E-textiles, hybrid products that incorporate electronic functionality into textiles, often need to withstand washing procedures to ensure textile typical usability. Yet, the washability—which is essential for many e-textile applications like medical or sports due to hygiene requirements—is often still insufficient. The influence factors for washing damage in textile integrated electronics as well as common weak points are not extensively researched, which makes a targeted approach to improve washability in e-textiles difficult.

1. Introduction and Context

If conceived to be worn on or near the body—and even for some non-wearable applications—hybrid electronic textiles (e-textiles), products that incorporate electronic or electrically conductive functionality into textiles, need to be clean- and washable

[1]. Only e-textiles that exhibit a textile typical usability (which includes washability) will be accepted by users and, thus, lead to commercially successful products

[2]. Although many experts agree that a lacking washability is one of the major hurdles that e-textiles need to overcome, there is still only limited research into the topic. While numerous publications on e-textiles do feature wash testing, washability is rarely the main issue, but rather one of a range of reliability tests run to evaluate the developed e-textiles. A difficulty in comparably assessing the washing results that are presented in these publications arises from the very different wash testing methods

[3]. While some wash according to, or at least loosely follow, different existing textile washing standards, others use a variety of household washing procedures or even alternative washing methods, like placing the samples in a beaker with water. Not only do the washing methods differ greatly, but also the number of cycles run to assess washability (between one and more than 50 cycles) as well as the use and type of detergent, the washing temperatures, and the subsequent drying of the samples

[3].

To improve the washability of e-textile systems, insight is needed into the typical damages brought about by washing and weak points in the e-textile that will fail first if subjected to washing procedures. This knowledge will allow researchers and developers a targeted approach towards e-textiles with improved washing reliability. Existing research into those topics is rarely done systematically, as washability is not the main focus in most e-textile related publications, as mentioned above. This review tries to alleviate this lack of insight, by bundling findings on common failure modes. The presented overview can be used as a basis for improved e-textile designs with enhanced washability. Detailed information regarding the employed washing methods for most of the cited sources can be found in a previous review of wash testing practices for e-textiles

[3]. An extensive research into relevant scientific publications was used as a basis. Similar information on commercially available e-textiles is rarely published; thus, the review is limited to academic research.

2. Effects of Washing on E-Textiles

During any washing process, the cleanable items are subjected to the four washing factors time, temperature, mechanical action, and chemistry/biology, also known as Sinners factors

[4][5][7,8]. The magnitude of these interdependent factors determines the outcome of a washing procedure, both the desired effects—cleanliness and hygiene—as well as the unwanted, so-called secondary washing effects (e.g., damages, ageing, or changes in shape or color)

[1]. Because of the influence of the four factors in combination with the washing water, an e-textile might exhibit any or all of the following secondary washing effects:

-

changes in electrical properties: the loss of conductivity or increase in resistance, altered capacitance

[1][6]9[7][8][9][10][11][12][13][14][15][16][17][18][19][20][21][22][23][24][25][26][][41][42][43][44][45][46][47][48][49][50],10[,1151,1227][28][][,132952][1,,14,15][,1630,17],18[31][32][,1933][34][35][36][37,20],21[,22,23,24,25,26,27,28,29,30,31,3238],33[39],34[,35,36,37,38,39,4040,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55]

-

changes in function: (partial) loss of function of one or more components (LEDs, …) or the whole e-textile system

[13][19][37][46][53][54][55][56][57][58][59][16,22,40,49,56,57,58,59,60,61,62]

-

changes in characteristics: e.g., changes in sensor ranges, antenna spectra, decreased read ranges, …

[7][8][16][27][35][37][49][50][60][61][62][63][64][65][66][67][68][69][10,11,19,30,38,40,52,53,63,64,65,66,67,68,69,70,71,72]

-

changes in integrity: e.g., delamination, loosening of wires, loss of components …

[1][10][17][29][36][39]][1,13[,2046],32[55],39[,4258,49,58,61]

-

changes in appearance: e.g., darkening, changes of the textile surface (pilling, fuzzing), wrinkling, shrinkage …

[12][16][19][27][39][50][55][66][69][15,19,22,30,42,53,58,69,72]

The extent of one or more of these changes after a certain number of washing cycles is used as an indicator of washability for e-textiles. The parameter(s) chosen often correlate with the complexity or the composition of the tested system. Most often—especially when testing only conductive textiles—a change in resistance is the parameter of choice to assess washability. Researchers washing antennas or sensors frequently evaluate changes in characteristics and, if added components are present (like LEDs) or fully functional systems are tested, then the estimation of washing reliability is often tied to a change in function

[3]. Because maintaining conductivity and/or functionality (within tolerances) is more of an issue when washing e-textiles than the textile integrity, changes in appearance and other textile changes are less often employed to assess the washability of e-textiles

[3]. Although, in some cases, a change in appearance and changes in resistance go hand-in-hand, as in research by Gaubert et al.: the amount of bleaching agents in the detergents used does not only influence the extent of darkening in the examined metallized textiles, but also reduces their conductivity accordingly

[16][19].

3. Washing Related E-Textile Failure Modes

When textile integrated electrically conductive or electronic components are subjected to (repeated) washing, damages can occur, which impairs the e-textile’s function, appearance, or characteristics. Because e-textiles are a very diverse group of products—not all of which can be found in a literary source featuring wash testing—the following listing is not exhaustive. Likewise, as new e-textiles are developed, previously non-existent failure modes might occur.

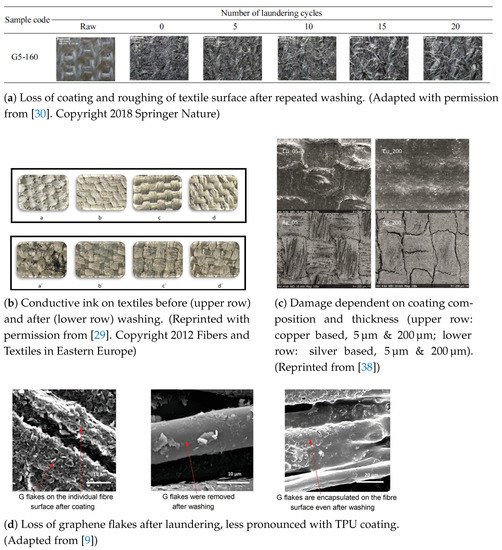

3.1. Damages to Conductive Coatings and Printed Conductive Structures

Zeagler et al. find that their silver-based printed conductive tracks exhibit cracks after six washing cycles, which results in increased resistance. They reason that the swelling of the hydrophilic cotton substrate, as well as bending occurring during washing, are responsible. In some samples, the printed ink is not only cracked, but also flaking off

[52][55]. Kim et al. wash aramid textiles coated with a graphene and polyurethane (PU) composite. After repeated washing, the graphene is (partially) lost and the fibers of the underlying textile substrate loosened and entangled (see a). The collision of the samples with other materials during the washing process is suspected to be the reason

[27][30]. When testing the washing reliability of differently formulated, metal based conductive coatings, Malm et al. observe a loss of and cracks in coating, with the severity of damages—and subsequent increase in resistance—being strongly dependent on the formulation and thickness of the coating (see c)

[35][38]. In woven fabric that is coated with graphene based ink, Afroj et al. observe a loss of graphene flakes after washing, which results in an increase in resistance (see d)

[6][9]. Shahariar et al. report crack formation of varying severity in their printed-on silver-based paste, as well as a delamination of the paste from the substrates

[42][45]. Other sources also suspect the loss of conductive coating or ink as the reason for increased resistance after washing

[7][45][10,48]. In a larger study with two types of silver-based conductive ink printed onto 14 different woven textiles, Kazani et al. observe a lost ink and resulting increased resistance for all samples, with differing severity dependent on the material combinations (see b)

[26][29]. Screen printed antennas in another publication by Kazani et al. also exhibit cracks after washing

[64][67].

Figure 1. Examples of damages to conductive textile coatings after washing.

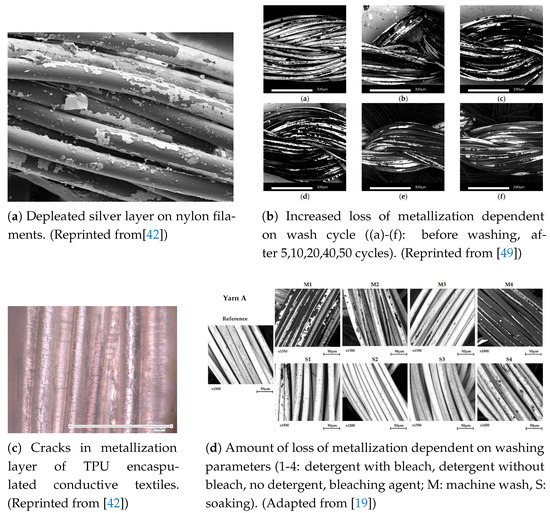

3.2. Damages to Metallization Layers

Failures that are similar to those described in the previous section occur when washing metallized yarns and textiles. Cai et al. measure the silver content of the washing water of their metallized textile and observe an increase after several cycles, indicating a gradual loss of the silver coating

[61][64]. Dhanawansha et al. also observe lost silver, but find that, with an increasing number of washing cycles, the amount of silver lost decreases, which suggests that silver loss is greatest during the first few washing cycles

[62][65]. In one publication, the loss of metallization is suspected to be the reason for increased resistance after washing, but not further investigated

[50][53]. Rotzler observes a loss of the metallization layer for knitted silver coated nylon fabric, which is dependent on the employed washing program (see a)

[39][42]. Similar observations are made by Gerhold

[17][20] and Foerster, who supposes the friction between the test samples and other textiles during washing is responsible for the loss of metallization

[15][18]. Other studies with similar damages to metallized yarns include Tao et al. and Gaubert et al. They observe that the amount of lost metallization increases with the number of washing cycles (see b)

[46][49], and it is dependent on the washing parameters (see d)

[16][19]. Lee et al. find the amount of metal lost, and related increase in resistance, is dependent on the combination of involved materials

[31][34]. uz Zaman et al. presume that mechanical wear is responsible for peeled off and abraded metal layers in metallized nylon fabric

[47][48][49][50,51,52]. When washing gold and copper coated yarns, Schwarz observes cracks in and a loss of metallization, also suspecting mechanical forces as the main cause

[40][43]. Depending on the washing conditions, cracks in the metallization can even occur when the conductive textile is covered by a protective layer of thermoplastic polyurethane (TPU) (see c), as a study by Rotzler et al. shows. The authors reason that, due to the conductive textile being covered by a protective layer, mechanical wear and abrasion are not the main cause of damages. Cyclic temperature changes during washing are more damaging to the silver layer, due to a mismatch of the thermal expansion coefficient in the involved materials

[1].

Figure 2. Examples of loss of metallization after washing.

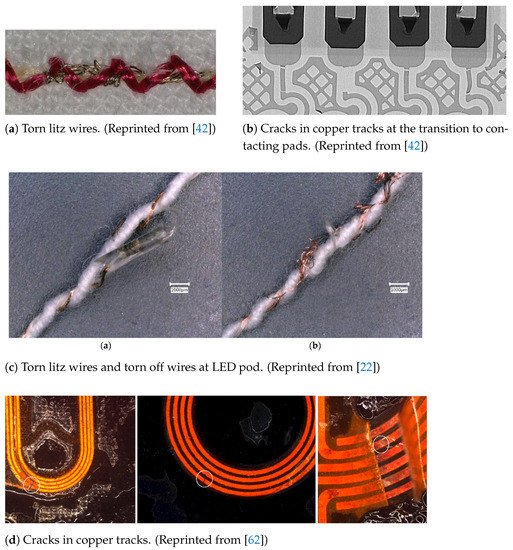

3.3. Damages to Wires, Conductive Tracks and Connections

When washing strips of flexible circuit board woven into textiles, Komolafe et al. observe cracks in the copper tracks, located only at the transition zone between tracks and bond pads, identifying these zones as weak points of the circuit

[54][57]. Hardy et al. wash different e-yarns of similar composition—wires that are wrapped around a textile core, with and without added functional components. They see wire breakages along the whole length of yarns, as well as broken and torn off wires at the added components, see c

[19][22]. Rotzler et al. conduct a washability study with different types of conductive tracks. In tracks made from meander shaped copper foil embedded in thermoplastic polymer (so-called stretchable circuit boards, SCB), they observe breakages in the copper mostly at the transition from conductive tracks to contacting pads, see b, as well as near the added dummy interposer. Torn litz wires occur in conductive yarn, embroidered onto the textile substrates using the tailored fibre placement (TFP) technique, see a. Similar to the results for the SCB tracks, the torn wires occur at a larger number at the contacting points and the interposer, and to a lesser extent along the length of the tracks

[1]. SCB tracks that were washed by Veske et al. also exhibit breakages in the tracks, located exclusively at the top and bottom of the meander shapes of the tracks, see d

[59][62]. Tao et al. register an increase in broken litz wires corresponding to the number of wash cycles. Another failure mode occurring are broken contacts between the embroidered and interwoven tracks and added LEDs

[46][49].

Figure 3. Examples of damages to wire- and foil based conductive tracks after washing.

When washing PU coated copper wires that were knitted into textiles, Li et al. observe breakages of the wires, leading to an increase in the resistance or complete electrical failure. The authors suspect the mechanical strain during washing and resulting deformation of the wires to be responsible

[32][35]. Molla et al. find that their embroidered tracks exhibit breakages of the metallized yarn—but the number of breakages is very low when compared to the number of samples with a decreased conductivity, indicating that not only yarn breakages occur, but also a loss of silver coating

[36][39].

Wires embroidered onto a knitted textile using the TFP technique show breakages only at the soldered interconnections to a flexible circuit board in research by Vervust et al. Added LEDs on the board still show function, indicating the board itself and its functional components did survive the washing, only the solder connections are not stable enough

[58][61]. Similar observations are made by Gui et al., their liquid metal tracks are still fully intact after washing, with the only defects presenting at the contacting points between the tracks and added components

[53][56]. Others also report damaged interconnections between tracks and components, circuit boards, or connectors

[1][19][29][36][57][1,22,32,39,60]. In polydimethylsiloxane (PDMS) encapsulated, textile integrated circuits, Ojuroye et al. detect wires that were torn from, as well as chips pulled from, solder joints after repeated washing, being attributed to abrasion, bending, and twisting affecting the samples during the cycles, see d

[55][58].

Figure 4. Examples of damages to protective layers due to washing.

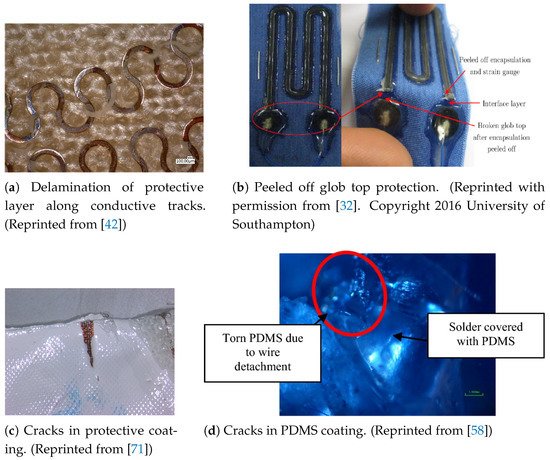

3.4. Damages to Protective Layers

Not only can the conductive materials and components of e-textiles get damaged during washing, but also protective layers or elements. Once these protective structures are corrupted, the underlying conductive or electronic components are more vulnerable to damages themselves

[36][39]. Berglund et al. observe the delamination of the protective PU film in their stitched stretch sensors, with the magnitude of delamination corresponding with an increase in resistance

[10][13]. When washing SCB type conductive tracks, delamination of the protective PU layer occurs along the copper foil tracks in the research conducted by Rotzler. The extent of the damages coincides with the harshness of the washing program, which indicates that frictional forces acting on the samples will lead to thinning and eventual breaks of the PU layer along the edges of the copper tracks (see a)

[39][42]. Textile-based radio-frequency identification (RFID) tags in a publication by Wang et al. exhibit a steady decrease in read range when subjected to washing cycles. Cracks in the protective coating of the tags, see c, which results from mechanical stresses during washing, are suspected to be among the reasons for this reduced functionality

[68][71]. Tao et al. also report the delamination of a TPU layer after washing, leading to an ingress of water and, thus, possibly responsible for increased resistance

[46][49]. When testing different protective films and tapes on embroidered tracks, Molla et al. observe delamination for some of the materials. The exposed tracks and components experience greater damage than intact samples

[36][39]. Komolafe reports peeled-off glob-top and encapsulation layers after washing (see b). Another failure mode that is connected to the protective layer occurring in the same publication is the encapsulation peeling off the underlying printed silver layer from an embedded component. The author suggests this is due to a stiffness difference, which makes the contact vulnerable to bending

[29][32]. The textile integrated touch sensors by Ojuroye et al. exhibit an increasingly limited functionality after each washing cycle. A microscopic analysis reveals cracks in the PDMS encapsulation (see d), which enables water to damage the encapsulated components

[55][58]. Even reversible effects on the protective layers can impact washability. Parkova et al. argue that their silicone coating will stretch during washing, which leads to damages and function loss of embedded LEDs

[37][40], while Gerhold observes the swelling of the PU layer on conductive textiles and suspects that this could lead to decreased conductivity

[17][20].

3.5. Textile Changes

When looking at e-textile washability in its entirety, maintaining not only electronic, but also textile, integrity should be considered, even though being less relevant for the continued functionality of the e-textile system. Several sources report changes and damages to the textile substrate. Ojuroje et al. observe wrinkling in their test samples

[55][58], Rotzler pilling

[39][42]—with varying severity depending on washing program and substrate, Quandt et al. entangling of fibers

[66][69], and Martinez-Estrada et al. the loss of fabric pre-treatment after washing

[65][68]. Du et al., Kim et al. (see a) and Zhao et al. notice an increase in yarn or textile surface roughing

[12][27][69][15,30,72]. Xu et al. observe a shrinkage in the wale direction of a knitted metallized textile, which results in a decrease in resistance after one wash cycle

[50][53]. Zhao et al. wash conductive yarn up to 20 times, with shrinkage occurring only during the first two cycles

[69][72], similar findings are made by Hardy et al.

[19][22].

3.6. Other Failures

Tao et al. report corrosion on some of their washed conductive yarns, as well as an oxidized battery in an ECG-device

[46][49]. The metallized textiles washed by Gaubert et al. show a darkening of the surface, indicating the oxidation of the silver coating

[16][19]. Rotzler sees a loss of interposers and Ojuroye et al. detached chips

[39][55][42,58]. Gerhold stops wash testing at the first incidence of detached LED modules from textile based conductive tracks

[17][20].

3.7. Summary of Failure Modes

Washing can lead to numerous issues in e-textiles, as this overview of failure modes shows. These failures can occur at specific points in the design or allover, depending on the type and composition of the e-textile. Weak points are contacts between different materials and components—especially if there is a high stiffness gradient—as well as transition areas within the same material (e.g., from conductor track to contact pad). In conductive yarn or textiles without some form of protection, damages can occur throughout the structure. Because added components in the researched publications are mostly encapsulated or otherwise protected, they fail less often than the conductive tracks connecting them or the contacts between tracks and components. For the same reasons, lost or detached components do not occur often. If the protective elements are themselves damaged during washing, though, the components are also vulnerable to damages, e.g., through water ingress. On the other hand, many of the cited sources do not include added components at all, which makes the findings of this paper concerning components less reliable.

4. Conclusion

This article provides an extensive overview of common damage types in e-textiles as a result of (repeated) washing. Although not without limitations, the findings provide much needed insight into how washing affects e-textiles. In doing so, this article can serve as a basis to tackle the pressing matter of washability from different angles and, thereby, create more reliable e-textiles. While some of the findings are applicable to most e-textiles, others are only valid for a specific type of textile-integrated electronics. For a future in-depth approach towards reliably washable e-textiles, a more differentiated examination will thus be necessary, discerning conductor and substrate materials and their requirements as well as the specific e-textile application more thoroughly than this relatively general overview. To achieve this, it will not be sufficient to access, in some cases, the very limited existing sources—as was done in this review. Instead specific, targeted research into single aspects of e-textile washability needs to be conducted.