1. Introduction

The need for energy is constantly rising around the world, which may be described as an exponential function. According to the Minister of Economy, the need for final natural gas energy in Poland will have risen by 20% in 20 years (from 2010)

[1]. Given the decreasing natural gas resources in conventional deposits, the world is facing a situation in which it is necessary to exploit this kind of hydrocarbons from less accessible reservoirs (so-called unconventional reservoirs). In Poland, there are high hopes for a natural gas extracted from the Lower Paleozoic shale. The shale belt, amounting to ca. 37,000 km

2, ranges from the northern parts of the country (the Baltic Basin), through the central regions (the Podlasie Basin), to the eastern reaches (Lublin Basin). The total estimated producible resources of natural gas in shale formations of the Polish land and the marine part of the Baltic-Podlasie-Lublin Basin may amount to a maximum of 1920 billion m

3 [2].

Taking into consideration the parameters of the evaluation, these resources are most likely approximately 346–768 billion m

3. Even the lowest amount can make an impressive influence on many branches of domestic industries. Nevertheless, exploiting this kind of hydrocarbons from the Lublin Basin using conventional technology is expensive and unprofitable. Hence, it is desirable to use technologies that are less costly and give the possibility to succeed. The old but renewed version of the rotary-percussion drilling method is supposed to be the most efficient

[3].

In the case of rotary-percussion drilling, a down-the-hole hammer operation is present. The driving factor may be either compressed air or fluid (water), which is directed to the hammer through drill pipes. Air or water also cleans the borehole from cuttings acting as a scrubber.

The air is blown out of the hammer through holes in the drill. The advantages of this kind of drilling are, especially, the lower price compared to the conventional method, lower negative influence on the environment, lower noise emission, and the possibility to operate in a small area. An additional perk is the rectilinearity of the borehole, especially for down-the-hole hydraulic hammers. Furthermore, using air instead of a drilling mud can reduce the formation damage. Formation damage during drilling, completion, and workover operations is a widely known and important issue to consider, as it reduces oil and gas recovery performance. Zhu et al.

[4] investigated the impact of the filtrated mud saturation and concluded that its determination could contribute to predicting the formation damage in underbalanced drilling operations. They noted that higher saturation occurred in formations with higher porosity and permeability, lower water saturation, and higher oil viscosity. Davarpanah and Nassabeh

[5] found that the determination of mechanical specific energy could assist with detecting drilling instabilities and checking drilling and bit performance. It could help with the optimization of drilling parameters. Both of the abovementioned papers presented a cost-effective way to aid the drilling operation. The rotary-percussion drilling technique has been known for its economic viability combined with an increased rate of penetration. It is generally recommended for the use in hard, abrasive rock formations due to its rock-fracturing efficiency

[2,5,6,7][2][5][6][7].

The rotary-percussion method has been widely studied in order to further enhance its benefits. It has been proven that the rate of penetration can be increased by over 30% by using the rotary-percussion drilling method in comparison to the conventional rotary drilling method

[7,8,9][7][8][9]. Derdour et al.

[10] presented their work on penetration rate optimization of rotary-percussion drilling in the Hadjer Soud quarry. They have taken into consideration the air pressure, the specific-advanced pressure, the rotation speed, and the bit diameter and used the Taguchi method, signal-to-noise ratio, ANOVA (analysis of variance), and RMS (root mean square) for modeling. They concluded that air pressure had the most impact on the rate of penetration, followed by the specific advance pressure, as well as proved that the analyses used were effective in practical applications. Liu et al.

[7] stated that by adjusting the impulse frequency, higher drilling efficiency could be obtained. Wu and Ye

[6] noted that the impulse load and the speed of bit rotation had a significant influence on the efficiency of rock fracturing, while the impact of impulse frequency was smaller in comparison. Dong and Chen

[8] mentioned that drilling parameters did not have a linear relationship with the efficiency of rock fracturing. They noted that the use of the rotary-percussion drilling method in shale formation needed to be further investigated due to the mechanical properties of shale. They recommended a small lateral movement and reasonable axial vibration frequency to achieve energetically efficient rock fracturing. Xiaohua et al.

[11] researched the rock-breaking mechanism and concluded that volume breaking was caused by the torsional shear stress. It was then further accelerated together with crack extension by the tensile shear stress, and the compressive stress was identified as a secondary factor for the rock breaking.

2. Possibility of Rotary-Percussion Drilling

The rotary-percussion drilling method applies a hammer tool to produce percussion on a rock formation. A top hammer system transfers approximately 84% of the energy to the drill bit, while a down-the-hole (DTH) hammer is more efficient in this regard—almost 100% of the energy is being transferred

[39,40][12][13]. The mechanism works as follows: rotation is caused by the head located on the top of a drilling rig. The rotation is transferred through the drill string to the hammer and further to the drill bit. As the pipes are connected by a thread, the drill string can be lengthened while drilling.

DTH may be driven by compressed air or fluid (also water), which flows via rotating the drill string to the hammer located behind the drill bit. The medium powering the DTH flows out through the holes in the drill bit’s face and carries the cuttings from the bottom of a borehole to the surface

[41][14].

Water-powered DTH works well for drilling long and straight boreholes, also in delicate areas, preventing the occurrence of doglegs. Such a tool is able to penetrate the majority of rock formations while maintaining a high penetration rate and accuracy (

wassara.com, access on 20 June 2020

[42][15]); however, it requires a high flow rate of water. Drilling fluid recycling systems are being proposed to minimize this disadvantage

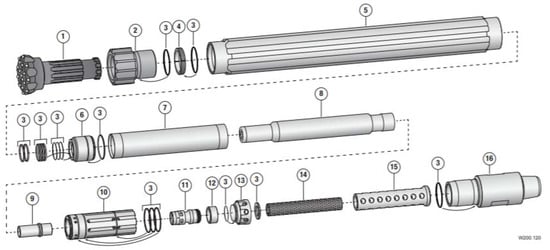

[43][16]. An example of a water-powered 203.2 mm (8″) DTH hammer example is presented in . shows examples of DTH drill bits.

Figure 1. Wassara’s W200 DTH water-powered hammer (1—drill bit; 2—chuck; 3—seal kit; 4—bit retainer; 5—hammer case; 6—piston housing; 7—inner tube; 8—piston; 9—sliding case; 10—valve house; 11—valve; 12—sleeve; 13—guided lid; 14—filter; 15—filter support; 16—backhead API 4 ½” IF; source: wassara.com

[42][15]).

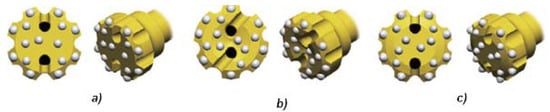

Figure 2. Heads of drill bits (

a) flat—to be used in hard, medium-hard, and abrasive rocks (e.g., granite, basalt, and hard limestone); (

b) concave—to be used in hard, medium-hard, and homogeneous rocks (e.g., granite, hard limestone). Good control of borehole axis deflection and washing of the bottom of the borehole; (

c) convex—to be used in soft and medium-hard rocks, not in abrasive rock (e.g., shales, limestone, sandstones). Very good advance of drilling works)

[44][17].

The selection of the drilling method, equipment, and drill string, particularly regarding the drill bit and the drilling technology parameters, is a key factor in the borehole drilling process. Among the rotary-percussion drilling methods, DTH is popular in practice, as it is more effective than drilling using top hammers. The quality of the selection is significantly dependent on the borehole design and on the available information regarding the properties of rocks to be drilled. Below is an exemplary selection of DTH drill bits for Sandvik (Sandvik Top Hammer Rock Drilling Tools—Catalog) by choosing the appropriate codes marked with letters for the rocks intended for drilling, depending on:

- (a) compressive strength (hardness)

-

compressive strength (hardness)-

H: for very hard to hard rocks, with compressive strength above 250 MPa;

M: for medium hard rocks, with compressive strength between 150 and 250 MPa;

S: for soft rocks, with compressive strength below 150 MPa;

- (b) rock homogeneity

-

rock homogeneity-

C: for homogeneous (competent) rocks;

F: for fissured rocks;

- (c) rock abrasion

-

rock abrasion-

V: for very abrasive rocks with a silica content above 40%;

A: for abrasive rocks with a silica content between 20 and 40%;

N: for non-abrasive rocks with a silica content below 0–20%.

A similar tool selection for rock drilling is presented by Copco Secoroc Atlas (Secoroc Rock Drilling Tools, Product catalog—DTH equipment). The selection is limited to the bit profile, hard and abrasive formations, and shows rock examples.

Another criterion for the drilling method selection is the system for cleaning the bottom of the borehole and carrying drill cuttings to the surface. In practice, both the water-to-power down-the-hole (DTH) percussion hammer and the air-powered DTH hammer are applied. Compared to conventional air-powered DTH hammers and water-powered DTH hammers, we can say that DTH offers a wide range of advantages, including low energy consumption, minimal hole deviation, a cleaner environment, deeper drilling capabilities, and a minimal impact on the surrounding ground. Water-powered DTHs do not create dust and using water as a flushing medium also better cleans the borehole.

The rotary-percussion drilling method with the DTH tool may be divided into two types: with a single and a double drill string. The single drill string method is used mainly in solid rocks, with a low risk of crumbling walls. In case loose rock layers precede the solid rock layer, to prevent the crumbling of borehole walls, the initial drilling is done by a casing string with a drill bit. The mechanism of the rotary-percussion drilling method with a single drill string is based on a DTH being controlled remotely by an air compressor. The double drill string method is used mainly in loose or less concise rocks. Drilling is done by simultaneous operation of two strings: a casing string equipped with a drill bit, being rotated counter-clockwise by the lower head, and a drill string equipped with a hammer or saw tooth type of drill bits are rotated clockwise by the upper head

[41][14].

Various types of drill bits are used in the rotary-percussion drilling method

[44][17]: A flat type is used for hard, medium-hard, and abrasive rocks. A concave drill bit is used for hard, medium-hard, and homogenous rocks, making deviation control and borehole scrubbing less difficult than other drill types. A convex drill bit is used for soft and medium-hard rocks with an advantage of an increased rate of penetration.

The drilling progress is also influenced by the shape of the drill bit inserts. Spherically shaped cemented carbides are resistant to cracking but do not guarantee high penetration rates. Semi-ballistic cemented carbide inserts have lower resistance to cracking in comparison to the spherically shaped ones but provide much better penetration rates. Ballistic cemented carbide inserts have lower resistance to cracking than both spherical and semi-ballistic inserts but guarantee a high drilling speed. Cylinder cemented carbide inserts are highly prone to cracking but guarantee very good drilling progress.

Drilling fluids used with the rotary-percussion drilling method are mainly air, water, or foam. They can be run through a pressure booster when drilling deep boreholes for more efficient removal of cuttings to the surface and pressure loss reduction.

Air pressure may be increased by a pressure booster up to 20 MPa at once and up to 170 MPa gradually over a few cycles. For water, with the use of a pressure booster, the borehole can reach a depth of approximately 3500 m. The rule of thumb is to increase the water pressure by 0.1 MPa for every 10 m drilled and add 0.7 MPa on a drill bit. With the use of foam, an additional 30% of the originally assumed borehole depth can be reached, cuttings and formation fluids removal are more efficient, and if the water influx is high, the returning pressure on the hammer is decreased

[41][14].