Diatoms have an ability that is unique among the unicellular photoautotrophic organisms to synthesize an intricately ornamented siliceous (biosilica) exoskeleton with an ordered, hierarchical, three-dimensional structure on a micro- to nanoscale. The unique morphological, structural, mechanical, transport, photonic, and optoelectronic properties of diatomaceous biosilica make it a desirable material for modern technologies. This review presents a summary and discussion of published research on the metabolic insertion of chemical elements with specific functional activity into diatom biosilica. Included in the review is research on innovation in methods of synthesis of a new generation of functional siliceous materials, where the synthesis process is “outsourced” to intelligent microorganisms, referred to here as microtechnologists, by providing them with appropriate conditions and reagents.

- diatoms

- diatomaceous biosilica

- metal doping

- metabolic inserting

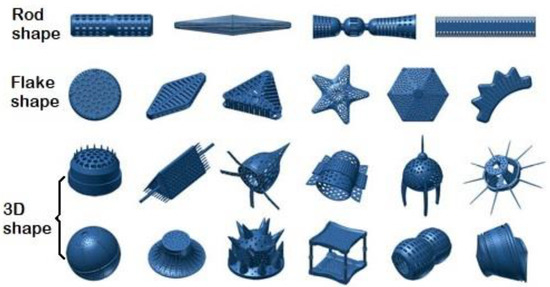

The use of microorganisms, especially unicellular microalgae, is a novel approach in the design and synthesis of new inorganic composite nanomaterials [1][2]. Some microorganisms have the ability to synthesize unique mineral composites with complex, hierarchical structures on a micro- to nanoscale [3]. The single-celled photoautotrophic microorganisms—diatoms (Bacillariophyceae)—have an astonishing variety of intricately ornamented siliceous exoskeletons, called frustules or valves, with a unique three-dimensional structure (

Figure 1 [4]) in more than 100,000 known species [5]. Such a variety of unique, precise siliceous structures with orderly pore (areola) systems makes them a desirable material for modern technologies [6,7,8,9,10,11,12,13,14].[4]) in more than 100,000 known species [5]. Such a variety of unique, precise siliceous structures with orderly pore (areola) systems makes them a desirable material for modern technologies [6][7][8][9][10][11][12][13][14].

The concept of using diatomaceous biosilica as an implementation material in modern technologies, especially in nanotechnology, is relative new and was proposed in 1994 by Gordon R. and Drum R. W. [15]. Since then, the phenomenal ability of diatoms to synthesize unique three-dimensional structures with specific physicochemical (optical, electrical, filtration, thermal, mechanical) properties from amorphous silica has held growing fascination for biologists, chemists, and physicists [6][16][17][18][19][20][21]. Currently, diatomaceous biosilica, due to its three-dimensional, porous structure, wide availability, and the possibility of biosynthesis through the cultivation of diatoms under artificial conditions, is one of the most frequently used substitutes for mesoporous silica materials in modern technologies. These materials, despite their biocompatibility and large specific surface area [22], are difficult to synthesize because of the necessity of considerable financial input, a large amount of energy, and an association of toxic materials using [23].

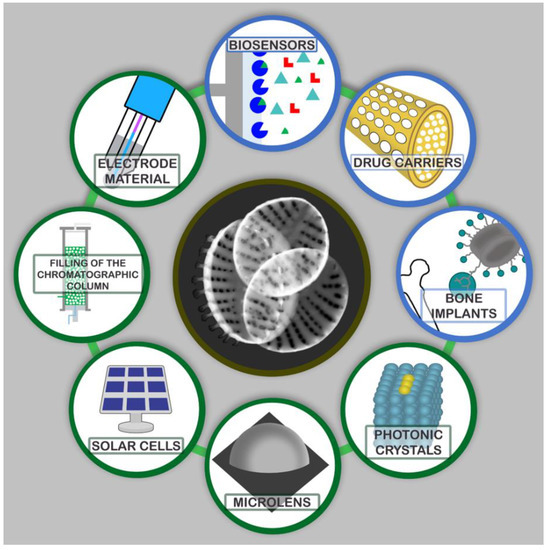

The unique, hierarchically porous 3D structure of diatom frustules makes them an attractive source of solutions for the development of modern material engineering. There are a wide range of possibilities for the use of such materials, e.g., in the production of biosensors, optical devices, catalysts, semiconductors, effective adsorbents, templates for nanolithography, and in designing drug carriers or bone implants [6][11][17][18][20][23][24][25]. The range of perspectives for the use of diatomaceous biosilica is shown in

Figure 2..

A range of possibilities to use diatomaceous biosilica.

Diatomaceous biosilica can be successfully used as an electrode material for energy generation and storage, or as photonic crystals [26][27][28][29][30][31]. Diatom frustules can be used as microlenses, as they are able to focus light below the diffraction limit, and their ability to accumulate high-intensity light can lead to the development of modern solar cells [32][33][34][35][36]. High thermal and mechanical resistance as well as unique optical properties make diatomaceous biosilica an inspiration in the development of modern optoelectronic devices [23][24][30][37]. However, many of the possible applications for diatomaceous biosilica as an industrial material are limited by the chemistry of the silica in diatom frustules. For this reason, considerable efforts have been made recently to modify the structure of diatom frustules to make them more technologically functional, whilst preserving their unique shape and morphology [23][33][38][39][40][41][42]. An extremely exciting proposal for the modification of biosilica is its reduction to pure silicon, without destroying its three-dimensional structure, which would be associated with new, broad possibilities in the field of microelectronics [18][38]. Promising results have been obtained using diatomaceous biosilica as a matrix in the chemical synthesis of nanomaterials [20][27][43][44]. Umernura et al. [41] proposed using fragmented diatomaceous biosilica as a matrix for luminescence in the liquid phase. The potential for placing specific proteins, enzymes, or antibodies within the structure of diatoms could allow for the production of microchip-sized hybrid biosensors, which would be a medical breakthrough [16][18][45].

Test results so far have indicated a great potential for the application of diatomaceous biosilica as a component of solar cells, in place of expensive titanium dioxide [37][46][47][48]. An extremely interesting but not yet fully developed idea is the ability to modify the structure of diatomaceous biosilica. There are two basic methods for the functionalization of diatoms [49]. The first one is the in vitro method involving the attachment, via a condensation reaction, of functional groups on the surface of the diatomaceous frustule after its purification, i.e., the removal of the organic matrix of the diatomaceous cell. The second one is the in vivo method based on the stable incorporation of the modifying element into the nanostructural architecture of diatomaceous biosilica during cultivation [50]. The in vitro method can be used to give magnetic properties to diatom frustules by adding iron nanoparticles treated with dopamine [51], as well as to create antibody matrices that can be applied in such techniques as immunoprecipitation [27]. The functionalization of diatoms in vivo is possible when modifying elements are added to the culture medium. This enables the incorporation of the doping element into the structure of the diatom frustules. So far, a few publications report the ability of diatoms to metabolically introduce metal oxides such as titanium or germanium into the structure of silica frustules [3][19][52][53][54][55][56][57][58][59][60][61][62]. There are also results of initial studies on the possibility of metabolic substitution of silicon atoms with nickel, zirconium, tin, zinc, calcium, aluminum, iron, and europium in diatomaceous biosilica [19][63][64][65][66][67][68][69][70][71].

In this review we summarize and discuss the research published to date on the metabolic insertion of chemical elements with specific functional activity (metals or semimetals) into the diatomaceous biosilica structure. Attention is drawn to the culture conditions (culture medium, type of salt and concentration range of admixed elements, pH), physicochemical properties of the biosilica obtained, the amount embedded and distribution of the element in the biosilica structure, and prospects for the use of the doped biosilica. We hope this work will encourage interest in metabolic insertion as a novel and innovative approach to the synthesis of new materials, where the synthesis itself is “outsourced” to the microorganisms as “microtechnologists” who need only the appropriate conditions and reagents.

References

- Gross, M. The mysteries of the diatoms. Curr. Biol. 2012, 22, 581–585.

- Görlich, S.; Pawolski, D.; Zlotnikov, I.; Kröger, N. Control of biosilica morphology and mechanical performance by the conserved diatom gene Silicanin-1. Commun. Biol. 2019, 2, 245.

- Aubrey K. Davis; Mark Hildebrand; A self-propagating system for Ge incorporation into nanostructured silica. Chemical Communications 2008, ., 4495, 10.1039/b804955f.

- Deyuan Zhang; Yu Wang; Jun Cai; Junfeng Pan; Xinggang Jiang; Yonggang Jiang; Bio-manufacturing technology based on diatom micro- and nanostructure. Chinese Science Bulletin 2012, 57, 3836-3849, 10.1007/s11434-012-5410-x.

- David G. Mann; Pieter Vanormelingen; An Inordinate Fondness? The Number, Distributions, and Origins of Diatom Species. Journal of Eukaryotic Microbiology 2013, 60, 414-420, 10.1111/jeu.12047.

- Wang, J.K.; Seibert, M. Prospects for commercial production of diatoms. Biotechnol. Biofuels 2017, 10, 1–13.

- Popovich, C.A.; Pistonesi, M.; Hegel, P.; Constenla, D.; Bielsa, G.B.; Martín, L.A.; Damiani, M.C.; Leonardi, P.I. Unconventional alternative biofuels: Quality assessment of biodiesel and its blends from marine diatom Navicula cincta. Algal Res. 2019, 39, 101438.

- Fu, W.; Nelson, D.R.; Mystikou, A.; Daakour, S.; Salehi-Ashtiani, K. Advances in microalgal research and engineering development. Curr. Opin. Biotechnol. 2019, 59, 157–164.

- Sasirekha, R.; Sheena, T.S.; Anitha, R.; Santhanam, P.; Kulandaivel, J. Characterizations and analysis of genus Amphora diatom frustules: A promising biomaterial. Bioinspired Biomim. Nanobiomater. 2019, 8, 224–230.

- Panwar, V.; Dutta, T. Diatom Biogenic Silica as a Felicitous Platform for Biochemical Engineering: Expanding Frontiers. ACS Appl. Bio Mater. 2019, 2, 2295–2316.

- Maher, S.; Maher, S.; Aw, M.S.; Losic, D. Diatom Silica for Biomedical Applications. Diatoms Fundam. Appl. 2019, 511–536.

- Vinayak, V.; Joshi, K.B.; Sarma, P.M. DiafuelTM (Diatom Biofuel) vs Electric Vehicles, a Basic Comparison: A High Potential Renewable Energy Source to Make India Energy Independent. In Diatoms: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2019; pp. 537–582.

- Gordon, R.; Merz, C.R.; Gurke, S.; Schoefs, B. Bubble Farming: Scalable Microcosms for Diatom Biofuel and the Next Green Revolution. Diatoms Fundam. Appl. 2019, 583–654.

- Vinayak, V.; Gautam, S. Diatoms in Forensics: A Molecular Approach to Diatom Testing in Forensic Science. Diatoms Fundam. Appl. 2019, 435–470.

- Richard Gordon; Ryan W. Drum; The Chemical Basis of Diatom Morphogenesis. Natural and Engineered Resistance to Plant Viruses, Part II 1994, 150, 243-372, 10.1016/s0074-7696(08)61544-2.

- Gordon, R.; Losic, D.; Tiffany, M.A.; Nagy, S.S.; Sterrenburg, F.A.S. The Glass Menagerie: Diatoms for novel applications in nanotechnology. Trends Biotechnol. 2009, 27, 116–127.

- Bozarth, A.; Maier, U.G.; Zauner, S. Diatoms in biotechnology: Modern tools and applications. Appl. Microbiol. Biotechnol. 2009, 82, 195–201.

- Nassif, N.; Livage, J. From diatoms to silica-based biohybrids. Chem. Soc. Rev. 2011, 40, 849–859.

- Basharina, T.N.; Danilovtseva, E.N.; Zelinskiy, S.N.; Klimenkov, I.V.; Likhoshway, Y.V.; Annenkov, V.V. The Effect of Titanium, Zirconium and Tin on the Growth of Diatom Synedra acus and Morphology of Its Silica Valves. Silicon 2012, 4, 239–249.

- Mishra, M.; Arukha, A.P.; Bashir, T.; Yadav, D.; Prasad, G.B.K.S. All new faces of diatoms: Potential source of nanomaterials and beyond. Front. Microbiol. 2017, 8, 1–8.

- Athanasakoglou, A.; Kampranis, S.C. Diatom isoprenoids: Advances and biotechnological potential. Biotechnol. Adv. 2019, 37.

- Marina Martínez-Carmona; Yurii K. Gun’Ko; Vallet- Regi; Mesoporous Silica Materials as Drug Delivery: “The Nightmare” of Bacterial Infection. Pharmaceutics 2018, 10, 279, 10.3390/pharmaceutics10040279.

- U.T. Uthappa; Varsha Brahmkhatri; G. Sriram; Ho-Young Jung; Jingxian Yu; Nikita Kurkuri; T. M. Aminabhavi; Tariq Altalhi; Gururaj M. Neelgund; Mahaveer D. Kurkuri; et al. Nature engineered diatom biosilica as drug delivery systems. Journal of Controlled Release 2018, 281, 70-83, 10.1016/j.jconrel.2018.05.013.

- De Tommasi, E.; Gielis, J.; Rogato, A. Diatom Frustule Morphogenesis and Function: A Multidisciplinary Survey. Mar. Genom. 2017, 35, 1–18.

- De Stefano, L.; Rotiroti, L.; De Stefano, M.; Lamberti, A.; Lettieri, S.; Setaro, A.; Maddalena, P. Marine diatoms as optical biosensors. Biosens. Bioelectron. 2009, 24, 1580–1584.

- Anderson, N.J. Miniview: Diatoms, temperature and climatic change. Eur. J. Phycol. 2000, 35, 307–314.

- Townley, H.E.; Parker, A.R.; White-Cooper, H. Exploitation of diatom frustules for nanotechnology: Tethering active biomolecules. Adv. Funct. Mater. 2008, 18, 369–374.

- De Stefano, L.; Maddalena, P.; Moretti, L.; Rea, I.; Rendina, I.; De Tommasi, E.; Mocella, V.; De Stefano, M. Nano-biosilica from marine diatoms: A brand new material for photonic applications. Superlattices Microstruct. 2009, 46, 84–89.

- He, J.; Chen, D.; Li, Y.; Shao, J.; Xie, J.; Sun, Y.; Yan, Z.; Wang, J. Diatom-templated TiO2 with enhanced photocatalytic activity: Biomimetics of photonic crystals. Appl. Phys. A Mater. Sci. Process. 2013, 113, 327–332.

- Nowak, A.P.; Sprynskyy, M.; Brzozowska, W.; Lisowska-Oleksiak, A. Electrochemical behavior of a composite material containing 3D-structured diatom biosilica. Algal Res. 2019, 41, 101538.

- Norberg, A.N.; Wagner, N.P.; Kaland, H.; Vullum-Bruer, F.; Svensson, A.M. Silica from diatom frustules as anode material for Li-ion batteries. RSC Adv. 2019, 9, 41228–41239.

- Toster, J.; Iyer, K.S.; Xiang, W.; Rosei, F.; Spiccia, L.; Raston, C.L. Diatom frustules as light traps enhance DSSC efficiency. Nanoscale 2013, 5, 873–876.

- Wang, Y.; Cai, J.; Jiang, Y.; Jiang, X.; Zhang, D. Preparation of biosilica structures from frustules of diatoms and their applications: Current state and perspectives. Appl. Microbiol. Biotechnol. 2013, 97, 453–460.

- Chandrasekaran, S.; Sweetman, M.J.; Kant, K.; Skinner, W.; Losic, D.; Nann, T.; Voelcker, N.H. Silicon diatom frustules as nanostructured photoelectrodes. Chem. Commun. 2014, 50, 10441–10444.

- Huang, D.R.; Jiang, Y.J.; Liou, R.L.; Chen, C.H.; Chen, Y.A.; Tsai, C.H. Enhancing the efficiency of dye-sensitized solar cells by adding diatom frustules into TiO2 working electrodes. Appl. Surf. Sci. 2015, 347, 64–72.

- Lin, K.B.; Shen, T.W.; Su, Y.H. Silicon-Based Solar Cells: Emergent Upconversion Sustainable Micro-Optical Trapping Device (Part. Part. Syst. Charact. 7/2019). Part. Part. Syst. Charact. 2019, 36, 1970017.

- Clayton Jeffryes; Jeremy Campbell; Haiyan Li; Jun Jiao; Gregory L. Rorrer; The potential of diatom nanobiotechnology for applications in solar cells, batteries, and electroluminescent devices. Energy & Environmental Science 2011, 4, 3930, 10.1039/c0ee00306a.

- Bao, Z.; Weatherspoon, M.R.; Shian, S.; Cai, Y.; Graham, P.D.; Allan, S.M.; Ahmad, G.; Dickerson, M.B.; Church, B.C.; Kang, Z.; et al. Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature 2007, 446, 172–175.

- Kroth, P. Molecular biology and the biotechnological potential of diatoms. Adv. Exp. Med. Biol. 2007, 616, 23–33.

- Leonardo, S.; Prieto-Simón, B.; Campàs, M. Past, present and future of diatoms in biosensing. TrAC Trends Anal. Chem. 2016, 79, 276–285.

- Umemura, K.; Gao, Y.; Nishikawa, T. Preparation of photocatalyst using diatom frustules by liquid phase deposition method. J. Nanosci. Nanotechnol. 2010, 10, 4883–4888.

- Huang, W.; Daboussi, F. Genetic and metabolic engineering in diatoms. Philos. Trans. R. Soc. B Biol. Sci. 2017, 372.

- Yang, W.; Lopez, P.J.; Rosengarten, G. Diatoms: Self assembled silica nanostructures, and templates for bio/chemical sensors and biomimetic membranes. Analyst 2011, 136, 42–53.

- Irimia-Vladu, M.D.; Glowacki, E.S.; Sariciftci, N.; Bauer, S.; Ragni, R.; Cicco, S.R.; Vona, D.; Farinola, G.M. Nanostructured Silica from Diatoms Microalgae: Smart Materials for Photonics and Electronics. Green Mater. Electron. 2017, 287–313.

- Monica Terracciano; Luca De Stefano; Ilaria Rea; Diatoms Green Nanotechnology for Biosilica-Based Drug Delivery Systems. Pharmaceutics 2018, 10, 242, 10.3390/pharmaceutics10040242.

- Ramachandra, T.V.; Mahapatra, D.M.; Karthick, B.; Gordon, R. Milking diatoms for sustainable energy: Biochemical engineering versus gasoline-secreting diatom solar panels. Ind. Eng. Chem. Res. 2009, 48, 8769–8788.

- Zglobicka, I.; Chmielewska, A.; Topal, E.; Kutukova, K.; Gluch, J.; Krüger, P.; Kilroy, C.; Swieszkowski, W.; Kurzydlowski, K.J.; Zschech, E. 3D Diatom–Designed and Selective Laser Melting (SLM) Manufactured Metallic Structures. Sci. Rep. 2019, 9, 1–9.

- Bandara, T.M.W.J.; Furlani, M.; Albinsson, I.; Wulff, A.; Mellander, B.E. Diatom frustules enhancing the efficiency of gel polymer electrolyte based dye-sensitized solar cells with multilayer photoelectrodes. Nanoscale Adv. 2020, 2, 199–209.

- Kröger, N.; Dubey, N.C.; Kumari, E. CHAPTER 6: Immobilization of Proteins on Diatom Biosilica. In RSC Nanoscience and Nanotechnology; Royal Society of Chemistry: London, UK, January 2018; Volume 2018, pp. 126–149. ISBN 9781782624585.

- Roberta Ragni; Stefania Cicco; Danilo Vona; Gabriella Leone; Gianluca Maria Farinola; Biosilica from diatoms microalgae: smart materials from bio-medicine to photonics. Journal of Materials Research 2016, 32, 279-291, 10.1557/jmr.2016.459.

- Lydia Köhler; Susanne Machill; Anja Werner; Carolin Selzer; Stefan Kaskel; Eike Brunner; Are Diatoms “Green” Aluminosilicate Synthesis Microreactors for Future Catalyst Production?. Molecules 2017, 22, 2232, 10.3390/molecules22122232.

- Qin, T.; Gutu, T.; Chang, C.H.; Jiao, J.; Rorrer, G.L. Biological fabrication of photoluminescent nanocomb structures by metabolic incorporation of germanium into the biosilica of the diatom Nitzschia frustulum. ACS Nano 2008, 2, 1296–1304.

- Gale, D.K.; Jeffryes, C.; Gutu, T.; Jiao, J.; Chang, C.H.; Rorrer, G.L. Thermal annealing activates amplified photoluminescence of germanium metabolically doped in diatom biosilica. J. Mater. Chem. 2011, 21, 10658–10665.

- Ali, D.M.; Divya, C.; Gunasekaran, M.; Thajuddin, N. Biosynthesis and Characterization of Silicon-Germanium Oxide Nanocomposite By Diatom. Dig. J. Nanomater. Biostruct. 2011, 6, 117–120.

- Jeffryes, C.; Gutu, T.; Jiao, J.; Rorrer, G.L. Metabolic Insertion of Nanostructured TiO2 into the Patterned Biosilica of the Diatom. ACS Nano 2008, 2, 2103–2112.

- Van Eynde, E.; Hu, Z.Y.; Tytgat, T.; Verbruggen, S.W.; Watté, J.; Van Tendeloo, G.; Van Driessche, I.; Blust, R.; Lenaerts, S. Diatom silica-titania photocatalysts for air purification by bio-accumulation of different titanium sources. Environ. Sci. Nano 2016, 3, 1052–1061.

- Chauton, M.S.; Skolem, L.M.B.; Olsen, L.M.; Vullum, P.E.; Walmsley, J.; Vadstein, O. Titanium uptake and incorporation into silica nanostructures by the diatom Pinnularia sp. (Bacillariophyceae). J. Appl. Phycol. 2015, 27, 777–786.

- Skolem, L.M.B. Biosynthesis and Characterization of Ti- Doped Silica-Based Nanostructures Formed by the Diatoms Pinnularia sp. and Coscinodiscus wailesii; Norwegian University of Science and Technology: Trondheim, Norway, 2011; Volume 801.

- Maeda, Y.; Niwa, Y.; Tang, H.; Kisailus, D.; Yoshino, T.; Tanaka, T. Development of Titania-Integrated Silica Cell Walls of the Titanium-Resistant Diatom, Fistulifera solaris. ACS Appl. Bio Mater. 2018, 1, 2021–2029.

- Lang, Y.; Monte, F.D.; Rodriguez, B.J.; Dockery, P.; Finn, D.P.; Pandit, A. Integration of TiO2 into the diatom Thalassiosira weissflogii during frustule synthesis. Sci. Rep. 2013, 3, 1–11.

- Rorrer, G.L.; Chang, C.H.; Liu, S.H.; Jeffryes, C.; Jiao, J.; Hedberg, J.A. Biosynthesis of silicon-germanium oxide nanocomposites by the marine diatom Nitzschia frustulum. J. Nanosci. Nanotechnol. 2005, 5, 41–49.

- Jeffryes, C.; Gutu, T.; Jiao, J.; Rorrer, G.L. Two-stage photobioreactor process for the metabolic insertion of nanostructured germanium into the silica microstructure of the diatom Pinnularia sp. Mater. Sci. Eng. C 2008, 28, 107–118.

- Townley, H.E.; Woon, K.L.; Payne, F.P.; White-Cooper, H.; Parker, A.R. Modification of the physical and optical properties of the frustule of the diatom Coscinodiscus wailesii by nickel sulfate. Nanotechnology 2007, 18, 14–19.

- Gannavarapu, K.P.; Ganesh, V.; Thakkar, M.; Mitra, S.; Dandamudi, R.B. Nanostructured Diatom-ZrO2 composite as a selective and highly sensitive enzyme free electrochemical sensor for detection of methyl parathion. Sens. Actuators B Chem. 2019, 288, 611–617.

- Leone, G.; Vona, D.; Lo Presti, M.; Urbano, L.; Cicco, S.; Gristina, R.; Palumbo, F.; Ragni, R.; Farinola, G.M. Ca2+-in vivo doped biosilica from living Thalassiosira weissflogii diatoms: Investigation on Saos-2 biocompatibility. Mater. Res. Soc. 2017, 2, 1047–1058.

- Li, J.; Han, J.; Sun, Q.; Wang, Y.; Mu, Y.; Zhang, K.; Dou, X.; Kong, M.; Chen, X.; Feng, C. Biosynthetic calcium-doped biosilica with multiple hemostatic properties for hemorrhage control. J. Mater. Chem. B 2018, 6, 7834–7841.

- Machill, S.; Kohler, L.; Ueberlein, S.; Hedrich, R.; Kunaschk, M.; Paasch, S.; Schulze, R.; Brunner, E. Analytical studies on the incorporation of aluminium in the cell walls of the marine diatom Stephanopyxis turris. BioMetals 2013, 26, 141–150.

- Gehlen, M.; Beck, L.; Calas, G.; Flank, A.M.; Van Bennekom, A.J.; Van Beusekom, J.E.E. Unraveling the atomic structure of biogenic silica: Evidence of the structural association of Al and Si in diatom frustules. Geochim. Cosmochim. Acta 2002, 66, 1601–1609.

- Jaccard, T.; Ariztegui, D.; Wilkinson, K.J. Incorporation of zinc into the frustule of the freshwater diatom Stephanodiscus hantzschii. Chem. Geol. 2009, 265, 381–386.

- Ellwood, M.J.; Hunter, K.A. The incorporation of zinc and iron into the frustule of the marine diatom Thalassiosira pseudonana. Limnol. Oceanogr. 2000, 45, 1517–1524.

- Zhang, G.; Jiang, W.; Wang, L.; Liao, X.; Liu, P.; Deng, X.; Li, J. Preparation of silicate-based red phosphors with a patterned nanostructure via metabolic insertion of europium in marine diatoms. Mater. Lett. 2013, 110, 253–255.