network; Kawa, A., Maryniak, A., Eds.; Springer International Publishing: Cham, Germany, 2019; pp. 21–46.

- Wang, Y.; Singgih, M.; Wang, J.; Rit, M. Making sense of blockchain technology: How will it transform supply chains? Int. J. Prod. Econ. 2019, 211, 221–236.

- Petersen, M.; Hackius, N.; von See, B. Mapping the sea of opportunities: Blockchain in supply chain and logistics. Inf. Technol. 2018, 60, 263–271.

- Niu, X.; Li, Z. Research on Supply Chain Management Based on Blockchain Technology. J. Phys. Conf. Ser. 2019, 1176, 042039.

- Babich, V.; Hilary, G. OM Forum—Distributed Ledgers and Operations: What Operations Management Researchers Should Know About Blockchain Technology. Manuf. Serv. Oper. Manag. 2020, 22, 223–240.

- Giungato, P.; Rana, R.; Tarabella, A.; Tricase, C. Current Trends in Sustainability of Bitcoins and Related Blockchain Technology. Sustainability 2017, 9, 2214.

- Tijan, E.; Aksentijević, S.; Ivanić, K.; Jardas, M. Blockchain Technology Implementation in Logistics. Sustainability 2019, 11, 1185.

- Di Ciccio, C. Blockchain-Based Traceability of Inter-organisational Business Processes. In Business Modeling and Software Design, Bmsd 2018; Shishkov, B., Ed.; Springer: Berlin, Germany, 2018; Volume 319, pp. 56–68.

- Roeck, D.; Sternberg, H.; Hofmann, E. Distributed ledger technology in supply chains: A transaction cost perspective. Int. J. Prod. Res. 2019, 58, 2124–2141.

- Al-Jaroodi, J.; Mohamed, N. Industrial Applications of Blockchain; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2019; pp. 550–555.

- Christidis, K.; Devetsikiotis, M. Blockchains and Smart Contracts for the Internet of Things. IEEE Access 2016, 4, 2292–2303.

- Abdelhamid, M.; Hassan, G. Blockchain and Smart Contracts; ACM: New York, NY, USA, 2019; pp. 91–95.

- Chung, G.; González-Peralta, J.; Turner, K.; Gockel, B. Blockchain in Logistics-Perspectives on the Upcoming Impact of Blockchain Technology and Use Cases for the Logistics Industry. 2018, p. 28. Available online: (accessed on 21 June 2021).

- Karamitsos, I.; Papadaki, M.; Al Barghuthi, N.B. Design of the Blockchain Smart Contract: A Use Case for Real Estate. J. Inf. Secur. 2018, 9, 177–190.

- Demestichas, K.; Peppes, N.; Alexakis, T.; Adamopoulou, E. Blockchain in Agriculture Traceability Systems: A Review. Appl. Sci. 2020, 10, 4113.

- Choi, T.-M. Blockchain-technology-supported platforms for diamond authentication and certification in luxury supply chains. Transp. Res. Part E Logist. Transp. Rev. 2019, 128, 17–29.

- Azzi, R.; Chamoun, R.K.; Sokhn, M. The power of a blockchain-based supply chain. Comput. Ind. Eng. 2019, 135, 582–592.

- Hinckeldeyn, J. Blockchain-Technologie in der Supply Chain: Einführung und Anwendungsbeispiele; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019.

- Arena, A.; Bianchini, A.; Perazzo, P.; Vallati, C.; Dini, G. Bruschetta: An IoT Blockchain-Based Framework for Certifying Extra Virgin Olive Oil Supply Chain; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2019; pp. 173–179.

- Bumblauskas, D.; Mann, A.; Dugan, B.; Rittmer, J. A blockchain use case in food distribution: Do you know where your food has been? Int. J. Inf. Manag. 2020, 52, 102008.

- Barge, P.; Biglia, A.; Comba, L.; Aimonino, D.R.; Tortia, C.; Gay, P. Radio Frequency IDentification for Meat Supply-Chain Digitalisation. Sensors 2020, 20, 4957.

- Zhang, X.; Sun, P.; Xu, J.; Wang, X.; Yu, J.; Zhao, Z.; Dong, Y. Blockchain-Based Safety Management System for the Grain Supply Chain. IEEE Access 2020, 8, 36398–36410.

- European Union. Guidelines of 5 November 2013 on Good Distribution Practice of Medicinal Products for Human Use Text with EEA Relevance. 2013, p. 14. Available online: (accessed on 21 June 2021).

- Modum. Data Integrity for Supply Chain Operations Powered by Blockchain Technology, Modum. August 2017. Available online: (accessed on 19 June 2020).

More