Although weathering is primarily a surface phenomenon, it is an important issue for wood products as it affects their appearance, service life, and wood-coating performance. To encourage the use of wood as a material for joinery and other building components, the results of research into increasing the weathering resistance of wood are extremely significant. The development of weathering protection methods is of great importance to reduce the maintenance requirements for wood exposed outdoors and can have a major environmental impact.

- wood surface

- weathering

- photostabilizers

- coatings

- nanoparticles

- plasma deposition

- chemical modification

- thermal modification

1. Introduction

Wood is a renewable, natural material that has been used for centuries in various applications, mostly for furniture and in building construction. In addition to many desirable properties, such as an attractive appearance, good strength, low density, and good insulating properties, wood also has some less desirable properties, such as hygroscopicity, flammability, susceptibility to biological attack, and surface degradation due to weathering.

Colour change is the first sign of complex chemical reactions on the surface of wood exposed to weather, initiated by solar radiation, especially the ultraviolet (UV) part of the spectrum. The phenolic hydroxyl groups in lignin react with UV radiation to form aromatic free radicals (phenoxy radicals), which further react with oxygen to form quinoid structures that are responsible for the yellowing of wood [6,7][1][2]. The surface of light coloured woods usually turns yellow or brown, and darker types of wood that are rich in extractives may first fade and then turn yellow or brown. Although earlier research by Hon and Ifju [14][3] indicated that UV light penetrates wood 75 µm, more recent research reported that UV light penetrates the wood deeper, mostly up to 150 µm [15,16,17,18,19][4][5][6][7][8].

The mechanism of weathering as well as its influence on the surface properties of wood has been investigated by many authors. A good review of the research in this area is given in several review papers [1,3,5,10,12,30,31][9][10][11][12][13][14][15]. Although weathering is primarily a surface phenomenon, it is an important issue for wood products exposed outdoors as it affects their appearance, service life, and wood-coating performance.

The weathering durability of wood can be tested using outdoor exposure or using special devices that can simulate outdoor weathering. The device for artificial weathering is usually equipped with temperature control, a light irradiation source (xenon lamps or fluorescent UV lamps), water spray, and condensation units. The results of natural exposure are difficult to compare with the results of accelerated exposure due to different mechanisms of material degradation. In addition, biological impact and air pollution are lacking in artificial weathering.

In order to improve the weathering durability of the wood and achieve a long life for wood products, the various methods of protecting wood against weathering are applied. The aim of this paper is to review recent developments in the methods of protecting wood from weathering. Treatments of wood with inorganic metal compounds and bio-based water repellents;Section 6. Modification of wood and wood surface with thermosetting resins, furfuryl alcohol, and DMDHEU; andSection 8.

2. Protection with Coatings

The primary function of a coating is to protect the wood from the two main causes of the natural weathering process, UV radiation and moisture, and to help maintain its appearance. Furthermore, the absorption of UV radiation into the coating and the wood under the coating can cause serious and complex chemical reactions that result in the loss of the protective function of the coating and in the deterioration of the coating and wood substrate [70,71][16][17]. In order to extend the lifetime of wood and maintain the natural and attractive appearance of wood, research and development of clear coatings with minimal use of harmful chemicals has become very important for wood finishing [67][18]. However, clear coatings transmit harmful solar radiation which causes changes on the wood surface [5,71,72,73][11][17][19][20].

The first is based on reflection (filter effect) using pigments, the second on the suppression of the reaction by removing newly formed free radicals using HALS, and the third on the absorption of UV radiation before the formation of free radicals using UV absorbers. The main disadvantage of adding pigments into the coating is completely hiding the texture and colour of the wood (opaque coatings) or changing the colour of the wood without hiding wood texture (stains). HALS can be applied directly on wood as an aqueous solution or primer, and they can also be used as an additive in a topcoat [77][21]. state that lignin stabilizers play a significant role in protecting wood from UV light.

Organic UV absorbers that are added into the coating to protect wood and coatings from harmful UV radiation are based on benzophenone, benzotriazole, triazine, malonate, and oxalanilide [67][18]. However, organic UV absorbers, due to their relatively low molecular weight, can migrate to the surface of the coating or into the wood. [81][22] found that the addition of organic UV absorbers into the coating protected the wood from discolouration at the beginning of artificial weathering, but this protection was not long lasting due to the migration and decay of the absorbers during artificial weathering. The efficiency of UV absorbers is determined by their absorption properties, concentration in the coating, coating thickness, chemical interaction with the binder, and other additives in the coating during photodegradation [69][23].

The accelerated development of nanotechnology has enabled the application of nanoparticles of metal oxides to protect coatings and wood surface without significantly affecting the transparency of the coating. [85][24] state that inorganic nanoparticles can be efficient UV absorbers in coatings depending on the type, loading size, and dispersion of the nanoparticles. When mixing nanoparticles with a coating, it is important to achieve the most uniform dispersion of nanoparticles in the coating and ensure the compatibility of nanoparticles with the coating ingredients to avoid a decrease of coating transparency, an increase of coating viscosity, a sudden deposition of nanoparticles, and a large agglomeration of nanoparticles in the coating. [89][25] found that TiO2and ZnO nanoparticles increase the colour stability of waterborne polyacrylate coating during natural and accelerated weathering, and the result was better with a higher concentration of nanoparticles.

[90][26] found that TiO2nanoparticles added into the varnish reduced the colour change of tropical wood species during natural and accelerated weathering. [83][27] found that an acrylate coating with ZnO nanoparticles reduced colour change and mould growth on beech wood during natural weathering. Moreover, studies have also shown that the combined protection of coatings with UV absorbers (organic and inorganic) and HALS has a positive effect on the protection of wood from UV radiation. However, most studies have shown that UV absorbers have a positive effect on the performance of clear coating, but clear coatings can fail on wood due to the influence of water and fungi in combination with solar radiation [74][28].

Although nanotechnology has more effectively solved various problems in wood science than traditional methods, it is still necessary to conduct a large number of tests and introduce a large number of regulations before the commercial application of nanotechnology in protecting wood and coatings, especially in interior environments [66][29]. There are considerable concerns growing about the impact of nanomaterials on human health and the environment. Due to their small size, nanomaterials can have a negative effect on the respiratory and digestive tracts, eyes, and skin [92,93][30][31].

3. Treatments of Wood with Inorganic Metal Compounds and Bio-Based Water Repellents

Numerous studies have shown that treatments of wood with aqueous solutions of inorganic metal compounds, such as chromic acid, copper and cobalt chromates, ferric chloride and nitrate, and various manganese, titanium, and zirconium compounds, enhanced the photostability of wood surfaces and improved the durability of clear coatings and stains applied to treated surfaces [119,120,121,122,123][32][33][34][35][36]. Many of these treatments change the colour of the wood, which is often a disadvantage in their application in the photostabilization of the wood surface. It has been shown that a simple dip or brush application of 5% aqueous chromic acid to a wood surface prevented extractive staining, improved dimensional stability, retarded weathering of unfinished wood, and prolonged the life of finishes [121][34]. To protect the wood surface from the harmful effects of UV light, less harmful metal treatments that do not cause the unwanted colouring of the wood surface should be used.

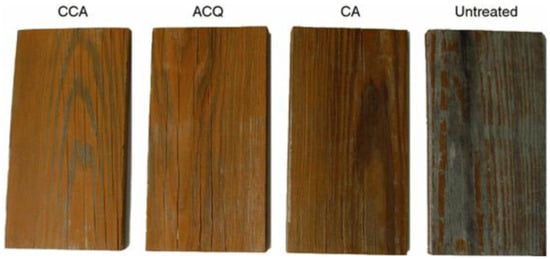

Wood preservatives can also play a role in protecting wood from photodegradation [7][2]. It was reported that copper-based preservatives, such as chromated copper arsenate and ammoniacal copper quat, reduce the photodegradation of wood by retarding the formation of carbonyl groups and delignification [131,132,133][37][38][39]. The authors speculated that this might have been due to a reaction of copper ethanolamine with phenolic groups of lignin to form phenolate which retards the formation of phenoxy radicals involved in colour change. The preservative-treated wood samples exhibited less colour change and better visual ratings than untreated wood samples during weathering (Figure 31) [40].

Figure 1. Samples untreated and treated with coper-based preservatives and coated with alkyd-acrylic water-base coating after three years of natural weathering (CCA-chromated copper arsenate, ACQ-alkaline copper quat, CA-copper azole) [40]. Reprinted with permission from Springer Nature: Springer Nature, Journal of Coatings Technology and Research (Exterior wood coatings. Part-1: Performance of semitransparent stains on preservative-treated wood, Nejad, M. and Cooper, P.), [136]2011.

They reported that monoethanolamine pretreatment of wood surfaces enhanced the durability of semitransparent penetrating stains after 1000 h of artificial weathering. However, further research is needed to determine whether copper monoethanolamine treatment can be used as an effective photoprotective primer for semitransparent penetrating stains [137][41]. Chehreh and Mastari Farahani [138][42] found that treatment of poplar (Populus deltoids) sapwood with a nanocopper oxide suspension reduced colour and contact angle changes of a wood surface after 180 days of natural weathering. Vacuum treatment of Southern pine wood with nano-ZnO dispersion has been shown to reduce the greying of wood after 12 months of natural weathering compared to untreated wood samples.

In recent years, there has been an increased interest in using bio-based coatings that are environmentally friendly and consumer friendly. It has been reported that linseed and tung oil are very efficient in protecting wood surface against water uptake [139][43]. Tall oil treatment was not found resistant to accelerated weathering when used alone in Scots pine wood, but in combination with iron oxide, it was found to be effective in reducing the weathering degradation of the wood surface [140][44]. Epoxidized soybean oil applied to chemically modified wood with succinic anhydride exhibited efficient wood protection against UV light [142][45].

Waxes are important water repellents which can be used for the nonbiocidal protection of wood surfaces in outdoor applications. In the past, waxes were used exclusively as additives in water-repellent finishes and preservatives, and today there are commercial wax treatments designed for external use without biocides [145][46] found that that the treatment of wood with high loadings of wax can reduce moisture absorption and slow down the photodegradation process of spruce wood during artificial accelerated weathering. To increase the effectiveness of waxes and oils in preventing discolouration due to UV light and water, it is suggested that they should contain photoprotective additives [12][13] or pigments [146][47].

4. Chemical Modification of Wood

Chemical modification of wood is defined as a chemical reaction between the wood polymeric constituents and a chemical reagent, resulting in the formation of a covalent bond between the reagent and wood substrate [147][48]. Although most research on chemical modification has been aimed at increasing the dimensional stability and decay resistance of wood [148][49], there are also studies that have been concerned with the protection of wood against weathering and photodegradation (Table 1).

| Chemical Reagent | Findings | Reference |

|---|---|---|

| acetic anhydride |

|

[50][51][52] [51][52] [53][54] [55] [56] [51][57][58][59] |

| benzoyl chloride |

|

[59] [60][61] |

| palmitoyl chloride |

|

[62] |

| fatty acid chlorides |

|

[63] |

| succinic anhydride propionic anhydride |

|

[64] |

| vinyl benzoate |

|

[65] |

| vinyl cinnamate |

|

[65] |

| vinyl-4-T-butylbenzoate |

|

[65] |

| isopropyl glycidyl ether |

|

[66] |

These studies are included in this chapter. The most common methods of chemical modification are esterification and etherification of hydroxyl groups in the cell wall. The most often used chemicals for wood esterification are anhydrides, acid chlorides, carboxylic acids, and isocyanates, and for wood etherification, alkyl halogenides, epoxides, lactones, and α, β-unsaturated compounds [165][66].

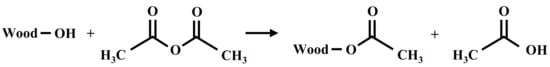

Among the various wood esterification treatments, acetylation has been the most studied [148][49]. Acetylation is an example of the chemical modification of wood where the reaction of acetic anhydride with wood results in esterification of the accessible hydroxyl groups in the cell wall (Figure 42), with the formation of byproduct acetic acid [166][67].

Figure 42. Reaction of wood with acetic anhydride [156][57]. Reprinted by permission from Springer Nature: Springer Nature, Journal of Journal of Coatings Technology and Re-search (Performance of finishes on wood that ischemically modified by acetylation, Beckers, E.P.J. et al.), 1998.

Photodegradation of acetylated wood differs from unmodified wood but is not prevented [149,167][50][68]. It has been established that acetylation is ineffective in protecting lignin at wood surfaces during accelerated weathering [149[50][56][69][70],155,168,169], although some photoprotective effects of acetylation to 20% weight gain have been reported on holocellulose and on the morphology of wood cell walls [155,170,171][56][71][72]. However, the photoprotective effect of acetylation was found to be lost with prolonged exposure of the acetylated wood to the weather because the deacetylation of the wood surface occurred [155][56]. Schaller and Rogez [173][73] reported that acetylation only partly protects lignin from photodegradation, but there is still a need to protect the acetylated wood with coating that has sufficient UV–

Acetylation is shown to have a positive effect on the performance of coatings during accelerated weathering [150,156][51][57]. This is probably due to the higher dimensional stability of acetylated wood, which reduces the stresses in the coating that originate from the dimensional changes of the substrate. Acetylation in combination with a transparent stain improved the resistance of wood against UV degradation, but the removal of the UV absorber from the stain caused the degradation of the polymers within the coating and the loss of adhesion [156][57]. [157][58] reported that acetylated wood had a significantly better result with respect to long-term coating performance compared to unmodified wood.

[159][60] chemically modified (esterified) thin strips (veneers) of Scots pine wood (Pinus sylvestrisL.) to high weight gains with benzoyl chloride and assessed the photostability of the chemically modified wood. Benzoylation to high weight gain reduced the quantity of free radicals formed in the wood during exposure to UV light and caused large losses in the tensile strength of thin wood strips. They found that the esterification of wood with benzoyl chloride stabilized the wood colour against photodegradation and reduced the lignin degradation and generation of carbonyl groups on the surface of irradiated wood. Pandey and Srinivasa [158][59] evaluated the weathering performance of uncoated wood modified with benzoyl chloride and benzoylated wood coated with commercially available polyurethane-based transparent and opaque coatings.

The modification of rubber wood (Hevea brasiliensis) by esterification with palmitoyl chloride has been shown to be effective in photostabilizing wood surfaces to a considerable extent [177][74]. [162][63] modified rubber wood specimens with three fatty acid chlorides (hexnoyl chloride, decanoyl chloride, and tetradecanoyl chloride) and found that the esterification of rubber wood with fatty acid chlorides was effective in restricting photodegradation to some extent, and photoprotection increased with the carbon chain length of fatty acid chloride. [164][65] esterified wood with three different aromatic vinyl esters, viniyl benzoate, vinyl cinnamate, and vinyl-4-T-butylbenzoate, and examined the photostability of the modified wood. They found that the modification of wood with vinyl benzoate at high weight gains (>30%) was effective in the protection of lignin and cellulose from photodegradation, while the modification of wood with ninyl-4-T-butylbenzoate did not provide such protection.

References

- Pandey, K.K. Study of the Effect of Photo-Irradiation on the Surface Chemistry of Wood. Polym. Degrad. Stab. 2005, 90, 9–20.

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and Photostabilisation of Wood—The State of the Art. Polym. Degrad. Stab. 2005, 88, 268–274.

- Hon, D.N.-S.; Ifju, G. Measuring Penetration of Light into Wood by Detection of Photoinduced Free Radicals. Wood Sci. 1978, 11, 118–127.

- Kataoka, Y.; Kiguchi, M. Depth Profiling of Photo-Induced Degradation in Wood by FT-IR Microspectroscopy. J. Wood Sci. 2001, 47, 325–327.

- Jirouš-Rajković, V.; Turkulin, H.; Miller, E.R. Depth Profile of UV-Induced Wood Surface Degradation. Surf. Coat. Int. B Coat. Trans. 2004, 87, 241–247.

- Kataoka, Y.; Kiguchi, M.; Williams, R.S.; Evans, P.D. Violet Light Causes Photodegradation of Wood beyond the Zone Affected by Ultraviolet Radiation. Holzforschung 2007, 61, 23–27.

- Živković, V.; Arnold, M.; Radmanović, K.; Richter, K.; Turkulin, H. Spectral Sensitivity in the Photodegradation of Fir Wood (Abies Alba Mill.) Surfaces: Colour Changes in Natural Weathering. Wood Sci. Technol. 2014, 48, 239–252.

- Volkmer, T.; Noël, M.; Arnold, M.; Strautmann, J. Analysis of Lignin Degradation on Wood Surfaces to Create a UV-Protecting Cellulose Rich Layer. Int. Wood Prod. J. 2016, 7, 156–164.

- Feist, W.C. Weathering and Protection of Wood; American Wood-Preservers Association: Kansas City, MO, USA, 1983; Volume 79, pp. 195–205.

- Feist, W.C. Outdoor Wood Weathering and Protection. In Archaeological Wood: Properties, Chemistry, and Preservation; Rowell, R.M., Barbour, R.J., Eds.; American Chemical Society: Los Angeles, CA, USA, 1989.

- Feist, W.C.; Hon, D.N.-S. Chemistry of weathering and protection. In The Chemistry of Solid Wood; Advances in Chemistry Series; Rowell, R.M., Ed.; American Chemical Society: Washington, DC, USA, 1984; pp. 401–451. ISBN 978-0-8412-0796-7.

- Williams, R.S. Weathering of Wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-0-203-49243-7.

- Evans, P.D.; Urban, K.; Chowdhury, M.J.A. Surface Checking of Wood Is Increased by Photodegradation Caused by Ultraviolet and Visible Light. Wood Sci. Technol. 2008, 42, 251–265.

- Cogulet, A.; Blanchet, P.; Landry, V. The Multifactorial Aspect of Wood Weathering: A Review Based on a Holistic Approach of Wood Degradation Protected by Clear Coating. BioResources 2018, 13, 2116–2138.

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, Accelerated, and Simulated Weathering of Wood: A Review. BioResources 2020, 15, 9998–10062.

- Teacă, C.A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural Changes in Wood under Artificial UV Light Irradiation Determined by FTIR Spectroscopy and Color Measurements—A Brief Review. BioResources 2013, 8, 1478–1507.

- Miklečić, J.; Turkulin, H.; Jirouš-Rajković, V. Weathering Performance of Surface of Thermally Modified Wood Finished with Nanoparticles-Modified Waterborne Polyacrylate Coatings. Appl. Surf. Sci. 2017, 408, 103–109.

- Miklečić, J. Durability of Polyacrylate Nanocoatings on Themally Modified Wood. Ph.D. Thesis, Faculty of Forestry, Zniversity of Zagreb, Zagreb, Croatia, 2013.

- Kalnins, M.A.; Steelink, C.; Tarkow, H. Light-Induced Free Radicals in Wood; Forest Products Laboratory: Madison, WI, USA, 1966.

- Deka, M.; Petrič, M. Photo-Degradation of Water Borne Acrilic Coated Modified and Non-Modified Wood during Artificial Light Exposure. BioResources 2008, 3, 346–362.

- Schaller, C.; Rogez, D. New Approaches in Wood Coating Stabilization. J. Coat. Technol. Res. 2007, 4, 401–409.

- Allen, N.S.; Edge, M.; Ortega, A.; Sandoval, G.; Liauw, C.M.; Verran, J.; Stratton, J.; McIntyre, R.B. Degradation and Stabilisation of Polymers and Coatings: Nano versus Pigmentary Titania Particles. Polym. Degrad. Stab. 2004, 85, 927–946.

- Pospı́šil, J.; Nešpurek, S. Photostabilization of Coatings. Mechanisms and Performance. Prog. Polym. Sci. 2000, 25, 1261–1335.

- Nikolic, M.; Lawther, J.M.; Sanadi, A.R. Use of Nanofillers in Wood Coatings: A Scientific Review. J. Coat. Technol. Res. 2015, 12, 445–461.

- Miklečić, J.; Blagojević, S.L.; Petrič, M.; Jirouš-Rajković, V. Influence of TiO2 and ZnO Nanoparticles on Properties of Waterborne Polyacrylate Coating Exposed to Outdoor Conditions. Prog. Org. Coat. 2015, 89, 67–74.

- Moya, R.; Rodríguez-Zúñiga, A.; Vega-Baudrit, J.; Puente-Urbina, A. Effects of Adding TiO2 Nanoparticles to a Water-Based Varnish for Wood Applied to Nine Tropical Woods of Costa Rica Exposed to Natural and Accelerated Weathering. J. Coat. Technol. Res. 2017, 14, 141–152.

- Akbarnezhad, M.; Rasouli, D.; Yousefi, H.; Mashkour, M. Weath Ering Performance of Beech Wood Coated with Acrylic Paint Containing UV Stabilizers of Dihydroxy Benzophenone and Nano Zinc Oxide. Drv. Ind. 2020, 71, 403–409.

- Evans, P.; Haase, J.; Seman, A.; Kiguchi, M. The Search for Durable Exterior Clear Coatings for Wood. Coatings 2015, 5, 830–864.

- Mishra, P.K.; Giagli, K.; Tsalagkas, D.; Mishra, H.; Talegaonkar, S.; Gryc, V.; Wimmer, R. Changing Face of Wood Science in Modern Era: Contribution of Nanotechnology. NANOTEC 2018, 12, 13–21.

- Monteiro-Riviere, N.A.; Nemanich, R.J.; Inman, A.O.; Wang, Y.Y.; Riviere, J.E. Multi-Walled Carbon Nanotube Interactions with Human Epidermal Keratinocytes. Toxicol. Lett. 2005, 155, 377–384.

- Wiesner, M.R.; Lowry, G.V.; Jones, K.L.; Hochella, M.F., Jr.; di Giulio, R.T.; Casman, E.; Bernhardt, E.S. Decreasing Uncertainties in Assessing Environmental Exposure, Risk, and Ecological Implications of Nanomaterials. Environ. Sci. Technol. 2009, 43, 6458–6462.

- Black, J.M.; Mraz, E.A. Inorganic Surface Treatments for Weather-Resistant Natural Finishes; USDA Forst Service Research Paper FPL 232; Forest Products Laboratory Madison, US Department of Agriculture Forest Service: Madison, WI, USA, 1974.

- Chang, S.-T.; Hon, D.N.-S.; Feist, W.C. Photodegradation and Photoprotection of Wood Surfaces. Wood Fiber 1982, 14, 104–117.

- Williams, R.S.; Feist, W.C. Wood Modified by Inorganic Salts: Mechanism and Properties. I. Weathering Rate, Water Repellency, and Dimensional Stability of Wood Modified with Chromium (III) Nitrate versus Chromic Acid. Wood Fiber Sci. 1985, 17, 184–198.

- Schmalzl, K.J.; Evans, P.D. Wood Surface Protection with Some Titanium, Zirconium and Manganese Compounds. Polym. Degrad. Stab. 2003, 82, 409–419.

- Pandey, K.K.; Pitman, A.J. Weathering Characteristics of Modified Rubberwood (Hevea Brasiliensis). J. Appl. Polym. Sci. 2002, 85, 622–631.

- Jin, L.; Archer, K.; Preston, A. Surface Characteristics of Wood Treated with Various AACs, ACQ and CCA Formulations after Weathering; IRG/WP/2369; The International Research Group on Wood Preservation: Kyoto, Japan, 1991; p. 10.

- Liu, R.; Ruddick, J.N.R.; Jin, L. The Influence of Copper (II) Chemicals on Weathering of Treated Wood, Part I ACQ Treatment of Wood on Weathering; IRG/WP/30040; The International Research Group on Wood Preservation: Nusa Dua, Indonesia, 1994; p. 9.

- Temiz, A.; Yildiz, U.C.; Aydin, I.; Eikenes, M.; Alfredsen, G.; Çolakoglu, G. Surface Roughness and Color Characteristics of Wood Treated with Preservatives after Accelerated Weathering Test. Appl. Surf. Sci. 2005, 250, 35–42.

- Nejad, M.; Cooper, P. Exterior Wood Coatings. Part-1: Performance of Semitransparent Stains on Preservative-Treated Wood. J Coat. Technol. Res. 2011, 8, 449–458.

- Isaji, S.; Kojima, Y. Application of Copper Monoethanolamine Solutions as Primers for Semitransparent Exterior Wood Stains. Eur. J. Wood Prod. 2017, 75, 305–314.

- Chehreh, F.; Mastari Farahani, M. Surface Droplet Contact Angle and Colour Characteristics of Eastern Cottonwood Treated with Nano-Copper Oxide and Exposed to Natural Weathering. Int. Wood Prod. J. 2015, 6, 69–71.

- Humar, M.; Lesar, B. Efficacy of Linseed- and Tung-Oil-Treated Wood against Wood-Decay Fungi and Water Uptake. Int. Biodeterior. Biodegrad. 2013, 85, 223–227.

- Sivrikaya, H.; Can, A. Effect of Weathering on Wood Treated with Tall Oil Combined with Some Additives. Maderas Cienc. Tecnol. 2016, 18, 723–732.

- Rosu, D.; Bodîrlău, R.; Teacă, C.; Rosu, L.; Varganici, C. Epoxy and Succinic Anhydride Functionalized Soybean Oil for Wood Protection against UV Light Action. J. Clean. Prod. 2016, 112, 1175–1183.

- Lesar, B.; Pavlič, M.; Petrič, M.; Škapin, A.S.; Humar, M. Wax Treatment of Wood Slows Photodegradation. Polym. Degrad. Stab. 2011, 96, 1271–1278.

- Schauwecker, C.; Preston, A.; Morell, J.J. A New Look at the Weathering Performance of Solid-Wood Decking Materials. J. Coat. Technol. 2009, 6, 32–38.

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; Wiley Series in Renewable Resources; John Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2006; ISBN 978-0-470-02172-9.

- Rowell, R.M. Chemical modification of wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-0-8493-1588-6.

- Torr, K.M.; Dawson, B.S.W.; Ede, R.M.; Singh, J. Surface Changes on Acetylation and Exposure to Ultraviolet Radiation of Pinus Radiata Using X-Ray Photoelectron Spectroscopy. Holzforschung 1996, 50, 449–456.

- Dunningham, E.A.; Plackett, D.V.; Singh, A.P. Weathering of Chemically Modified Wood. Holz Roh Werkst. 1992, 50, 429–432.

- Fodor, F.; Lankveld, C.; Németh, R. Testing Common Hornbeam (Carpinus betulus L.) Acetylated with the Accoya Method under Industrial Conditions. iForest 2017, 10, 948–954.

- Chang, S.-T.; Chang, H.-T. Comparisons of the Photostability of Esterified Wood. Polym. Degrad. Stab. 2001, 71, 261–266.

- Pu, Y.; Ragauskas, A.J. Structural Analysis of Acetylated Hardwood Lignins and Their Photoyellowing Properties. Can. J. Chem. 2005, 83, 2132–2139.

- Ohkoshi, M. FTIR-PAS Study of Light-Induced Changes in the Surface of Acetylated or Polyethylene Glycol-Impregnated Wood. J. Wood Sci. 2002, 48, 394–401.

- Evans, P.D.; Wallis, A.F.A.; Owen, N.L. Weathering of Chemically Modified Wood Surfaces. Wood Sci. Technol. 2000, 34, 151–165.

- Beckers, E.P.J.; Meijer, M.; Militz, H.; Stevens, M. Performance of Finishes on Wood That Is Chemically Modified by Acetylation. J. Coat. Tech. 1998, 70, 59–67.

- Bongers, F.; Creemers, J.; Kattenbroek, B.; Homan, W. Performance of Coatings on Acetylated Scots Pine after More than Nine Years Outdoor Exposure. In Proceedings of the Wood Modification: Processes, Properties and Commercialisation, Göttingen, Germany, 6–7 October 2005; Militz, H., Hill, C., Eds.; ECWM: Spring, MD, USA, 2005; pp. 125–129.

- Pandey, K.K.; Srinivas, K. Performance of Polyurethane Coatings on Acetylated and Benzoylated Rubberwood. Eur. J. Wood Prod. 2015, 73, 111–120.

- Evans, P.D.; Owen, N.L.; Schmid, S.; Webster, R.D. Weathering and Photostability of Benzoylated Wood. Polym. Degrad. Stab. 2002, 76, 291–303.

- Pandey, K.K.; Chandrashekar, N. Photostability of Wood Surfaces Esterified by Benzoyl Chloride. J. Appl. Polym. Sci. 2006, 99, 2367–2374.

- Prakash, G.K.; Pandey, K.K.; Ram, R.K.D.; Mahadevan, K.M. Dimensional Stability and Photostability of Octanoylated Wood. Holzforschung 2006, 60, 539–542.

- Salla, J.; Pandey, K.K.; Prakash, G.K.; Mahadevan, K.M. Photobleaching and Dimensional Stability of Rubber Wood Esterified by Fatty Acid Chlorides. J. Wood Chem. Technol. 2012, 32, 121–136.

- Bhat, I.-H.; Abdul Khalil, H.P.S.; Awang, K.B.; Bakare, I.O.; Issam, A.M. Effect of Weathering on Physical, Mechanical and Morphological Properties of Chemically Modified Wood Materials. Mater. Des. 2010, 31, 4363–4368.

- Jebrane, M.; Sèbe, G.; Cullis, I.; Evans, P.D. Photostabilisation of Wood Using Aromatic Vinyl Esters. Polym. Degrad. Stab. 2009, 94, 151–157.

- Chang, H.-T.; Chang, S.-T. Modification of Wood with Isopropyl Glycidyl Ether and Its Effects on Decay Resistance and Light Stability. Bioresour. Technol. 2006, 97, 1265–1271.

- Rowell, R.M. Acetylation of Wood-Journey from Analytical Technique to Commercial Reality. For. Prod. J. 2006, 56, 4–12.

- Hon, D.N.-S. Stabilization of Wood Color: Is Acetylation Blocking Effective? Wood Fiber Sci. 1995, 27, 360–367.

- Kalnins, M.A. Photochemical Degradation of Acetylated, Methylated, Phenylhydrazine-Modified, and ACC-Treated Wood. J. Appl. Polym. Sci. 1984, 29, 105–115.

- Dawson, B.; Torr, K. Spectroscopic and Colour Studies on Acetylated Radiata Pine Exposed to UV and Visible Light. In Chemical Modification of Lignocellulosics; Forest Research Institute: Rotorua, New Zealand, 1992; pp. 41–51.

- Feist, W.C.; Rowell, R.M.; Ellis, W.D. Moisture Sorption and Accelerated Weathering of Acetylated and Methacrylated Aspen. Wood Fiber Sci. 1991, 23, 128–136.

- Imamura, Y. Morphological Changes in Acetylated Wood Exposed to Weathering. Wood Res. Bull. Wood Res. Inst. Kyoto Univ. 1993, 79, 54–61.

- Schaller, C.; Rogez, D. Light Stabilization of Modified Wood Species. In Proceedings of the Third European Conference on Wood Modification, Cardiff, UK, 16 October 2007.

- Prakash, G.K.; Mahadevan, K.M. Enhancing the Properties of Wood through Chemical Modification with Palmitoyl Chloride. Appl. Surf. Sci. 2008, 254, 1751–1756.