Limiting the increase in CO2 concentrations in the atmosphere, and at the same time, meeting the increased energy demand can be achieved by applying carbon capture, utilization and storage (CCUS) technologies, which hold potential as the bridge for energy and emission-intensive industries to decarbonization goals. At the moment, the only profitable industrial large-scale carbon sequestration projects are large-scale carbon dioxide enhanced oil recovery (CO2-EOR) projects. This paper gives a general overview of the indirect and direct use of captured CO2 in CCUS with a special focus on worldwide large-scale CO2-EOR projects. On the basis of scientific papers and technical reports, data from 23 contemporary large-scale CO2-EOR projects in different project stages were aggregated, pointing out all the specificities of the projects. The specificities of individual projects, along with the lack of standardized methodologies specific for estimating the full lifecycle emissions resulting from CO2-EOR projects, pose a challenge and contribute to uncertainties and wide flexibilities when estimating emissions from CO2-EOR projects, making the cross-referencing of CO2-EOR projects and its comparison to other climate-mitigation strategies rather difficult. Pointing out the mentioned project’s differentiations and aggregating data on the basis of an overview of large-scale CO2-EOR projects gives useful information for future work on the topic of a CO2-EOR project’s lifecycle emissions.

1. Introduction

The Paris Agreement came into force in 2016 with the intention of mitigating global warming by keeping the global average temperature increase under 2 °C, and preferably even under 1.5 °C, when compared to pre-industrial levels. The only way to do this is through full harmonization with the energy and climate targets, which are comprised of a significant reduction of greenhouse gas emissions by 2030 (by 45%), as well as total decarbonization by 2050, based on the application of energy efficiency, renewable energy use and carbon capture and storage (CCS), or carbon capture, utilization and storage (CCUS). CCS technology implies avoiding CO

2 emissions to the atmosphere by capturing and storing it in geological formations characterized with long-term containment capability [1][2]. As per the strategies submitted to the United Nations Framework Convention on Climate Change (UNFCCC), CCUS is often recognized as a favorable option to fight climate change due to the turning of unwanted greenhouse gas into valuable products [3]. In order to be reused for various purposes (used for yield boosting or for the production of fuels, chemicals, building materials, etc.) CO

emissions to the atmosphere by capturing and storing it in geological formations characterized with long-term containment capability [1,2]. As per the strategies submitted to the United Nations Framework Convention on Climate Change (UNFCCC), CCUS is often recognized as a favorable option to fight climate change due to the turning of unwanted greenhouse gas into valuable products [3]. In order to be reused for various purposes (used for yield boosting or for the production of fuels, chemicals, building materials, etc.) CO 2

is captured from different sources, such as fossil fuel-based power plants, ammonia production plants, biomass fermentation facilities, natural gas processing plants, or it can be captured (removed) directly from the air. The commercial-industrial source of CO

2

should be at least 0.01 to 0.5 Mt CO

2/year [3][4].

At the moment, even though energy efficiency, use of renewable energy sources and fuel switching are often required as the exclusive priority in achieving climate goals, the world’s high dependency on fossil fuel is still very much present. Therefore, the fossil fuel production industry (oil, gas and coal industry) has been undertaking different carbon-reduction initiatives in order to retain market competitiveness by providing a constant energy supply with an ecological footprint that is as low as possible [5][6].

At the moment, even though energy efficiency, use of renewable energy sources and fuel switching are often required as the exclusive priority in achieving climate goals, the world’s high dependency on fossil fuel is still very much present. Therefore, the fossil fuel production industry (oil, gas and coal industry) has been undertaking different carbon-reduction initiatives in order to retain market competitiveness by providing a constant energy supply with an ecological footprint that is as low as possible [5,6].

Significant experience and existing infrastructure for underground fluid injection represent an essential basis for the development of CO

2

underground deposition technology. Additional oil production by CO

2

injection and CO

2 permanent storage within depleted oil and gas reservoirs or suitable geological formations seem to be sustainable options, which provide multiple benefits [7][8].

permanent storage within depleted oil and gas reservoirs or suitable geological formations seem to be sustainable options, which provide multiple benefits [7,8].

Keeping in mind that CO

2

usage for different products should not necessarily result in overall emission reduction, the benefits of each utilization/storage project must be evaluated by performing a comprehensive lifecycle analysis. This requires clear methodological guidelines that are temporarily under development by several expert groups. Furthermore, the retention time for CO

2

differs significantly, being in the range from one year, in the case of fuel generation, up to millions of years, in the case of carbonation [3]. Carbonation refers to a natural reaction of metal oxides, i.e., calcium (Ca) or magnesium (Mg) containing minerals (e.g., serpentine, olivine, wollastonite) with CO 2

, which results in the production of calcium or magnesium carbonates (CaCO

3

or MgCO

3

). Such processes can be considered as a CO

2

utilization or storage option. While the utilization refers to the recently developed, accelerated ex situ carbonation, able to produce valuable construction materials, a storage option refers to the last of the trapping mechanisms occurring within a geological formation (underground storage), which enables the permanent retention of CO

2

. Since the use of pure CO

2 is not essential for mineralization (impurities simply do not interfere with the reaction), a purification step can be avoided, which results in lower costs [9][10].

is not essential for mineralization (impurities simply do not interfere with the reaction), a purification step can be avoided, which results in lower costs [9,10].

Although, as stated before, emission-reduction results differentiate from project to-project, it is obvious that the best results, in terms of both sequestrated CO

2

quantities and sequestration permanency, can be achieved by just performing CCS projects. Other CCUS options, in fact, delay emissions to a greater or lesser extent, but due to economical profitability (they produce valuable products), today, at a time of a relatively low CO

2

market price, such projects are more preferable. However, due to residual oil production, currently, the only form of large-scale industrial carbon sequestration profitable projects are CO

2

-EOR projects. Although fossil fuel combustion and waste gas generated during CO

2

-EOR operations at an EOR site result in new emissions, substantial quantities of CO

2

remain permanently stored within the depleted reservoirs. Since there are some disagreements over CO

2

-EOR emission assessment, a lack of standardized methods for measuring the full lifecycle emissions resulting from CO

2

-EOR projects (needed for crediting EOR’s carbon reductions) hinders CO

2

-EOR application as CCUS technology.

In this paper, captured CO

2

utilization, an overview of the worldwide CO

2

-EOR projects and an analysis of CO

2

-EOR lifecycle emissions are presented.

2. Discussion

Climate issues related to increasing concentrations of CO2

, mainly released during fossil fuel combustion during power production, put strong initiatives to limit the use of fossil fuels and to increase the employment of alternative power production solutions like renewable energy sources. On the other hand, due to variability in the availability of renewable energy sources, the cost of energy production from it, along with energy storage issues and the constantly increasing global energy demand, especially in developing countries, the world still strongly depends on fossil fuels, and the transition to a carbon-free society will take place over several decades. A possible solution for the transition is seen in CCS and CCUS technologies, which allow the use of fossil fuels while eliminating the adverse climate change impacts associated with greenhouse gas emissions. Both technologies eliminate a facility’s direct CO2

emissions. Although the primary goal of CCS and CCUS technologies is CO2

sequestration, both technologies result in a certain amount of emissions. Even though CCUS, along with CO2

sequestration, creates additional benefits (production of new products), sometimes, depending on the type of project, it is a less favorable solution compared to CCS (in cases when CO2

retention time is relatively short).

CCS comprises various technical and technological solutions depending on the size and type of CO2

source, capture technology, transportation mean, and the final storage destination (distance from the CO2

source, depth and characteristics of the geological formation, etc.). Currently, the only type of large-scale CCUS projects are CO2

-EOR projects (see ,

, and

and ), which, along with CO

), which, along with CO2 sequestration, also result in residual oil production. According to the KAPSARC database [11], in 2018, 11 of 23 large-scale CO

sequestration, also result in residual oil production. According to the KAPSARC database [42], in 2018, 11 of 23 large-scale CO2

-EOR projects were in operation (48%) (see ), grouped, by related industries where applied, into natural gas processing (6 projects, or 55%), fertilizer production (2 projects, or 18%), power generation (1 project, or 9%), synthetic natural gas (1 project, or 9%), and hydrogen production (1 project, or 9%). The rest of the projects were in the execution stage (5 projects, or 22%), definition stage (5 projects, or 22%) or evaluation stage (2 projects, or 9%). With regard to the large-scale CO

), grouped, by related industries where applied, into natural gas processing (6 projects, or 55%), fertilizer production (2 projects, or 18%), power generation (1 project, or 9%), synthetic natural gas (1 project, or 9%), and hydrogen production (1 project, or 9%). The rest of the projects were in the execution stage (5 projects, or 22%), definition stage (5 projects, or 22%) or evaluation stage (2 projects, or 9%). With regard to the large-scale CO2

-EOR projects in the execution phases, there is a visible shift towards smaller capacity projects and other industry applications, such as iron and steel production, fertilizer production and oil refining ().

).

Table 1. CO

Regarding the capture capacity of these projects, projects related to natural gas processing (52%) have the largest share of capture capacity. This is expected since, as mentioned before, most of the large-scale CO2-EOR projects, status overview 2018. Modified according to [14].

| Project Name |

CO2

Capture

Capacity (Mt/y) |

Stage |

Location |

Industry |

| 1. |

Petrobras Lula Oil Field CCS Project |

0.7 |

Operate |

Brazil |

Natural gas processing |

| 2. |

Alberta Carbon Trunk Line (“ACTL”) with Agrium CO2 Stream |

0.6 |

Execute |

Canada |

Fertilizer production |

| 3. |

Alberta Carbon Trunk Line (“ACTL”) with North West Sturgeon Refinery CO2 Stream |

1.4 |

Execute |

Oil refining |

| 4. |

Boundary Dam Carbon Capture and Storage Project |

1 |

Operate |

Power generation |

| 5. |

Great Plains Synfuel Plant and Weyburn-Midale Project |

3 |

Operate |

Synthetic natural gas |

| 6. |

PetroChina Jilin Oil Field EOR Project (Phase 2) |

0.5 |

Define |

China |

Natural gas processing |

| 7. |

Sinopec Qilu Petrochemical CCS Project |

0.5 |

Define |

Chemical production |

| 8. |

Yanchang Integrated Carbon Capture and Storage Demonstration Project |

0.4 |

Define |

| 9. |

Sinopec Shengli Power Plant CCS Project |

1 |

Define |

Power generation |

| 10. |

Huaneng GreenGen IGCC Project (Phase 3) |

2 |

Evaluate |

| 11. |

Uthmaniyah CO2-EOR Demonstration Project |

0.8 |

Operate |

Saudi Arabia |

Natural gas processing |

| 12. |

Abu Dhabi CCS Project (Phase 1 being Emirates Steel Industries (ESI) CCS Project) |

0.8 |

Execute |

United Arab Emirates |

iron and steel production |

| 13. |

Texas Clean Energy Project |

2.4 |

Define |

United States |

Power generation |

| 14. |

Kemper County Energy Facility |

3 |

Execute |

| 15. |

Petra Nova Carbon Capture Project |

1.4 |

Execute |

| 16. |

Air Products Steam Methane Reformer EOR Project |

1 |

Operate |

Hydrogen production |

| 17. |

Coffeyville Gasification Plant |

1 |

Operate |

Fertilizer production |

| 18. |

Enid Fertilizer CO2-EOR Project |

0.7 |

Operate |

| 19. |

Lost Cabin Gas Plant |

0.9 |

Operate |

Natural gas processing |

| 20. |

Shute Creek Gas Processing Facility |

7 |

Operate |

| 21. |

Val Verde Natural Gas Plants |

1.3 |

Operate |

| 22. |

Riley Ridge Gas Plant |

2.5 |

Evaluate |

| 23. |

Century Plant |

8.4 |

Operate |

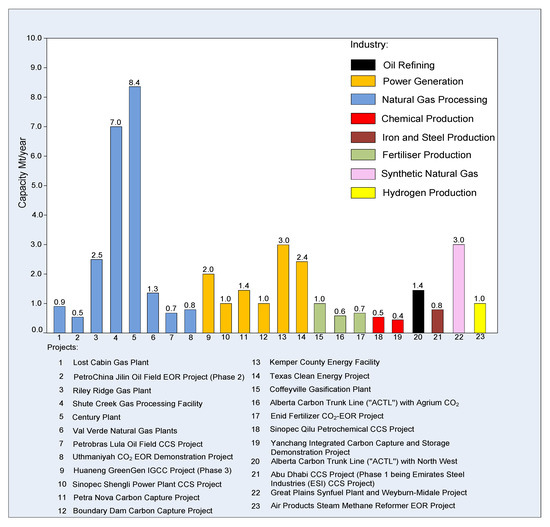

Figure 1. Large CO

-EOR projects are related to natural gas processing, which is not surprising since CO2-EOR projects in different project stages by applied industries (according to [14]).

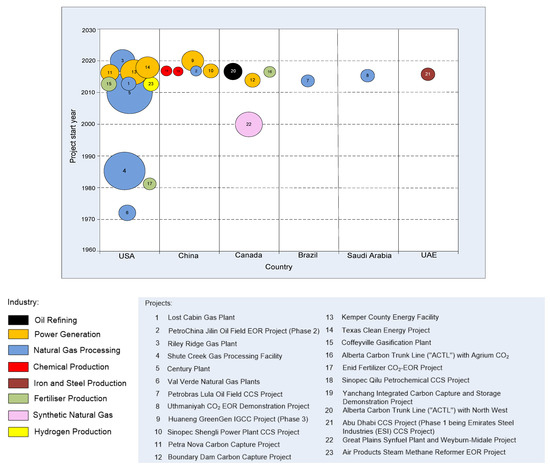

Figure 2. Development timeline of the EOR projects by capacity and country (according to [14]). and are complementary to each other. The circles differ by colors (industry type), sizes (capture capacity) and numbers (ordinal number of the project).

Regarding the capture capacity of these projects, projects related to natural gas processing (52%) have the largest share of capture capacity. This is expected since, as mentioned before, most of the large-scale CO

injection technology was developed by the petroleum industry. The capture capacity of large-scale CO2-EOR projects are related to natural gas processing, which is not surprising since CO2 injection technology was developed by the petroleum industry. The capture capacity of large-scale CO2-EOR projects related to power production is 26%, fertilizer production 5%, synthetic natural gas 7%, oil refining 3%, iron and steel production 2% and hydrogen production 2%.

-EOR projects related to power production is 26%, fertilizer production 5%, synthetic natural gas 7%, oil refining 3%, iron and steel production 2% and hydrogen production 2%.

Most of the projects, at different project stages, are conducted in the USA (48%) and China (22%), followed by Canada (17%), Brazil (4%), Saudi Arabia (4%) and the United Arab Emirates (4%) (,

, ).

).

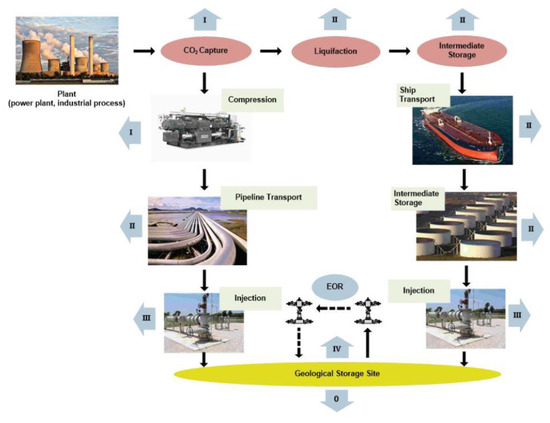

As can be seen, all of the mentioned projects differ by CO2

Figure 3. Potential greenhouse gas emissions sources and types of emissions in CCS and/or CO

source type and size (and if the same, they differ by fuel type, net output, efficiency, capture technology, capture capacity, captured CO2-EOR value chain. Modified according to [39].

As can be seen, all of the mentioned projects differ by CO

purity, etc.), CO2 source type and size (and if the same, they differ by fuel type, net output, efficiency, capture technology, capture capacity, captured CO

transport (choice of the transportation system and used fuel, distance from the CO2 purity, etc.), CO

capture point to injection/storage point, etc.), injection/storage site characteristics, time horizon, the geographical location of CO2 transport (choice of the transportation system and used fuel, distance from the CO

-EOR value chain elements (thus different environmental impact due to different ecological sensitivity) and different market conditions (cost of CO2 capture point to injection/storage point, etc.), injection/storage site characteristics, time horizon, the geographical location of CO

, oil price). All of these differences pose a challenge when estimating emissions from CO2-EOR value chain elements (thus different environmental impact due to different ecological sensitivity) and different market conditions (cost of CO

-EOR projects. The mentioned varieties between CO2, oil price). All of these differences pose a challenge when estimating emissions from CO

-EOR projects (and generally CCS/CCUS projects), but also the lack of standardized methods for estimating the full lifecycle emissions resulting from CO2-EOR projects. The mentioned varieties between CO2-EOR projects (and generally CCS/CCUS projects), but also the lack of standardized methods for estimating the full lifecycle emissions resulting from CO2-EOR projects, result in various uncertainties and wide flexibilities on how to estimate emissions from these kinds of projects.

-EOR projects, result in various uncertainties and wide flexibilities on how to estimate emissions from these kinds of projects.

Narrow-analysis of case-specific data could be done, but generally, there is a lack of appropriate lifecycle emission estimation methodologies specific to CO2

-EOR projects (CCS/CCUS projects). In addition, due to the mentioned specifics, in order to estimate the full lifecycle emissions resulting from CO2

-EOR projects, normalization and a set of benchmark information should be done, which will allow the cross-referencing of CO2

-EOR projects and its comparison to other climate-mitigation strategies. Pointing out the mentioned differentiation and giving an overview of large-scale CO2

-EOR projects gives useful information for the future development of standardized methods for estimating the full lifecycle emissions resulting from CO2

-EOR projects.

3. Conclusions

CCUS will have an important role in achieving the Paris Amendment goal, as it has proven the potential to deliver significant emission reductions across the energy sector. Even though there are many technologies considered as CCUS, at the moment, the only profitable CCUS projects are large-scale CO2

-EOR projects, which along with the sequestration of greenhouse gas, resulting in the production of additional value, i.e., incremental oil.

Due to the increasing global crude oil demand caused by economic growth in developing countries and rising needs in the transport sector, especially in market segments with poor or no fuel alternatives (such as aviation), the petroleum industry through the EOR projects could be an option which gives both, energy security and lower emissions.

According to the KAPSARC data source, in 2018, there were 23 large-scale CO2

-EOR projects in different implementation phases. Most of the projects were in North America utilizing CO2

from natural gas processing. Considering the number of projects in the definition/evaluation phase and the CO2

capture capacity of these projects, CO2

-EOR projects have a significant potential to play an important role in mitigating climate change in China.

However, besides using CO2

for commercial activity, the main aim of the CCUS projects is CO2

sequestration. They do not necessarily result in overall net negative emissions due to the fact that the CO2

retention time significantly differs among the projects ranging from one year, in case of fuel generation, to up to millions of years, in case of carbonation.

With regard to CO2

-EOR projects, all the conducted studies on lifecycle emissions have shown substantial benefits in CO2

emission reduction. Studies have shown that CO2

-EOR lifecycle emissions for every barrel of incremental oil produced are 37% less than in the case of conventional oil production methods. The practice has shown that about 60% of the CO2

, injected with the purpose of a solvent used for driving the production of residual oil, remains trapped in the reservoir pore space, while 40% of it is reproduced with oil production. Ultimately, if a closed-loop injection system is applied, which is a common case when CO2

is a commodity that must be purchased or when it is generated as waste during natural gas processing, up to 95% of the cumulatively injected CO2

within the CO2

-EOR project remains permanently sequestrated in the oil reservoir.

When considering lifecycle emissions of CO2

-EOR projects, within the “gate-to-gate” (only CO2

-EOR activities), the most carbon (and energy) intensive component is gas compression. When conducting “gate-to-grave”, and especially when conducting “cradle-to-grave” lifecycle emission analysis, due to various possible variants of all the processes involved within all the segments covered by the analysis (upstream-CO2

generation, CO2

-EOR activities and downstream-utilization of the produced oil), and the lack of LCA methodologies specific for CO2

-EOR projects (and CCUS/CCS projects in general), emission assessment is quite complex resulting in various uncertainties and wide flexibilities, which impedes the cross-referencing and comparison of CO2

-EOR projects to other climate-mitigation strategies.