Industry 4.0 (I4.0) technologies have been highlighted in recent literature as enablers of servitisation. Simultaneously, businesses are advised to implement a circular economy (CE) to bring new opportunities. However, it is pertinent to mention that little attention has been given to assess the role of I4.0 in adopting the CE and servitisation in a fully integrated manner. This research fills this gap by developing a conceptual framework through a systematic literature review of 139 studies investigating the relationship between the I4.0, CE, and servitisation. This study identifies the impact of these variables on a firm’s operational and financial performance (revenue stream, growth, and profitability). Our research findings advocate that adopting I4.0 technologies to the business and manufacturing model enables sustainability, energy and resource efficiency while enhancing performance and offering innovative products through smart services. Thus, firms must systematically adopt I4.0 technologies to support a CE model that creates value through servitisation. This study identifies the research gaps that are unexplored for practitioners and future researchers while providing insight into the role of I4.0 in implementing CE in the servitisation business model.

1. Introduction

Technology plays a vital role in today’s dynamic world. It continuously transforms how organisations operate by reshaping products, processes, services, strategies and adopting sustainable business models to perform better

[1][2][3][1,2,3]. The fourth industrial revolution, called Industry 4.0 (I4.0), integrates IoT, cloud computing, cyber-physical systems (CPS), smart manufacturing/factories, artificial intelligence (AI) and big data analytics for value creation that enables the binding of a smart, decentralised, and digitised value chain

[4]. Innovative products with high functionality are in great demand with enhanced technological advancement that utilises cautious resources (capital resources, human resources, and material resources). Therefore, I4.0 has been deliberated as a suitable solution for addressing contemporary issues such as innovation cycles, enhanced demand volatility, and increasing customisation

[5]. The primary focus of this integration is to modify a business model (BM) while providing new revenues and value-producing opportunities that reduce a product’s manufacturing time and efforts

[6].

In addition to this, industrial organisations are expected to create sustainable value, such as contributing to society by pursuing social, ecological, and economic objectives as the circular economy (CE)

[7]. In simple terms, I4.0 plays a critical role in strengthening and maintaining future global competitiveness

[8]. I4.0 is an innovative approach that adds value to manufacturing processes and thus possesses a marked improvement for its sustainability

[9] and supports servitisation

[10]. Therefore, it is within the interests of businesses to enable and enhance technical development within the BM. This vision aims at higher flexibility, and improved quality and commercial (economic) returns to gain a competitive market advantage

[4].

A common perception among academics is that this revolution will create digitally enhanced machines that will efficiently substitute human labour

[11]. The usage of these intelligent machines comes under servitisation and subsequently improves an organisation’s overall performance

[12]. Industries continuously work towards increasing production, but they have been trying to do so by providing products alone without technology-enabled services in the past years.

[8]. Hence, in today’s competitive market, I4.0 technologies possess the potential to catalyse the rapid development of the CE paradigm through specialised service design. Servitisation disrupts the economy and forces it to evolve by advancing technology, creating professional employment opportunities, opening new markets, and boosting goods and services through sustainable life-cycle integration

[13]. This systematic transformation is based on the CE paradigm that generates revenue from an undervalued waste stream

[14]. It encompasses organisations’ innovative techniques to use energy, resources, and materials while reducing their environmental impact

[3][4][3,4] efficiently and effectively. Questions remain regarding how to manage this progressive integration solution.

The academics and practitioners actively adapt to the CE paradigm and adopt pivotal technologies to enhance their operational efficiency and financial performance

[15]. This unprecedented change persuades firms to adopt digitalisation through software empowered products

[16]. CE’s comprehensive methodology provides organisations with environmental, social, and monetary benefits when it replaces the traditional linear-economy model

[17]. At the same time, servitisation offers “outcome as a service” instead of a one-off sale

[18]. Consequently, in today’s competitive world, the demand for the next generation of intelligent products with improved functionality and value-added services is rising

[19][20][19,20]. Products must be integrated with closed-loop processes across the supply chain

[21], and service provision constitutes a massive share in the revenue stream for manufacturers

[22][23][22,23].

The focus of this study is to find the answer to the following research questions: what are the focal discoveries by previous researchers of (i) I4.0, (ii) servitisation, and (iii) CE? How do firms perceive the collective potentials of combining them? The literature review presented in this paper explores the relationship among the key variables, i.e., I4.0, servitisation, and CE, to investigate the disposition of this fast-moving global revolution. It also analyses how this relationship influences firms’ operational and financial performance to clarify the impact and consequences of the above-mentioned three megatrends. The preliminary part of this paper will briefly explain the main variables of this research study. Furthermore, this paper will present an in-depth, cross-theme analysis of the variables and evaluate their relationship.

2. Selections of Studies

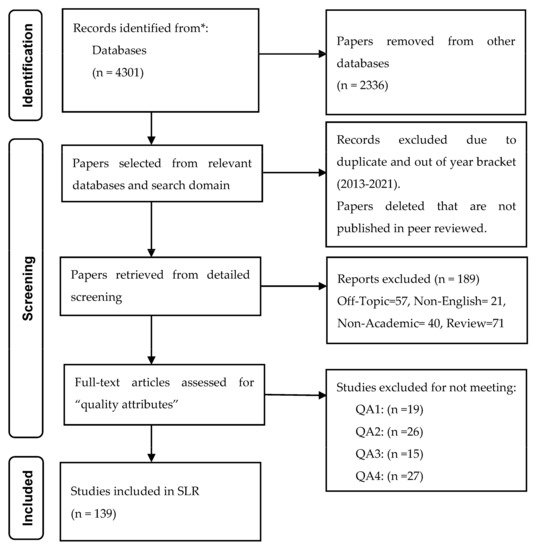

The initial research started by searching the keywords (I4.0, servitisation, and CE) to select the papers for review. Figure

12 shows a PRISMA flow diagram and explains the rigorous process followed in the selection of papers. The authors found 4301 papers overall within the databases and selected 1965. Various filters were used to refine the keywords with Boolean logic, concentrating the search to 614 papers.

Figure 12.

PRISMA flow diagram showing the search and screening process.

3. Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy

The SLR results are characterised into three groups. Firstly, how the key variables (I4.0, servitisation, and CE) have been studied in the business and management domain. The second objective is to analyses their hybrid affiliation by investigating how each variable plays a role in enabling another. Lastly, an in-depth analysis of how I4.0, servitisation, and CE impact a firm’s performance.

3.1. Key Variables

This section discusses the three main concepts, I4.0, servitisation, and CE. A brief description of these concepts is presented below.

3.1.1. Industry 4.0

I4.0 technologies (IoT, cloud computing, predictive analytics, and big data) offers a sophisticated interconnected platform that combines hardware and software

[24][25][31,32]. A general assertion shared among scholars and researchers is that 14.0 connects the physical and digital world

[4][12][16][4,12,16]. IoT technologies in industrial manufacturing and production systems help digitalise these systems

[26][33] and contribute to value creation

[27][34].

I4.0 was initially developed in 2011 as a zero-sum method based on the impact of innovation

[16][28][16,35] on future production systems and as a scheme to establish Germany’s competitiveness in the fourth period of economic change

[28][35]. The term “I4.0” was coined by Klaus Schwab, a German industrial strategist, in 2015

[29][36]. It provides an intrinsically accessible platform for businesses to adapt to unforeseeable market conditions

[15].

It supports management processes by streamlining decision-making about operations, digital transformations and enhancing the customer experience while improving the return on investment

[4]. It was founded on the principle of intelligent, vertical, horizontal, and real-time connections of machines, people, information, objects, and communication systems to manage complex systems vigorously

[30][28].

From the I4.0 literature analysis, it is noted that the present increasing attention and interest of organisations in I4.0 technologies encapsulate the technical foundations of its general implications on business

[2][3][31][2,3,37]. Most studies focus on the challenges of I4.0 for organisations

[29][32][36,38], in the form of reviews or opinions that critically relate to BM designs

[33][34][35][39,40,41] and how I4.0 can help organisations’ deliver, capture, and create value in this context

[4]. The vital influence of I4.0 in BMs has critically received limited attention from researchers

[16][36][16,42].

In a BM, the value proposition is being reformed by the technology known as I4.0 that critically contributes towards improving consumer operations procedures

[8]. Experts believe l4.0 is a cluster of opportunities

[30][37][28,43]. This perception aligns with the results gathered from papers that indicate that I4.0 supports firms in improving their performance

[12][38][39][12,44,45]. Another common perception within the literature is related to the role of l4.0 technologies adapted for different roles within a firm

[28][35]. The analysis showcases a positive outcome on the internal infrastructure within a business management context

[12], the principal constituent of the business operations model

[14][40][14,46], and customer relationship management

[12][41][12,47] when the system is accustomed accordingly.

Likewise, Rymaszewska

[1] suggested a service-based operating model that essentially constitutes the manufacturing assets and provision of production along with associated analytics services, full-service operations, information services, and efficient mass customisation via end-user integration. Presently in companies or factories using I4.0, equipment is connected as a collaborative community

[42][48].

This type of evolution supports the usage of advanced prediction devices

[10][25][43][10,32,49]. Data gathered can be methodically administered to identify uncertainties and develop well-versed solutions to overcome barriers to a more collaborative, sustainable, and resilient supply-chain network

[10][44][10,50]. Thus, it can be said that I4.0 is an advanced version of predominantly information technology (IT) that drives transformations in the current manufacturing operations and systems

[31][32][45][37,38,51]. Experts have also shown consensus about l4.0, suggesting that such development not only infuses technological advancement but is accompanied by versatile organisational repercussions as well

[12][21][46][12,21,52].

3.1.2. Servitisation

Industries and manufacturing organisations are encountering many changes and revolutions resulting from the past few decades. Technology has changed the criteria related to how organisations do business with customers and develop, supply, and manufacture products

[27][34]. The two existing macro-phenomena I4.0 and servitisation have an impact on and significantly challenge organisations’ BMs.

Servitisation is principally linked to the demand-pull innovation trajectory

[27][34]. As the present industries and markets shift from product consumption towards result-oriented demand, consumers anticipate receiving supplementary services that improve their overall experience while making purchases or getting in touch with their goods and services

[1].

In some situations, rather than finding ways to pay for the product or services itself, the consumer wants to obtain the worth integrally presented using the merchandise, consequently using it as a service

[47][53]. This drastic transformation has resulted in the introduction of servitisation approaches within manufacturing organisations, including initiating a shifting from the product-centred organisations towards the PSS

[48][54]. PSS and servitisation are used alternatively in the literature

[49][55].

PSS is customer-focused and substantially impacts product development, life-cycle management, and cost analysis

[13][50][51][13,56,57]. Servitisation is defined as the transformation procedure from the product-centric towards a service-oriented BM

[49][55]; servitisation defines the productivity of this process

[8]. It integrates services and goods that offer diverse functionalities to stakeholders and consumers and offer environmental advantages

[52][58].

According to Witell et al.

[53][59] and Kuhl et al.

[54][60], transformations are significantly rooted in the value architecture of organisations. They consist of value creation, capture mechanisms, delivery, acting, and complementarities as a manifestation of a company’s business approaches that are critically referred to as business model innovation (BMI).

The most common understanding of servitisation is that it brings competitive and strategic aids for implementing this innovated BM

[55][61]. Several research papers have deliberated a relationship of servitisation within the manufacturing industry

[1][18][56][1,18,62], and further researches in this domain have significantly increased in the past two decades

[18][55][18,61]. There are different definitions for the term servitisation; we have picked the one more relevant to our research studies given in Table 1.

Table 1. Definition of servitisation.

| Author |

Definition |

| Tim Baines [13] |

“Servitisation is the concept of manufacturers offering services tightly coupled to their products”. |

| Andy Neely [22] |

“The innovation of organisations’ capabilities and processes to better create mutual value through a shift from selling products to selling PSSs”. |

| Bart van Looy [56] | Bart van Looy [62] |

“A trend in which manufacturing firms adopt more and more service components in their offerings”. |

Servitisation is one of the cost-effective megatrends of the present technological society

[55][61]. It is a process that helps create value for the manufactured goods by adding services to products

[1]. This current and rising megatrend of the BM is called servitisation

[13][57][58][13,63,64]. Many companies have initiated models that have machines and products with intelligent digital systems to operate and communicate with other devices and systems independently

[13][25][59][13,32,65]. As a result of this growing trend, many companies have started to use digital systems

[12][60][12,66] to offer various services to their clients and customers

[18].

3.1.3. Circular Economy

The current dominant economic development model, known as the “take, make, and dispose of” model, is presently being questioned

[61][67]. On both the global and regional level, sustainable methods of managing and consuming provisions and natural resources have become significantly important

[62][68]. As Majeed

[3] suggested, resource intake’s dominant economic development model is dependent on carrying out business activities by utilising material resources.

Throughout the diversification and evolution of the linear economy, the industrial economy had hardly moved away from the initially established primary characteristics developed in the preliminary days of industrialism

[63][69]. When companies use the linear model, they harvest, extract, manufacture, and sell products in the market, and subsequently, these are entirely discarded when no longer used

[61][67]. The linear model depends on the excessive availability of resources; therefore, there is an immense need to change its entire operation

[64][70].

According to Kristensen

[64][70], “The CE has gained traction as a pathway towards more sustainable economic growth”. CE is referred to as an industrial economy that aims to be restorative, critically relies on alternate energy, reduces, eliminates and tracks the utilisation of toxic substances, and reduces waste via cautious design

[4][62][4,68]. The CE concept goes beyond the mechanics of consumption and production of products and services, particularly in areas that need to be redefined, such as rebuilding capital involving natural and social aspects and shifting clients from customers to users

[46][51][52,57]. The perception of the CE is initiated from the study of non-linear systems, specifically the living ones

[46][52].

Copani

[65][71] explain that the idea of circular suggests embracing new techniques for industries and organisations that create value not previously attained for both the consumers and the company itself. The principles of CE entailing the 10R-strategy explain ways for value creation, such as re-using the used product or using its component as a by-product for a new product; rethinking the BM; reducing the usage of virgin resources and enhancing efficiency; reusing a used product by outsourcing; repairing and maintenance of a defected product; refurbishing and restoring products through upgrades; remanufacturing, i.e., using a component of the discarded product in a new product with same functionality; repurposing a redundant product with different functionality, and recycling of products or materials

[46][66][52,72].

Consequently, De Moura

[55][61] claimed that this idea of CE proposes that the synchronised formation of economic and environmental benefits can produce employment opportunities in the industry. These sustainable financial goals will directly contribute to employment creation where businesses acquire human resources to take care of related services

[64][70].

3.2. Relationship Among the Three Key Variables

The second objective of this SLR is to understand how each variable plays a role in enabling the other variable and vice versa. Initially, of the 139 scientific articles were selected, 40 described the direct and indirect relationships between I4.0 and servitisation. The authors identified that 68 papers described the relationship between I4.0 and CE, and 31 articles dealt with the relationship between servitisation and the CE. An initial overview of the literature was undertaken from various perspectives to test the link between these three key variables.

3.3. Impact on the Firm’s Performance

3.3. Impact on the Firm’s Performance

I4.0, CE, and servitisation critically impact a firm’s performance by increasing production efficiency and significantly contributing to business systems effectiveness

[17][64][67][68][69][17,70,77,90,135]. The IoT and other innovative technologies help complement product life-cycle approaches

[70][71][80,82], enabling the efficient incorporation of product-related information from the formulation of ideas towards describing the products, evaluating the businesses cases, product design and solution, and product improvements

[13].

Similarly, with digitisation and servitisation, companies can integrate digital technologies for production and consumer management

[70][80]. In simple terms, I4.0 is playing a significant role in supporting and preserving future global competitiveness

[8]. On the other hand, due to the uncertainty in IoT’s implications and actual effects, there are still contradictory proclamations related to its potential risks and benefits from practitioners, politicians, researchers, and consultants

[17][59][70][17,65,80].

A cost management assessment of this relationship is pivotal in justifying a firm’s operational and capital expenditure during and after the transition phase

[70][80]. Cost management mainly focuses on three significant areas: impact on the revenue stream, growth, and profitability. A brief description of financial measures is used to assess a firm’s economic performance

[72][73][136,137].

After careful consideration, the authors identified that numerous papers focused on investigating the redesigning of the operational stream of a firm, variations in operational efficacy

[74][132], or disparities in operational performance after the transformation of a firm. In contrast, some have broadly presented the idea of assessing financial arrangements

[66][75][72,105]. However, none have provided any concrete evidence of economic parameters

[76][138]. Moreover, the authors rarely evaluated the performance of firms from a legal or regulatory perspective

[77][84].

Therefore, Table 6 highlights the studies according to the metrics or parameters that the authors used to investigate the performance of service-centric firms when they adopted a CE with I4.0 technologies. A brief explanation about the operational and financial performance indicators is given below:

-

Operational Performance

-

Financial Performance