Inorganic pyrophosphatase (PPase) is a ubiquitous enzyme that converts pyrophosphate (PPi) to phosphate and, in this way, controls numerous biosynthetic reactions that produce PPi as a byproduct. PPase activity is generally assayed by measuring the product of the hydrolysis reaction, phosphate. This reaction is reversible, allowing PPi synthesis measurements and making PPase an excellent model enzyme for the study of phosphoanhydride bond formation.

- pyrophosphate assay

- phosphate assay

- malachite green

- methyl green

- luciferase

- ATP sulfurylase

Note: The following contents are extract from your paper. The entry will be online only after author check and submit it.

1. Introduction

Inorganic pyrophosphatase (inorganic diphosphatase; EC 3.6.1.1; PPase) is a constitutive, highly specific enzyme that converts pyrophosphate (PP

), a byproduct and regulator of numerous biosynthetic reactions [1], into a metabolizable phosphate. Ubiquitous soluble PPases dissipate PP

energy as heat, whereas less common membrane-bound PPases use the energy to transport H

or Na

across lipid membranes [2][3]. Both PPase types can also catalyze the reverse reaction of PP

synthesis from P

, and this activity of membrane-bound PPases is also considered physiologically important [4][5]. Soluble PPases are additionally divided into two nonhomologous families—family I, known for nearly a hundred years and found in all kingdoms of life, and family II found in 1998 in prokaryotes [6][7]. Several nonspecific phosphatases also exhibit PPase-like activity [8][9][10].

Although the primary structures of the three groups of specific PPases are completely different, their mechanisms and active sites reveal close similarity, making these enzymes remarkable examples of convergent evolution. All PPases are Mg

-dependent enzymes, but family II PPases additionally require a transition metal ion (Mn

or Co

) for maximal activity [11]. In total, three to four metal ions per active site are required for PP

conversion [7]. These metal ions, coordinated by numerous protein carboxylates and substrate phosphates, play key roles in catalysis. PP

hydrolysis involves a direct attack of an activated water molecule on a phosphorus atom and a stepwise release of two phosphate molecules. The value of

for soluble PPases reaches 10

s

for PP

hydrolysis and 10

s

for PP

values for most PPases with PP

as substrate lie in the micromolar range.

PPase is generally assayed by measuring phosphate, the product of PP

hydrolysis. Depending on the task, PPase activity is assayed at sub-

PP

concentrations (in mechanistic studies) or a saturating PP

concentration (in high-throughput screening procedures). The former assay is more demanding concerning sensitivity because of the low

value, especially with family I and membrane PPases. Sensitivity is also the limiting factor in PP

synthesis studies because the equilibrium PP

⇆ 2P

is largely shifted to the right.

2. Continuous Low-Substrate Assay of PPi-Hydrolyzing Activity

The low value of the Michaelis constant of PPases makes it necessary to use highly sensitive assays in kinetic studies conducted at sub-

substrate concentrations. The assay currently used in our labs combines two approaches to achieve high sensitivity: first, it measures the formation of the intensively colored complex of 12-molibdophosphoric acid with a triphenylmethane dye, methyl green, and, second, it is continuous. The PPase reaction mixture and two-color reagents are continuously pumped off by a peristaltic pump and mixed, and the absorbance of the resulting solution is measured at 620 or 660 nm in a flow photometer. Even though the background absorbance is relatively high, it is automatically subtracted in this continuous assay mode, allowing the precise recording of much smaller changes in absorbance (P

concentration) compared to a fixed-time assay. The principal advantage of the methyl green dye in this application is its low tendency to deposit on the optical cuvette [12].

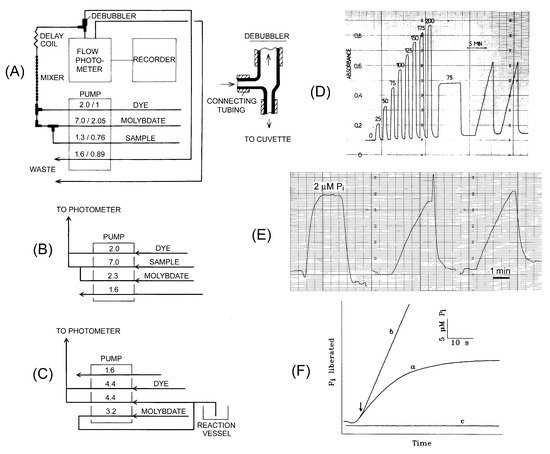

The phosphate analyzer consists of three main parts: a four-channel peristaltic pump, flow photometer, and paper recorder (

A). Alternatively, the photometer’s output can be directed to a computer, which calculates initial velocity from the absorbance time-course. However, we found that the manual procedure, using paper recordings, is less sensitive to signal fluctuations and provides more accurate data. We have used a four-channel Gilson Minipuls pump equipped with Tygon tubings. Three pump channels are used to deliver a sample, acid/molybdate, and dye/Triton X-305 solutions. Their initial mixing occurs in tubing T-joints and is completed in a mixing device consisting of a glass tube of 1.3 mm inner diameter with 12–15 bubbles of 3.5 mm inner diameter. The fourth pump channel eliminates any air bubbles from the final mixed solution before it is directed to the flow photometer. To prevent excessive air from entering the flow system, the pump is stopped when the sample inlet tubing is transferred between the samples and water. To ensure that the color reaction proceeds to completion, the time intervals between the two mixing events and between the second mixing event and entry to the photometer cuvette should be adjusted to 12 and 32 s, respectively, by using connecting tubings of appropriate diameter and length. The small nonlinearity of the calibration plot at low phosphate content is eliminated by adding a small amount of phosphate to the stock acid/molybdate solution. We have been using ISCO UA-5 and 229 flow photometers. These instruments are no longer produced but can be replaced by any flow photometer operating at 620–660 nm wavelengths and a flow rate of approximately 10 mL/min. Alternatively, one can use a standard spectrophotometer with a flow cuvette, such as a Helma model 178-010-10-40 (10 mm pathlength, 80 µL internal volume).

The phosphate analyzer is used to assay PPase activity in a continuous way. (

) Flow diagram for the phosphate analyzer in standard mode; (

) Tubing connections on the pump in the high-sensitivity mode; (

) tubing connections in the low dead-time mode. Numbers on the pump refer to flow rate in mL/min (before the slash) and tubing diameter in mm (panel A) or flow rate in mL/min (panels B and C). (

) Actual P

accumulation recordings in setup A with photometer sensitivity of 1 absorbance unit per recorder scale. The calibration data shown at the beginning of the recording was obtained by adding 0–200 µM P

to the reaction buffer. (

) Actual P

accumulation recordings in setup B with photometer sensitivity of 0.1 absorbance unit per recorder scale. The assay mixture of 40 mL volume contained 140 µM PP

, 5 mM MgCl

, 50 mM MOPS–KOH, pH 7.2, and 0.03 nM

PPase with a specific activity of 480 s

. (

) Actual recordings of P

accumulation in the setup C for rat liver PPase in the presence (a) or absence (b) of slow-binding inhibitor (10 mM fluoride). The arrow marks the moment of enzyme addition. Part of the figure was taken with permission from references [13] (panels A and D) and [14] (panels C and F).

Three setups of the phosphate analyzer were found useful for standard, high-sensitivity, and low dead-time measurements (

A–C). A five-fold increase in sensitivity was achieved in version B by interchanging the sample and molybdate tubings on the pump (

B). As the response is linear up to approximately 0.5 absorbance unit, the photometer sensitivity is adjusted to 0.5 absorbance unit per recorder scale in the standard mode (version A) and down to 0.1 unit in the high-sensitivity mode (version B). These settings correspond to approximately 100 and 4 µM P

, respectively, per recorder scale. As each PP

molecule yields 2 molecules of P

, this sensitivity is sufficient for a reliable measurement of initial velocities at PP

concentrations down to 0.5 µM (see

for further details). PPase concentration in the assay is typically in the pM range when activity is determined at saturating substrate concentrations and optimal pH and temperature values. We have successfully used the phosphate analyzer to determine PPase reaction kinetics over a broad temperature range (reaction mixture temperature 20–60 °C).

The dead-time between withdrawing the sample and mixing it with acid/molybdate is 10 s in the standard mode but can be decreased to 1 s by shifting the first mixing point to the pump inlet (

C). In this version, the sample is withdrawn from the reaction vessel at a rate of 1.2 mL/min due to differences in the two lowest pump tubes’ flow rates. This setup helps monitor reactions demonstrating nonlinear progress curves because of enzyme activation or inactivation during the reaction. Reagent concentrations were adjusted in versions B and C as indicated in

to ensure the same optimal final concentrations in the photometer cuvette.

Assays measuring PP

hydrolysis. Instrument setups for the continuous assay versions A–C are shown in

A–C.

| Assay Type and Procedure | Comments |

|---|---|

| Continuous, version A [13] Stock dye solution contains 80 mg/L methyl green and 3.4 g/L Triton X-305. Stock acid/molybdate solution contains 0.55 M H2SO4 (32 mL concentrated H2SO4 per 1 L final solution 1), 12 g/L ammonium molybdate, and 2 µM Pi. The mixing ratio sample: acid/molybdate:dye is 1.5:7:2. Washing solution: 0.1 M NaOH and 2 g/L Triton X-305. The enzymatic reaction is performed in a thermostated vessel with magnetic stirring at 10–60 °C; the reaction volume is typically 5 mL. |

Methyl green and Triton X-305 are from Sigma-Aldrich, ammonium molybdate from Fisher Scientific. Phosphate-free sulfuric acid (1.83 g/cm3) is used. When switching to a new batch of Triton X-305, its concentration may need adjustment to ensure linearity of the calibration plot and low baseline drift because of dye deposition on the photometer cuvette. |

| Continuous, version B [13] Stock dye solution contains 86 mg/L methyl green and 3.7 g/L Triton X-305. Stock acid/molybdate solution contains 1.8 M H2SO4 (105 mL concentrated H2SO4 per 1 L final solution), 39 g/L ammonium molybdate, and 7 µM Pi. The mixing ratio sample:acid/molybdate:dye is 7:2.3:2. The PPase reaction volume is typically 25–40 mL. |

Acid-resistant Iso-Versinic tubing is preferable on the pump for the acid/molybdate solution in this case. |

| Continuous, version C [14] Stock dye solution contains 30 mg/L methyl green and 1.3 g/L Triton X-305. Stock acid/molybdate solution contains 1.0 M H2SO4 (59 mL concentrated H2SO4 per 1 L final solution), 22 g/L ammonium molybdate, and 4 µM Pi. The mixing ratio sample: acid/molybdate:dye is 1.2:3.2:4.4. |

|

| Fixed-time [15,16][15][16] Stock dye/molybdate solution (stable for months in a refrigerator): 115 mg of malachite green are dissolved in 100 mL of 2.5 M H2SO4, followed by 1.4 g of ammonium molybdate. On the day of use, 0.25 mL of 10% Tween-20 (w/w) is added per 10 mL of the dye/molybdate solution. The PPase reaction is performed in a total volume of 0.2 mL in 96-well plates and terminated by adding 0.05 mL of the color reagent. Absorbance at 630 nm is measured after 10 min. |

Malachite green is from Sigma-Aldrich, Tween-20 from Ferak Berlin. Tween-20 (0.05%, w/w) can be added instead to the PPase assay mixture, which typically contains 0.05 M Tris-HCl or another buffer, 0.05 mM PPi, and 5 mM MgCl2. |

The continuous P

assay is robust and tolerates the presence of many biochemical compounds, including magnesium ions at high concentrations (up to 40 mM). In contrast, Mg

interferes with the P

assay based on 12-molibdophosphoric acid reduction [17]. Nevertheless, it is wise to calibrate the instrument by measuring phosphate standard against background each time when a new component is added to the sample assayed, especially when working in the high-sensitivity mode (version B). Importantly, PP

at high concentrations was found to suppress the P

signal (by 25% for 1.5 mM PP

) in this mode. This should be taken into consideration in measurements of PPase activity at a variable substrate concentration. The effect is proportional to PP

concentration and likely results from the competitive formation of 12-molibdopyrophosphoric acid, detected by Raman spectroscopy [18].

Other known continuous assays of PPase activity monitor, depending on pH, uptake or release of hydrogen ions during PP

conversion to P

concentration using synthetic PP

sensors [21][22][23][24][25]. These assays are less sensitive and less convenient in that the signal is not proportional to the degree of conversion.

Substances that modulate PPase activity will interfere with any assay. Among them, Tris and other amine buffers were found to dramatically increase the Michaelis constant for family I and membrane PPases [26][27][28]. Accordingly, zwitterionic buffers, such as Tes, Mops, and HEPES, are preferable for work at sub-

substrate concentrations. Tetramethylammonium hydroxide was found to be useful as the second component of the zwitterionic buffers in experiments measuring K

and Na

effects on K

-dependent membrane PPase. However, some batches of this strongly basic compound supplied in glass containers were found to nonspecifically inactivate this enzyme when used as a buffer component instead of KOH.

3. Sensitive Fixed-Time Assay of PPi-Hydrolyzing Activity

Fixed-time assays measuring the product P

are perhaps most suitable for high-throughput screening of compound libraries for the effects on PPase activity. Most published procedures determine P

as reduced 12-molybdophosphoric acid [29] and perform well with 10

–10

M P

concentrations. Although this sensitivity suffices for most applications, the identification of samples with low PPase activity or assays performed at low PP

concentrations (<10 µM) would require a more sensitive P

assay, such as the assay based on the shift of malachite green spectrum upon binding to 12-molybdophosphoric acid. However, low dye solubility, leading to its precipitation, was a serious drawback of the original malachite green-based procedure [30] and its many later variants.

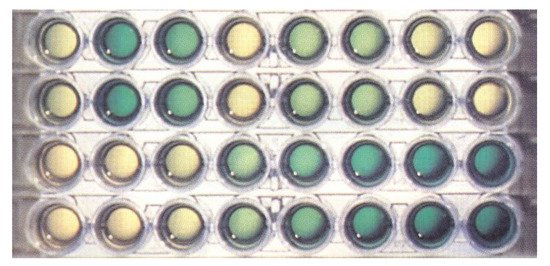

A solution to this problem was finding that increased acid concentration (2.5 M H

SO

) in stock dye solution surprisingly increases dye solubility and stability [15]. This finding allowed the formulation of a single stable color reagent that stops the enzymatic reaction and produces a green-blue color (630 nm), whose intensity is proportional to P

concentration. The color reagent is made daily by adding the nonionic detergent Tween-20 (color stabilizer) to the stock dye/molybdate solution (

). The signal produced by 2 µM P

(corresponding to 1 µM PP

hydrolyzed) is 0.15 absorbance units in a 1 cm cuvette. The assay can be performed in a 96-well plate (

) and quantified with a plate reader.

PPase assay using the malachite green procedure. Two bottom rows show a duplicate series of phosphate dilutions from 0 µM (left) to 10 µM (right). Two top rows show typical results of a duplicate screening test of a library of potential inhibitors of

PPase. The yellow color indicates strong inhibition, dark green color—no inhibition.

4. Continuous and Fixed-Time Assays of PPi-Synthesizing Activity

Like any catalyst, PPase accelerates the attainment of thermodynamic equilibrium PP

⇆ 2P

in both directions. Although the equilibrium is shifted to the right (∆G

= −20–25 kJ/mol), it allows the formation of measurable amounts of PP

under physiological conditions. For instance, the concentration of PP

at equilibrium with 10 mM P

(pH 7, 25 °C, 1 mM Mg

) is approximately 1 µM [31], which is below the detection limits of most analytical methods for PP

determination. However, micromolar sensitivity has been claimed for several assays based on fluorogenic and electrochemical PP

sensors [21][22][23][24][25]. Some of them are commercially available. However, they are of limited use in measurements of initial velocities of PP

synthesis, which require that PP

concentration in the medium does not exceed 10% of the equilibrium concentration to prevent product inhibition.

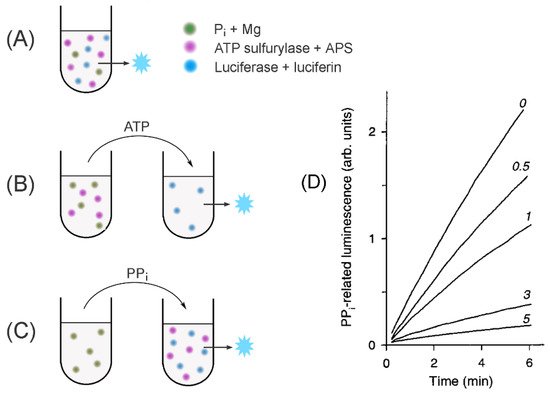

This problem is elegantly obviated in the coupled-enzyme luminescent procedure of Nyrén and Lundin [32], which later became a core element of “pyrosequencing”, a well-established DNA sequencing method [33]. In their procedure, PP

is converted to ATP by reaction with adenosine-5′-phosphosulfate (APS), catalyzed by ATP sulfurylase (E.C. 2.7.7.4), and the ATP formed is detected with a firefly luciferase/luciferin system. This method is used in three versions in PPase studies (

and

). In the first version, all components of the detection system, including ATP sulfurylase, luciferase, APS, and luciferin, are added to the PPase assay mix, and PP

formation is recorded continuously. This became possible because neither APS nor luciferin affects PPase activity, and both ATP sulfurylase and PPase need Mg

as a cofactor. The synthesized PP

is continuously converted into ATP at such a high rate that the steady-state PP

level is not inhibitory for PPase and luciferase activities. This is ensured by maintaining high ATP sulfurylase concentration, such that its doubling does not increase the measured rate of ATP accumulation. In the second assay version, the PPase reaction mix contains ATP sulfurylase/APS, which continuously converts the formed PP

into ATP, whose concentration is determined at fixed time points with luciferase/luciferin in a separate tube. Importantly, PPase does not hydrolyze ATP in the presence of Mg

. Both assay versions combine the high sensitivity of the luciferase ATP determination with the possibility to accumulate detectable amounts of ATP while keeping the steady-state concentration of PP

at a sub-equilibrium, non-inhibitory level. ATP sulfurylase and luciferase act thus as amplifiers of the PP

-generated signal and allow the measurement of the initial velocities of PP

synthesis from P

.

Schematics of the assays to measure PPase-catalyzed PP

synthesis. (

) A continuous assay of the medium PP

synthesis; (

) fixed-time assay of the medium PP

synthesis; (

) determination of enzyme-bound PP

. The assayed PPase is added to all far-left tubes. Three other major components are shown as colored spots. The principal analytes transferred between the tubes are indicated above the arrows. The blue star refers to the luminescence signal. (

) Actual PP

accumulation recordings in the assay version A for baker’s yeast PPase in the presence of slow-binding inhibitor (fluoride; its concentrations in mM are indicated on the curves). Panel D was taken with permission from reference [34].

Assays measuring PP

formation.

| Assay Type and Procedure | Comments |

|---|---|

| PPi synthesis (continuous) [34] Assay mixture contains calculated amounts of potassium phosphate and MgCl2, 0.7 U/mL ATP-sulfurylase, 10 µM APS, 5 µL of luciferin/luciferase solution (Sigma ATP assay mix, catalog no. FLAAM, reconstituted with 5 mL of water), 1 mM dithiothreitol, 0.8 mg/mL bovine serum albumin and 0.1 M MOPS–KOH buffer in a total volume of 0.2 mL. The reaction is initiated by adding PPase, and the time-course of luminescence is followed with a luminometer (e.g., LKB model 1250). After the PPi-generated signal stabilizes, 2 µL of 10 µM ATP are added for internal calibration. |

ATP sulfurylase is from BioLabs (UK). Its concentration should be sufficiently high so that its doubling does not change the measured rate of ATP accumulation. The luminescence-versus-time dependencies are slightly curved because of the slow inactivation of luciferase in the reaction medium. |

| PPi synthesis (fixed-time) [35] Assay mixture contains calculated amounts of potassium phosphate and MgCl2, 0.7 U/mL ATP-sulfurylase, 10 µM APS, and 0.1 M MOPS–KOH buffer in a total volume of 100 µL. The reaction is initiated by adding PPase and carried out for 10 min. Aliquots (15 µL) are withdrawn at various times, quenched with 15 µL of 1 M trifluoroacetic acid, incubated for 4 min at room temperature, and neutralized with 15 µL of 1.5 M Tris. The ATP formed is quantitated by adding 10 µL of the mixture to 200 µL of 0.2 M Tris-HCl buffer, pH 8.0 containing 6 µL of the luciferin/luciferase solution (Sigma ATP assay mix, catalog No. FLAAAM, reconstituted with 5 mL of water) and measuring the luminescence. After the signal stabilizes, 2 µL of 10 µM ATP are added for internal calibration. |

Crystalline phosphoric acid (Fluka) is freed from PPi contamination as described in the text. |

| Enzyme-bound PPi formation [36] PPase (typically 20–100 µM) is preequilibrated with Pi and Mg2+ under appropriate conditions in a 50 µL volume and quenched with 10 µL of 5 M trifluoroacetic acid. After several minutes, precipitated protein is removed by centrifugation, a 10 µL aliquot of the supernatant is added to 0.2 mL of the PPi assay cocktail (0.2 M Tris-HCl, pH 8.0, 0.4 U/mL ATP sulfurylase, 10 µM APS, 6 µL of the luciferase/luciferin solution, 1 mM dithiothreitol, 0.8 mg bovine serum albumin, 30 µM EGTA), and the luminescence is recorded. After the signal stabilizes, 2 µL of 10 µM PPi are added for internal calibration. |

Determined PPi content refers to the sum of enzyme-bound and medium PPi. The latter is measured similarly but using a 100 times lower enzyme concentration and subtracted. |

The third version of the PP

assay accesses the equilibrium of the PP

⇆ 2P

reaction in the active site of PPase. This information is required to estimate the rate constants for individual steps of PPase catalysis [37][38]. This equilibrium is markedly shifted to the left by comparing the equilibrium in solution—up to 20% of enzyme-bound P

is converted to PP

[37][38]. To assay, the enzyme-bound PP

, the enzyme (20–100 µM) is incubated with P

and Mg

, inactivated by trifluoroacetic acid to release enzyme-bound PP

into solution, and an aliquot is taken to assay PP

using the coupled ATP sulfurylase/luciferase procedure.

Several comments on the assay procedure are appropriate. First, phosphoric acid and its salts are often contaminated with PP

, leading to high background luminescence. A low-PP

potassium phosphate can be prepared in the following way: phosphoric acid is diluted to 0.2 M with water, boiled for 3 h, and neutralized with KOH [39]. Second, low but significant background luminescence results from APS being a poor substrate for luciferase. Third, as P

is added in high concentrations, care should be taken to ensure the assay mixture’s desired pH. It is not enough to adjust to this value the pH of the stock P

solution because the formation of the MgHPO

complex from H

PO

upon mixing stock P

and Mg

solutions would cause acidification of the medium (by 0.10 pH unit with 50 mM P

, 5 mM Mg

in 0.1 M MOPS–KOH buffer, pH 7.2). This effect is compensated by adding an appropriate amount of KOH to the assay mixture. An Excel subroutine to calculate this amount, which depends on P

, Mg

, and H

concentrations and reaction volume, is available (

). Alternatively, one can adjust the pH of the stock P

solution used at each Mg

concentration to the value (above the desired assay pH) determined in a trial titration.

A different coupled-enzyme assay with similar characteristics has been described [40]. In this assay, PP

is converted to adenosine 5’-triphosphate (ATP) by pyruvate phosphate dikinase in the presence of its substrates, pyruvate phosphate and AMP. The ATP formed is similarly determined by the firefly luciferase reaction. The detection limit for PP

is approximately 10

M. The use of this assay in PPase studies has not yet been reported.

References

- Heinonen, J.K. Biological Role of Inorganic Pyrophosphate; Kluwer Academic Publishers: London, UK, 2001.

- Baykov, A.A.; Malinen, A.M.; Luoto, H.H.; Lahti, R. Pyrophosphate-fueled Na+ and H+ transport in prokaryotes Microbiol. Mol. Biol. Rev. 2013, 77, 267–276.

- Tsai, J.-Y.; Kellosalo, J.; Sun, Y.-J.; Goldman, A. Proton/sodium pumping pyrophosphatases: The last of the primary ion pumps. Curr. Opin. Struct. Biol. 2014, 27, 38–47.

- Gaxiola, R.A.; Regmi, K.; Paez-Valencia, J.; Pizzio, G.; Zhang, S. Plant H+-PPases: Reversible enzymes with contrasting functions dependent on membrane environment. Mol. Plant. 2016, 9, 317–319.

- Scholz-Starke, J.; Primo, C.; Yang, J.; Kandel, R.; Gaxiola, R.A.; Hirschi, K.D. The flip side of the Arabidopsis type I proton-pumping pyrophosphatase (AVP1): Using a transmembrane H+ gradient to synthesize pyrophosphate. J. Biol Chem. 2019, 294, 1290–1299.

- Baykov, A.A.; Cooperman, B.S.; Goldman, A.; Lahti, R. Cytoplasmic inorganic pyrophosphatases. Progr. Mol. Subcell. Biol. 1999, 23, 127–150.

- Kajander, T.K.; Kellosalo, J.; Goldman, A. Inorganic pyrophosphatases: One substrate, three mechanisms. FEBS Lett. 2013, 587, 1863–1869.

- Chappelet-Tordo, D.; Fosset, M.; Iwatsuba, M.; Gache, C.; Lazdunski, M. Intestinal alkaline phosphatase: Catalytic properties and half of the sites reactivity. Biochemistry 1974, 13, 1788–1795.

- Lee, H.S.; Cho, Y.; Kim, Y.-J.; Lho, T.O.; Cha, S.-S.; Lee, J.-H.; Kang, S.G. A novel inorganic pyrophosphatase in Thermococcus onnurineus NA1. FEMS Microbiol. Lett. 2009, 300, 68–74.

- Huang, H.; Patskovsky, Y.; Toro, R.; Farelli, J.D.; Pandya, C.; Almo, S.C.; Allen, K.N.; Dunaway-Mariano, D. Divergence of structure and function in the haloacid dehalogenase enzyme superfamily: Bacteroides thetaiotaomicron BT2127 is an inorganic pyrophosphatase. Biochemistry 2011, 50, 8937–8949.

- Baykov, A.A.; Anashkin, V.A.; Salminen, A.; Lahti, R. Inorganic pyrophosphatases of Family II—two decades after their discovery. FEBS Lett. 2017, 591, 3225–3234.

- Van Belle, H. New and sensitive reaction for automatic determination of inorganic phosphate and its application to serum. Anal. Biochem. 1970, 33, 132–142.

- Baykov, A.A.; Avaeva, S.M. A simple and sensitive apparatus for continuous monitoring of orthophosphate in the presence of acid-labile compounds. Anal. Biochem. 1982, 116, 1–4.

- Baykov, A.A.; Alexandrov, A.P.; Smirnova, I.N. A two-step mechanism of fluoride inhibition of rat liver inorganic pyrophosphatase. Arch. Biochem. Biophys. 1992, 294, 238–243.

- Baykov, A.A.; Evtushenko, O.A.; Avaeva, S.M. A malachite green procedure for orthophosphate determination and its use in alkaline phosphatase-based enzyme immunoassay. Anal. Biochem. 1988, 171, 266–270.

- Baykov, A.A.; Kasho, V.N.; Avaeva, S.M. Inorganic pyrophosphatase as a label in heterogeneous enzyme immunoassay. Anal. Biochem. 1988, 171, 271–276.

- Vidilaseris, K.; Kellosalo, J.; Goldman, A. A high-throughput method for orthophosphate determination of thermostable membrane-bound pyrophosphatase activity. Anal. Methods 2018, 10, 646–651.

- Himeno, S.; Ueda, T.; Shiomi, M.; Hori, T. Raman studies on the formation of 12-molybdopyrophosphate. Inorg. Chim. Acta 1997, 262, 219–223.

- Cooperman, B.S.; Chiu, N.Y.; Bruckmann, R.H.; Bunick, G.J.; McKenna, G.P. Yeast inorganic pyrophosphatase. I. New methods of purification, assay, and crystallization. Biochemistry 1973, 12, 1665–1669.

- Shakhov, Y.A.; Nyrén, P. A sensitive and rapid method for determination of pyrophosphatase activity. Acta Chem. Scand. 1982, B36, 689–694.

- Kim, S.K.; Lee, D.H.; Hong, J.-I.; Yoon, J. Chemosensors for pyrophosphate. Acc. Chem. Res. 2009, 42, 23–31.

- Zeng, Z.; Torriero, A.A.J.; Bond, A.M.; Spiccia, L. Fluorescent and electrochemical sensing of polyphosphate nucleotides by ferrocene functionalised with two Zn(II)(TACN)(pyrene) complexes. Chem. Eur. J. 2010, 16, 9154–9163.

- Liu, D.J.; Credo, G.M.; Su, X.; Wu, K.; Lim, H.C.; Elibol, O.H.; Bashir, R.; Varma, M. Surface immobilizable chelator for label-free electrical detection of pyrophosphate. Chem. Commun. 2011, 47, 8310–8312.

- Terenteva, E.A.; Apyari, V.V.; Dmitrienko, S.G.; Garshev, A.V.; Volkov, P.A.; Zolotov, Y.A. Determination of pyrophosphate and sulfate using polyhexamethylene guanidine hydrochloride-stabilized silver nanoparticles. Talanta 2018, 180, 346–351.

- Lin, Y.; Hu, L.; Li, L.; Wang, K.; Ji, Y.; Zou, H. Electrochemical determination of pyrophosphate at nanomolar levels using a gold electrode covered with a cysteine nanofilm and based on competitive coordination of Cu(II) ion to cysteine and pyrophosphate. Microchim. Acta 2015, 182, 2069–2075.

- Baykov, A.A.; Hyytia, T.; Turkina, M.V.; Efimova, I.S.; Kasho, V.N.; Goldman, A.; Cooperman, B.S.; Lahti, R. Functional characterization of Escherichia coli inorganic pyrophosphatase in zwitterionic buffers. Eur. J. Biochem. 1999, 260, 308–317.

- Baykov, A.A.; Sergina, N.V.; Evtushenko, O.A.; Dubnova, E.B. Kinetic characterization of Rhodospirillum rubrum H+-pyrophosphatase in membrane-bound and isolated states. Eur. J. Biochem. 1996, 236, 121–127.

- Gordon-Weeks, R.; Korenkov, V.D.; Steele, S.H.; Leigh, R.A. Tris is a competitive inhibitor of K+ activation of the vacuolar H+-pumping pyrophosphatase. Plant. Physiol. 1997, 114, 901–905.

- Nagul, E.A.; McKelviea, I.D.; Worsfold, P.; Kolev, S.D. The molybdenum blue reaction for the determination of orthophosphate revisited: Opening the black box. Anal. Chim. Acta 2015, 890, 60–82.

- Itaya, K.; Ui, M. A new micromethod for the colorimetric determination of inorganic phosphate. Clin. Chim. Acta 1966, 14, 361–366.

- Flodgaard, H.; Fleron, P. Thermodynamic parameters for the hydrolysis of inorganic pyrophosphate at pH 7.4 as a function of [Mg2+], [K+], and ionic strength determined from equilibrium studies of the reaction. J. Biol. Chem. 1974, 249, 3465–3474.

- Nyrén, P.; Lundin, A. Enzymatic method for continuous monitoring of inorganic pyrophosphate synthesis. Anal. Biochem. 1985, 151, 504–509.

- Ronaghi, M.; Uhlén, M.; Nyrén, P. A sequencing method based on real-time pyrophosphate. Science 1998, 281, 363–365.

- Baykov, A.A.; Fabrichniy, I.P.; Pohjanjoki, P.; Zyryanov, A.B.; Lahti, R. Fluoride effects along the reaction pathway of pyrophosphatase. Evidence for a second enzyme⋅pyrophosphate intermediate. Biochemistry 2000, 39, 11939–11947.

- Belogurov, G.A.; Malinen, A.M.; Turkina, M.V.; Jalonen, U.; Rytkönen, K.; Baykov, A.A.; Lahti, R. Membrane-bound pyrophosphatase of Thermotoga maritima requires sodium for activity. Biochemistry 2005, 44, 4004–4010.

- Fabrichniy, I.P.; Kasho, V.N.; Hyytia, T.; Salminen, T.; Halonen, P.; Dudarenkov, V.Y.; Heikinheimo, P.; Chernyak, V.Y.; Goldman, A.; Lahti, R.; et al. Structural and functional consequenses of substitutions at the tyrosine 55-lysine 104 hydrogen bond in Escherichia coli inorganic pyrophosphatase. Biochemistry 1997, 36, 7746–7753.

- Springs, B.; Welsh, K.M.; Cooperman, B.S. Thermodynamics, kinetics, and mechanism in yeast inorganic pyrophosphatase catalysis of inorganic pyrophosphate: Inorganic phosphate equilibration. Biochemistry 1981, 20, 6384–6391.

- Baykov, A.A.; Shestakov, A.S.; Kasho, V.N.; Vener, A.V.; Ivanov, A.H. Kinetics and thermodynamics of catalysis by the inorganic pyrophosphatase of Escherichia coli in both directions. Eur. J. Biochem. 1990, 194, 879–887.

- Smirnova, I.N.; Kasho, V.N.; Volk, S.E.; Ivanov, A.H.; Baykov, A.A. Rates of elementary steps catalyzed by rat liver cytosolic and mitochondrial inorganic pyrophosphatases in both directions. Arch. Biochem. Biophys. 1995, 318, 340–348.

- Arakawa, H.; Karasawa, K.; Igarashi, T.; Suzuki, S.; Goto, N.; Maeda, M. Detection of cariogenic bacteria genes by a combination of allele-specific polymerase chain reactions and a novel bioluminescent pyrophosphate assay. Anal. Biochem. 2004, 333, 296–302.