Light-initiated polymerization processes are currently an important tool in various industrial fields. The advancement of technology has resulted in the use of photopolymerization in various biomedical applications, such as the production of 3D hydrogel structures, the encapsulation of cells, and in drug delivery systems. The use of photopolymerization processes requires an appropriate initiating system which, in biomedical applications, must meet additional criteria: high water solubility, non-toxicity to cells, and compatibility with visible low-power light sources. This article is a literature review on those compounds that act as photoinitiators of photopolymerization processes in biomedical applications. The division of initiators according to the method of photoinitiation was described and the related mechanisms were discussed. Examples from each group of photoinitiators are presented, and their benefits, limitations and applications are outlined.

- water-soluble photoinitiators

- type I photoinitiators

- type II photoinitiators

- two-photon initiators (2PP), photopolymerization

- biomedical applications

- free-radical photopolymerization

- cationic photopolymerization

Figure 1. Graphical abstract.

Graphical abstract.Currently,

Currently,polymerization processes

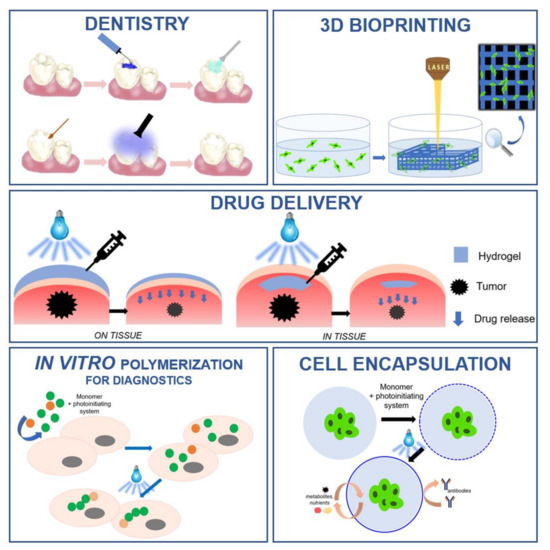

are one of the most widely used chemical processes in various fields of industry. One of the most modern and rapidly developing methods of obtaining polymers is light-induced polymerization, i.e., photopolymerization. The technique of converting liquid monomers to solid polymers under the influence of applied light is widely developed in the polymer materials sector in the industry of solvent-free paints, varnishes, and adhesives, in optoelectronics, in the printing industry for 3D printing materials, and many others. Numerous advantages of photopolymerization, such as performing reactions at ambient temperature, lack of solvents, and extremely short processing times, made light-initiated polymerization perfectly suited for biomedical applications (Figure 1) .

Figure 2. Examples of light-induced polymerization processes in biomedical applications.

Examples of light-induced polymerization processes in biomedical applications.The global market for photopolymerization in biomedical applications can be divided into various groups based on the area of application in the medical sector. The main segments are: dentistry

The global market for photopolymerization in biomedical applications can be divided into various groups based on the area of application in the medical sector. The main segments are: dentistry , tissue engineering, bioimaging, drug delivery systems, and medical devices. In dentistry, photochemical-initiated processes are used for the filling of hard dental tissue cavities with photocured polymer composites. An interesting application of photopolymerization processes is the production of photo-crosslinked polymeric biomaterials especially those based on totally or partially degradable materials, scaffolds for tissue culture, and diagnostic genetic or cellular matrixes .The unquestionable advantages of the photopolymerization technique in the context of applications in tissue engineering and biomedical science are primarily its ability to form structures of any geometry as well as the deposition of such materials on various carriers. Lack of these possibilities is often a limitation of the functionality of biomaterials obtained through conventional polymerization processes.

The unquestionable advantages of the photopolymerization technique in the context of applications in tissue engineering and biomedical science are primarily its ability to form structures of any geometry as well as the deposition of such materials on various carriers. Lack of these possibilities is often a limitation of the functionality of biomaterials obtained through conventional polymerization processes.Due to the mechanisms of polymerization as well as the type of used monomers and initiating systems, there is a distinction between radical photopolymerization and cationic photopolymerization, which are the basic processes used in light-initiated polymerization technologies.

Due to the mechanisms of polymerization as well as the type of used monomers and initiating systems, there is a distinction between radical photopolymerization and cationic photopolymerization, which are the basic processes used in light-initiated polymerization technologies.Radical photopolymerization

is a chain reaction consisting of three main stages: initiation, propagation, chain growth, and termination (which may be accompanied by side reactions). Free-radical photopolymerization is mainly used for acrylate and methacrylate monomers. The factor that limits the usefulness of radical photopolymerization is the occurrence of oxygen inhibition caused by the presence of atmospheric oxygen during the polymerization process. The negative influence of oxygen on polymerization is reflected, for example, by extinguishing the excited states of the initiator, which, in turn, affects the efficiency of the whole process. It is the free-radical polymerization, however, that is mostly used in biomedical applications, as proven by numerous literature reports .The second type of polymerization is

The second type of polymerization iscationic photopolymerization

, which is particularly interesting and relatively widespread in industrial applications, since it has a number of major advantages that make this process practical. The living nature of cationic photopolymerization guarantees that the reaction continues to be effective even after shutting down the radiation source. This enables a high degree of conversion to be achieved, which plays an extremely important role in the industrial practice. For this reason, photoinitiated cationic polymerization is becoming increasingly prevalent in global markets as an easy and energy-saving method for obtaining cross-linked polymers. Despite its numerous advantages, cationic polymerization is very unlikely to be used in biomedical applications. One of the reasons is that cationic initiators generate strong protonic acids during initiation, whose acidic character negatively affects cell cultures[42]

. The second reason is the sensitivity of cationic photopolymerization to moisture and water. Numerous scientific articles prove that the presence of water slows down or inhibits the polymerization reaction. In addition, water can act as a chain transfer agent and promote the growth of new chains, which reduces the average molecular weight of the obtained polymer[43].

.One of the basic requirements of photocuring systems used in biomedical sciences is their total or partial solubility in water.

Water-based photocuring systems have already garnered interest since the late 1970s. Even then, it was well known that the use of water as a non-toxic, green, and cheap solvent was the solution to many problems related to the classical, organic compositions[44]. In addition, aqueous formulations can, in many cases, provide a reaction efficiency that cannot be achieved with conventional organic systems. Interestingly, the oxygen concentration in aqueous systems is an inch lower than in organic preparations, which significantly reduces oxygen inhibition for radical photopolymerization processes. Therefore, the use of water-soluble photoinitiators in aqueous systems for light-initiated polymerization is of great importance in the rapidly growing medical industry, and this article provides an overview of the literature related to the development of water-soluble initiators and their use in biomedical applications.

. In addition, aqueous formulations can, in many cases, provide a reaction efficiency that cannot be achieved with conventional organic systems. Interestingly, the oxygen concentration in aqueous systems is an inch lower than in organic preparations, which significantly reduces oxygen inhibition for radical photopolymerization processes. Therefore, the use of water-soluble photoinitiators in aqueous systems for light-initiated polymerization is of great importance in the rapidly growing medical industry, and this article provides an overview of the literature related to the development of water-soluble initiators and their use in biomedical applications.Types of photoinitiators

Types of photoinitiatorsThe initiating systems based on one-component, two-component or multi-component photoinitiators undoubtedly play a key role in photopolymerization processes

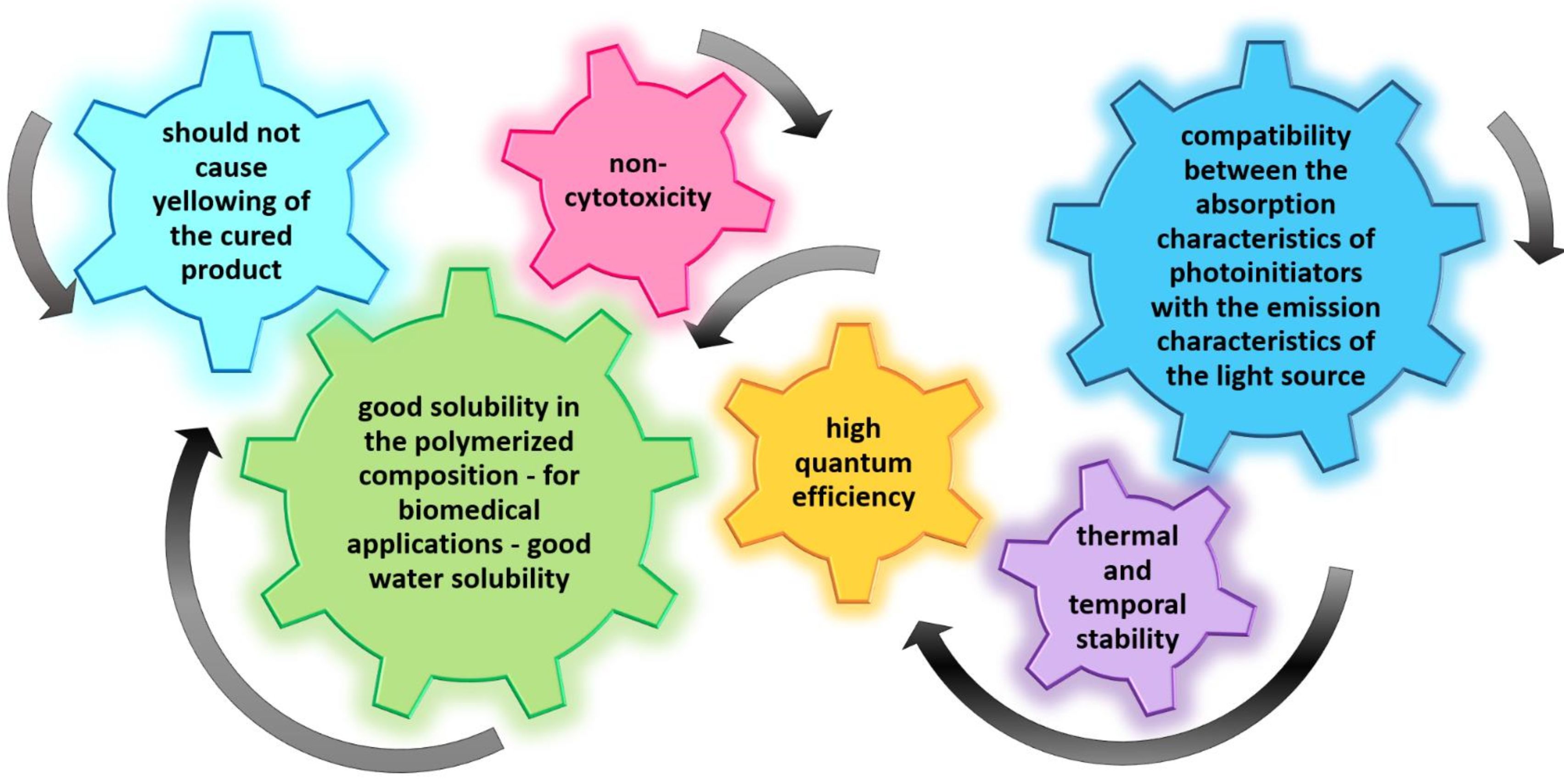

The initiating systems based on one-component, two-component or multi-component photoinitiators undoubtedly play a key role in photopolymerization processes. Photoinitiating systems not only determine the mechanism of the reaction, but also affect its performance, curing speed and final properties of the polymer, such as hardness and viscosity. The selection of a photoinitiator is essential to achieve the right photopolymerization reaction rate and the desired polymer properties. The basic parameters determining the selection of the photoinitiator are, among others, maximum absorption wavelength λmax

and molar extinction coefficient ε. The efficiency of the photoinitiator is directly related to its structure, which influences the range of absorption and quantum efficiency of the photochemical and photophysical processes taking place in excited states[48]

. Regardless of the type and mechanism of initiation, the photoinitiator should exhibit the following features (Figure 3):- thermal and temporal stability

- compatibility between the absorption characteristics of photoinitiators and the emission characteristics of the light source

- high quantum efficiency

- good solubility in the polymerized composition – for biomedical applications – good water solubility

- non-cytotoxicity

- should not cause yellowing of the cured product

- thermal and temporal stability

- compatibility between the absorption characteristics of photoinitiators and the emission characteristics of the light source

- high quantum efficiency

- good solubility in the polymerized composition – for biomedical applications – good water solubility

- non-cytotoxicity

- should not cause yellowing of the cured product

Other factors to be taken into account when performing the photopolymerization reaction are the structure and physicochemical properties of the monomers, the phenomenon of oxygen inhibition (in the case of free-radical polymerization), the influence of stabilisers or other additives present in the monomers, the thickness of the polymerizing layer, the type and intensity of the light source and the viscosity of the composition. In the case of an in vivo photopolymerization reaction, it is particularly important to reduce the toxicity of the initiator, especially when exposed to light. Free radicals produced during initiation may react with the main components of living cells, such as proteins and nucleic acids, which may affect the condition and viability of cells. Based on the mechanism of initiation of photoinitiators, a distinction is made between radical and cationic photoinitiators. In biomedical applications, radical photopolymerization processes are dominant.

Other factors to be taken into account when performing the photopolymerization reaction are the structure and physicochemical properties of the monomers, the phenomenon of oxygen inhibition (in the case of free-radical polymerization), the influence of stabilisers or other additives present in the monomers, the thickness of the polymerizing layer, the type and intensity of the light source and the viscosity of the composition. In the case of an in vivo photopolymerization reaction, it is particularly important to reduce the toxicity of the initiator, especially when exposed to light. Free radicals produced during initiation may react with the main components of living cells, such as proteins and nucleic acids, which may affect the condition and viability of cells. Based on the mechanism of initiation of photoinitiators, a distinction is made between radical and cationic photoinitiators. In biomedical applications, radical photopolymerization processes are dominant.

Figure 3. Highlights of initiators' requirements.

Highlights of initiators' requirements.Free-radical photopolymerization is an example of a classic photochemical chain reaction in three main stages: initiation, propagation and termination, leading to the formation of oligomers or polymers

Free-radical photopolymerization is an example of a classic photochemical chain reaction in three main stages: initiation, propagation and termination, leading to the formation of oligomers or polymers[49]

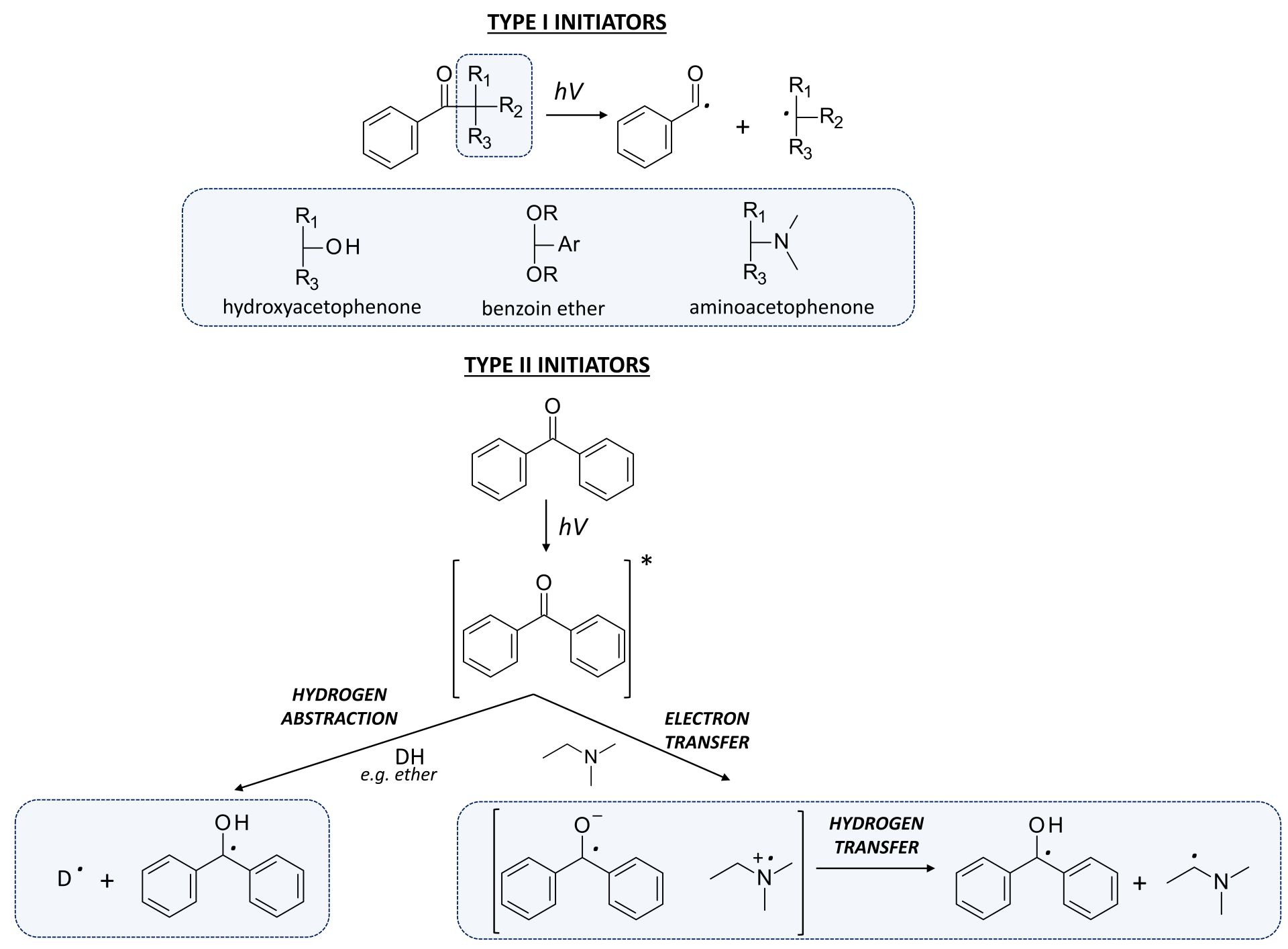

. Depending on the structure of a radical photoinitiator, free radicals may be formed in the process of homolytic photodissociation of the photoinitiator molecule – type I photoinitiators. This group of photoinitiators includes peroxides, peresters, iminosulphones or ketones, where photofragmentation is performed by binding, for example, O-O, S-S, S-N or C-C at α or β – carbon atom to the carbonyl group[50]

. In the case of Type II photoinitiators, the excited initiator molecule reacts with the appropriate co-initiator, for example, an electron donor or acceptor, or a hydrogen donor in order to produce the appropriate radicals or radical-ions[51]

. The photoinitiation process using type I or type II initiators is presented in Figure 4. Types I and II photoinitiations are single- and two-molecular processes respectively. The second type is usually slower and less efficient due to the presence of competitive processes during the excitation of the photoinitiator by the monomer, co-initiator and atmospheric oxygen. Conversely, the photon energy in the visible range is generally lower than the dissociation energy of individual organic compound bonds, so it is particularly difficult to obtain a highly efficient initiator operating in the visible range. Therefore, it is often in this range that the bimolecular systems are used. Examples of Type I initiators are: Irgacure 2959[52]

, LAP[53]

, BAPO-OLi, VA-086[56]

, and as Type II initiators following compounds are used: Eosine Y[57]

, Camphorquinone[58]

, Riboflavine[59].

.

Figure 4. The photoinitiation process using: A. type I initiator; B. type II initiator.

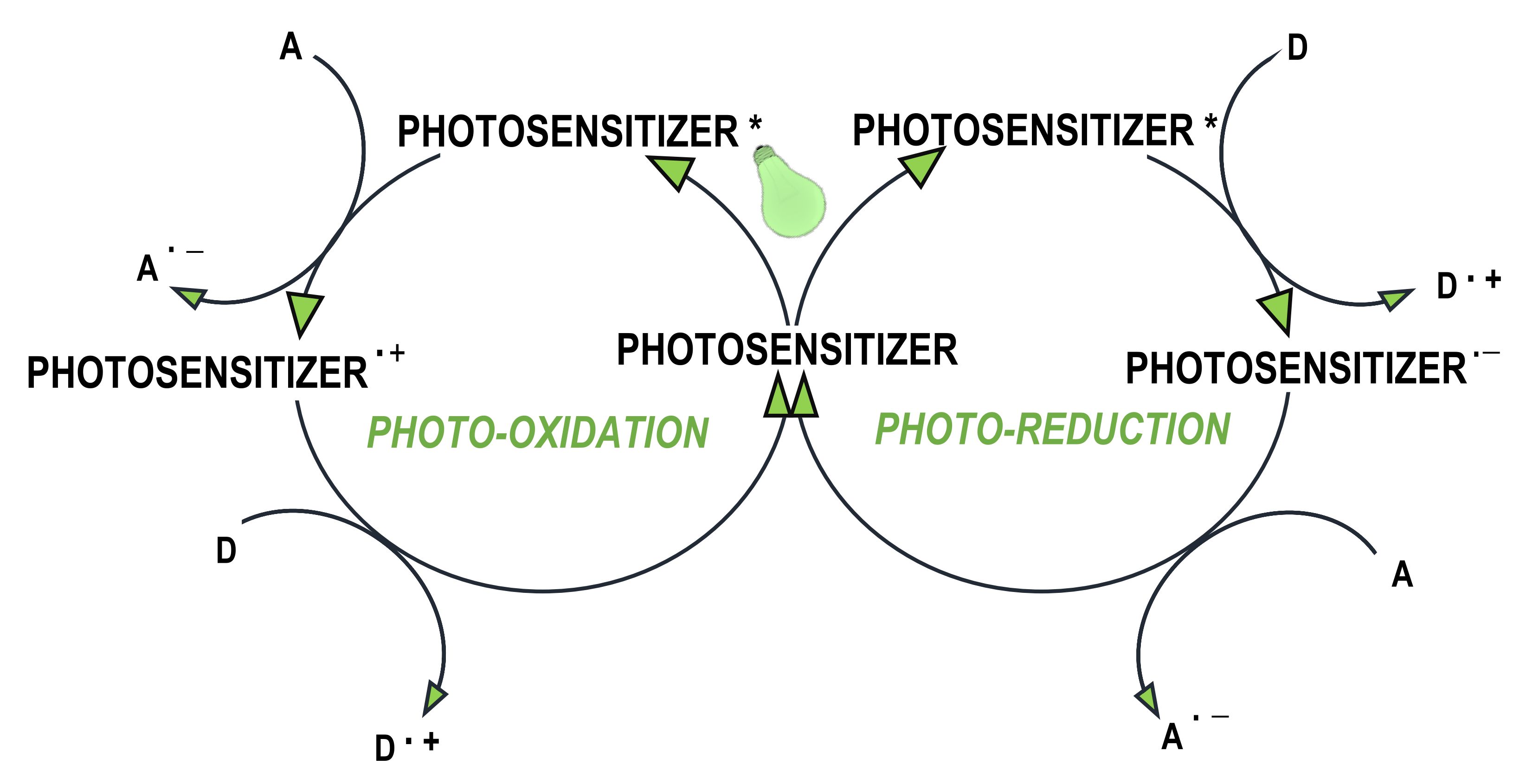

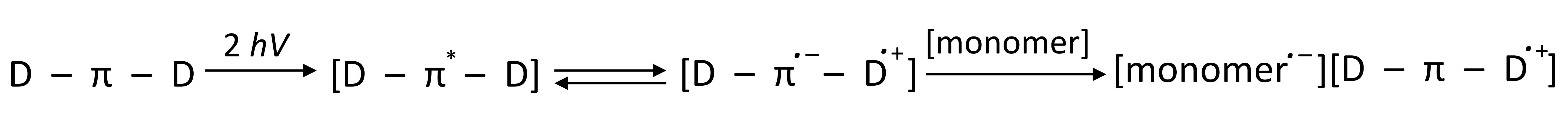

Currently, multi-component photoinitiation systems, based on electron transfer, and systems based on hydrogen abstraction, are interesting options. The reaction of electron transfer is based on the interaction of an excited electron donor or acceptor with a second component (electron acceptor or donor respectively) in the ground state, which is responsible for the photoinduced electron transfer process. An excited photosensitiser molecule, as the primary light absorber in multiradical systems, can perform a dual role (Figure 5) [

The photoinitiation process using: A. type I initiator; B. type II initiator.60]:

- where the photosensitiser acts as an electron donor, the transfer of the electron to the co-initiator creates a cationic radical of the sensitiser particle and an anionic radical of the co-initiator;

- where the photosensitiser acts as an electron donor, the transfer of the electron to the co-initiator creates a cationic radical of the sensitiser particle and an anionic radical of the co-initiator;

- where the photosensitiser is an electron acceptor, it undergoes photoreduction, and the electron transfer products are the anionic radical formed on the sensitiser molecule and the cationic radical formed on the co-initiator

- where the photosensitiser is an electron acceptor, it undergoes photoreduction, and the electron transfer products are the anionic radical formed on the sensitiser molecule and the cationic radical formed on the co-initiator.

Figure 5. Initiation in multi-component systems: D – electron donor; A – electron acceptor.

Initiation in multi-component systems: D – electron donor; A – electron acceptor.In addition to the classic single, binary and multi-component photoinitiators, there are also two-photon initiators (2PP) that undergo two-photon polymerization. This type of process is a powerful tool to build a variety of 3D matrices with micro- and nano-accuracy. Two-photon polymerization process is characterised by high penetration depth and high spatial selectivity. In this case, it is possible to use live cells to create 3D structures, thanks to the use of low-energy photons, which are safe for cells

In addition to the classic single, binary and multi-component photoinitiators, there are also two-photon initiators (2PP) that undergo two-photon polymerization. This type of process is a powerful tool to build a variety of 3D matrices with micro- and nano-accuracy. Two-photon polymerization process is characterised by high penetration depth and high spatial selectivity. In this case, it is possible to use live cells to create 3D structures, thanks to the use of low-energy photons, which are safe for cells[61]

. Two-photon photoinitiators should be sensitive to absorption because during the initiation they absorb two photons from the near infrared (NIR) area. In addition, they are characterised by highly conjugated π-systems and strong donor–acceptor groups[42]

. The initiation process is not fully clarified, but it is suspected that after absorbing the photons, the electron is transferred from the initiator's donor–acceptor group to the π-electron core[62]

. The transfer of the electron between the initiator and the monomer generates an exciplex and results in the formation of radicals that initiate the polymerization reaction (Figure 6)[63]

. Examples of two photon initiators are: WSPI[64]

, BDEA[65]

, P2CK[66].

.

Figure 6. Schematic mechanism of initiation using two-photon photoinitiators.

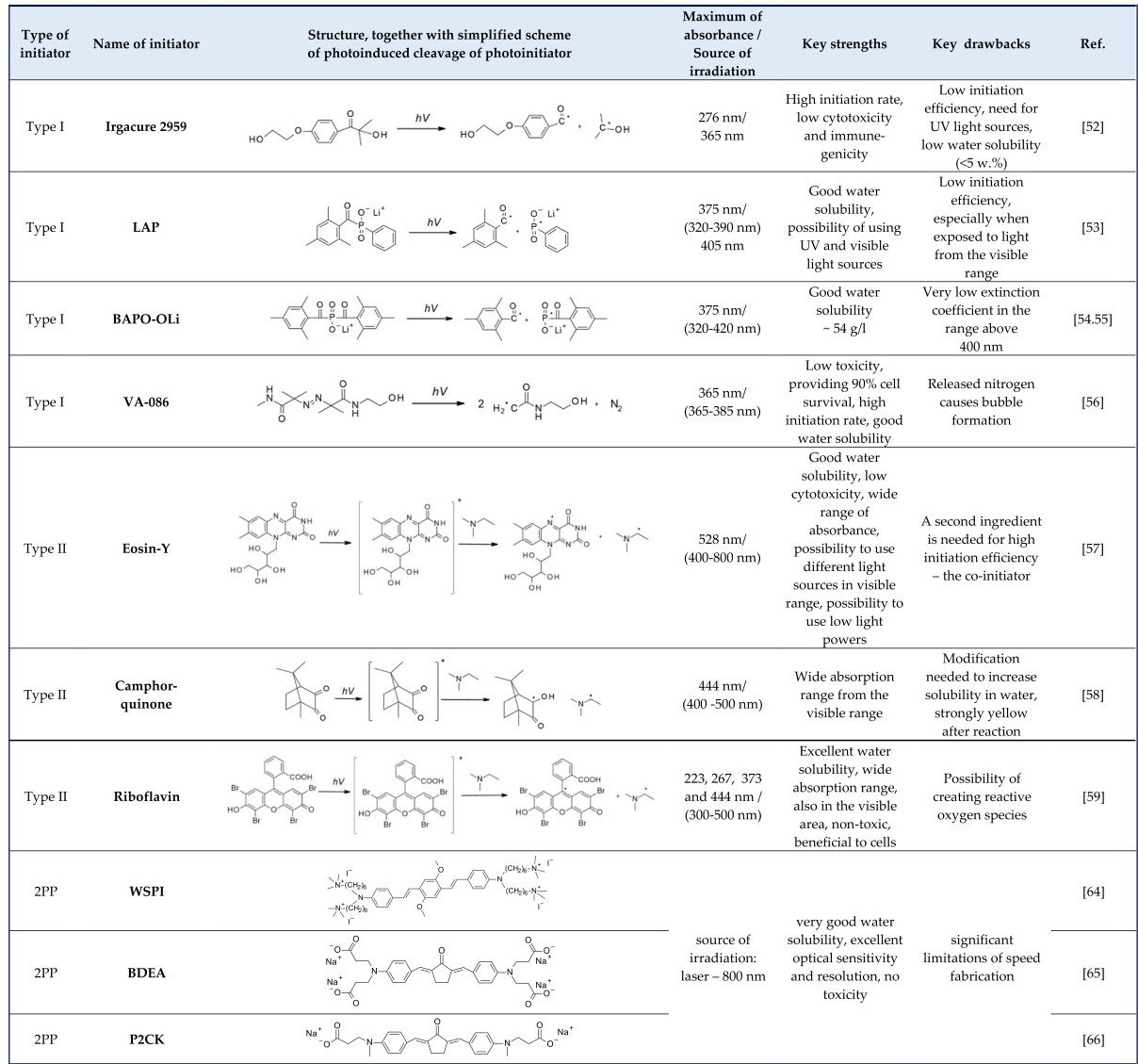

Schematic mechanism of initiation using two-photon photoinitiators.Summary of the main water-soluble initiators used in biomedical applications, their basic properties and photoinduced cleavage of photoinitiators is presented below:

Summary of the main water-soluble initiators used in biomedical applications, their basic properties and photoinduced cleavage of photoinitiators is presented below:

Figure 7. Summary of the main water-soluble initiators used in biomedical applications, their basic properties and photoinduced cleavage of photoinitiators.

Summary of the main water-soluble initiators used in biomedical applications, their basic properties and photoinduced cleavage of photoinitiators.Fields of application for water-soluble photoinitiators

Fields of application for water-soluble photoinitiatorsIn recent years, polymeric hydrogels have garnered a lot of interest in terms of their potential application, due to the fact that their structural and biochemical properties are similar to those of the extracellular matrix (ECM) of most tissues

In recent years, polymeric hydrogels have garnered a lot of interest in terms of their potential application, due to the fact that their structural and biochemical properties are similar to those of the extracellular matrix (ECM) of most tissues[67]

. Moreover, they show high porosity, which ensures high permeability to nutrients, oxygen and metabolic products. The properties of these materials can also be adapted to the mechanical properties of soft tissues. Hydrogels for tissue engineering should be hydrophilic in order to promote cell adhesion, while the three-dimensional structure of these scaffolds should be porous to facilitate cell and nutrient diffusion[68]

. Hydrogels are produced by cross-linking hydrophilic monomers or oligomers. Although hydrogels can be formed by conventional polymerization methods, e.g. thermally, using thermal initiators or initiators acting on the principle of redox reaction, polymerization under the influence of light is of greatest interest. Compared to other methods, photopolymerization has many advantages: it is a very fast reaction (lasting from a few seconds to a few minutes) and allows spatial control over the resulting hydrogel, which permits the creation of various shapes that fit into the tissue structure. Currently, photoinduced systems for the production of hydrogels include: radical polymerization under the influence of ultraviolet (UV) and visible (Vis) lights in water, or two-photon photopolymerization and thiol-en photopolymerization. Hydrogels with an interpenetrating polymer network structure are also becoming increasingly more popular[70]

. Photocured hydrogel materials are used in numerous applications, e.g. biosensing, encapsulation[73]

, drug delivery systems[74]

, scaffolding for cell culture , in situ polymerization[77]

and even direct polymerization in living cells. All techniques of 3D printing are highly developed , including laser writing , inkjet bioprinting[82]

and stereolithography[83]

. Other applications include the production of various materials, including scaffolds[84]

and layered hydrogels using surface photopolymerization[85].

.Conclusion and outlook

Conclusion and outlookIn conclusion, interest in water-soluble photoinitiators has been ongoing for almost half a century. Significant developments in medicine, including nanomedicine, promote the advancement of photopolymerization processes, as well as the necessary initiating systems in the near future. The currently available modern technologies of nanomedicine, such as targeted drug therapy, modern analysis and diagnostics of diseases, and the production of materials for cell or tissue culture, will require new and increasingly improved initiators that will meet all the criteria for the introduction of materials into the medical market.The development of water-soluble initiating systems is likely to take two directions. First, it will be based on the synthesis of completely new Type I or Type II photoinitiators, with a wide absorption range reaching the visible range and, additionally, fulfilling a number of other requirements, such as lack of cytotoxicity, biocompatibility and high initiation efficiency. Such photoinitiators can be applied, among others, in the processes of in situ polymerization, in targeted drug delivery and in cell encapsulation, which may positively affect the treatment of some diseases, such as type I diabetes by the encapsulation of islets of Langerhans.The second direction of development is the study of two-photon photoinitiators (2PP), which will allow the effective production of hydrogel materials containing living cells with the use of 3D laser printing with extremely high resolution. The constant challenge is to obtain initiators with a simple and inexpensive synthesis path, the scale of which can be easily transferred to the industry.This literature review has presented previous achievements in the field of water-soluble initiators in biomedical applications and has pointed at likely development paths and potential applications of photopolymerization processes.

In conclusion, interest in water-soluble photoinitiators has been ongoing for almost half a century. Significant developments in medicine, including nanomedicine, promote the advancement of photopolymerization processes, as well as the necessary initiating systems in the near future. The currently available modern technologies of nanomedicine, such as targeted drug therapy, modern analysis and diagnostics of diseases, and the production of materials for cell or tissue culture, will require new and increasingly improved initiators that will meet all the criteria for the introduction of materials into the medical market.The development of water-soluble initiating systems is likely to take two directions. First, it will be based on the synthesis of completely new Type I or Type II photoinitiators, with a wide absorption range reaching the visible range and, additionally, fulfilling a number of other requirements, such as lack of cytotoxicity, biocompatibility and high initiation efficiency. Such photoinitiators can be applied, among others, in the processes of in situ polymerization, in targeted drug delivery and in cell encapsulation, which may positively affect the treatment of some diseases, such as type I diabetes by the encapsulation of islets of Langerhans.The second direction of development is the study of two-photon photoinitiators (2PP), which will allow the effective production of hydrogel materials containing living cells with the use of 3D laser printing with extremely high resolution. The constant challenge is to obtain initiators with a simple and inexpensive synthesis path, the scale of which can be easily transferred to the industry.This literature review has presented previous achievements in the field of water-soluble initiators in biomedical applications and has pointed at likely development paths and potential applications of photopolymerization processes.References

- Yusuf Yagci; Steffen Jockusch; Nicholas J. Turro; Photoinitiated Polymerization: Advances, Challenges, and Opportunities. Macromolecules 2010, 43, 6245-6260, 10.1021/ma1007545.

- Shunsuke Chatani; Christopher J. Kloxin; Christopher N. Bowman; The power of light in polymer science: photochemical processes to manipulate polymer formation, structure, and properties. Polymer Chemistry 2014, 5, 2187-2201, 10.1039/c3py01334k.

- Iwona Kamińska; Joanna Ortyl; Roman Popielarz; Mechanism of interaction of coumarin-based fluorescent molecular probes with polymerizing medium during free radical polymerization of a monomer. Polymer Testing 2016, 55, 310-317, 10.1016/j.polymertesting.2016.09.013.

- Katarzyna Kostrzewska; Joanna Ortyl; Robert Dobosz; Janina Kabatc; Squarylium dye and onium salts as highly sensitive photoradical generators for blue light. Polymer Chemistry 2017, 8, 3464-3474, 10.1039/C7PY00621G.

- Robert Liska; M. Schuster; R. Inführ; C. Turecek; C. Fritscher; B. Seidl; V. Schmidt; L. Kuna; Anja Haase; F. Varga; et al.Helga LichteneggerJ. Stampfl Photopolymers for rapid prototyping. Journal of Coatings Technology and Research 2007, 4, 505-510, 10.1007/s11998-007-9059-3.

- Ali Bagheri; Jianyong Jin; Photopolymerization in 3D Printing. ACS Applied Polymer Materials 2019, 1, 593-611, 10.1021/acsapm.8b00165.

- Wiktoria Tomal; Maciej Pilch; Chachaj- Brekiesz; Joanna Ortyl; Anna Chachaj-Brekiesz; Development of New High-Performance Biphenyl and Terphenyl Derivatives as Versatile Photoredox Photoinitiating Systems and Their Applications in 3D Printing Photopolymerization Processes. Catalysts 2019, 9, 827, 10.3390/catal9100827.

- Emilia Hola; Monika Topa; Anna Chachaj-Brekiesz; Maciej Pilch; Paweł Fiedor; Mariusz Galek; Joanna Ortyl; New, highly versatile bimolecular photoinitiating systems for free-radical, cationic and thiol–ene photopolymerization processes under low light intensity UV and visible LEDs for 3D printing application. RSC Advances 2020, 10, 7509-7522, 10.1039/c9ra10212d.

- John P Fisher; David Dean; Paul S. Engel; Antonios G. Mikos; Photoinitiated Polymerization of Biomaterials. Annual Review of Materials Research 2001, 31, 171-181, 10.1146/annurev.matsci.31.1.171.

- Biancamaria Baroli; Photopolymerization of biomaterials: issues and potentialities in drug delivery, tissue engineering, and cell encapsulation applications. Journal of Chemical Technology & Biotechnology 2006, 81, 491-499, 10.1002/jctb.1468.

- † Jeffrey W. Stansbury; Curing dental resins and composites by photopolymerization.. Journal of esthetic dentistry 2000, 12, 300-308, 10.1111/j.1708-8240.2000.tb00239.x.

- M. E. Khosroshahi; Mohammad Atai; M. S. Nourbakhsh; Photopolymerization of dental resin as restorative material using an argon laser. Lasers in Medical Science 2007, 23, 399-406, 10.1007/s10103-007-0487-1.

- S. H. Dickens; J. W. Stansbury; K. M. Choi; C. J. E. Floyd; Photopolymerization Kinetics of Methacrylate Dental Resins. Macromolecules 2003, 36, 6043-6053, 10.1021/ma021675k.

- Nicholas A. Peppas; J. Z. Hilt; A. Khademhosseini; Robert Langer; Hydrogels in Biology and Medicine: From Molecular Principles to Bionanotechnology. Advanced Materials 2006, 18, 1345-1360, 10.1002/adma.200501612.

- Jamie L. Ifkovits; Jason A. Burdick; Review: Photopolymerizable and Degradable Biomaterials for Tissue Engineering Applications. Tissue Engineering 2007, 13, 2369-2385, 10.1089/ten.2007.0093.

- Maya Gonen-Wadmany; Liat Oss-Ronen; Dror Seliktar; Protein–polymer conjugates for forming photopolymerizable biomimetic hydrogels for tissue engineering. Biomaterials 2007, 28, 3876-3886, 10.1016/j.biomaterials.2007.05.005.

- Amy E. Herr; Anup K. Singh; Photopolymerized Cross-Linked Polyacrylamide Gels for On-Chip Protein Sizing. Analytical Chemistry 2004, 76, 4727-4733, 10.1021/ac049686u.

- Qian Cao; Tobias Heil; Baris Kumru; Markus Antonietti; Bernhard V. K. J. Schmidt; Visible-light induced emulsion photopolymerization with carbon nitride as a stabilizer and photoinitiator. Polymer Chemistry 2019, 10, 5315-5323, 10.1039/c9py01157a.

- R. Censi; Tina Vermonden; M.J. Van Steenbergen; H. Deschout; K. Braeckmans; Stefaan C. De Smedt; Cornelus F. Van Nostrum; P. Di Martino; Wim E. Hennink; Photopolymerized thermosensitive hydrogels for tailorable diffusion-controlled protein delivery. Journal of Controlled Release 2009, 140, 230-236, 10.1016/j.jconrel.2009.06.003.

- J. Elisseeff; K. Anseth; D. Sims; W. McIntosh; M. Randolph; Robert Langer; Transdermal photopolymerization for minimally invasive implantation. Proceedings of the National Academy of Sciences 1999, 96, 3104-3107, 10.1073/pnas.96.6.3104.

- Qiang Ye; Jonggu Park; Elizabeth Topp; Paulette Spencer; Effect of photoinitiators on the in vitro performance of a dentin adhesive exposed to simulated oral environment. Dental Materials 2009, 25, 452-458, 10.1016/j.dental.2008.09.011.

- Kunio Ikemura; Takeshi Endo; A review of the development of radical photopolymerization initiators used for designing light-curing dental adhesives and resin composites.. Dental Materials Journal 2010, 29, 481-501, 10.4012/dmj.2009-137.

- Vinícius Esteves Salgado; Diogo Cavassoni; Ana Paula R. Gonçalves; Carmem Pfeifer; Rafael R. Moraes; Luis Felipe Schneider; Photoinitiator system and water effects on C=C conversion and solubility of experimental etch-and-rinse dental adhesives. International Journal of Adhesion and Adhesives 2017, 72, 6-9, 10.1016/j.ijadhadh.2016.09.001.

- Jason D. Clapper; Jessica M. Skeie; Robert F. Mullins; C. Allan Guymon; Development and characterization of photopolymerizable biodegradable materials from PEG–PLA–PEG block macromonomers. Polymer 2007, 48, 6554-6564, 10.1016/j.polymer.2007.08.023.

- Kemin Wang; Jian Lu; Ruixue Yin; Lu Chen; Shuang Du; Yan Jiang; Qiang Yu; Preparation and properties of cyclic acetal based biodegradable gel by thiol-ene photopolymerization. Materials Science and Engineering: C 2013, 33, 1261-1266, 10.1016/j.msec.2012.12.024.

- Frederik Claeyssens; Erol A. Hasan; Arune Gaidukeviciute; Demetra S. Achilleos; A. Ranella; Carsten Reinhardt; Aleksandr Ovsianikov; Xiao Shizhou; Costas Fotakis; Maria Vamvakaki; et al.Boris ChichkovMaria Farsari Three-Dimensional Biodegradable Structures Fabricated by Two-Photon Polymerization. Langmuir 2009, 25, 3219-3223, 10.1021/la803803m.

- Jennifer Elisseeff; Winnette McIntosh; Karen Fu; Torsten Blunk; Robert Langer; Controlled-release of IGF-I and TGF-β1 in a photopolymerizing hydrogel for cartilage tissue engineering. Journal of Orthopaedic Research 2001, 19, 1098-1104, 10.1016/s0736-0266(01)00054-7.

- Stephanie J. Bryant; Garret D. Nicodemus; Idalis Villanueva; Designing 3D Photopolymer Hydrogels to Regulate Biomechanical Cues and Tissue Growth for Cartilage Tissue Engineering. Pharmaceutical Research 2008, 25, 2379-2386, 10.1007/s11095-008-9619-y.

- Heyun Wang; Yakai Feng; Bo An; Wencheng Zhang; Minglin Sun; Zichen Fang; Wenjie Yuan; Massuri Khan; Fabrication of PU/PEGMA crosslinked hybrid scaffolds by in situ UV photopolymerization favoring human endothelial cells growth for vascular tissue engineering. Journal of Materials Science: Materials in Electronics 2012, 23, 1499-1510, 10.1007/s10856-012-4613-7.

- Aleksander Skardal; Jianxing Zhang; Lindsi McCoard; Xiaoyu Xu; Siam Oottamasathien; Glenn D. Prestwich; Photocrosslinkable Hyaluronan-Gelatin Hydrogels for Two-Step Bioprinting. Tissue Engineering Part A 2010, 16, 2675-2685, 10.1089/ten.tea.2009.0798.

- Chao Zhong; Jun Wu; C.A. Reinhart-King; C. C. Chu; Cynthia A. Reinhart-King; Synthesis, characterization and cytotoxicity of photo-crosslinked maleic chitosan–polyethylene glycol diacrylate hybrid hydrogels. Acta Biomaterialia 2010, 6, 3908-3918, 10.1016/j.actbio.2010.04.011.

- Di Zhou; Yoshihiro Ito; Visible light-curable polymers for biomedical applications. Science China Chemistry 2014, 57, 510-521, 10.1007/s11426-014-5069-z.

- Jennifer L. West; Jeffrey A. Hubbell; Comparison of covalently and physically cross-linked polyethylene glycol-based hydrogels for the prevention of postoperative adhesions in a rat model. Biomaterials 1995, 16, 1153-1156, 10.1016/0142-9612(95)93579-3.

- Ilse De Paepe; Heidi Declercq; Maria Cornelissen; Etienne Schacht; Novel hydrogels based on methacrylate-modified agarose. Polymer International 2002, 51, 867-870, 10.1002/pi.945.

- Ine Van Nieuwenhove; Sandra Van Vlierberghe; Achim Salamon; Kirsten Peters; Hugo Thienpont; Peter Dubruel; Photo-crosslinkable biopolymers targeting stem cell adhesion and proliferation: the case study of gelatin and starch-based IPNs. Journal of Materials Science: Materials in Electronics 2015, 26, 1-8, 10.1007/s10856-015-5424-4.

- Jinho Hyun; Ashutosh Chilkoti; Surface-Initiated Free Radical Polymerization of Polystyrene Micropatterns on a Self-Assembled Monolayer on Gold. Macromolecules 2001, 34, 5644-5652, 10.1021/ma002125u.

- Christian Heller; Martin Schwentenwein; Günter Russmüller; Thomas Koch; Doris Moser; Christian Schopper; Franz Varga; Jürgen Stampfl; Robert Liska; Vinylcarbonates and vinylcarbamates: Biocompatible monomers for radical photopolymerization. Journal of Polymer Science Part A: Polymer Chemistry 2010, 49, 650-661, 10.1002/pola.24476.

- Mustafa Uygun; Muhammet Kahveci; Dilek Odaci; Suna Timur; Yusuf Yagci; Antibacterial Acrylamide Hydrogels Containing Silver Nanoparticles by Simultaneous Photoinduced Free Radical Polymerization and Electron Transfer Processes. Macromolecular Chemistry and Physics 2009, 210, 1867-1875, 10.1002/macp.200900296.

- Jennifer H. Ward; Nicholas A. Peppas; Preparation of controlled release systems by free-radical UV polymerizations in the presence of a drug.. Journal of Controlled Release 2001, 71, 183-192, 10.1016/s0168-3659(01)00213-9.

- Joanna Ortyl; Jarosław Wilamowski; Piotr Milart; Mariusz Galek; Roman Popielarz; Relative sensitization efficiency of fluorescent probes/sensitizers for monitoring and acceleration of cationic photopolymerization of monomers. Polymer Testing 2015, 48, 151-159, 10.1016/j.polymertesting.2015.10.006.

- Joanna Ortyl; Piotr Milart; Roman Popielarz; Applicability of aminophthalimide probes for monitoring and acceleration of cationic photopolymerization of epoxides. Polymer Testing 2013, 32, 708-715, 10.1016/j.polymertesting.2013.03.009.

- Kytai Truong Nguyen; Jennifer L. West; Photopolymerizable hydrogels for tissue engineering applications. Biomaterials 2002, 23, 4307-4314, 10.1016/s0142-9612(02)00175-8.

- R. A. A. Upul Ranaweera; Schuman P. Thomas; Rongpeng Wang; Bradley D. Miller; Kathleen V. Kilway; Effect of moisture on cationic polymerization of silicone epoxy monomers. Journal of Applied Polymer Science 2015, 132, 41831, 10.1002/app.41831.

- P. Barker; J. T. Guthrie; M. J. Davis; A. A. Godfrey; P. N. Green; Sensitized photoinitiated grafting of N-vinyl-2-prrolidone (NVP) to woolen substrates. Journal of Applied Polymer Science 1981, 26, 521-527, 10.1002/app.1981.070260212.

- Aleksandr Ovsianikov; Andrea Deiwick; Sandra Van Vlierberghe; Peter Dubruel; Lena Möller; Gerald Dräger; Boris Chichkov; Laser Fabrication of Three-Dimensional CAD Scaffolds from Photosensitive Gelatin for Applications in Tissue Engineering. Biomacromolecules 2011, 12, 851-858, 10.1021/bm1015305.

- Xiaojun Wan; Yuxia Zhao; Jianqiang Xue; Feipeng Wu; Xiangyun Fang; Water-soluble benzylidene cyclopentanone dye for two-photon photopolymerization. Journal of Photochemistry and Photobiology A: Chemistry 2009, 202, 74-79, 10.1016/j.jphotochem.2008.10.029.

- Zhiquan Li; Jan Torgersen; Aliasghar Ajami; Severin Mühleder; Xiao-Hua Qin; Wolfgang Husinsky; Wolfgang Holnthoner; Aleksandr Ovsianikov; Jürgen Stampfl; Robert Liska; et al. Initiation efficiency and cytotoxicity of novel water-soluble two-photon photoinitiators for direct 3D microfabrication of hydrogels. RSC Advances 2013, 3, 15939, 10.1039/c3ra42918k.

- Thomas Weiß; Gerhard Hildebrand; Ronald Schade; Klaus Liefeith; Thomas Weiß; Two-Photon polymerization for microfabrication of three-dimensional scaffolds for tissue engineering application. Engineering in Life Sciences 2009, 9, 384-390, 10.1002/elsc.200900002.

- Bruce A. Reinhardt; Lawrence L. Brott; Stephen J. Clarson; Ann G. Dillard; Jayprakash C. Bhatt; Ramamurthi Kannan; Lixiang Yuan; Guang S. He; Paras N. Prasad; Highly Active Two-Photon Dyes: Design, Synthesis, and Characterization toward Application. Chemistry of Materials 1998, 10, 1863-1874, 10.1021/cm980036e.

- Han Young Woo; Janice W. Hong; Bin Liu; Alexander Mikhailovsky; Dmitry Korystov; Guillermo C. Bazan; Water-Soluble [2.2]Paracyclophane Chromophores with Large Two-Photon Action Cross Sections. Journal of the American Chemical Society 2005, 127, 820-821, 10.1021/ja0440811.

- Maximilian Tromayer; Ágnes Dobos; Peter Gruber; Aliasghar Ajami; Roman Dědic; Aleksandr Ovsianikov; Robert Liska; A biocompatible diazosulfonate initiator for direct encapsulation of human stem cells via two-photon polymerization. Polymer Chemistry 2018, 9, 3108-3117, 10.1039/c8py00278a.

- Benjamin D. Fairbanks; Michael Schwartz; Christopher N. Bowman; Kristi S. Anseth; Photoinitiated polymerization of PEG-diacrylate with lithium phenyl-2,4,6-trimethylbenzoylphosphinate: polymerization rate and cytocompatibility. Biomaterials 2009, 30, 6702-7, 10.1016/j.biomaterials.2009.08.055.

- Stephan Benedikt; Jieping Wang; Marica Markovic; Norbert Moszner; Kurt Dietliker; Aleksandr Ovsianikov; Hansjörg Grützmacher; Robert Liska; Highly efficient water-soluble visible light photoinitiators. Journal of Polymer Science Part A: Polymer Chemistry 2015, 54, 473-479, 10.1002/pola.27903.

- Georgina Müller; Michal Zalibera; Georg Gescheidt; Amos Rosenthal; Gustavo Santiso-Quiñones; Kurt Dietliker; Hansjörg Grützmacher; Simple One-Pot Syntheses of Water-Soluble Bis(acyl)phosphane Oxide Photoinitiators and Their Application in Surfactant-Free Emulsion Polymerization. Macromolecular Rapid Communications 2015, 36, 553-557, 10.1002/marc.201400743.

- Paola Occhetta; Roberta Visone; Laura Russo; Laura Cipolla; Matteo Moretti; Marco Rasponi; VA-086 methacrylate gelatine photopolymerizable hydrogels: A parametric study for highly biocompatible 3D cell embedding. Journal of Biomedical Materials Research Part A 2014, 103, 2109-2117, 10.1002/jbm.a.35346.

- Seda Kızılel; Victor H. Perez-Luna; Fouad Teymour; Seda Kizilel; Photopolymerization of Poly(Ethylene Glycol) Diacrylate on Eosin-Functionalized Surfaces. Langmuir 2004, 20, 8652-8658, 10.1021/la0496744.

- Elbadawy A. Kamoun; Andreas Winkel; Michael Eisenburger; Henning Menzel; Carboxylated camphorquinone as visible-light photoinitiator for biomedical application: Synthesis, characterization, and application. Arabian Journal of Chemistry 2016, 9, 745-754, 10.1016/j.arabjc.2014.03.008.

- R. R. Batchelor; G. Kwandou; Patrick T. Spicer; Martina H. Stenzel; (-)-Riboflavin (vitamin B2) and flavin mononucleotide as visible light photo initiators in the thiol–ene polymerisation of PEG-based hydrogels. Polymer Chemistry 2017, 8, 980-984, 10.1039/C6PY02034H.

- Sajjad Dadashi-Silab; Cansu Aydogan; Yusuf Yagci; Shining a light on an adaptable photoinitiator: advances in photopolymerizations initiated by thioxanthones. Polymer Chemistry 2015, 6, 6595-6615, 10.1039/C5PY01004G.

- Stephanie J. Bryant; Charles R. Nuttelman; Kristi S. Anseth; Cytocompatibility of UV and visible light photoinitiating systems on cultured NIH/3T3 fibroblasts in vitro.. Journal of Biomaterials Science, Polymer Edition 2000, 11, 439-457, 10.1163/156856200743805.

- Andrit Allushi; Ceren Kütahya; Cansu Aydogan; Johannes Kreutzer; Gorkem Yilmaz; Yusuf Yagci; Conventional Type II photoinitiators as activators for photoinduced metal-free atom transfer radical polymerization. Polymer Chemistry 2017, 8, 1972-1977, 10.1039/C7PY00114B.

- Adina I. Ciuciu; Piotr J. Cywiński; Two-photon polymerization of hydrogels – versatile solutions to fabricate well-defined 3D structures. RSC Advances 2014, 4, 45504-45516, 10.1039/c4ra06892k.

- Anna Eibel; David E. Fast; Georg Gescheidt; Choosing the ideal photoinitiator for free radical photopolymerizations: predictions based on simulations using established data. Polymer Chemistry 2018, 9, 5107-5115, 10.1039/c8py01195h.

- Frederic Dumur; Recent advances on carbazole-based photoinitiators of polymerization. European Polymer Journal 2020, 125, 109503, 10.1016/j.eurpolymj.2020.109503.

- Junyi Zhou; Xavier Allonas; Ahmad Ibrahim; Xiaoxuan Liu; Progress in the development of polymeric and multifunctional photoinitiators. Progress in Polymer Science 2019, 99, 101165, 10.1016/j.progpolymsci.2019.101165.

- D. J. Lougnot; C. Turck; J. P. Fouassier; Water-soluble polymerization initiators based on the thioxanthone structure: a spectroscopic and laser photolysis study. Macromolecules 1989, 22, 108-116, 10.1021/ma00191a022.

- Itsuro Tomatsu; Ke Peng; Alexander Kros; Photoresponsive hydrogels for biomedical applications. Advanced Drug Delivery Reviews 2011, 63, 1257-1266, 10.1016/j.addr.2011.06.009.

- Xiao-Hua Qin; Aleksandr Ovsianikov; Jürgen Stampfl; Robert Liska; Additive manufacturing of photosensitive hydrogels for tissue engineering applications. BioNanoMaterials 2014, 15, 49-70, 10.1515/bnm-2014-0008.

- Andrea M. Kasko; Darice Y Wong; Two-photon lithography in the future of cell-based therapeutics and regenerative medicine: a review of techniques for hydrogel patterning and controlled release. Future Medicinal Chemistry 2010, 2, 1669-1680, 10.4155/fmc.10.253.

- Tugce Nur Eren; Jacques Lalevée; Duygu Avci; Water soluble polymeric photoinitiator for dual-curing of acrylates and methacrylates. Journal of Photochemistry and Photobiology A: Chemistry 2020, 389, 112288, 10.1016/j.jphotochem.2019.112288.

- Molamma P. Prabhakaran; J. Venugopal; Dan Kai; Seeram Ramakrishna; Biomimetic material strategies for cardiac tissue engineering. Materials Science and Engineering: C 2011, 31, 503-513, 10.1016/j.msec.2010.12.017.

- Jane Ru Choi; Kar Wey Yong; Jean Yu Choi; Alistair C Cowie; Recent advances in photo-crosslinkable hydrogels for biomedical applications. BioTechniques 2019, 66, 40-53, 10.2144/btn-2018-0083.

- Saburo Fukui; Kenji Sonomoto; Nobuya Itoh; Atsuo Tanaka; Several novel method for immobilization of enzymes, microbial cells and organelles. Biochimie 1980, 62, 381-386, 10.1016/s0300-9084(80)80169-6.

- J.F. Almeida; Paula Ferreira; A. Lopes; Maria Helena Gil; Photocrosslinkable biodegradable responsive hydrogels as drug delivery systems. International Journal of Biological Macromolecules 2011, 49, 948-954, 10.1016/j.ijbiomac.2011.08.010.

- E.B. Masurovsky; E.R. Peterson; Photo-reconstituted collagen gel for tissue culture substrates. Experimental Cell Research 1973, 76, 447-448, 10.1016/0014-4827(73)90399-6.

- Sien Lin; Wayne Yuk-Wai Lee; Qian Feng; Liangliang Xu; Bin Wang; Gene Chi Wai Man; Yuanfeng Chen; Xiaohua Jiang; Liming Bian; Liao Cui; et al.Bo WeiGang Li Synergistic effects on mesenchymal stem cell-based cartilage regeneration by chondrogenic preconditioning and mechanical stimulation.. Stem Cell Research & Therapy 2017, 8, 221, 10.1186/s13287-017-0672-5.

- Chaoliang He; Fengfu Li; Jae Il Ahn; Malcolm Latorre; May Griffith; Photo-induced in situ forming hydrogels based on collagen and a biocompatible macromolecular photoinitiator. Journal of Controlled Release 2011, 152, e207-e208, 10.1016/j.jconrel.2011.09.012.

- Jin Geng; Weishuo Li; Yichuan Zhang; Neelima Thottappillil; Jessica Clavadetscher; Annamaria Lilienkampf; Mark Bradley; Radical polymerization inside living cells. Nature Chemistry 2019, 11, 578-586, 10.1038/s41557-019-0240-y.

- Jianmin Yang; Jingchao Li; Xinlong Wang; Xiaomeng Li; Naoki Kawazoe; Guoping Chen; Single mammalian cell encapsulation by in situ polymerization.. Journal of Materials Chemistry B 2016, 4, 7662-7668, 10.1039/c6tb02491b.

- Stephanie K. Seidlits; Christine E. Schmidt; Jason B. Shear; High-Resolution Patterning of Hydrogels in Three Dimensions using Direct-Write Photofabrication for Cell Guidance. Advanced Functional Materials 2009, 19, 3543-3551, 10.1002/adfm.200901115.

- Elli Käpylä; Tomáš Sedlačík; Dogu Baran Aydogan; Jouko Viitanen; Frantisek Rypacek; Minna Kellomäki; Direct laser writing of synthetic poly(amino acid) hydrogels and poly(ethylene glycol) diacrylates by two-photon polymerization. Materials Science and Engineering: C 2014, 43, 280-289, 10.1016/j.msec.2014.07.027.

- Guifang Gao; Tomo Yonezawa; Karen Hubbell; Guohao Dai; Xiaofeng Cui; Inkjet-bioprinted acrylated peptides and PEG hydrogel with human mesenchymal stem cells promote robust bone and cartilage formation with minimal printhead clogging. Biotechnology Journal 2015, 10, 1568-1577, 10.1002/biot.201400635.

- Zongjie Wang; Raafa Abdulla; Benjamin Parker; Roya Samanipour; Sanjoy Ghosh; Keekyoung Kim; A simple and high-resolution stereolithography-based 3D bioprinting system using visible light crosslinkable bioinks. Biofabrication 2015, 7, 045009, 10.1088/1758-5090/7/4/045009.

- B. Husár; M. Hatzenbichler; V. Mironov; R. Liska; J. Stampfl; Aleksandr Ovsianikov; Photopolymerization-based additive manufacturing for the development of 3D porous scaffolds. Biomaterials for Bone Regeneration 2014, 6, 149-201, 10.1533/9780857098104.2.149.

- Seda Kızılel; Erin Sawardecker; Fouad Teymour; Victor Perez Luna; Seda Kizilel; Sequential formation of covalently bonded hydrogel multilayers through surface initiated photopolymerization. Biomaterials 2006, 27, 1209-1215, 10.1016/j.biomaterials.2005.08.025.