Biogas production is a relevant component in renewable energy systems. Model approaches of biogas production show different levels of detail. They can be classified as white, gray, and black box, or bottom-up and top-down approaches. On the one hand, biogas modeling can supply dynamic information on the anaerobic digestion process, e.g., to predict biogas yields or to optimize the anaerobic digestion process. These models are characterized by a bottom-up approach with different levels of detail: the comprehensive ADM1 (white box), simplifications and abstractions of AD models (gray box), or highly simplified process descriptions (black box). On the other hand, biogas production is included in energy system models. These models usually supply aggregated information on regional biogas potentials and greenhouse gas emissions. They are characterized by a top-down approach with a low level of detail. Most energy system models reported in literature are based on black box approaches. Considering the strengths and weaknesses of the integration of detailed and deeply investigated process models in energy system models reveals the opportunity to develop dynamic and fluctuating business models of biogas usage.

- biogas

- modeling

- anaerobic digestion

- energy system

- geoinformation system

- GIS

- life cycle assessment

- LCA

- greenhouse gas emissions

1. Introduction

Biogas is a relevant component of an increasingly renewable energy system in many countries. Biogas plants feature some specific properties compared to other renewable energy plants such as flexible provision of electricity and heat by gas storage, or possible contribution of energy to the transport sector.

With anaerobic digestion (AD), the main transformation process from organic matter to biogas is a biological one. The complex processes of hydrolysis, acidogenesis, acetogenesis, and methanogenesis are well known and described [1]. AD works with various types of organic feedstock, such as municipal sludge from wastewater treatment plants, municipal solid waste, animal waste, algae, or energy crops. Some of those are constantly available, while others are subject to regional and seasonal restrictions. Main product of the anaerobic digestion is biogas, primarily methane and carbon dioxide (CO2). The side product is a nutrient-rich digestate. Biogas can be converted to different energy products, such as heat (by combustion), electricity and heat (combined heat and power plant: CHP), electricity (by turbines), natural gas (by the separation of CO2), or fuels (e.g., by increasing the methane fraction or CO2-assisted catalytic reforming) [2]. A common pathway for the energetic use of biogas is electricity and heat production in a CHP. The focus in many countries lies on the production of electricity. In Germany, for instance, the privileged feed-in of renewable electricity from biogas CHPs is regulated by the Renewable Energy Act [3]. In comparison to other renewable energy sources, electricity production from biogas is not weather-dependent. Biogas plants can produce electricity flexibly according to demand, by utilizing the possibility of storing feedstock and biogas [4]. This provides a distinguished role for biogas plants in the energy sector. Furthermore, biogas can also participate in the supply of heat and fuel where the share of renewable energies, for example, in Germany, it is much lower than for electricity. The shares of renewable energies for electricity, heat, and transport in Germany in 2019 were 37.8, 13.9, and 5.6%, respectively [5].

Biogas plant operation needs continuous monitoring and process control because the AD process is based on microbiological activities that require a complex biocenosis of different microorganisms. This is where process modeling comes into focus.

Biogas process modeling was originally developed for the prediction of possible biogas yields and optimization of the AD process (e.g., [6][7][8]), as well as for process control and staff training (e.g., [9][10]). Those models—often assigned to the water sector—focus on a very detailed description of microbiological transformation. Early papers on AD modeling, for instance, go back to the 1970s [11][12][13]. Since 2002, the anaerobic digestion model (ADM1) has been a commonly used tool to model physical and biological processes within biogas fermenters.

Biogas plants in energy systems are mostly investigated from an agricultural or energy economical point of view. Energy system modeling often regards biogas plants as black box models. They basically tend to be included as gas storage combined with a CHP unit (e.g., [14]). The modeling of biogas plants within future energy systems with high shares of renewable energies needs to look further into the biological process, though, in order to answer new questions due to the dynamic nature of energy supply and demand, such as:

- -How can electricity production be adjusted to electricity demand profiles?

- -How can biogas plants contribute to energy sector coupling?

- -Which pathway of biogas exploitation is most beneficial for the energy system?

- -Which pathway of biogas exploitation offers a business model for the operator?

-How can electricity productionbe adjusted to electricity demand profiles?

-How can biogas plants contribute to energy sector coupling?

-Which pathway of biogas exploitation is most beneficial for the energy system?

-Which pathway of biogas exploitation offers a business model for the operator?

Goal of the transition from fossil to renewable energies is the decarbonization of the energy sector, which aims to address the question of the environmental impact of biogas plants, i.e., their carbon footprint (e.g., [15]). Renewable energy production is often much more decentralized than fossil energy production. Biogas production is widely applied in rural areas. This also poses new questions, such as:

-

-What is the carbon footprint of biogas-based energy products?

-

-What feedstock mixture is most sustainable and are there regional limitations?

-

-How can biogas plants be included in regional energy systems?

-

Such regional aspects of substrate availability and energy-related infrastructure are commonly modeled with geoinformation systems (GIS; e.g., [16]).

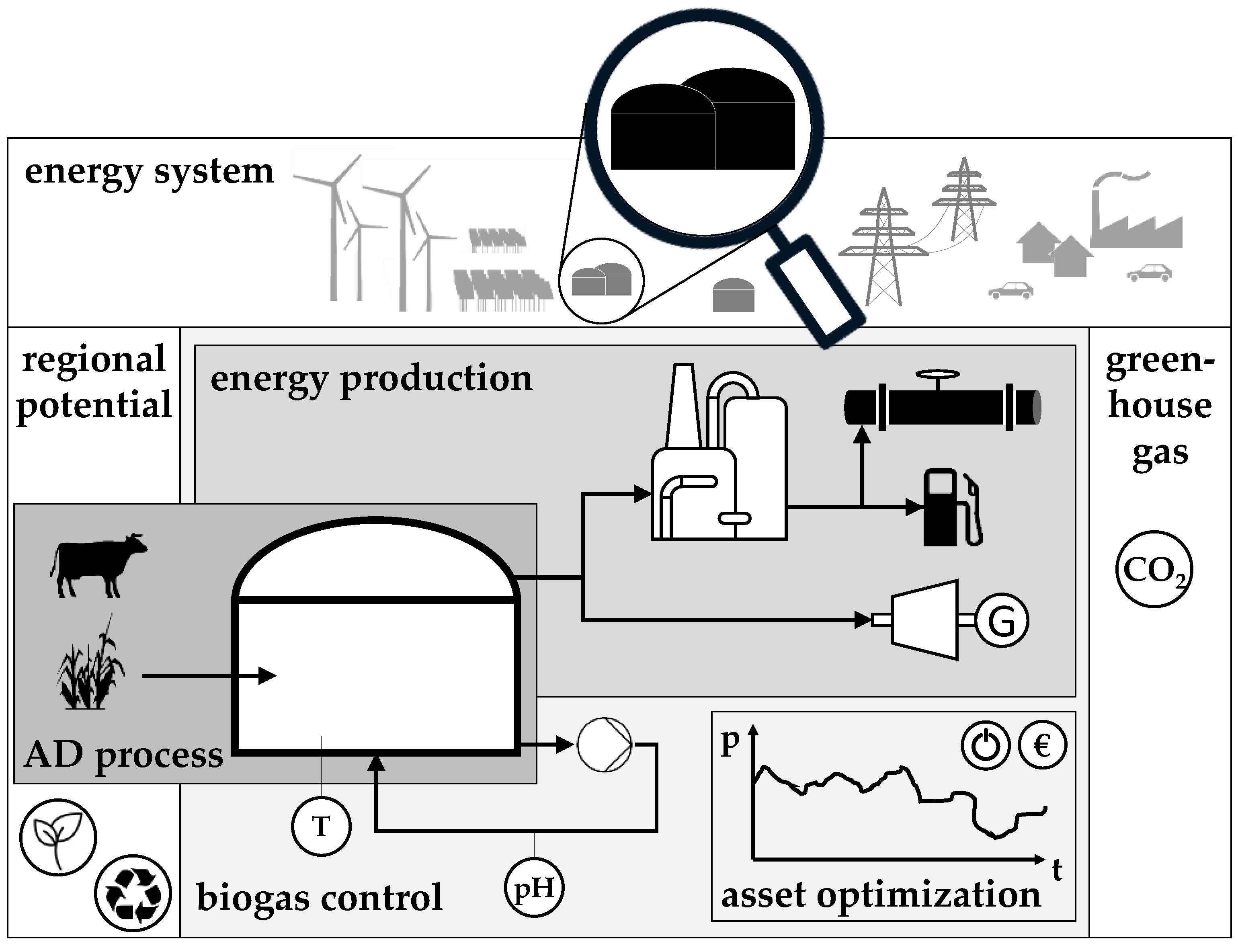

The integration of biogas plants in energy systems thus links water or agricultural economies with the energy economy. This requires information transfer between the different sectors. Figure 1 shows possible system boundaries for different views on biogas plants from energy systems to microbiological processes in the AD process.

Figure 1. System boundaries for different views on biogas plants.

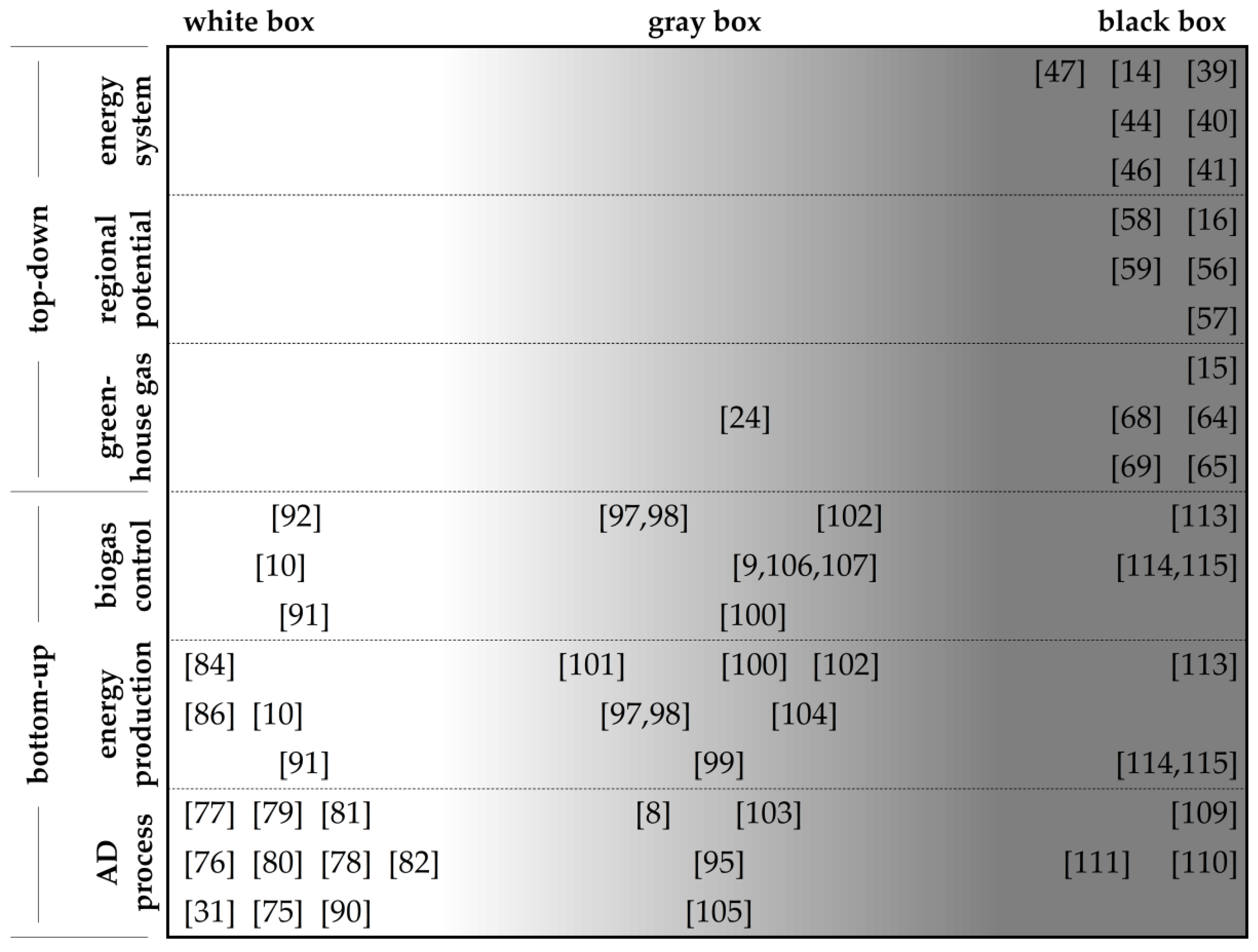

2. Biogas Plants in Renewable Energy Systems

Substantial research and development of models for biogas production was carried out in the last 18 years. Regarding biogas modeling on a process level (anaerobic digestion), these models differ substantially from modeling biogas for potential analysis, GHG emissions and in an energy system. This is reflected in Table 1 and Table 2: Table 2 (top-down) contains biogas model on process level that are not reflected in Table 1 (bottom-up) with models of potential analysis, GHG emissions and energy systems. This different modeling approach of the energy system and the AD perspective can broadly be regarded as top-down and bottom-up approaches, respectively.

Dynamic biogas models contain detailed information about AD processes, technical systems and time-dependent conditions and, thus, generate a complexity that is not to be disregarded. This bottom-up modeling approach differs from the top-down modeling approach used in energy systems, LCA and GIS models. In these models, holistic effects are modeled on a national or regional level [17].

Figure 5Figure 2 shows the complexity of the mathematical mapping of biogas production within the discipline or view on the biogas system that the different studies represent.

Figure 52. Classification of the references regarding their respective level of detail and field of application.

Figure 52. Classification of the references regarding their respective level of detail and field of application.Table 1. Biogas top-down modeling (energy systems, regional impact, greenhouse gas (GHG) emission).

Table 2. Biogas bottom-up modeling (process dynamics)

Ref. View on Biogas Plants AD Model Coding/Software Feedstock Energy Production Region Additional Models [39] AD process ADM1:

24 species,

19 reactions- - - - physiochemical

digester model[40] AD process ADM1 SIMBA#:

C#-based- - - - [41] AD process ADM1 SIMBA# pig manure - - - [42] AD process ADM1 AQUASIM:

C++-based- - - - [43] AD process ADM1 AQUASIM sludge - - - [44] AD process ADM1 AQUASIM water thyme - - - [45] AD process ADM1 MATLAB®

Simulink-code:

C-based S-Function- - - - [46] AD process ADM1 ADMS 1.0:

Python GUI and

MATLAB® ADM1- - - - [47] AD process ADM1 MATLAB®-code - - - - [48] AD process ADM1 BioOptim [9] bio waste - - - [8] AD process modified ADM1 MATLAB®

Simulinkpig manure & glycerin - - - [49] AD process 2 species,

2 reactionsMATLAB®

Simulinkmaize silage - - - [50] AD process 1 reaction not known manure - - heat flow,

thermodynamics of digester[51] AD process 13 species,

10 reactionsMATLAB® fictive waste

composition- - heat flow,

thermodynamics of digester[52] AD process ANN:

one specific digesterMATLAB® agricultural waste (landfill) - - - [53] AD process ANN:

25 digestersNeuroSolutions® manure, banana stem, sawdust - - - [54] AD process ANN of ADM1 MATLAB®: ADM1 and

Python: ANNfictive

(result of ADM1)- - - [55] energy

productionADM1 MATLAB®

Simulinkmanure electricity

(micro gas turbine)- power electronics of micro gas turbine [56] energy

productionADM1 MATLAB®

SimulinkMultiple electricity (CHP) thermodynamics of digester [57] energy

production4 species,

4 reactionsMATLAB® Simulink manure electricity

(micro gas turbine)- synchronous electrical generator of micro gas turbine, gas storage, thermodynamics of digester [58] energy

production1 reaction MATLAB®

Simulinkhousehold garbage electricity (CHP),

heatdomestic use profile (China) heat storage (water tank),

electrical gas compressor,

gas storage, battery (buffer)[59] energy

production1 time-dependent function MATLAB®

Simulinkmanure electricity (CHP) - gas storage [10] biogas control ADM1 BioOptim:

MATLAB®

Simulink- electricity (CHP) - digestate storage,

pumps, heating system,

energy sinks and sources[60] biogas control ADM1 DyBiM:

MATLAB®

Simulinkgrass silage,

cattle manure,

agricultural substrateselectricity (CHP) Sweden gas storage [61] biogas control ADM1 MATLAB® maize silage, rye,

triticale, sugar beets, potato pieces, potato peel- Germany PI controller [9][62][63] biogas control 13 equations,

2 reactionsFORTRAN and

WinErs for GUI and

automation- - - tanks,

valves, pumps[64][65] biogas control ADM1 simplification [66] not known not known electricity (CHP) Germany (EPEX) gas storage [67] biogas control linear equation HOMER® undifferentiated electricity

(CHP, photovoltaic,

fuel cell)India (off-grid) heat storage,

energy storage (battery)[68] biogas control 1 species,

1 reactionMATLAB® and

Microsoft Excel®maize silage,

grass silage,

manureelectricity (CHP),

fuel (CNG)Germany (EPEX) biogas to CNG upgrade plant (black box),

vehicle fleet[69] biogas control none RedSim fixed gas

characteristicselectricity (CHP) Germany

(spot market)gas storage (mass balance) [70][71] biogas control none IPSEpro® real data gas

characteristicselectricity (CHP),

fuel (methane)- gas storage, heat storage, tanks, gas upgrade (black box) Ref. View on Biogas Plants Coding/Software Biomass Modeling Region Additional Modeling [18] energy system oemof [19] annual chemical biogas potential northwestern Germany time-dependent electricity production (wind and photovoltaic) and demand [20] energy system oemof [19] annual chemical biogas potential northwestern Germany time-dependent electricity production (wind and photovoltaic) and demand [21] energy system Engineering Equation Solver [22] daily chemical biogas potential based on chicken manure and maize silage - electrical energy production (wind, photovoltaic), thermal energy production (photovoltaic), chemical energy production (hydrogen), electrical and thermal energy storage [23] energy system Balmorel [24]

linear optimization

(CPLEX-solver)annual energy potential (stable and increasing 1.3% per year) Denmark, Germany, Finland, Norway, Sweden different waste to energy technologies (e.g., gasification, co-combustion) and other technologies (e.g., heater, steam turbine), all with fixed efficiencies [14] energy system EnergyPLAN [25] annual chemical biomass potential Denmark electrical energy production (wind, photovoltaic, wave, CHP, power plants), biogas purification [26] energy system Sifre annual energy potential of manure and straw Danish municipality - [27] energy system TIMES annual energy potential of degradable feedstock Ireland - [16] regional potential - electrical energy potential of manure Northwestern Portugal - [28] regional potential - sectoral biogas potential of manure (cattle, pigs, sheep, poultry) Greece chronological sequence since 1970; contemplation of regional gas grid [29] regional potential - time-dependent (seasons) biogas potential of agricultural residues and municipal waste Croatia residue-to-product ratios, sustainable removal rates [30] regional potential - methane potential of manure, grass silage, municipal waste Finland Maximum feasible use of regional feedstock due to 30-day HRT; optimizing GHG emissions [31] regional potential - municipal waste, sludge, manure, silage and crop residues Finland optimizing biogas plant placing [15] GHG emission GaBi [32] methane yield of maize Germany regional methane yield [33] GHG emission GaBi [32] methane yield of manure, maize silage and grass silage with different mixture ratios - CHP size and efficiency [34] GHG emission SimaPro [35] methane yield of maize, grass, rye silage, chicken manure - demand-oriented energy production by

HRT for mass flow calculation in digester[36] GHG emission - mass-specific energy of grass - influence of grass treatment [37] GHG emission Umberto biogas yield of cultivated crops (maize, triticale, rye, hemp) - emissions of farming, digestion, purification and upgrading to biomethane, transportation [38] GHG emission SimaPro [35]

MATLAB®dynamic AD model (AMOCO) Germany demand-oriented energy production with dynamic AD modeling Many studies are available in the field of dynamic AD process modeling which deal with ADM1 at a high level of detail. These studies also published programs and source code, allowing great transparency of their results. In addition to complex AD process modeling, simplified AD models have been developed and applied many times. These are based partly on the well-known ADM1, but studies also developed simplified models without relying on ADM1 findings. They led to an easier use of AD models with less parameter input compared to ADM1. On a low-detail level (black box), ANNs were used for different types of problem description: Modeling the behavior of a specific plant, different feedstock conditions, or generating a black box model of the deeply detailed ADM1. Both detailed ADM1 and simplified AD models and black box models are applied for energy conversion and biogas control of full-scale biogas plants. Research in the area of dynamic process modeling is well penetrated in terms of both highly detailed and highly abstracted models, including the thermal behavior of digesters. Energy production models with a detailed and simplified AD process description were focused on studies including additional components, such as micro gas turbines with power electronics or CHP units.

The field of top-down models that regard the biogas plant as part of a greater energy system, on the other hand, contains a very high proportion of black box assumptions regarding anaerobic biogas production. No publications that model the behavior of biogas production dynamically have been found within this literature study at the regional level or in energy system modeling. The top-down approaches are used to determine, capture and further process biogas potentials via simple linear equations. The picture is similar in the area of GHG emissions. The prediction of GHG emissions was modeled mostly by including simple dependencies of biogas production. Only one publication was found that used a dynamic AD model (AMOCO) and is backed by LCA data to be able to reduce GHG emissions within a dynamic model.

References

- Chmiel, H. Bioprozesstechnik; G. Fischer: Stuttgart, Germany, 2011.Möller, C.; Rosenberger, S.; Faulstich, M. Speicherbedarf in energieregionen unter berücksichtigung verschiedener autarkiegrade. In Proceedings of the 9 Internationale Energiewirtschaftstagung an der TU Wien, Vienna, Austria, 19 October 2015.

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives: A review. Environ. Sci. Pollut. Res. Int. 2019, 26, 11631–11661.Hilpert, S.; Kaldemeyer, C.; Krien, U.; Günther, S.; Wingenbach, C.; Plessmann, G. The Open Energy Modelling Framework (oemof)—A new approach to facilitate open science in energy system modelling. Energy Strategy Rev. 2018, 22, 16–25.

- Thrän, D.; Schaubach, K.; Majer, S.; Horschig, T. Governance of sustainability in the German biogas sector—Adaptive management of the Renewable Energy Act between agriculture and the energy sector. Energy Sustain. Soc. 2020, 10.Möller, C.; Faulstich, M.; Rosenberger, S. Urban-rural relations in renewable electric energy supply—The case of a German energy region. Int. J. Sustai. Energy Plan. Manag. 2019, 21.

- Trommler, M.; Dotzauer, M.; Hennig, C. Flexibilisierung von Biogasanlagen in Deutschland: Ein Überblick zu technischen Ansätzen, Rechtlichen Rahmen und Bedeutung für das Energiesystem; DBFZ Deutsches Biomasseforschungszentrum gemeinnützige GmbH: Leizpig, Germany, 2016.Bamisile, O.; Huang, Q.; Li, J.; Dagbasi, M.; Desire Kemena, A.; Abid, M.; Hu, W. Modelling and performance analysis of an innovative CPVT, wind and biogas integrated comprehensive energy system: An energy and exergy approach. Energy Convers. Manag. 2020, 209, 112611.

- Fachagentur Nachwachsende Rohstoffe e.V. (FNR) Agency for Renewable Resources. In Bioenergy in Germany Facts and Figures 2020: Solid Fuels, Biofuels, Biogas; Fachagentur Nachwachsende Rohstoffe e.V.: Gülzow, Germany, 2020.F-Chart Software. EES: Engineering Equation Solver. Available online: (accessed on 10 February 2021).

- Biernacki, P.; Steinigeweg, S.; Borchert, A.; Uhlenhut, F.; Brehm, A. Application of Anaerobic Digestion Model No. 1 for describing an existing biogas power plant. Biomass Bioenergy 2013, 59, 441–447.Münster, M.; Meibom, P. Optimization of use of waste in the future energy system. Energy 2011, 36, 1612–1622.

- Page, D.I.; Hickey, K.L.; Narula, R.; Main, A.L.; Grimberg, S.J. Modeling anaerobic digestion of dairy manure using the IWA Anaerobic Digestion Model no. 1 (ADM1). Water Sci. Technol. 2008, 58, 689–695.The Balmorel Open Source Project. Balmorel Energy System Model. Available online: (accessed on 15 February 2021).

- Astals, S.; Ariso, M.; Galí, A.; Mata-Alvarez, J. Co-digestion of pig manure and glycerine: Experimental and modelling study. J. Environ. Manag. 2011, 92, 1091–1096.Korberg, A.D.; Skov, I.R.; Mathiesen, B.V. The role of biogas and biogas-derived fuels in a 100% renewable energy system in Denmark. Energy 2020, 199, 117426.

- Blesgen, A.; Hass, V.C. Operator training simulator for anaerobic digestion processes. IFAC Proc. Vol. 2010, 43, 353–358.Department of Development and Planning, Aalborg University. EnergyPLAN—Advanced Energy System Analysis Computer Model. Available online: (accessed on 15 February 2021).

- Gaida, D.; Wolf, C.; Bongards, M. MATLAB Toolbox for biogas plant modelling and optimization. In Proceedings of the Progress in Biogas II, Stuttgart-Hohenheim, Germany, 30 March–1 April 2011.Sveinbjörnsson, D.; Ben Amer-Allam, S.; Hansen, A.B.; Algren, L.; Pedersen, A.S. Energy supply modelling of a low-CO2 emitting energy system: Case study of a Danish municipality. Appl. Energy 2017, 195, 922–941.

- Hill, D.T.; Barth, C.L. A dynamic model for simulation of animal waste digestion. Water Pollut. Control Fed. 1977, 49, 2129–2143.Chiodi, A.; Gargiulo, M.; Rogan, F.; Deane, J.P.; Lavigne, D.; Rout, U.K.; Ó Gallachóir, B.P. Modelling the impacts of challenging 2050 European climate mitigation targets on Ireland’s energy system. Energy Policy 2013, 53, 169–189.

- Andrews, J.F.; Graef, S.P. Dynamic modeling and simulation of the anaerobic digestion process. Anaerob. Biol. Treat. Process. 1971, 105, 126–162.Silva, S.; Alçada-Almeida, L.; Dias, L.C. Multiobjective programming for sizing and locating biogas plants: A model and an application in a region of Portugal. Comput. Oper. Res. 2017, 83, 189–198.

- Andrews, J.F. Dynamic model of the anaerobic digestion process. J. Sanit. Eng. Div. 1969, 95, 95–116.Batzias, F.A.; Sidiras, D.K.; Spyrou, E.K. Evaluating livestock manures for biogas production: A GIS based method. Renew. Energy 2005, 30, 1161–1176.

- Korberg, A.D.; Skov, I.R.; Mathiesen, B.V. The role of biogas and biogas-derived fuels in a 100% renewable energy system in Denmark. Energy 2020, 199, 117426.Lovrak, A.; Puksec, T.; Duic, N. A Geographical Information System based approach for assessing the spatial distribution and seasonal variation of biogas production potential from agricultural residues and municipal biowaste. Appl. Energy 2020, 267, 115010.

- Dressler, D.; Loewen, A.; Nelles, M. Life cycle assessment of the supply and use of bioenergy: Impact of regional factors on biogas production. Int. J. Life Cycle Assess. 2012, 17, 1104–1115.Huopana, T.; Song, H.; Kolehmainen, M.; Niska, H. A regional model for sustainable biogas electricity production: A case study from a Finnish province. Appl. Energy 2013, 102, 676–686.

- Silva, S.; Alçada-Almeida, L.; Dias, L.C. Multiobjective programming for sizing and locating biogas plants: A model and an application in a region of Portugal. Comput. Oper. Res. 2017, 83, 189–198.Höhn, J.; Lehtonen, E.; Rasi, S.; Rintala, J. A Geographical Information System (GIS) based methodology for determination of potential biomasses and sites for biogas plants in southern Finland. Appl. Energy 2014, 113, 1–10.

- Herbst, A.; Toro, F.; Reitze, F.; Jochem, E. Introduction to energy systems modelling. Swiss J. Econ. Stat. 2012, 148, 111–135.Dressler, D.; Loewen, A.; Nelles, M. Life cycle assessment of the supply and use of bioenergy: Impact of regional factors on biogas production. Int. J. Life Cycle Assess. 2012, 17, 1104–1115.

- Sphera Solutions, Inc. GaBi Solutions. Available online: (accessed on 10 February 2021).

- Lansche, J.; Müller, J. Life cycle assessment of energy generation of biogas fed combined heat and power plants: Environmental impact of different agricultural substrates. Eng. Life Sci. 2012, 12, 313–320.

- Ertem, F.C.; Martínez-Blanco, J.; Finkbeiner, M.; Neubauer, P.; Junne, S. Life cycle assessment of flexibly fed biogas processes for an improved demand-oriented biogas supply. Bioresour. Technol. 2016, 219, 536–544.

- PRé Sustainability B.V. SimaPro. Available online: (accessed on 15 February 2021).

- Navickas, K.; Venslauskas, K.; Zuperka, V.; Nekrosius, A.; Kulikauskas, T. Influence of different biomass treatment technologies on efficiency of biogas production. In Proceedings of the 11 International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 24–25 May 2012.

- Jury, C.; Benetto, E.; Koster, D.; Schmitt, B.; Welfring, J. Life Cycle Assessment of biogas production by monofermentation of energy crops and injection into the natural gas grid. Biomass Bioenergy 2010, 34, 54–66.

- Ertem-Kappler, F.C. Life Cycle Assessment and Modelling Approaches as a Combined Evaluation Tool for Sustainable Control Strategies at Biogas Plants. Ph.D. Thesis, Technische Universität Berlin, Berlin, Germany, 2019.

- IWA Task Group for Mathematical Modelling of Anaerobic Digestion. Anaerobic Digestion Model No. 1 (ADM1); IWA Publishing: London, UK, 2002; ISBN 9781780403052.

- ifak—Institut für Automation und Kommunikation. SIMBA#Biogas. Available online: (accessed on 10 February 2021).

- Wett, B.; Schoen, M.; Phothilangka, P.; Wackerle, F.; Insam, H. Model-based design of an agricultural biogas plant: Application of anaerobic digestion model no. 1 for an improved four chamber scheme. Water Sci. Technol. 2007, 55, 21–28.

- Eawag Aquatic Research. Software. Available online: (accessed on 10 February 2021).

- Ersahin, M.E. Modeling the dynamic performance of full-scale anaerobic primary sludge digester using Anaerobic Digestion Model No. 1 (ADM1). Bioprocess Biosyst. Eng. 2018, 41, 1539–1545.

- Chen, X.; Chen, Z.; Wang, X.; Huo, C.; Hu, Z.; Xiao, B.; Hu, M. Application of ADM1 for modeling of biogas production from anaerobic digestion of Hydrilla verticillata. Bioresour. Technol. 2016, 211, 101–107.

- Jeppsson, U. Investigation of Anaerobic Digestion Alternatives for Henriksdal’s WWTP; Department of Industrial Electrical Engineering and Automation, Lund University: Lund, Sweden, 2007.

- Carlini, M.; Castellucci, S.; Mennuni, A.; Selli, S. Simulation of anaerobic digestion processes: Validation of a novel software tool ADM1-based with AQUASIM. Energy Rep. 2020, 6, 102–115.

- Danielsson, O. Modeling and Simulation of Anaerobic Manure Digestion into Biogas. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2014.

- Glivin, G.; Sekhar, S. Experimental and Analytical Studies on the Utilization of Biowastes Available in an Educational Institution in India. Sustainability 2016, 8, 1128.

- Blesgen, A.; Hass, V.C. Operator training simulator for anaerobic digestion processes. IFAC Proc. Vol. 2010, 43, 353–358.

- Astals, S.; Ariso, M.; Galí, A.; Mata-Alvarez, J. Co-digestion of pig manure and glycerine: Experimental and modelling study. J. Environ. Manag. 2011, 92, 1091–1096.

- Rieke, C.; Stollenwerk, D.; Dahmen, M.; Pieper, M. Modeling and optimization of a biogas plant for a demand-driven energy supply. Energy 2018, 145, 657–664.

- Axaopoulos, P.; Panagakis, P.; Tsavdaris, A.; Georgakakis, D. Simulation and experimental performance of a solar-heated anaerobic digester. Sol. Energy 2001, 70, 155–164.

- Calise, F.; Cappiello, F.L.; Dentice d’Accadia, M.; Infante, A.; Vicidomini, M. Modeling of the Anaerobic Digestion of Organic Wastes: Integration of Heat Transfer and Biochemical Aspects. Energies 2020, 13, 2702.

- Abu Qdais, H.; Bani Hani, K.; Shatnawi, N. Modeling and optimization of biogas production from a waste digester using artificial neural network and genetic algorithm. Resour. Conserv. Recycl. 2010, 54, 359–363.

- Gueguim Kana, E.B.; Oloke, J.K.; Lateef, A.; Adesiyan, M.O. Modeling and optimization of biogas production on saw dust and other co-substrates using Artificial Neural network and Genetic Algorithm. Renew. Energy 2012, 46, 276–281.

- Wagner, D.; Schlüter, W. Vorhersage und Regelung der Methanproduktion durch maschinelles Lernen. In Proceedings of the ASIM SST 2020, 25. ASIM Symposium Simulationstechnik, 14–15 October 2020; Deatcu, C., Lückerath, D., Ullrich, O., Durak, U., Eds.; ARGESIM Publisher: Vienna, Austria, 2020; pp. 159–166, ISBN 9783901608933.

- Morales Garcia, L.A.; Rodriguez Vargas, A.D.; Rojas Cubides, H.E. Computational Model of an Electric Power Generation System based on Biogas obtained from Cattle Manuerodelo. Pist. Educ. 2020, 42, 1091–1110.

- Brouwer, A.F.; Grimberg, S.J.; Powers, S.E. The Dynamic Anaerobic Reactor & Integrated Energy System (DARIES) model: Model development, validation, and sensitivity analysis. Water Environ. Res. 2012, 84, 2090–2098.

- Saeed, M.; Fawzy, S.; El-Saadawi, M. Modeling and simulation of biogas-fueled power system. Int. J. Green Energy 2019, 16, 125–151.

- Wang, D.; Duan, Q.; Li, Y.; Tian, X.; Rahman, S. Simulation of a solar-biogas hybrid energy system for heating, fuel supply, and power generation. Int. J. Energy Res. 2017, 41, 1914–1931.

- Zepter, J.M.; Gabderakhmanova, T.; Andreasen, K.M.; Boesgaard, K.; Marinelli, M. Biogas Plant Modelling for Flexibility Provision in the Power System of Bornholm Island. In Proceedings of the 2020 55th International Universities Power Engineering Conference (UPEC), Torino, Italy, 1–4 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6, ISBN 978-1-7281-1078-3.

- Gaida, D.; Wolf, C.; Bongards, M. MATLAB Toolbox for biogas plant modelling and optimization. In Proceedings of the Progress in Biogas II, Stuttgart-Hohenheim, Germany, 30 March–1 April 2011.

- Grim, J.; Nilsson, D.; Hansson, P.-A.; Nordberg, Å. Demand-Orientated Power Production from Biogas: Modeling and Simulations under Swedish Conditions. Energy Fuels 2015, 29, 4066–4075.

- Peters, L.; Biernacki, P.; Quaghebeur, W.; Uhlenhut, F.; Steinigeweg, S. Model-based control for a demand-driven biogas production to cover residual load rises. Bioprocess Biosyst. Eng. 2019, 42, 1829–1841.

- Blesgen, A. Entwicklung und Einsatz eines Interaktiven Biogas-Echtzeit-Simulators. Ph.D. Thesis, Universität Bremen, Bremen, Germany, 2009.

- Hass, V.C. Verbesserung der bioverfahrenstechnischen Ausbildung durch einen “Virtuellen Bioreaktor”. Chem. Ing. Tech. 2005, 77, 161–167.

- Winkler, M.; Mauky, E.; Weinrich, S. Model-based process optimization of biogas plant operation. In Proceedings of the IV CMP International Conference on Monitoring & Process Control of Anaerobic Digestion Plants, Leipzig, Germany, 26–27 March 2019.

- Mauky, E.; Weinrich, S.; Nägele, H.-J.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Model Predictive Control for Demand-Driven Biogas Production in Full Scale. Chem. Eng. Technol. 2016, 39, 652–664.

- Weinrich, S. Praxisnahe Modellierung von Biogasanlagen. Ph.D. Thesis, Universität Rostock, Rostock, Germany, 2017.

- Castellanos, J.G.; Walker, M.; Poggio, D.; Pourkashanian, M.; Nimmo, W. Modelling an off-grid integrated renewable energy system for rural electrification in India using photovoltaics and anaerobic digestion. Renew. Energy 2015, 74, 390–398.

- Gökgöz, F.; Winkler, M.; Barchmann, T.; Weinrich, S.; Liebetrau, J.; Nelles, M. Combining Electricity and Fuel Supply: Operational Strategies for Biogas Plants. Chem. Eng. Technol. 2021, 44, 183–193.

- Hochloff, P.; Braun, M. Optimizing biogas plants with excess power unit and storage capacity in electricity and control reserve markets. Biomass Bioenergy 2014, 65, 125–135.

- Saracevic, E.; Woess, D.; Friedl, A.; Miltner, A. Dynamic Simulation of a Biogas Plant Providing Control Energy Reserves. Chem. Eng. Trans. 2017, 61, 931–936.

- Saracevic, E.; Woess, D.; Theuretzbacher, F.; Friedl, A.; Miltner, A. Techno-economic assessment of providing control energy reserves with a biogas plant. Front. Chem. Sci. Eng. 2018, 12, 763–771.