Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Faouzi Ben Rebah and Version 2 by Catherine Yang.

Aloe vera plant offers a sustainable solution for the removal of various pollutants from water. Due to its chemical composition, Aloe vera has been explored as coagulant/flocculant and biosorbent for water treatment.

- Aloe vera

- water treatment

1. Introduction

Industrial development generates large amounts of polluted effluents. Released in the environment, pollutants damage the soil, the ground, and the surface water—leading to ecosystem degradation and causing health risks [1][2][3][4][1,2,3,4]. In order to reduce the environmental problems associated with these effluents, industries utilize various methods of wastewater treatments. Depending on the characteristics of the wastewater, a combination of a number of physical, chemical, and biological processes can be applied to remove various pollutants (carbon, nitrogen, turbidity heavy metals, dyes, etc.) [5][6][5,6]. The physical methods include mainly the adsorption, ion exchange, and membrane technologies. The chemical treatment induces chemical reactions, coagulation, precipitation, oxidation, advanced oxidation, ion exchange, neutralization, and stabilization, etc. However, the biological treatment systems involve membrane bioreactors, biofilter, sequential batch reactor, activated sludge, etc. [7][8][9][10][7,8,9,10]. Although their ability to efficiently remove pollutants from various effluents, these processes may have some disadvantages such as the use of chemicals in the coagulation–flocculation technique. For example, aluminum salts and polyacrylamides remain in water after treatment and may cause health concerns (genotoxicity, neurotoxicity, etc.) for organisms [11][12][11,12]. Besides, the activated carbon used as adsorbent for wastewater treatment is expensive, non-selective, and needs regeneration after rapid saturation [13][14][15][13,14,15]. Therefore, depending on the characteristics of the industrial effluent, the applied process to remove pollutants may not be economically justified and sustainable, with a high environmental cost related to the adverse effects of its secondary effluent on the environment. In order to be sustainable, wastewater treatment should involve biological materials aiming to minimize energy consumption and negative impacts on the environment. As reported in the literature, the sustainable strategy involving the use of biological materials constitutes a promising solution for pollutants removal. For example, biological natural materials such as cactus, moringa, Aloe vera, bean, etc. have been explored for their eventual use for pollutants removal [16][17][18][16,17,18]. Interestingly, the removal of various pollutants (dyes, turbidity, metals, etc.) by Aloe vera (AV) via its utilization in many processes (adsorption, coagulation–flocculation, degradation, etc.) was reported. AV is biodegradable, safe, and abundant in various regions over the world.

2. Aloe vera as Coagulant/Flocculant for Wastewater Treatment

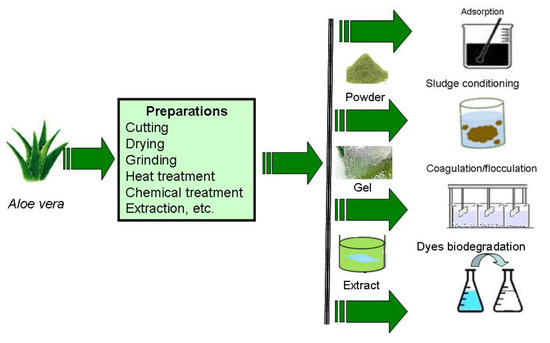

Coagulation/flocculation is a common process used for the removal of various pollutants (suspended solids, organic, and inorganic materials). In this operation, chemicals such as aluminum salts, acrylamides are added to water to destabilize colloidal materials and allow the agglomeration of small particles into larger settleable flocs [19][20][19,20]. However, these chemicals remain in treated water leading to various health problems (neurotoxicity, genotoxicity, etc.) [12]. Furthermore, during the treatment, these chemicals may react with other compounds producing new products with unknown health risks. Various diseases such as Alzheimer are reported to be related to the use of alum [21]. Therefore, it is necessary to consider alternative flocculants/coagulants. These alternative materials should be available, cost effective, biodegradable, and without health risks. Various parts (seeds, leaves, pieces, roots, fruits, etc.) of plants (cactus, moringa, etc.,) were used as potential sources of flocculants/coagulants [18][22][18,22]. Interestingly, the use of AV as a promising natural material to substitute chemicals in the coagulation/flocculation process [23][24][25][26][27][28][29][30][31][32][33][34][35][36][37][38][39][40][41][42][23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42] has been reported. Various investigations reported the use of AV as coagulant, flocculant, or coagulant/flocculant aid for water treatment. Figure 1 shows the scheme of Aloe vera preparations and applications for wastewater treatment using various processes.

Figure 1.

The scheme of

Aloe vera

preparations and applications for wastewater treatment.