Pomegranate (Punica granatum L.) is an ancient fruit-bearing deciduous shrub that belongs to the Punicaceae family. The juice is ethe major food product obtained from arils. It contains in average 85.4% water and 15.6% dry substance, composed of sugars, organic acids, pectins, anthocyanins, polyphenols, vitamins and minerals. Pomegranate juice exhibits high antioxidant capacity because of its rich content of polyphenols, which represent the highest proportion of phytochemicals in pomegranate.

ConvThentional pressure-driven membrane operations and implementation of innovative membrane operations, such as osmotic distillation and pervaporation, are discussed in relation to their potential intechnologies that provide minimum influence of juice clarification, fractionation, concentration and aroma recovery. Their implementation in integrated systems offer new opportunities to processing and preservation on functional properties is a topic of growing interest for the improve the healthiness and quality of the ment of juice as well as to recover, purifquality and concentrate bioactive compounds for the formulathe production of functional ingredients.

- Pomegranate juice

- Antioxidants

- Membrane operations

- Integrated membrane systems

- Functional ingredients

- Bioactive compounds

- Polyphenols

1. IDefintroductition

Pomegranate (Punica granatum L.), also called “seeded apple” or “granular apple,” is an ancient fruit-bearing deciduous shrub that belongs to the Punicaceae family.

2. Introduction

Due to its good adaptation to a wide range of climate and soil conditions, pomegranate is grown in many different geographical regions including tropical and subtropical regions [1]. Currently, Mediterranean countries, India, Iran and California are the main producers. India, China, Iran and Turkey have the largest area of production [2].

The genetic diversity of pomegranate is demonstrated by an excess of 500 globally distributed varieties, approximately 50 of which are known to be commercially cultivated [3].

The global pomegranate market was valued at USD 8.2 billion in 2018 and is expected to reach USD 23.14 Billion by year 2026, at a Compound Annual Growth Rate (CAGR) of 14.0 percent [4]. Increasing demand for pomegranate and its derivatives (such as pomegranate powder, pomegranate juice, functional beverages) as well as other pomegranate-derived products is driven by its widespread popularity as a functional food and a source of nutraceuticals [5][6].

Pomegranate juice is the major food product obtained from arils, which constitute about 50% of the fruit weight and contain about 78% juice and 22% seeds [7].

Pomegranate-based “superfruits” have become mainstream within the juice and functional beverage category thanks to their properties to deliver nutritional benefit and antioxidants into the diet [8].

23. The Production Process of Pomegranate Juice

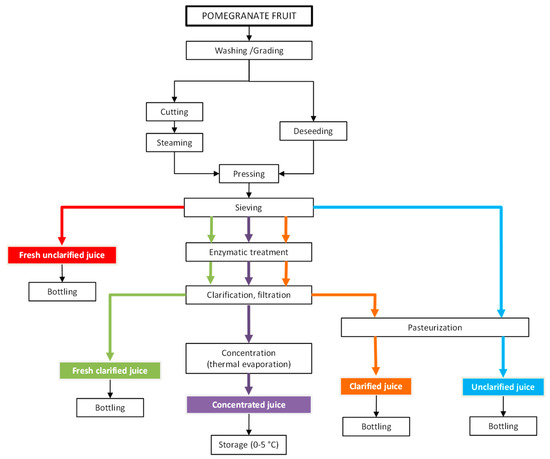

The production process of pomegranate juice, as reported in Figure 1, includes several steps such as washing, crushing, deshelling, pressing, clarification and pasteurization [9]. Traditional methods of clarification involve many steps, such as enzymatic treatment (depectinization), cooling, flocculation (gelatin, silica sol, bentonite and diatomaceous), decantation and filtration, which are labour and time consuming. In addition, these methods use large amounts of coadiuvants and additives with further drawbacks, such as the risk of dust inhalation caused by handling and disposal, environmental problems and significant disposal costs. Although the conventional thermal treatments do inactivate native enzymes and reduce the microbial load, they negatively impact the juice organoleptic properties. Flavour notes can be deteriorated, and juice darkening notes due to enzymatic browning and Millard reactions can occur. Off-flavour formation, colour change, reduction of nutritional values and high energy consumption are also typical drawbacks of thermal effects during evaporation processes for juice concentration [10]. Therefore, the use of mild technologies able to minimize the degradation of the functional molecules of the juice is strongly recommended to promote the development of high-quality products [11][12].

Figure 1. Flow diagram of processing operations for pomegranate juice production (adapted from [9]).

34. Juice Composition and Health Properties

Pomegranates produce a reddish-purple, moderately acidic juice containing in average 85.4% water and 15.6% dry substance, composed of sugars, organic acids, pectins, anthocyanins, polyphenols, vitamins and minerals. However, the juice composition, as well as organoleptic attributes, is strictly correlated to the pomegranate variety and juice production technology. Juices obtained from sarcotestas alone contain approximately 15% solids, lower than juices produced from whole fruits (16–17%). This is because sarcotestas are mainly sources of sugars, acids and minerals, while the rind is rich in polyphenolic compounds. On the other hand, juice pressed from whole fruits has a typical bitter taste due to the high content of phenolics [13].

The typical composition of three varieties of pomegranate juice (Wonderful, Chaca and Codpa) from squeezed arils of fresh fruits at the full ripe of maturity is reported in Table 1.

Table 1. Pomegranate juice composition from three varieties (Wonderful, Chaca and Codpa) at full ripe stage (adapted from [14]).

|

Parameter |

|

Variety |

|

|

Wonderful |

Chaca |

Codpa |

|

|

pH |

3.61 ± 0.01 |

3.68 ± 0.02 |

3.66 ± 0.02 |

|

TSS, °Brix |

18.7 ± 0.3 |

18.4 ± 0.1 |

18.0 ± 0.1 |

|

TTA, % citric acid |

1.04 ± 0.01 |

0.92 ± 0.01 |

1.04 ± 0.01 |

|

Ratio, L juice kg−1 arils |

0.56 |

0.59 |

0.60 |

|

TPC, (mg GAE 100 L−1) |

1930 ± 20 |

2100 ± 50 |

1600 ± 70 |

|

Antioxidant activity, (mmol trolox equivalent L−1) |

11.5 ± 0.3 |

12.2 ± 0.3 |

14.9 ± 0.05 |

|

Delphinidin 3,5-diglucoside (mg Mv3 100 mL−1) |

13.5 ± 1.2 |

11.7 ± 1.0 |

17.5 ± 1.2 |

|

Cyanidin 3,5-diglucoside (mg Mv3 100 mL−1) |

36.4 ± 2.4 |

23.8 ± 0.7 |

34.7 ± 1.5 |

|

Pelargonidin 3,5-diglucoside (mg Mv3 100 mL−1) |

0.7 ± 0.02 |

0.21 ± 0.02 |

1.9 ± 0.06 |

|

Delphinidin 3-glucoside (mg Mv3 100 mL−1) |

1.4 ± 0.06 |

1.0 ± 0.04 |

2.5 ± 0.06 |

|

Cyanidin 3-glucoside (mg Mv3 100 mL−1) |

10.6 ± 0.9 |

3.0 ± 0.4 |

11.8 ± 1.3 |

|

Pelargonidin 3-glucoside (mg Mv3 100 mL−1) |

0.3 ± 0.02 |

0.2 ± 0.01 |

0.4 ± 0.002 |

|

Total anthocyanin content (mg Mv3 100 mL−1) |

62.8 ± 3.7 |

43 ± 0.6 |

68.7 ± 1.0 |

TSS, total soluble solids; TTA, total titratable acidity; TPC, total phenolic content; GAE, gallic acid equivalents; Mv3, Malvidin-3-glucoside.

The antioxidant activity of thibie juice is much higher than that of red wine and green tea as well as of other juices including black cherry, cranberry, apple, orange and blueberry juices [15][16]. Thanks to this hiability the juice is used as a natural bio-preservative as alternative to the use of synthetic antioxidants that have toxic side effects.

Pomegranate juice exh ibits high antioxidant capacity because of its rich content of polyphenols, which represent the highest proportion of phytochemicals in pomegranate. In particular, the antioxidant activity of the juice can be attributed mainly to ellagic acid and its derivatives, anthocyanins and hydrolysable tannins [1417].

The soluble polyphenol content in pomegranate juice varies within the range of 0.2–1.0%, depending on variety, including mainly hydrolysable tannins, ellagic acid derivatives and flavonoids.

Punicalagin, a large polyphenol with a molecular weight greater than 1000 belonging in the family of ellagitannins is responsible for more than the half pomegranate juice’s antioxidant effect [1518].

Pomegranate juice is an important source of flavonoids including flavonols (catechin, epicatechin, gallocatechin) and anthocyanins. Anthocyanins are water-soluble plant pigments responsible of the red colour of both fruits and juice. They include 3-glucosides and 3,5-glucosides of delphinidin, cyanidin, and pelargonidin [1619].

Phenolic acids include hydroxybenzoic acids (mainly gallic acid and ellagic acid) and hydroxycinnamic acids, principally caffeic acid, chlorogenic acid and p-coumaric acid [1720][1821]. Other chemical constituents in pomegranate juice include sugars (glucose, fructose, sucrose), organic acids (citric acid, malic acid, tartaric acid, fumaric acid, succinic acid, ascorbic acid, etc.), amino acids (proline, valine, methionine, glutamic acid, aspartic acid), indoleamines (tryptamine, serotonin, melatonin), tocopherols and minerals (Fe, Ca, Cl, Cu, K, Mg, Mn, Na, Sn and Zn) [1922].

Pomegranate juice, being rich in bioactive compounds like polyphenols, has shown many health-related properties, such as antioxidant, anti-inflammatory, antihypertensive and antiatherogenic effects through in vivo and in vitro studies [2023][2124]. The healthiest constituents are ellagitannins, ellagic acid, punicic acid, anthocyanidins, anthocyanins, flavonols and flavones.

Ellagitannins have been associated to the prebiotic potential and antimicrobial activity of the juice [2225]. In vitro studies have established the potential of pomegranate extracts as an antitumorigenic agent against various cancers including prostate cancer, renal cell carcinoma, papillary thyroid carcinoma cells and cervical cancer cell lines [2326]. Mechanistic studies have revealed that Punica extracts and its components, individually or in combination, can modulate and target key proteins and genes involved in breast cancer [2427]. A wide variety of molecules can be targeted by pomegranate to suppress tumour growth and metastasis, including those involved in cell-cell and cell-extracellular matrix adhesions, modulators of cytoskeleton dynamics and regulators of cancer cell anoikis and chemotaxis, pro-inflammatory and pro-angiogenic molecules [2528].

Ellagic acid and punicalagin, have shown the ability to inhibit amine oxidases, α-glucosidase, dipeptidyl peptidase-4, lipase, triglyceride accumulation and adipogenesis-related genes, as well as to decrease lipogenesis and lipolysis in mouse and human adipose cells. These results support the development of functional foods for the prevention obesity, diabetes and dyslipidemias [2629]. Studies with mice models have demonstrated that pomegranate juice exhibits a protective effect against oxidative damage in Parkinson’s disease as well as antileishmanial activity [2730][2831].

Finally, human studies have shown the beneficial effects of the juice on blood pressure, serum triglycerides, high-density lipoprotein (HDL) cholesterol, oxidative stress and inflammation in haemodialysis patients [2932]. The juice consumption allows also to reduce the serum erythropoietin level [3033] as well as systolic and diastolic blood pressure in patients with type 2 diabetes [3134].

All these studies confirm the interest for the implementation of innovative technologies, including membrane operations, that provide minimum influence of juice processing and preservation on functional properties. These technologies represent also a useful approach for recovering phytochemical compounds from second-quality and over-ripe pomegranate fruits not suitable for commercialization, which can be exploited for the formulation of functional ingredients. The processing of these fruits wasted as by-products generates more profits and minimizes production losses along with the subsequent environmental benefits.

4. Membrane operations in pomegranate juice processing

Microfiltration and ultrafiltration represent a valid alternative to the conventional clarification procedures of pomegranate juice resulting in savings in labour and capital costs, short processing time,

increased juice yield and avoidance of fining agents and filter aids. Juice freshness, aroma and nutritional value are well preserved in comparison to the use of fining agents allowing to obtain high-quality, natural fresh-tasting and additive-free clarified products[32]. Tight ultrafiltration and nanofiltration membranes offer new perspectives in juice fractionation aimed at recovering and purifying bioactive compounds of interest for the production of functional ingredients[33]. Reverse osmosis and osmotic distillation represent useful alternatives to thermal evaporation for juice concentration. High levels of total soluble solids can be reached through osmotic distillation operating at low pressure and temperatures so avoiding mechanical and thermal stress of the processed juice. The overall results indicate that the process is very effcient in preserving the original characteristics of the fresh juice including colour, total antioxidant activity, phenolic compounds and organic acids[34].

A flow diagram for the production of clarified and concentrated juice by integrated membrane process is schematically depicted in Figure 2.

Pervaporation is a promising tool for the concentration of aroma compounds from pomegranate juice since it can be operated at moderate temperatures[35].

References

- Holland, D.; Hatib, K.; Bar-Ya’akov, I. Pomegranate: Botany, horticulture, breeding. In Horticultural Reviews;Janick, J., Ed.; JohnWiley & Sons: Hoboken, NJ, USA, 2009; Volume 35, pp. 127–191.

- Kahramanoglu, I.; Usanmaz, S. Pomegranate Production and Marketing; CRC Press Taylor & Francis Group:Boca Raton, FL, USA, 2016.

- IPGRI. Regional Report CWANA 1999–2000; International Plant Genetic Resources Institute: Rome, Italy, 2001;pp. 20–28.

- APEDA. Market Intelligence Bulletin. Available online: https://agriexchange.apeda.gov.in/Weekly_eReport/Pomegranate_Report.pdf (accessed on 4 June 2020).

- Johanningsmeier, S.D.; Harris, G.K. Pomegranate as a functional food and nutraceutical source. Annu. Rev.Food Sci. Technol. 2011, 2, 181–201.

- Surek, E.; Nilufer-Erdil, D. Changes in phenolics and antioxidant activity at each step of processing frompomegranate into nectar. Int. J. Food Sci. Nutr. 2014, 65, 194–202.

- Kulkarni, A.P.; Aradhya, S.M. Chemical changes and antioxidant activity in pomegranate arils during fruitdevelopment. Food Chem. 2005, 93, 319–324.

- Beaulieu, J.C.; Stein-Chisholm, R.E. HS-GC-MS volatile compounds recovered in freshly pressed ‘Wonderful’cultivar and commercial pomegranate juices. Food Chem. 2016, 190, 643–656.

- Mena, P.; Martí, N.; García-Viguera, C. The impact of processing and storage on the (poly)phenolic fractionof pomegranate (Punica granatum L.) juices. In Processing and Impact on Antioxidants in Beverages, 1st ed.;Preedy, V., Ed.; Elsevier: San Diego, CA, USA, 2014; pp. 173–184.

- Maskan, M. Production of pomegranate (Punica granatum L.) juice concentrate by various heating methods:Colour degradation and kinetics. J. Food Eng. 2006, 72, 218–224.

- Ferrari, G.; Maresca, P.; Ciccarone, R. The application of high hydrostatic pressure for the stabilization offunctional foods: Pomegranate juice. J. Food Eng. 2010, 100, 245–253.

- Putnik, P.; Kresoja, Z.; Bosiljkov, T.; Jambrak, A.R.; Barba, F.J.; Lorenzo, J.M.; Roohinejad, S.; Granato, D.;Zuntar, I.; Kovacevic, D.B. Comparing the effects of thermal and non-thermal technologies on pomegranatejuice quality: A review. Food Chem. 2019, 279, 150–161.

- Oziyci, H.R.; Karhan, M.; Tetik, N.; Turhan, I. Effects of processing method and storage temperature on clearpomegranate juice turbidity and color. J. Food Process. Preserv. 2013, 37, 899–906.

- Kalaycioglu, Z.; Bedia Erim, F. Total phenolic contents, antioxidant activities, and bioactive ingredients ofjuices from pomegranate cultivars worldwide. Food Chem. 2017, 221, 496–507.Labbé, M.; Ulloa, P.A.; López, F.; Sáenz, C.; Peña, A.; Salazar, F.N. Characterization of chemical compositionsand bioactive compounds in juices from pomegranates (‘Wonderful’, ‘Chaca’ and ‘Codpa’) at di erentmaturity stages. Chil. J. Agric. Res. 2016, 76, 479–486.

- Seeram, N.; Lee, R.; Hardy, M.; Heber, D. Rapid large scale purification of ellagitannins from pomegranatehusk, a by-product of the commercial juice industry. Sep. Purif. Technol. 2005, 41, 49–55.Gil, M.I.; Tomas-Barberan, F.A.; Hess-Pierce, B.; Holcroft, D.M.; Kader, A.A. Antioxidant activity ofpomegranate juice and its relationship with phenolic composition and processing. J. Agric. Food Chem. 2000,50, 4581–4589.

- Viuda-Martos, M.; Fernández-López, J.; Pérez-Álvarez, J.A. Pomegranate and its many functional componentsas related to human health: A review. Crit. Rev. Food Sci. Nutr. 2010, 9, 635–654.Seeram, N.P.; Aviram, M.; Zhang, Y.; Henning, S.M.; Feng, L.; Dreher, M.; Heber, D. Comparison of antioxidantpotency of commonly consumed polyphenol-rich beverages in the United States. J. Agric. Food Chem. 2008,56, 1415–1422.

- Amakura, Y.; Okada, M.; Tsuji, S.; Tonogai, Y. High-performance liquid chromatographic determination withphotodiode array detection of ellagic acid in fresh and processed fruits. J. Chromatogr. A 2000, 896, 87–93.Kalaycioglu, Z.; Bedia Erim, F. Total phenolic contents, antioxidant activities, and bioactive ingredients ofjuices from pomegranate cultivars worldwide. Food Chem. 2017, 221, 496–507.

- Poyrazoglu, E.; Gökmen, V.; Artik, N. Organic acids and phenolic compounds in pomegranates (Punicagranatum L.) grown in Turkey. J. Food Comp. Anal. 2002, 15, 567–575.Seeram, N.; Lee, R.; Hardy, M.; Heber, D. Rapid large scale purification of ellagitannins from pomegranatehusk, a by-product of the commercial juice industry. Sep. Purif. Technol. 2005, 41, 49–55.

- Kazakos, S.; Mantzourani, I.; Plessas, S. Assessment of pomegranate juice as an alternative “substrate” forprobiotic delivery. Recent advances and prospects. Fermentation 2020, 6, 24.Viuda-Martos, M.; Fernández-López, J.; Pérez-Álvarez, J.A. Pomegranate and its many functional componentsas related to human health: A review. Crit. Rev. Food Sci. Nutr. 2010, 9, 635–654.

- Bonesi, M.; Tundis, R.; Sicari, V.; Loizzo, M.R. The juice of pomegranate (Punica granatum L.): Recent studieson its bioactivities. In Quality Control in the Beverage Industry; Grumezescu, A.M., Holban, A.M., Eds.;Academic Press: New York, NY, USA, 2019; Volume 17, pp. 459–489.Amakura, Y.; Okada, M.; Tsuji, S.; Tonogai, Y. High-performance liquid chromatographic determination withphotodiode array detection of ellagic acid in fresh and processed fruits. J. Chromatogr. A 2000, 896, 87–93.

- Kandylis, P.; Kokkinomagoulos, E. Food applications and potential health benefits of pomegranate and itsderivatives. Foods 2020, 9, 122.Poyrazoglu, E.; Gökmen, V.; Artik, N. Organic acids and phenolic compounds in pomegranates (Punicagranatum L.) grown in Turkey. J. Food Comp. Anal. 2002, 15, 567–575.

- Bialonska, D.; Ramnani, P.; Kasimsetty, S.G.; Muntha, K.R.; Gibson, G.R.; Ferreira, D. The influence ofpomegranate by-product and punicalagins on selected groups of human intestinal microbiota. Int. J.Food Microbiol. 2010, 140, 175–182.Kazakos, S.; Mantzourani, I.; Plessas, S. Assessment of pomegranate juice as an alternative “substrate” forprobiotic delivery. Recent advances and prospects. Fermentation 2020, 6, 24.

- Yao, X.; Cheng, X.; Zhang, L.; Yu, H.; Bao, J.; Guan, H.; Lu, R. Punicalagin from pomegranate promoteshuman papillary thyroid carcinoma BCPAP cell death by triggering ATM-mediated DNA damage response.Nutr. Res. 2017, 47, 63–71.Bonesi, M.; Tundis, R.; Sicari, V.; Loizzo, M.R. The juice of pomegranate (Punica granatum L.): Recent studieson its bioactivities. In Quality Control in the Beverage Industry; Grumezescu, A.M., Holban, A.M., Eds.;Academic Press: New York, NY, USA, 2019; Volume 17, pp. 459–489.

- Vini, R.; Sreeja, S. Punica granatum and its therapeutic implications on breast carcinogenesis: A review.Biofactors 2015, 41, 78–89.Kandylis, P.; Kokkinomagoulos, E. Food applications and potential health benefits of pomegranate and itsderivatives. Foods 2020, 9, 122.

- Ahmadiankia, N. Molecular targets of pomegranate (Punica granatum) in preventing cancer metastasis. Iran. J.Basic Med. Sci. 2019, 22, 977.Bialonska, D.; Ramnani, P.; Kasimsetty, S.G.; Muntha, K.R.; Gibson, G.R.; Ferreira, D. The influence ofpomegranate by-product and punicalagins on selected groups of human intestinal microbiota. Int. J.Food Microbiol. 2010, 140, 175–182.

- Les, F.; Carpéné, C.; Arbonés-Mainar, J.M.; Decaunes, P.; Valero, M.S.; López, V. Pomegranate juice andits main polyphenols exhibit direct effects on amine oxidases from human adipose tissue and inhibit lipidmetabolism in adipocytes. J. Funct. Foods 2017, 33, 323–331.Yao, X.; Cheng, X.; Zhang, L.; Yu, H.; Bao, J.; Guan, H.; Lu, R. Punicalagin from pomegranate promoteshuman papillary thyroid carcinoma BCPAP cell death by triggering ATM-mediated DNA damage response.Nutr. Res. 2017, 47, 63–71.

- Kujawska, M.; Jourdes, M.; Kurpik, M.; Szulc, M.; Szaefer, H.; Chmielarz, P.; Kreiner, G.; Krajka-Ku´zniak, V.;Mikołajczak, P.L.; Teissedre, P.L.; et al. Neuroprotective e ects of pomegranate juice against Parkinson’sdisease and presence of ellagitannins-derived metabolite—Urolithin a—In the brain. Int. J. Mol. Sci. 2020,21, 202.Vini, R.; Sreeja, S. Punica granatum and its therapeutic implications on breast carcinogenesis: A review.Biofactors 2015, 41, 78–89.

- Alkathiri, B.; El-Khadragy, M.; Metwally, D.; Al-Olayan, E.; Bakhrebah, M.; Abdel Moneim, A.Pomegranate (Punica granatum) juice shows antioxidant activity against cutaneous leishmaniasis-inducedoxidative stress in female BALB/c mice. Int. J. Environ. Res. Public Health 2017, 14, 1592.Ahmadiankia, N. Molecular targets of pomegranate (Punica granatum) in preventing cancer metastasis. Iran. J.Basic Med. Sci. 2019, 22, 977.

- Barati Boldaji, R.; Akhlaghi, M.; Sagheb, M.M.; Esmaeilinezhad, Z. Pomegranate juice improvescardiometabolic risk factors, biomarkers of oxidative stress and inflammation in hemodialysis patients:A randomized crossover trial. J. Sci. Food Agric. 2020, 100, 846–854.Les, F.; Carpéné, C.; Arbonés-Mainar, J.M.; Decaunes, P.; Valero, M.S.; López, V. Pomegranate juice andits main polyphenols exhibit direct effects on amine oxidases from human adipose tissue and inhibit lipidmetabolism in adipocytes. J. Funct. Foods 2017, 33, 323–331.

- Banihani, S.A.; Shuaibu, S.M.; Al-Husein, B.A.; Makahleh, S.S. Fresh pomegranate juice decreases fastingserum erythropoietin in patients with type 2 diabetes. Int. J. Food Sci. 2019, 2019, 1269341.Kujawska, M.; Jourdes, M.; Kurpik, M.; Szulc, M.; Szaefer, H.; Chmielarz, P.; Kreiner, G.; Krajka-Ku´zniak, V.;Mikołajczak, P.L.; Teissedre, P.L.; et al. Neuroprotective e ects of pomegranate juice against Parkinson’sdisease and presence of ellagitannins-derived metabolite—Urolithin a—In the brain. Int. J. Mol. Sci. 2020,21, 202.

- Sohrab, G.; Roshan, H.; Ebrahimof, S.; Nikpayam, O.; Sotoudeh, G.; Siasi, F. Effects of pomegranate juiceconsumption on blood pressure and lipid profile in patients with type 2 diabetes: A single-blind randomizedclinical trial. Clin. Nutr. ESPEN 2019, 29, 30–35.Alkathiri, B.; El-Khadragy, M.; Metwally, D.; Al-Olayan, E.; Bakhrebah, M.; Abdel Moneim, A.Pomegranate (Punica granatum) juice shows antioxidant activity against cutaneous leishmaniasis-inducedoxidative stress in female BALB/c mice. Int. J. Environ. Res. Public Health 2017, 14, 1592.

- Galiano, F.; Figoli, A.; Conidi, C.; Menichini, F.; Bonesi, M.; Loizzo, M.R.; Cassano, A.; Tundis, R.Functional properties of Punica granatum L. juice clarified by hollow fiber membranes. Processes 2016,4, 21.Barati Boldaji, R.; Akhlaghi, M.; Sagheb, M.M.; Esmaeilinezhad, Z. Pomegranate juice improvescardiometabolic risk factors, biomarkers of oxidative stress and inflammation in hemodialysis patients:A randomized crossover trial. J. Sci. Food Agric. 2020, 100, 846–854.

- Conidi, C.; Cassano, A.; Caiazzo, F.; Drioli, E. Separation and purification of phenolic compounds frompomegranate juice by ultrafiltration and nanofiltration membranes. J. Food Eng. 2017, 195, 1–13.Banihani, S.A.; Shuaibu, S.M.; Al-Husein, B.A.; Makahleh, S.S. Fresh pomegranate juice decreases fastingserum erythropoietin in patients with type 2 diabetes. Int. J. Food Sci. 2019, 2019, 1269341.

- Cassano, A.; Conidi, C.; Drioli, E. Clarification and concentration of pomegranate juice (Punica granatum L.)using membrane processes. J. Food Eng. 2011, 107, 366–373.Sohrab, G.; Roshan, H.; Ebrahimof, S.; Nikpayam, O.; Sotoudeh, G.; Siasi, F. Effects of pomegranate juiceconsumption on blood pressure and lipid profile in patients with type 2 diabetes: A single-blind randomizedclinical trial. Clin. Nutr. ESPEN 2019, 29, 30–35.

- Raisi, A.; Aroujalian, A.; Kaghazchi, T. Multicomponent pervaporation process for volatile aroma compoundsrecovery from pomegranate juice. J. Membr. Sci. 2008, 322, 339–348.