Fiber-reinforced geopolymer composite (FRGC) is emerging as one of the alternative materials for cement in the construction industry. FRGC is considered an eco-friendly material due to its role in the global reduction in emission of CO2 to the environment. Simultaneously, the composite provides good mechanical strength of flexural modulus, loss modulus, post-impact strength, and durability for a definite period at room and elevated temperatures. A positive aspect of the geopolymer matrix used for this composite is that could provide a finite period of durability at elevated temperatures without releasing toxic gases to the surroundings. Fibers enhanced the brittle behavior of the geopolymer matrix into ductile one with improved mechanical strength and residual impact strength.

- fiber

- geopolymer

- fiber-reinforced geopolymer composite (FRGC)

1. The Physical, Chemical, and Mechanical Domains of Geopolymer-Based Composite

1.1. Chemical Structure of Geopolymer Matrix

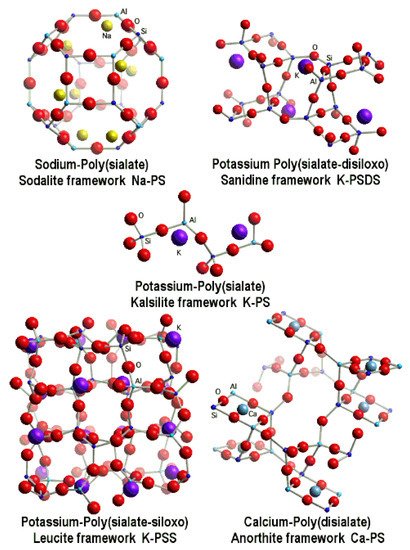

A silioxo group has been emerged from low to high technology in the ratio of Si:Al group with various properties. Emerging technology from 2D to 3D network could offer fire- and heat-resistant fiber composites materials. Inorganic matrix of chemical composition poly(sialate) to poly(sialate-disoloxo) with Na, K, and Ca network structure were largely used. Network structures of this geopolymer inorganic matrix are shown in

.

A framework of geopolymer structure with Na, K, and Ca–poly (sialate-siloxo). Reprinted from

; with permission of Geopolymer Institute. Last accessed on 16 February 2021.

1.2. The Domain of Composites in Various Fields

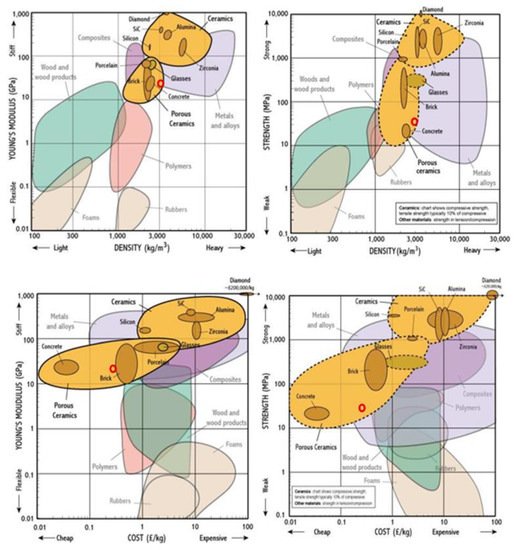

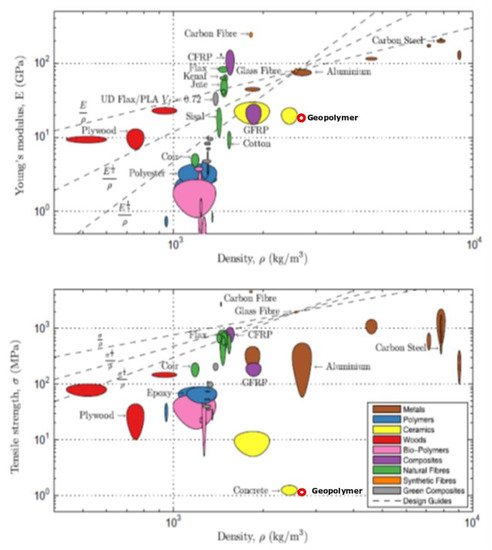

Composites are fall in the category of economic benefit material in terms of density and cost. Composites show Young’s modulus more than 100 GPa, which represents the market demand. Nowadays, composites dominate the material market due to being lighter weight, strong materials with higher toughness. Composites, including those based on geopolymers, stand as the most efficient material in the market in comparison to ceramic and metallic materials.

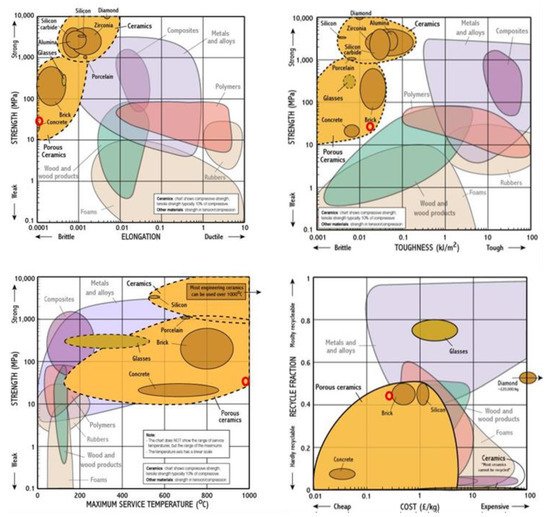

Regarding the operational environment and the service temperature, composite strength and Young’s modulus as a function of elongation, toughness, density, and cost are plotted as examples in

and

. Although composite is expensive in the market, the material can be fully recycled.

Schematic representation of Young’s modulus and strength as a function of density and cost for various materials (geopolymer is marked in red for comparison). Reprinted from

. Last accessed 16 February 2021.

Schematic representation of strength as a function of elongation, toughness, and maximum service temperature, and the cost of recycled fraction for the various materials (geopolymer is marked in red for comparison). Reprinted from

. Last accessed 16 February 2021.

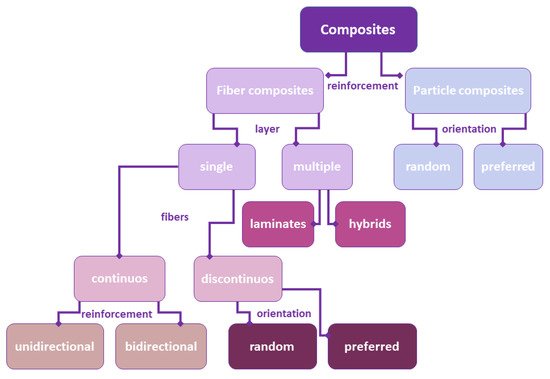

The composite performance based on polymer matrices at service temperature is of major concern in various application fields. As it releases CO

into the surrounding, it becomes economically endangered. The matrix has been categorized into several kinds such as thermosets, thermoplastics, metals, and ceramics in the category of organic, synthetic types. Composites are prepared by various routes or procedures such as chemical vapor deposition scheme, sol–gel processing, and vapor phase grow/reaction process. Fibers such as long and short fibers, woven fabric, whiskers, and particulates are used in various matrices for the composite preparation. These materials are categorized into various typologies such as fiber-reinforced or particle-reinforced composites and in various combinations. Furthermore, fiber-reinforced composites can be categorized into single- and multi-layered composites with preferred orientations in various directions. Based on the various categorizations, composites are represented in

.

Schematization of different composite materials based on their constitution.

2. Characterization of Pure Geopolymer and Fiber-Reinforced Composite

2.1. Characterization of Pure Geopolymer

Physical, chemical, structural, thermal, and mechanical characterizations of geopolymer are largely analyzed and investigated

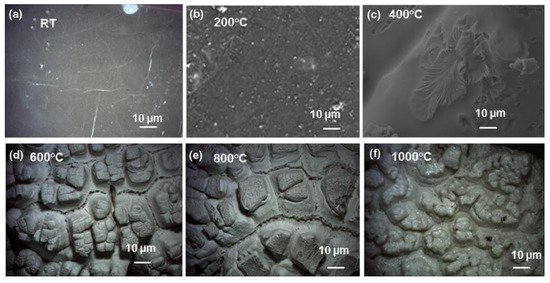

. The matrix geopolymer is based on fly ash or metakaolin binder; the minerals that characterized silicate-oxo compounds show very different physical, chemical, and mechanical properties. The reaction process of polymerization has a strong influence on the chemistry of the material. The metakaolin binders show distinct sharp edges, while the fly ash particle is spherical in surface features. The thermal characterization of the geopolymer matrix shows the evolution of exothermic and endothermic peaks as a function of the temperature. The particle size distribution of geopolymer powder falls within the range of 0.1 to 100 µm. Although at RT, the geopolymer matrix shows compactness, at elevated temperature, it shows expansion in the volume of the matrix with cracks on the surface (

). The shrinkage of the geopolymer matrix as a function of the curing temperature and time of exposure is 13.2 with a density of 1.8 g/cm

.

Microstructural evolution of (

) pure geopolymer matrix and (

–

) sintered geopolymer at various temperatures from 200–1000 °C. Reprinted from

with permission from MDPI.

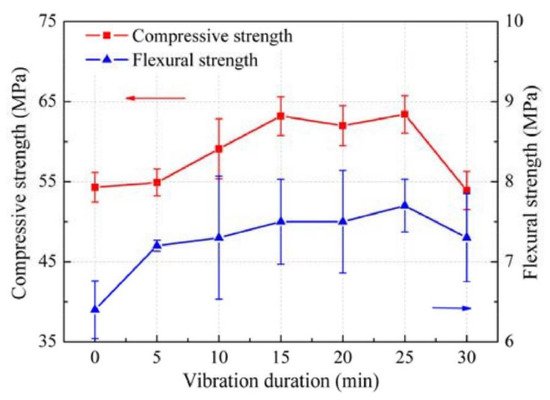

The mechanical properties of the geopolymer matrix fall within the range of 55–65 MPa. Its mixing vibration shows improved compressive strength for 15 min

. The compressive strength and flexural strength of the geopolymer matrix as a function of vibration time for the mixture is displayed in

, in which it is possible to observe an initial increase of both typologies of strength with reaching of a plateau between 15 and 25 min of vibration.

Compressive strength and flexural strength of the geopolymer matrix as the function of the vibration time of mixing. Reprinted from

with permission from Elsevier.

2.2. Fiber-Reinforced Geopolymer Characterization

2.2.1. Synthetic Fibers Such as Carbon, E-glass, and Basalt Fiber-Reinforced Geopolymer Composites

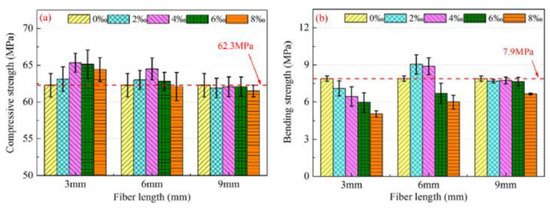

Synthetic fibers are considered as potential fillers such as short fiber, long fiber, and fiber in plain reinforcement in the geopolymer matrix. An example of short fibers is represented by the E-glass, which are used at various lengths in reinforcing the geopolymer matrix.

a,b shows the compressive and bending strength of geopolymer as a function of fiber length of E-glass fiber at various volume fractions.

Compressive (

) and bending (

) strength of geopolymer as the function of fiber length of E-glass fiber at various volume fractions. Reprinted from

with permission from Elsevier.

Based on the fiber-reinforced characterization, microstructural evolution results in a fiber–matrix interface with contributing mechanical properties

.

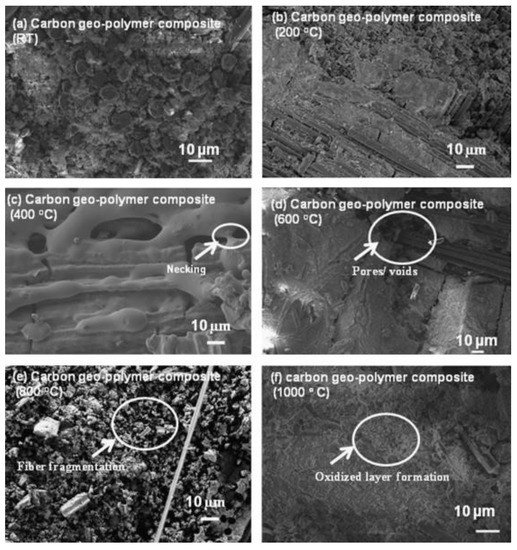

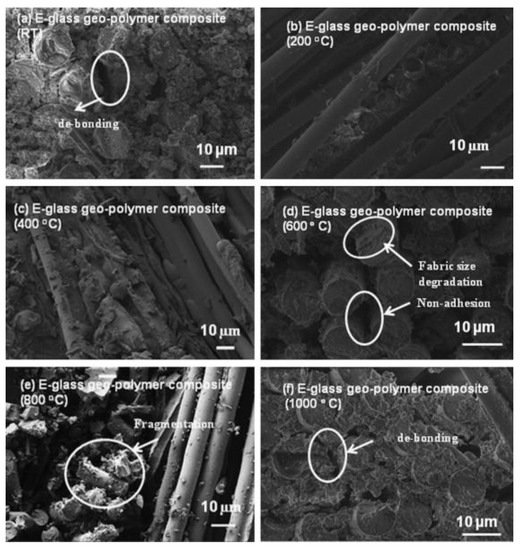

The microstructure evolution of fiber in plain reinforced geopolymer composite showed adhesion of the fiber at RT and evolution of the matrix and interface as a function of the exposure temperature.

a,f shows the carbon fiber reinforcement in the geopolymer matrix at RT and their microstructural reinforcement at various temperatures until 1000 °C for a definite period. Similarly, the microstructural evolution of E-glass and basalt fiber-reinforced geopolymer matrices are reported in

and

.

Microstructure evolution of (

) carbon fiber reinforced geopolymer composite at room temperature and (

–

) sintered at various temperatures from 200–1000 °C. Reprinted from

with permission from Elsevier.

Microstructure evolution of (

) E-glass fiber-reinforced geopolymer composite (FRGC) at room temperature (RT) and (

–

) sintered at various temperatures from 200–1000 °C. Reprinted from

with permission from Elsevier.

(

) Basalt fiber reinforced geopolymer composite at RT and (

–

) sintered at various temperatures from 200–1000 °C. Reprinted from

with permission from Elsevier.

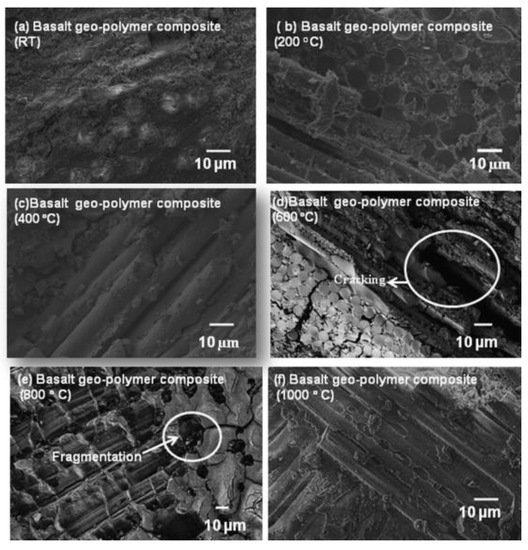

Carbon fiber reinforced composite shows better adhesion and homogeneity on the surface layers, while E-glass shows sliding behavior and detachment of fiber from the matrix at elevated temperature, leading to the fragmentation phenomenon

. In the case of basalt reinforced geopolymer composite, sintered porosity was observed, which may be developed due to the chemical interaction of basalt fibers with the geopolymer matrix. Basalt fiber has a composition derived from rocks and minerals; thus, an exchange of minerals from fiber to the matrix causes the composite materials to be more brittle in nature. Flexural strength and modulus of the geopolymer composite as a function of the temperature for carbon, E-glass, and basalt fiber reinforcement are shown in

.

Flexural strength (

) and modulus (

) of carbon, E-glass, and basalt fiber-reinforced geopolymer composite (FRGC) versus at various sintered temperatures. Reprinted from

with permission from Elsevier.

After sintered at various temperatures, carbon FRGCs could survive and retain two-thirds of their initial strength. However, E-glass FRGCs experience volumetric expansion at sintered temperatures. Basalt FRGCs undergo sintering and transform into a ceramic-like structure; as a result, the strength of the material is brittle.

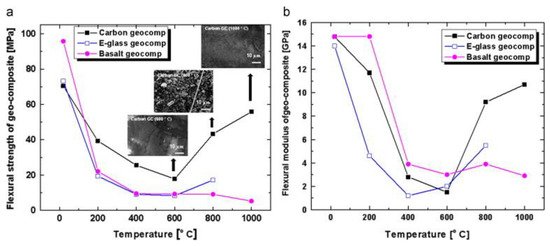

2.2.2. Durability on Impact of Fiber-Reinforced Composite

Force and displacement versus time for the (

) carbon, (

) E-glass, and (

) basalt fiber reinforced geopolymer composite. Reprinted from

with permission from Elsevier.

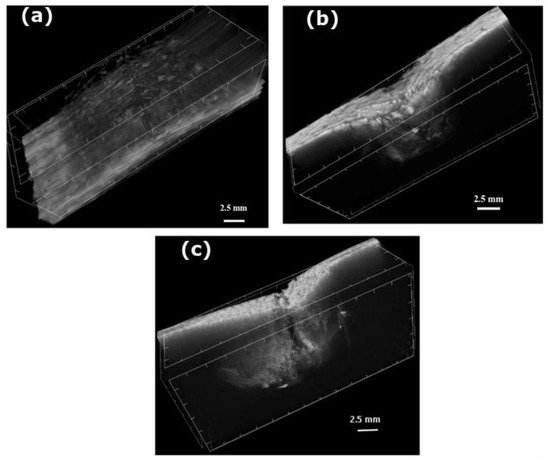

The inner volume of the composite could reveal the fiber orientation and the alignment within the volume of the matrix. The µ-CT scan reveals the inner volume and structure of the composite. Delamination, i.e., rupture of the fiber and matrix during impact from the damaged area to the surrounding area, is revealed from the image below (

). Based on the durability investigation, carbon fiber reinforced geopolymer composite shows less damage area with intact residual strength in the case of E-glass fibers, which remains with minimum loss in strength. In the case of basalt fiber reinforced geopolymer composites, the loss in strength is 65%. The minimum loss in strength of 27% in the case of E-glass fiber may have resulted due to the slipping mechanism of E-glass in the geopolymer matrix during impact. This leads to the weak interface bonding between E-glass fiber and the matrix within the composite

. The bonding is strong between carbon fiber and geopolymer matrix, which leads to the intact behavior of the fiber within the composite resulting in less damage.

Inner volume around the notch and damaged area of the composite with (

) carbon (

) E-glass, and (

) basalt fiber. Reprinted from

with permission from MDPI.

2.2.3. Natural Fibers Such as Cotton, Flax, Jute Fiber Reinforced Geopolymer Composites

There is a limitation on adding cotton fiber into the geopolymer matrix for the formation of the composite. The increase in the volume of the hydrophilic natural fibers, within the geopolymer matrix leads to a reverse effect on the strength of the composite.

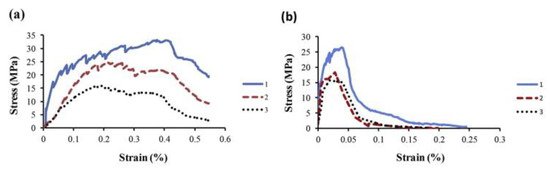

a,b represents stress–strain curves of geopolymer composites with cotton fabric alignment.

Stress–strain curves of geopolymer composites with the cotton fabric (

) horizontally aligned and (

) vertically aligned to the applied load. [Legend: (1) = 8.3 wt.%, (2) = 6.2 wt.%, (3) = 4.5 wt.%]. Reprinted from

with permission from Elsevier.

Cotton, flax, and jute types of natural fabrics have some limitations as geopolymer composites since they are unable to operate at high temperatures.

displays Young’s modulus and tensile strength of various fibers and materials as a function of density. It has been observed that carbon fiber reinforced geopolymer composite stands ahead and more reliable in terms of Young’s modulus and tensile strength

.

Young’s modulus and tensile strength as the function of density for various materials (geopolymer is marked in red for comparison). Reprinted from

with permission from Elsevier.

displays the summary of the geopolymer matrix and the possible fiber properties for the composites.

Bulk density, flexural strength, modulus, compression, elongation of geopolymer, and fibers

.

| Geopolymer | Bulk Density (g/cm3) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Compression |

|---|

| Matrix | 2.0± 0.1 | 27.8 ± 0.1 | 18.5 ± 0.1 | 11.7± 0.1 |

| Fibers | Bulk density (g/cm3) |

Tensile strength (MPa) | Elastic Modulus (GPa) | Ultimate Elongation (%) |

| Steel | 7.65–7.85 | 345–2850 | 200–210 | 0.5–3.5 |

| Carbon fiber, carbon nanotube | 1.4–2.2 | 500–3500 | 35–1800 | 0.3–2.5 |

| Synthetic Polymers | ||||

| PVA | 1.2–1.3 | 800–2500 | 29–42 | 5.7–7 |

| PP | 0.9–0.95 | 240–760 | 1.5–10 | 15–80 |

| PE | 0.92–0.97 | 80–3500 | 5–113 | 3–100 |

| Aramid | 1.38–1.47 | 2300–3500 | 63–120 | 2–4.5 |

| Acrylic | 1.16–1.18 | 270–1000 | 13.8–19.3 | - |

| Polyester | 1.22–1.38 | 580–1100 | 15 | 35 |

| Nylon | 1.13–1.41 | 440–1000 | 4.1–5.2 | 16–20 |

| PET | 1.3–1.4 | 420–450 | 3.1–10 | 11.2 |

| Natural Fiber | ||||

| Jute | 1.3–1.5 | 250–350 | 26–32 | 1.5–1.9 |

| Sisal | 1.34–1.45 | 280–750 | 13–26 | 3.0–5.0 |

| Coconut | 0.87–1.4 | 120–200 | 19–26 | 10.0–25.0 |

| Bamboo | 0.6–1.1 | 140–800 | 11–32 | 2.5–3.7 |

| Cotton | 1.5–1.6 | 390–600 | 5.8–11 | 6.0–10.0 |

| Palm | 1.3–1.46 | 21–60 | 0.6 | - |

| Wool | 1.3 | 160 | 3.5 | - |

| Hemp | 1.4–1.5 | 270–900 | 23.5–90 | 1–3.5 |

| Kenaf | 1.4 | 223–930 | 14.5–53 | 1.5–2.7 |

| Coir | 1.15–1.46 | 95–230 | 2.8–6 | 15–51.4 |

| Banana | 1.4 | 500 | 12.0 | 1.5–9 |

| Flax fabric | 1.5 | 500–1500 | 50–70 | 1.1 |

| Bagasse | 1.3 | 222–290 | 17–27 | - |

| Inorganic fibers | ||||

| E-Glass | 2.5–2.62 | 3100–3800 | 72.4 | 4.8 |

| S-Glass | 2.46–2.49 | 4020–4650 | 86.9 | 5.4 |

| C-glass | 2.6 | 3310 | 69 | 4.8 |

| AR-glass | 2.7 | 3240 | 73 | 4.4 |

| Basalt | 2.65–2.80 | 3000–4840 | 89–110 | 3.00–3.15 |

| Asbestos | 2.55 | 620 | 160 | - |

| Alumina | 3.3–3.95 | 1700–2000 | 300–380 | 0.4 |

| Alumina-silica | 3.4 | 1590–2550 | 200–248 | 0.8–1 |

| SiN | - | 2500–4800 | 195–300 | - |

| SiC | 2.5–2.7 | 2200–3450 | 221–250 | - |

| BN | 7.65–7.85 | 2100 | 345 | - |

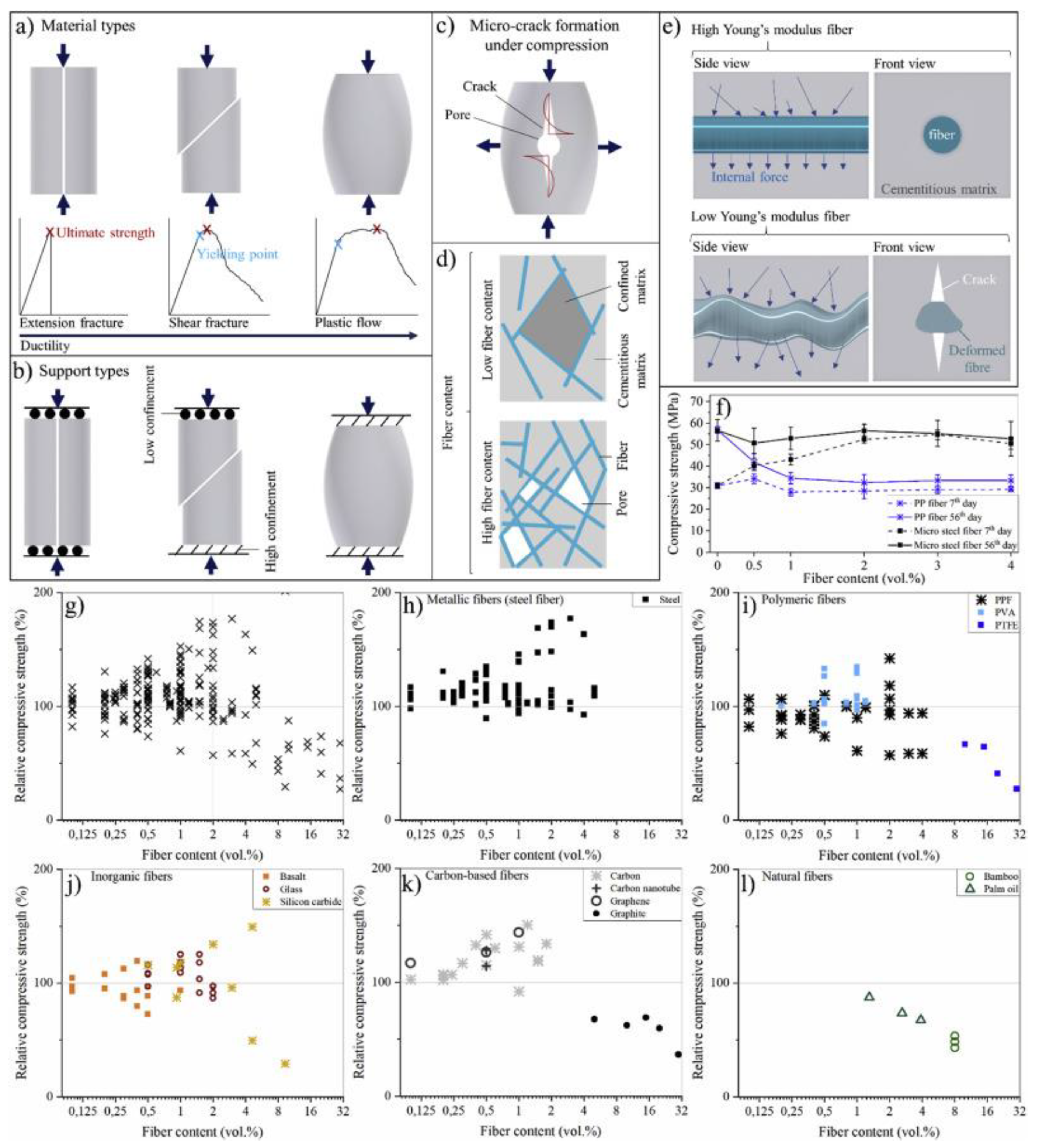

The summary of various types of fibers such as metallic, inorganic, polymeric, carbon-based, and natural fibers as a function of fiber content (%) for the determination of the relative compressive strength of composite materials is represented in

. Natural fibers reinforced geopolymer composite shows a compressive strength below 100%. The carbon-based geopolymer shows strength above 100%, with similar behavior from E-glass and Si-C ones. However, carbon fiber reinforced geopolymer composite stands ahead in terms of operational temperature at a value of 1000 °C. Regarding the strength and durability of the fiber-reinforced composites, carbon fibers composite displays better performance in mechanical strength with durability after damage

. In comparison with E-glass fibers, reinforced geopolymer composite shows optimum durability with residual strength. However, the remaining strength of carbon fiber reinforced geopolymer composite remains unchanged.

(

) Material strength in the various condition of fracture (

) Compression as the function of defor-mation (

) Crack formation mechanism (

) influence of fiber content on structure of the composites; (

) fiber performance under compression; (

) development of compressive strength of FRGC over time; the influence of fiber content (

) relative compressive strength as the function of fiber content for all fiber types, (

) steel fibers, (

) synthetic polymeric fibers, (

) inorganic fibers, (

) carbon-based fibers, and (

) natural polymeric fibers. Reprinted from

with permission of Elsevier.

References

- Samal, S.; Vlach, J.; Kolinova, M.; Kavan, P. Micro-computed tomography characterization of isotropic filler distribution in magnetorheological elastomeric composites. In Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials; Ohji, T., Singh, M., Halbig, M., Moon, K., Eds.; The American Ceramic Society: Westerville, OH, USA; Wiley: Hoboken, NJ, USA, 2016; pp. 57–69.

- Rashad, A.M. Effect of steel fibers on geopolymer properties—The best synopsis for civil engineer. Constr. Build. Mat. 2020, 246, 118534.

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548.

- Samal, S.; Thanh, N.P.; Marvalová, B.; Petríková, I. Thermal Characterization of Metakaolin-Based Geopolymer. JOM 2017, 69, 2480–2484.

- Samal, S.; Vlach, J.; Kavan, P. Improved mechanical properties of magneto rheological elastomeric composite with isotropic iron filler distribution. Ciênc. Tecnol. Mater. 2016, 28, 155–161.

- Kriven, W.M. Geopolymer based composites. Compr. Compos. Mater. II 2018, 5, 269–280.

- Bai, T.; Liu, B.; Wu, Y.; Huang, W.; Xia, Z. Mechanical properties of metakaolin-based geopolymer with glass fiber reinforcement and vibration preparation. J. Non Cryst. Solids 2020, 544, 120173.

- Hung, T.D.; Louda, P.; Kroisova, D.; Bortnovsky, O.; Xiem, N.T. New generation of geopolymer composite for fire-resistance. In Advances in Composite Materials—Analysis of Natural and Man-Made Materials; Tesinova, P., Ed.; InTech: London, UK, 2011; pp. 73–94.

- Mills-Brown, J.; Potter, K.; Foster, S.; Batho, T. The development of a high temperature tensile testing rig for composite laminates. Compos. A 2013, 52, 99–105.

- Samal, S.; Thanh, N.P.; Petríková, I.; Marvalová, B.; Vallons, K.A.M.; Lomov, S.V. Correlation of microstructure and mechanical properties of various fabric reinforced geo-polymer composites after exposure to elevated temperature. Ceram. Int. 2015, 41, 12115–12129.

- Alzeer, M.; MacKenzie, K.J.D. Synthesis and mechanical properties of new fiber-reinforced composites of inorganic polymers with natural wool fibers. J. Mater. Sci. 2012, 47, 6958–6965.

- Giancaspro, J.W.; Balaguru, P.N.; Lyon, R.E. Fire protection of flammable materials utilizing geopolymer. SAMPE J. 2004, 40, 42–49.

- Samal, S.; Marvalová, B.; Petríková, I.; Vallons, K.A.M.; Lomov, S.V.; Rahier, H. Impact and post-impact behavior of fabric reinforced geopolymer composite. Constr. Build. Mater. 2016, 127, 111–124.

- Ribero, D.; Kriven, W.M. Properties of Geopolymer Composites Reinforced with Basalt Chopped Strand Mat or Woven Fabric. J. Am. Ceram. Soc. 2016, 99, 1192–1199.

- Tran, D.H.; Kroisová, D.; Louda, P.; Bortnovsky, O.; Bezucha, P. Effect of curing temperature on flexural properties of silica-based geopolymer-carbon reinforced composite. J. Achiev. Mater. Manuf. Eng. 2009, 37, 492–497. Available online: (accessed on 1 April 2021).

- Samal, S.; Stuchlík, M.; Petrikova, I. Thermal behavior of flax and jute reinforced in matrix acrylic composite. J. Therm. Anal. Calorim. 2018, 131, 1035–1040.

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Effect of fabric orientation on mechanical properties of cotton fabric reinforced geopolymer composites. Mater. Des. 2014, 57, 360–365.

- Study of Interfacial Adhesion between Nickel-Titanium Shape Memory Alloy and a Polymer Matrix by Laser Surface Pattern. Appl. Sci. 2020, 10, 2172

- Zhang, Y.; Sun, W.; Li, Z.; Zhou, X.; Chau, C. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2008, 22, 370–383.

- Zhao, W.; Wang, Y.; Wang, X.; Wu, D. Fabrication, mechanical performance and tribological behaviors of polyacetal-fiber-reinforced metakaolin-based geopolymeric composites. Ceram. Int. 2016, 42, 6329–6341.

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A 2014, 56, 280–289.

- Samal, S. Effect of High temperature on the microstructural evolution of fiber-reinforced geopolymer composite. Heliyon 2019, 5, e01779.

- Samal, S.; Thanh, N.P.; Petríková, I.; Marvalová, B. Improved mechanical properties of various fabric-reinforced geocomposite at elevated temperature. JOM 2015, 67, 1478–1485.

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132.

- Ranjbar, N.; Zhang, M. Fiber-Reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498.

- Ganesan, N.; Abraham, R.; Deepa Raj, S. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476.

- Samal, S.; Škodová, M.; Abate, L.; Blanco, I. Magneto-Rheological Elastomer Composites. A Review. Appl. Sci. 2020, 10, 4899. https://doi.org/10.3390/app10144899

- Okada, K.; Imase, A.; Isobe, T.; Nakajima, A. Capillary rise properties of porous geopolymers prepared by an extrusion method using polylactic acid (PLA) fibers as the pore formers. J. Eur. Ceram. Soc. 2011, 31, 461–467.

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Metselaar, H.S.C.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81.

- Sanjay, M.R.; Arpitha, G.R.; Yogesha, B. Study on Mechanical Properties of Natural—Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Mater. Today Proc. 2015, 2, 2959–2967.