Non-thermal food processing refers to methods where the food materials receive microbiological inactivation without the direct application of heat. Such technologies, largely combined with hurdle technology to replace those conventional thermal food processing ones, are increasingly viewed as either emerging, novel, or new food processing methods. Such novel technologies have included pulsed electric fields (PEF), high-pressure processing (HPP), ozone treatment, pulsed light, non-thermal plasma/cold plasma (NTP), and ultrasound technology. The technologies can be grouped into two major groups: physical processes (pulse electric field, high-pressure processing, ultraviolet radiation, pulsed light, ultrasound, and ionizing radiation) and chemical processes (ozone treatment, and cold plasma).

1. Overview

The push for non-thermal food processing methods has emerged due to the challenges associated with thermal food processing methods, for instance, high operational costs and alteration of food nutrient components. Non-thermal food processing involves methods where the food materials receive microbiological inactivation without or with little direct application of heat. Besides being well established in scientific literature, research into non-thermal food processing technologies is constantly rising as applied to a wide range of food products. Due to such remarkable progress by scientists and researchers, there is a need for continuous synthesis of relevant scientific literature for the benefit of all actors in the agro-food value chain, most importantly the food processors, and to supplement existing information. This review, therefore, aimed to provide a technological update on some selected non-thermal food processing methods specifically focused on their operational mechanisms, their effectiveness in preserving various kinds of foods, as revealed by their pros (merits) and cons (demerits). Specifically, pulsed electric field, pulsed light, ultraviolet radiation, high-pressure processing, non-thermal (cold) plasma, ozone treatment, ionizing radiation, and ultrasound were considered. What defines these techniques, their ability to exhibit limited changes in the sensory attributes of food, retain the food nutrient contents, ensure food safety, extend shelf-life, and being eco-friendly were highlighted. Rationalizing the process mechanisms about these specific non-thermal technologies alongside consumer education can help raise awareness before any design considerations, improvement of cost-effectiveness, and scaling-up their capacity for industrial-level applications.

2. Food Processing

One of the major purposes of food processing technologies, from the very early to its later types over the years, has been to guarantee the safety of foodstuffs, as well as prolong their shelf-life. However, a diversity of changes have taken place as the many food processing technologies advanced and evolved, especially those within the agro-food industry/sector

[1][2][3][4][1,2,3,4]. Indeed, all have happened largely because of the evolving nature of consumer demands for fresh, nutritious foods and increased shelf life

[1][2][3][4][1,2,3,4]. Since consumers are the key players in the agro-food chain, their demands over the years have been a key push factor to other players in the agro-food chain, such as food technologists, in devising processes that ensure such demands are met.

For many years, the primary methods for treatments for the microbiological stabilization and the preservation of the sensory and nutritional properties of food products have largely been those associated with heat, which unfortunately has adversely affected both the nutrient contents and sensory characteristics of foods

[5][6][5,6]. Although one of the key aims of the heat processing technologies has been to reduce food spoilage and pathogenic microorganisms, they have in many situations resulted in many undesirable and unwanted modifications in food texture, appearance, sensory aspects, nutrients content, and the concentration of thermo-sensitive bioactive compounds. Therefore, the destruction of food nutritional components and the consumer demand for foods with desirable sensory qualities have remained the two key drivers towards the innovation of non-destructive food technologies

[4][7][4,7]. Such food technologies are designed in such a way that while they ensure microbial inactivation, the foods still retain their sensory aspects

[8][9][8,9].

Non-thermal food processing simply refers to methods where the food materials receive microbiological inactivation without the direct application of heat

[3][4][8][3,4,8]. Such technologies, largely combined with hurdle technology to replace those conventional thermal food processing ones, are increasingly viewed as either emerging, novel, or new food processing methods

[4][10][4,10]. Such novel technologies have included pulsed electric fields (PEF), high-pressure processing (HPP)

[6], ozone treatment

[11][12][13][11,12,13], pulsed light, non-thermal plasma/cold plasma (NTP) and ultrasound technology

[14][15][14,15]. The technologies can be grouped into two major groups: physical processes (pulse electric field, high-pressure processing, ultraviolet radiation, pulsed light, ultrasound, and ionizing radiation) and chemical processes (ozone treatment, and cold plasma).

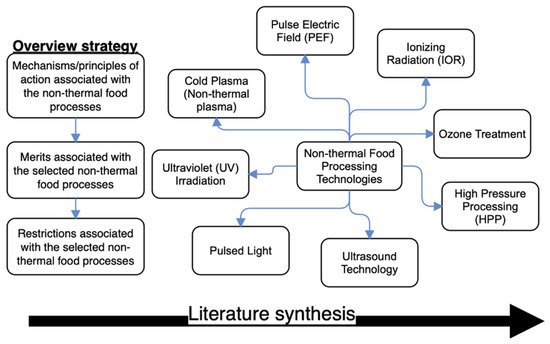

Besides being well established in scientific literature, research into non-thermal food processing technologies is constantly rising, as applied to a wide range of food products. Due to such remarkable progress by scientists and researchers, there is a need for continuous synthesis of relevant scientific literature, for the benefit of all actors in the agro-food supply chain, most importantly, the food processors, and to supplement the existing information. This review, therefore, aimed to provide a technological update on some selected non-thermal food processing methods specifically focused on their operational mechanisms, their effectiveness in preserving various kinds of foods, as revealed by their pros (merits) and cons (demerits). To compose this review paper, articles written in English and published between 2016 and 2021 (specific to those available 2021 as at the time of preparing this review) were retrieved from recognized scientific literature search engines (Science Direct, Scopus, Web of Knowledge, and Google Scholar) using the keywords “pulse electric field,” “pulsed light,” “ultraviolet light,” “high-pressure processing,” “non-thermal plasma,” “cold plasma,” “irradiation,” “ionizing irradiation,” and “ultrasound.” Other useful references have been added where deemed appropriate to strengthen the discussion of this synthesized update. The schematic representation of non-thermal food processing technologies specific to the overview strategy employed in composing this review is as shown in Figure 1.

Figure 1. Schematic representation of non-thermal food processing technologies synthesized (which include: pulsed electric field (PEF), pulsed light (PL), ultraviolet radiation (UV), ionizing irradiation (IOR), high-pressure processing (HPP), ozone treatment, cold plasma (non-thermal plasma), and ultrasound technology) with the overview strategy (which include: mechanisms/principles of action, and the associated merits, and restrictions).

3. Final Considerations

The action mechanism of the selected non-thermal technologies we have reviewed herein appears driven by a wide range of energy sources, for instance, electrical fields, light, and hydrostatic pressure. These techniques have proven their capacity in keeping foodstuffs near an original fresh state, which is much desired by consumers, different from the detrimental effects caused by many of the conventional heat application techniques. Some selected non-thermal technologies produce minimal effects on the nutritional composition of foodstuffs and promote the bioavailability of some bioactive components of foods.

Moreover, the design of equipment of large-scale application, formulation of rules and regulations governing the safety of foodstuffs being processed, expanding the process mechanisms of each technique, as well as raising awareness through consumer education, are among several essentials of such non-thermal technologies that make their adoption at industrial scale challenging

[16][133]. Since the majority of the novel non-thermal technologies are still utilized at a small scale (lab/pilot level), their scaling-up to an industrial level might prove expensive and therefore, the huge investment costs require consideration for sustainable implementation and utilization

[8]. Therefore, further design of such non-thermal technologies facility requires improvement, which could make the eventual process mechanisms better and cost-effective

[17][22].

Consumers will continue to demand nutritionally fresh foodstuffs, and for this reason, the onus remains on the food industry to push towards fully embracing non-thermal food processing technologies, especially those discussed in this review. To the consumers, this synthesis provides some relevant information that could help them in deciding their preferred foodstuffs to consume based on the non-thermal processing methods. Overall, this current synthesis can serve as a quick reference for food processors who intend to employ one or more of these selected technologies.

4. Future Prospects

As a way forward and into the future, it is important for food industries to fully understand the respective action mechanisms, as well as pros (merits) and cons (demerits) of non-thermal food technologies, before and even during their implementation. Streamlining the process mechanisms of each technique and consumer education about the strengths and prospects of non-thermal technologies could help to raise awareness, before considerations on how to amend their designs if their cost-effectiveness and scale-up capacity for industrial-level applications are to be improved.

Essentially, the implementation, as well as the selection of innovative non-thermal technologies within the food industry, should involve a deep evaluation of the processing line via hazard analysis and critical control points (HACCP) methodology. Such deep evaluation would require combined efforts of HACCP and quality assurance control points (QACP), which can help to enhance and sustain the improved food hygiene, quality, and safety processes

[18][193]. In addition, future studies should be directed to perform cost comparisons of the selected non-thermal food processing technologies. Such cost comparisons can help the food industries and their respective stakeholders select the appropriate non-thermal technology that meets their food production requirements based on their capacities and operational needs.

Additionally, the development of a (hurdle-like) non-thermal technology that combines several processing methods, designing the intended equipment particularly for large scale application, as well as formulating the rules/regulations governing the intended foodstuff safety when using these technologies, should be among the future priorities for the food industry and its stakeholders. It is important to reiterate here that when a target food industry that operates at either small-, medium- or large-scale desires to implement a specific non-thermal food processing technology, the prerequisites already prescribed by the manufacturers should be adhered to despite the variations in facilities/equipment, operational/production scales, intended food product(s), factors of production, as well as consumer targets.