Lignin nanomaterials have emerged as a promising alternative to fossil-based chemicals and products for some potential added-value applications, which benefits from their structural diversity and biodegradability. This review elucidates a perspective in recent research on nanolignins and their nanocomposites. It summarizes the different nanolignin preparation methods, emphasizing anti-solvent precipitation, self-assembly and interfacial crosslinking. Also described are the preparation of various nanocomposites by the chemical modification of nanolignin and compounds with inorganic materials or polymers. Additionally, advances in numerous potential high-value applications, such as use in food packaging, biomedical, chemical engineering and biorefineries, are described.

1. Introduction

With our continued in-depth understanding of the environmental pollution and resource crisis, the renewable and degradable properties of biomass materials are being increasingly valued [1][2]. As the second most abundant natural polymer material after cellulose, lignin has received extensive attention in recent years [3][4]. The development of bio-based products from lignin is an important part of any comprehensive biorefinery concept because of their biocompatibility and biodegradability [5]. They not only diversify the combination of products and markets, but also benefit waste recycling and economic sustainability [6][7]. Nevertheless, worldwide only 5% of the lignin is explored for high value development, therefore, there are still numerous challenges and opportunities for the in depth research and development of lignin applications [8].

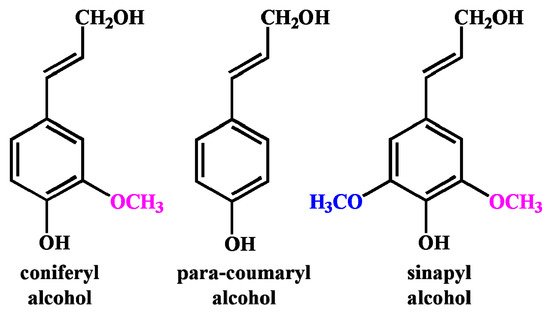

The three-dimensional network structure of lignin is formed by three phenylpropane monomers (para-coumaryl alcohol, sinapyl alcohol and coniferyl alcohol, Figure 1) which connect to each other through ether bonds and carbon-carbon bonds [9][10]. It contains multiple active functional groups, such as aliphatic, aromatic, hydroxyl groups, etc. The isolation technology of cellulose, hemicellulose and lignin in biomass is directly related to the effective utilization of biomass. The complexity and diversity of lignin structures mainly depend on their different sources, types, extraction and purification methods [11]. Different extraction methods and pulping procedures will produce lignin with different structures and properties, which determine its subsequent development and applications [12].

Figure 1. Three monomer structures of lignin.

The conventional separation and extraction methods for lignin mainly include grinding, acid/alkaline/thioacid hydrolysis, cellulose enzymolysis, organic solvent extraction and ionic liquid extraction [13][14]. Organic solvent pulping reduces the dependence on alkali or inorganic acids in the traditional pulping process [15]. Organic solvents such as alcohols, esters and amines can be used to dissolve the lignin in the raw materials to achieve the purpose of separation from cellulose [16].

In addition, biological enzymes are used to selectively degrade cellulose to achieve lignin separation. This biological treatment separates the lignin with less impact on its structure and chemical properties [17]. Therefore, it is particularly important to select suitable and efficient extraction methods for different raw materials without destroying the lignin structure. More importantly, the presence of different types of ions and the ionic strength of solutions is the foundation for the association and isolation of lignin [18]. The macromolecular and colloidal properties of lignin can be investigated in depth by studying the self-aggregation kinetics at some specific solution conditions [19]. The study of lignin solutions/colloidal behavior and the associative/dissociative processes also facilitates the understanding of its physicochemical properties [20].

Wide applications of lignin as an additive in composite materials and bio-based products from lignin deconstruction are being intensively developed [21][22]. However, it is not possible to completely achieve the high-value applications of lignin due to some unfavorable byproducts. The diversity of lignin sources and the complexity of the structures make the research on the potential applications of lignin have certain opportunities and challenges [23][24]. Therefore, the formation of lignin-based nanomaterials will open up a different perspective for expanding the high-value applications of lignin.

As for other materials and biopolymers, such as cellulose and chitosan, the rationale for the preparation of lignin nanomaterials is to gain new attractive properties occurring only when matter is organized on a nanoscale [25]. This can be due to the so-called “quantum effect” bringing new tunable properties at the nanoscale or simply by the expanded surface to volume ratio of nanomaterials [26]. Compared with traditional composite materials, nanocomposites have obvious advantages, especially new materials from biorenewable and sustainable sources [27]. Due to the compatibility, degradability and environmental friendliness of bionanocomposites, their potential applications in the food packaging industry and pharmaceuticals are being exploited [28]. Polymer nanocomposites are being further used in additive manufacturing technology to produce more complex and diverse parts and components [29]. In addition, the application of multifunctional nanocomposite materials in the field of optics is also becoming increasingly prominent [30]. In the last few years, the research on multifunctional nanofibers is helpful for the development of potential applications in the field of medicine, biological tissue engineering, etc., especially chitosan electrospun nanofibers [31]. Electrospun nanofibers can be used to reinforce composite materials due to their specific molecular orientation and excellent mechanical properties [32].

As for lignin, with its aromatic and highly cross-linked network structure and chemical complexity, lignin contains plentiful of functional groups that are accessible for further surface modification [33]. This laat asset increases the potential activity of nanolignin to achieve high value-added applications of lignin [4]. In addition, the utilization of economical and environmentally friendly nanolignin as feedstock for the evolution of chemical industry conforms to green chemistry principles and sustainable development concepts [13].

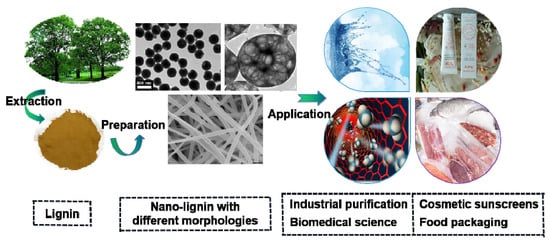

Currently, the exploitation of nanolignin is the subject of a tremendous amount of research [34]. Lignin nanoparticles with different morphologies (smooth colloidal, hollow, spherical and quasi-spherical, Figure 2) have been successfully synthesized by controlling the reaction conditions of solvent/anti-solvent, the lignin concentration, the temperature and pH of solution, etc. [35][36]. Lignin nanoparticles have potential applications in antioxidants, thermal/light stabilizers, reinforced materials and nanomicrocarriers owing to their advantages of non-toxicity, environmental resistance, excellent thermal stability and biocompatibility [37].

Figure 2. Nanolignins with different morphologies and their applications in different fields.

1. Introduction

With our continued in-depth understanding of the environmental pollution and

resource crisis, the renewable and degradable properties of biomass materials are being

increasingly valued [1,2]. As the second most abundant natural polymer material after

cellulose, lignin has received extensive attention in recent years [3,4]. The development

of bio-based products from lignin is an important part of any comprehensive biorefinery

concept because of their biocompatibility and biodegradability [5]. They not only diversify

the combination of products and markets, but also benefit waste recycling and economic

sustainability [6,7]. Nevertheless, worldwide only 5% of the lignin is explored for high

value development, therefore, there are still numerous challenges and opportunities for the

in depth research and development of lignin applications [8].

The three-dimensional network structure of lignin is formed by three phenylpropane

monomers (para-coumaryl alcohol, sinapyl alcohol and coniferyl alcohol, Figure 1) which

connect to each other through ether bonds and carbon-carbon bonds [9,10]. It contains

multiple active functional groups, such as aliphatic, aromatic, hydroxyl groups, etc. The

isolation technology of cellulose, hemicellulose and lignin in biomass is directly related to

the effective utilization of biomass. The complexity and diversity of lignin structures mainly

depend on their different sources, types, extraction and purification methods [11]. Different

extraction methods and pulping procedures will produce lignin with different structures

and properties, which determine its subsequent development and applications [12].

The conventional separation and extraction methods for lignin mainly include grinding,

acid/alkaline/thioacid hydrolysis, cellulose enzymolysis, organic solvent extraction

and ionic liquid extraction [13,14]. Organic solvent pulping reduces the dependence on

alkali or inorganic acids in the traditional pulping process [15]. Organic solvents such

as alcohols, esters and amines can be used to dissolve the lignin in the raw materials to

achieve the purpose of separation from cellulose [16].

In addition, biological enzymes are used to selectively degrade cellulose to achieve

lignin separation. This biological treatment separates the lignin with less impact on its

structure and chemical properties [17]. Therefore, it is particularly important to select

suitable and efficient extraction methods for different raw materials without destroying

the lignin structure. More importantly, the presence of different types of ions and the ionic

strength of solutions is the foundation for the association and isolation of lignin [18]. The

macromolecular and colloidal properties of lignin can be investigated in depth by studying

the self-aggregation kinetics at some specific solution conditions [19]. The study of lignin

solutions/colloidal behavior and the associative/dissociative processes also facilitates the

understanding of its physicochemical properties [20].

Wide applications of lignin as an additive in composite materials and bio-based

products from lignin deconstruction are being intensively developed [21,22]. However,

it is not possible to completely achieve the high-value applications of lignin due to some

unfavorable byproducts. The diversity of lignin sources and the complexity of the structures

make the research on the potential applications of lignin have certain opportunities and

challenges [23,24]. Therefore, the formation of lignin-based nanomaterials will open up a

different perspective for expanding the high-value applications of lignin.

As for other materials and biopolymers, such as cellulose and chitosan, the rationale for

the preparation of lignin nanomaterials is to gain new attractive properties occurring only

when matter is organized on a nanoscale [25]. This can be due to the so-called “quantum

effect” bringing new tunable properties at the nanoscale or simply by the expanded surface

to volume ratio of nanomaterials [26]. Compared with traditional composite materials,

nanocomposites have obvious advantages, especially new materials from biorenewable

and sustainable sources [27]. Due to the compatibility, degradability and environmental

friendliness of bionanocomposites, their potential applications in the food packaging

industry and pharmaceuticals are being exploited [28]. Polymer nanocomposites are being

further used in additive manufacturing technology to produce more complex and diverse

parts and components [29]. In addition, the application of multifunctional nanocomposite

materials in the field of optics is also becoming increasingly prominent [30]. In the last

few years, the research on multifunctional nanofibers is helpful for the development of

potential applications in the field of medicine, biological tissue engineering, etc., especially

chitosan electrospun nanofibers [31]. Electrospun nanofibers can be used to reinforce

composite materials due to their specific molecular orientation and excellent mechanical

properties [32].

As for lignin, with its aromatic and highly cross-linked network structure and chemical

complexity, lignin contains plentiful of functional groups that are accessible for further

surface modification [33]. This laat asset increases the potential activity of nanolignin

to achieve high value-added applications of lignin [4]. In addition, the utilization of

economical and environmentally friendly nanolignin as feedstock for the evolution of

chemical industry conforms to green chemistry principles and sustainable development

concepts [13].

Currently, the exploitation of nanolignin is the subject of a tremendous amount of

research [34]. Lignin nanoparticles with different morphologies (smooth colloidal, hollow,

spherical and quasi-spherical, Figure 2) have been successfully synthesized by controlling

the reaction conditions of solvent/anti-solvent, the lignin concentration, the

temperature and pH of solution, etc. [35,36]. Lignin nanoparticles have potential applications

in antioxidants, thermal/light stabilizers, reinforced materials and nanomicrocarriers

owing to their advantages of non-toxicity, environmental resistance, excellent thermal stability and

biocompatibility [37]

In recent years, the valorization of lignin, lignin nanoparticles and their nanocomposites

have been extensively reviewed. Figure 3 displays the number and subject areas of

published literature on lignin nanoparticles and nanocomposites over the last five years.

Tetyana et al. [38] focused on lignin-inorganic composite materials and applications in

energy storage. Mishra et al. [36] focused on non-covalent interactions and self-assembly

of lignin, briefly describing synthetic methods without mentioning specific applications.

Österberg et al. [39] provided only an overview of spherical lignin nanoparticles and their

applications in dispersants, coatings, adhesives and composites. Duval et al. [40] described

the structure and extraction process of lignin, as well as the applications of lignin-based

polymeric and micro/nano-structured materials.

Nanomaterials 2021, 11, x FOR PEER REVIEW 3 of 30

Currently, the exploitation of nanolignin is the subject of a tremendous amount of

research [34]. Lignin nanoparticles with different morphologies (smooth colloidal, hollow,

spherical and quasi-spherical, Figure 2) have been successfully synthesized by controlling

the reaction conditions of solvent/anti-solvent, the lignin concentration, the

temperature and pH of solution, etc. [35,36]. Lignin nanoparticles have potential applications

in antioxidants, thermal/light stabilizers, reinforced materials and nanomicrocarriers

owing to their advantages of non-toxicity, environmental resistance, excellent

thermal stability and biocompatibility [37].

In recent years, the valorization of lignin, lignin nanoparticles and their nanocomposites

have been extensively reviewed. Figure 3 displays the number and subject areas of

published literature on lignin nanoparticles and nanocomposites over the last five years.

Tetyana et al. [38] focused on lignin-inorganic composite materials and applications in

energy storage. Mishra et al. [36] focused on non-covalent interactions and self-assembly

of lignin, briefly describing synthetic methods without mentioning specific applications.

Österberg et al. [39] provided only an overview of spherical lignin nanoparticles and their

applications in dispersants, coatings, adhesives and composites. Duval et al. [40] described

the structure and extraction process of lignin, as well as the applications of lignin-based

polymeric and micro/nano-structured materials.

Therefore, in this review we would like to provide an outlook on this promising

research on nanolignin and its nanocomposites. We will emphasize lignin nanoparticle

synthesis methods and the characterizations of their structure and performance, along

with the effects of different reaction conditions on the morphology and dispersion of lignin

nanoparticles. Furthermore, the modification of lignin nanoparticles and multifunctional

lignin-based nanocomposites are described. The difference in the properties of the modified

lignin nanoparticles is emphasized. Finally, we will provide a novel perspective to the

value-added applications of lignin nanomaterials and many promising possibilities to

improve biotechnological developments.

2. Synthesis Methods of Lignin Nanoparticles

The physical and chemical properties such as non-toxicity, corrosion and UV-resistance,

antibacterial and anti-oxidation activity of lignin are attracting more and more attention

[3,33]. Therefore, the use of low-cost and abundant lignin raw materials to prepare

nanoparticles is an important aspect of expanding their high value-added utilization [41].

At the same time, finding simple, scientific and safe methods for preparing lignin nanoparticles

is of great significance. The current preparation methods of nano-lignin mainly

include anti-solvent precipitation, self-assembly, gradual addition and mechanical methods,

etc [1,7,10]. Some emerging methods, such as ice segregation-induced self-assembly,

aerosol-flow synthesis and electrospinning, are also being developed [35,42–45]. Figure 4

gives an overview of the synthesis and modification methods of nano-lignin. Lignin

nanoparticles with different morphologies and sizes, which can be prepared through these

different methods and conditions, will be of great value for their subsequent applications

in different fields [46].

3. The Value-Added Applications of Lignin Nanomaterials

In the process of exploring nanolignin materials, it was found that sometimes the

ordinary nanolignin cannot satisfy the diverse requirements in different application fields.

In addition to the basic thermal and mechanical properties of nanomaterials, some diverse

nanostructures and specific performance such as metal adsorption are widely required

[93,94]. Therefore, the ordinary nanolignin can be used to directly modify or

compound with other nanomaterials, which can take advantage of nanolignin structure

and further improve the performance of nanocomposite materials [95].

Lignin nanoparticles have attracted more and more attention because of their green,

renewable and abundant source, antioxidant, antibacterial or ultraviolet absorption properties,

biodegradability, biocompatibility, etc [96]. They are excellent substitutes for partially

harmful nanomaterials, which are extensively used in the fields of drug release and control

[97], food packaging, biomedicine, adsorbent materials, nanocarriers, environmental

restoration and so on [98–101]. This not only solves the potential safety hazards of traditional

nanomaterials from the source, but also broadens the value-added applications

of lignin nanomaterials, which conforms to the principles of green chemistry development

[102].

4. Conclusions and Future Perspectives

Overall, this review summarizes the current status of the preparation of nano-lignin by

sedimentation, mechanical, self-assembly and stepwise addition polymerization methods.

In order to provide a reference for the chemical deep processing of biomass resources

and the development of nano-lignin, the application characteristics of nano-lignin in UV

protection and anti-bacteria, nano-fillers and biomass-based carriers are also outlined.

Through the specific analysis of the preparation methods and application status of nanolignin,

it can promote the further research of nano-lignin and the development of novel

nano-lignin-based products. This is of great significance to the utilization and sustainable

development of lignin.

The multiple structures and the diverse properties of lignin make the prepared nanolignin

more complicated, which brings challenges to the research of the preparation and

performance of nano-lignin. Meanwhile, it provides broader prospects and opportunities

for the multi-functional and multi-field applications of nano-lignin. Nanometersized lignin

with high specific surface area and activity is a novel approach to achieve high value-added

utilization of lignin. Compared with the research of inorganic nanoparticles and renewable

nanocellulose, the preparation and application of nano-lignin are still in their infancy. The

scale and industrialization of nano-lignin-based products will become an important aspect

of future lignin research.

In view of the problems of complex process and toxic organic solvents in the preparation

of lignin nanoparticles, methods such as electrostatic spinning, self-assembly, ultrasonication

and homogenization can be utilized. In terms of multi-functional applications of

lignin-based nanomaterials, the range of use can be expanded by improving their strength,

electrical conductivity, thermal stability, crystallization performance, etc.

The following points need attention in the application of nanolignin materials. First

of all, achieving uniform dispersions of nanolignin in composite materials is a difficult

problem to solve. Lignin nanoparticles are extremely prone to agglomeration because of

the high surface energy and the large number of hydrogen bonds and Van der Waals forces

between the molecules. Therefore, completely solving the problem of particle agglomeration

and achieving the monodispersion of nano-lignin are the key to fully exerting the

nano-effect. Furthermore, the diversified morphology and size of lignin nanoparticles

are prerequisites for high value-added and multi-field applications of lignin. To solve the

interface and dispersion problems of nano-lignin materials, it is essential to find chemical

methods to modify nano-lignin and also supplement with effective physical dispersion

methods, such as mechanical stirring, ultrasonication and high shear homogenization. In

addition, the amount of nano-lignin added, the type of treatment agent and dispersing

equipment are all key factors that affect agglomeration, which need to be controlled and

improved during the preparation of lignin-based nanomaterials.

The structural and functional properties of lignin determine its extremely promising

applications in the field of biochemicals. Lignin and its derivatives have a wide range of

functionalities and can be used as dispersants, adsorbents/desorbents, oil recovery aids,

asphalt emulsifiers, etc. They can also be converted into aromatics, agrochemicals, polymers

and high-performance materials. However, all these processes depend on improvements

and innovations in the field of catalysis and product separation. Most importantly, to

realize the full industrial potential of lignin, further refinement of biopulp technology

is needed to achieve efficient separation of lignin and cellulose. It can be said that the

contribution of lignin to sustainable human development lies in its ability to provide a

stable and continuous source of organic matter. Thus it can truly guarantee sustainable

green development and energy supply.

In addition, the antioxidant and anti-UV effects of lignin are its most prominent properties,

so the application of lignin-based composites in food packaging and other fields has

been increasingly developed. The lignin-based nanocomposites are also excellent carriers

for a variety of metal ions and drug loading due to their unique nano-effects. They can be

used as bio-nanocomposite catalysts and reducing agents for heavy metal ions, which are of great importance for environmental protection and wastewater treatment. Furthermore,

the biocompatibility and non-toxicity of lignin are being intensively investigated.

Numerous scientific findings indicate that lignin-based nanocomposites have a very

promising future in the biomedical field. Specific lignins have significant anti-lipid peroxidation

and oxygen radical scavenging effects. Significant inhibitory effects of lignin

on the central nervous system or on cancer cell proliferation can also be observed. Most

importantly, lignin nanoparticles can be used as biological carriers for drug delivery and

targeted drug release. The molecular expression, biocompatibility and cytotoxicity of

lignin-based nanocomposites in cell lines have also been intensively studied. Conclusively,

the development of novel biomass materials and products will be applied to the medical

field and have a positive and effective impact on human life and health.

References

1. Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin:

Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 2018, 93, 233–269. [CrossRef]

2. Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and

nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [CrossRef]

3. Qian, Y.; Qiu, X.; Zhu, S. Lignin: A nature-inspired sun blocker for broad-spectrum sunscreens. Green Chem. 2015, 17, 320–324.

[CrossRef]

4. Sipponen, M.H.; Lange, H.; Crestini, C.; Henn, A.; Osterberg, M. Lignin for Nano- and Microscaled Carrier Systems: Applications,

Trends, and Challenges. ChemSusChem 2019, 12, 2039–2054. [CrossRef]

5. Dessbesell, L.; Paleologou, M.; Leitch, M.; Pulkki, R.; Xu, C. Global lignin supply overview and kraft lignin potential as an

alternative for petroleum-based polymers. Renew. Sustain. Energy Rev. 2020, 123. [CrossRef]

6. Zhu, J.; Yan, C.; Zhang, X.; Yang, C.; Jiang, M.; Zhang, X. A sustainable platform of lignin: From bioresources to materials and

their applications in rechargeable batteries and supercapacitors. Prog. Energy Combust. Sci. 2020, 76. [CrossRef]

7. Ago, M.; Tardy, B.L.; Wang, L.; Guo, J.; Khakalo, A.; Rojas, O.J. Supramolecular assemblies of lignin into nano- and microparticles.

MRS Bull. 2017, 42, 371–378. [CrossRef]

8. Anderson, E.M.; Stone, M.L.; Hülsey, M.J.; Beckham, G.T.; Román-Leshkov, Y. Kinetic Studies of Lignin Solvolysis and Reduction

by Reductive Catalytic Fractionation Decoupled in Flow-Through Reactors. ACS Sustain. Chem. Eng. 2018, 6, 7951–7959.

[CrossRef]

9. Wells, T., Jr.; Kosa, M.; Ragauskas, A.J. Polymerization of Kraft lignin via ultrasonication for high-molecular-weight applications.

Ultrason. Sonochem. 2013, 20, 1463–1469. [CrossRef]

10. Zhao, W.; Simmons, B.; Singh, S.; Ragauskas, A.; Cheng, G. From lignin association to nano-/micro-particle preparation:

Extracting higher value of lignin. Green Chem. 2016, 18, 5693–5700. [CrossRef]

11. Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and characterization of lignin from different

biomass resources. J. Mater. Res. Technol. 2015, 4, 26–32. [CrossRef]

12. Tian, D.; Chandra, R.P.; Lee, J.S.; Lu, C.; Saddler, J.N. A comparison of various lignin-extraction methods to enhance the

accessibility and ease of enzymatic hydrolysis of the cellulosic component of steam-pretreated poplar. Biotechnol. Biofuels 2017, 10,

157. [CrossRef]

13. Gillet, S.; Aguedo, M.; Petitjean, L.; Morais, A.R.C.; da Costa Lopes, A.M.; Łukasik, R.M.; Anastas, P.T. Lignin transformations for

high value applications: Towards targeted modifications using green chemistry. Green Chem. 2017, 19, 4200–4233. [CrossRef]

Nanomaterials 2021, 11, 1336 25 of 30

14. Yoo, C.G.; Meng, X.; Pu, Y.; Ragauskas, A.J. The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment

strategies: A comprehensive review. Bioresour. Technol. 2020, 301, 122784. [CrossRef]

15. Allegretti, C.; Fontanay, S.; Rischka, K.; Strini, A.; Troquet, J.; Turri, S.; Griffini, G.; D’Arrigo, P. Two-Step Fractionation of a

Model Technical Lignin by Combined Organic Solvent Extraction and Membrane Ultrafiltration. ACS Omega 2019, 4, 4615–4626.

[CrossRef]

16. Jääskeläinen, A.S.; Liitiä, T.; Mikkelson, A.; Tamminen, T. Aqueous organic solvent fractionation as means to improve lignin

homogeneity and purity. Ind. Crops Prod. 2017, 103, 51–58. [CrossRef]

17. Shen, X.-J.; Wen, J.-L.; Mei, Q.-Q.; Chen, X.; Sun, D.; Yuan, T.-Q.; Sun, R.-C. Facile fractionation of lignocelluloses by biomassderived

deep eutectic solvent (DES) pretreatment for cellulose enzymatic hydrolysis and lignin valorization. Green Chem. 2019,

21, 275–283. [CrossRef]

18. Dutta, S.; Theodore, M.; Garver, J.; Simo, S. Modes of association between kraft lignin components. ACS Symp. Ser. 1989, 397,

155–176. [CrossRef]

19. Magnus, N.; Håkan, E.; Lars, W. Aggregation of Lignin Derivatives under Alkaline Conditions. Kinetics and Aggregate Structure.

Langmuir 2002, 18, 2859–2865.

20. Lindström, T. The colloidal behaviour of kraft lignin. Part II. Coagulation of kraft lignin sols in the presence of simple and

complex metal ions. Colloid Polym. Sci. 1980, 258, 168–173. [CrossRef]

21. Liao, J.J.; Latif, N.H.A.; Trache, D.; Brosse, N.; Hussin, M.H. Current advancement on the isolation, characterization and

application of lignin. Int. J. Biol. Macromol. 2020, 162, 985–1024. [CrossRef] [PubMed]

22. Tribot, A.; Amer, G.; Abdou Alio, M.; de Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.-D.; Callois, J.-M.; Vial, C.; Michaud, P.; et al.

Wood-lignin: Supply, extraction processes and use as bio-based material. Eur. Polym. J. 2019, 112, 228–240. [CrossRef]

23. Vishtal, A.G.; Kraslawski, A. Challenges in industrial applications of technical lignins. BioResources 2011, 6, 3547–3568. [CrossRef]

24. Dong, H.; Zheng, L.; Yu, P.; Jiang, Q.; Wu, Y.; Huang, C.; Yin, B. Characterization and application of lignin–carbohydrate

complexes from lignocellulosic materials as antioxidants for scavenging in vitro and in vivo reactive oxygen species. ACS Sustain.

Chem. Eng. 2019, 8, 256–266. [CrossRef]

25. Pinem, M.P.; Wardhono, E.Y.; Nadaud, F.; Clausse, D.; Saleh, K.; Guenin, E. Nanofluid to Nanocomposite Film: Chitosan and

Cellulose-Based Edible Packaging. Nanomaterials 2020, 10, 660. [CrossRef] [PubMed]

26. Willner, I.;Willner, B. Biomolecule-based nanomaterials and nanostructures. Nano Lett. 2010, 10, 3805–3815. [CrossRef]

27. Ates, B.; Koytepe, S.; Ulu, A.; Gurses, C.; Thakur, V.K. Chemistry, Structures, and Advanced Applications of Nanocomposites

from Biorenewable Resources. Chem. Rev. 2020, 120, 9304–9362. [CrossRef]

28. Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial bio-nanocomposites and their potential applications in food packaging.

Food Control 2020, 112. [CrossRef]

29. Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent developments in polymers/

polymer nanocomposites for additive manufacturing. Prog. Mater. Sci. 2020, 111. [CrossRef]

30. Won Jang, H.; Zareidoost, A.; Moradi, M.; Abuchenari, A.; Bakhtiari, A.; Pouriamanesh, R.; Malekpouri, B.; Jafari Rad, A.;

Rahban, D. Photosensitive nanocomposites: Environmental and biological applications. J. Compos. Compd. 2020, 2, 50–60.

[CrossRef]

31. Ambekar, R.S.; Kandasubramanian, B. Advancements in nanofibers for wound dressing: A review. Eur. Polym. J. 2019, 117,

304–336. [CrossRef]

32. Palazzetti, R.; Zucchelli, A. Electrospun nanofibers as reinforcement for composite laminates materials—A review. Compos. Struct.

2017, 182, 711–727. [CrossRef]

33. Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290.

[CrossRef]

34. Richter, A.P.; Brown, J.S.; Bharti, B.;Wang, A.; Gangwal, S.; Houck, K.; Hubal, E.A.C.; Paunov, V.N.; Stoyanov, S.D.; Velev, O.D.

An environmentally benign antimicrobial nanoparticle based on a silver-infused lignin core. Nat. Nanotechnol. 2015, 10, 817–823.

[CrossRef]

35. Beisl, S.; Miltner, A.; Friedl, A. Lignin from Micro- to Nanosize: Production Methods. Int. J. Mol. Sci. 2017, 18, 1244. [CrossRef]

[PubMed]

36. Mishra, P.K.; Ekielski, A. The Self-Assembly of Lignin and Its Application in Nanoparticle Synthesis: A Short Review. Nanomaterials

2019, 9, 243. [CrossRef] [PubMed]

37. Henn, A.; Mattinen, M.L. Chemo-enzymatically prepared lignin nanoparticles for value-added applications. World J. Microbiol.

Biotechnol. 2019, 35, 125. [CrossRef] [PubMed]

38. Budnyak, T.M.; Slabon, A.; Sipponen, M.H. Lignin-Inorganic Interfaces: Chemistry and Applications from Adsorbents to Catalysts

and Energy Storage Materials. ChemSusChem 2020, 13, 4344–4355. [CrossRef]

39. Österberg, M.; Sipponen, M.H.; Mattos, B.D.; Rojas, O.J. Spherical lignin particles: A review on their sustainability and applications.

2. Synthesis Methods of Lignin Nanoparticles

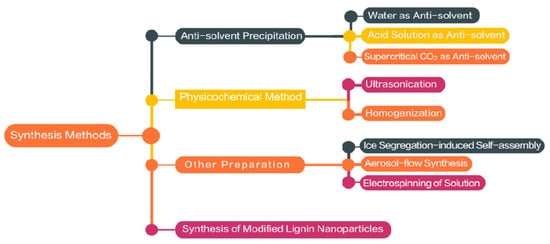

The physical and chemical properties such as non-toxicity, corrosion and UV-resistance, antibacterial and anti-oxidation activity of lignin are attracting more and more attention [3][33]. Therefore, the use of low-cost and abundant lignin raw materials to prepare nanoparticles is an important aspect of expanding their high value-added utilization [38]. At the same time, finding simple, scientific and safe methods for preparing lignin nanoparticles is of great significance. The current preparation methods of nano-lignin mainly include anti-solvent precipitation, self-assembly, gradual addition and mechanical methods, etc [1][7][10]. Some emerging methods, such as ice segregation-induced self-assembly, aerosol-flow synthesis and electrospinning, are also being developed [35][39][40][41][42]. Figure 3 gives an overview of the synthesis and modification methods of nano-lignin. Lignin nanoparticles with different morphologies and sizes, which can be prepared through these different methods and conditions, will be of great value for their subsequent applications in different fields [43].

Figure 3. Overview of the synthesis and modification methods of nano-lignin.

Green Chem. 2020, 22, 2712–2733. [CrossRef]

3. The Value-Added Applications of Lignin Nanomaterials

40. Duval, A.; Lawoko, M. A review on lignin-based polymeric, micro- and nano-structured materials. React. Funct. Polym. 2014, 85,

In the process of exploring nanolignin materials, it was found that sometimes the ordinary nanolignin cannot satisfy the diverse requirements in different application fields. In addition to the basic thermal and mechanical properties of nanomaterials, some diverse nanostructures and specific performance such as metal adsorption are widely required [44][45]. Therefore, the ordinary nanolignin can be used to directly modify or compound with other nanomaterials, which can take advantage of nanolignin structure and further improve the performance of nanocomposite materials [46]. 78–96. [CrossRef]

Lignin nanoparticles have attracted more and more attention because of their green, renewable and abundant source, antioxidant, antibacterial or ultraviolet absorption properties, biodegradability, biocompatibility, etc [47]. They are excellent substitutes for partially harmful nanomaterials, which are extensively used in the fields of drug release and control [48], food packaging, biomedicine, adsorbent materials, nanocarriers, environmental restoration and so on [49][50][51][52]. This not only solves the potential safety hazards of traditional nanomaterials from the source, but also broadens the value-added applications of lignin nanomaterials, which conforms to the principles of green chemistry development [53]. 41. Stewart, D. Lignin as a base material for materials applications: Chemistry, application and economics. Ind. Crops Prod. 2008, 27,

4. Conclusions and Future Perspectives

Overall, this review summarizes the current status of the preparation of nano-lignin by sedimentation, mechanical, self-assembly and stepwise addition polymerization methods. In order to provide a reference for the chemical deep processing of biomass resources and the development of nano-lignin, the application characteristics of nano-lignin in UV protection and anti-bacteria, nano-fillers and biomass-based carriers are also outlined. Through the specific analysis of the preparation methods and application status of nano-lignin, it can promote the further research of nano-lignin and the development of novel nano-lignin-based products. This is of great significance to the utilization and sustainable development of lignin.

The multiple structures and the diverse properties of lignin make the prepared nano-lignin more complicated, which brings challenges to the research of the preparation and performance of nano-lignin. Meanwhile, it provides broader prospects and opportunities for the multi-functional and multi-field applications of nano-lignin. Nanometersized lignin with high specific surface area and activity is a novel approach to achieve high value-added utilization of lignin. Compared with the research of inorganic nanoparticles and renewable nanocellulose, the preparation and application of nano-lignin are still in their infancy. The scale and industrialization of nano-lignin-based products will become an important aspect of future lignin research.

In view of the problems of complex process and toxic organic solvents in the preparation of lignin nanoparticles, methods such as electrostatic spinning, self-assembly, ultrasonication and homogenization can be utilized. In terms of multi-functional applications of lignin-based nanomaterials, the range of use can be expanded by improving their strength, electrical conductivity, thermal stability, crystallization performance, etc.

The following points need attention in the application of nanolignin materials. First of all, achieving uniform dispersions of nanolignin in composite materials is a difficult problem to solve. Lignin nanoparticles are extremely prone to agglomeration because of the high surface energy and the large number of hydrogen bonds and Van der Waals forces between the molecules. Therefore, completely solving the problem of particle agglomeration and achieving the monodispersion of nano-lignin are the key to fully exerting the nano-effect. Furthermore, the diversified morphology and size of lignin nanoparticles are prerequisites for high value-added and multi-field applications of lignin. To solve the interface and dispersion problems of nano-lignin materials, it is essential to find chemical methods to modify nano-lignin and also supplement with effective physical dispersion methods, such as mechanical stirring, ultrasonication and high shear homogenization. In addition, the amount of nano-lignin added, the type of treatment agent and dispersing equipment are all key factors that affect agglomeration, which need to be controlled and improved during the preparation of lignin-based nanomaterials.

The structural and functional properties of lignin determine its extremely promising applications in the field of biochemicals. Lignin and its derivatives have a wide range of functionalities and can be used as dispersants, adsorbents/desorbents, oil recovery aids, asphalt emulsifiers, etc. They can also be converted into aromatics, agrochemicals, polymers and high-performance materials. However, all these processes depend on improvements and innovations in the field of catalysis and product separation. Most importantly, to realize the full industrial potential of lignin, further refinement of biopulp technology is needed to achieve efficient separation of lignin and cellulose. It can be said that the contribution of lignin to sustainable human development lies in its ability to provide a stable and continuous source of organic matter. Thus it can truly guarantee sustainable green development and energy supply.

In addition, the antioxidant and anti-UV effects of lignin are its most prominent properties, so the application of lignin-based composites in food packaging and other fields has been increasingly developed. The lignin-based nanocomposites are also excellent carriers for a variety of metal ions and drug loading due to their unique nano-effects. They can be used as bio-nanocomposite catalysts and reducing agents for heavy metal ions, which are of great importance for environmental protection and wastewater treatment. Furthermore, the biocompatibility and non-toxicity of lignin are being intensively investigated.

Numerous scientific findings indicate that lignin-based nanocomposites have a very promising future in the biomedical field. Specific lignins have significant anti-lipid peroxidation and oxygen radical scavenging effects. Significant inhibitory effects of lignin on the central nervous system or on cancer cell proliferation can also be observed. Most importantly, lignin nanoparticles can be used as biological carriers for drug delivery and targeted drug release. The molecular expression, biocompatibility and cytotoxicity of lignin-based nanocomposites in cell lines have also been intensively studied. Conclusively, the development of novel biomass materials and products will be applied to the medical field and have a positive and effective impact on human life and health.

202–207. [CrossRef]