Smart and precise agriculture has increasingly been developed in the last decade, and with that, the idea of optimizing the tools commonly used in this field for harvesting tasks. One way to improve these devices, particularly cutting tools conceived for harvesting purposes, is to measure the shear energy consumption required for a particular plant. The proposed methodology aims to establish both a design criterion for cutting grippers and a quantifiable way to evaluate and classify a harvesting tool for a specific crop.

- robotic harvesting

- grippers

- cutters

- energy efficiency

- shear energy

- aubergines

- eggplants

- brinjal

In the last 30 years, a large amount of research effort has focused on developing robots for automating harvesting processes. To achieve this goal, special emphasis has been placed on advancing general topics such as machine vision and detection systems

1. Introduction

In the last 30 years, a large amount of research effort has focused on developing robots for automating harvesting processes. To achieve this goal, special emphasis has been placed on advancing general topics such as machine vision and detection systems

, decision-making architectures

, autonomous navigation

and dexterous manipulation

. In addition, some authors have focused on automating the harvesting of specific crops, which can be divided into three main groups according to the characteristics of the crop stalk. The first group are those that can be harvested by an indirect mechanical movement towards the fruit through a force applied to the plant itself, such as the harvesting of olives

[19]

, almonds

[20]

and pistachio nuts

[21]

, and this process does not include direct contact with the stalk of the same. The second group are those that, due to the fragile structure of the plant, cannot be shaken but need a mechanical force to be applied to the fruit itself; these actions are also known as plucking patterns (e.g., twisting, pulling and bending) actions and cause the fruits to be loosened from their peduncles

[22]

. Examples from this group are the harvesting of strawberries

, apples

and tomatoes

. The final group are those that need a direct mechanical movement, or other type of cutting method, applied directly to the stalk, because due to their morphology, they are connected to the plant by a hard peduncle that must be cut, such as in the harvesting of aubergines

, melons

[33]

, oranges

[34]

, cucumbers

and peppers

[37][38]. The proposed design criterion is devoted for tools used to harvest this last group of fruits and vegetables that require a cutting process.

. The proposed design criterion is devoted for tools used to harvest this last group of fruits and vegetables that require a cutting process.

2. Specifics

Although different types of harvesting tools and cutting devices have been developed to collect fruit

[31][34][37][38][39][40][41][42][43]

, their designs have been accomplished empirically in many cases without considering the optimal design as an objective in itself. On the other hand, there are a multitude of patented tools in the market aimed at cutting the stalks of a wide range of plants

. Nevertheless, due to the private development of these tools, it is not possible to find in the literature any type of study or test carried out for their designs that details the performance or optimization of the required cutting energy. To increase the efficiency of these tools, implement new technologies, and provide a significant improvement in the agricultural sector, several researchers

[46]

have advocated for conducting experiments related to measuring the energy required to cut plant stalks. In this way, with quantifiable data and reliable conclusions, it will be feasible to redesign cutting machines to reduce their energy costs and increase their potential applicability in autonomous tasks

.

With all these facts in mind, a novel design criterion for robotic harvesting grippers based on an analysis of shear energy measurements and other mechanical properties of crop stalks, such as shear force and ultimate shear stress, is presented. The proposed criterion will enable not only the design of tools that will reduce the energy consumed in pursuit of increasing the autonomy of agricultural harvesting robots but also the testing and benchmarking of different harvesting tool designs.

For the cutting of peduncles, there are several techniques that can be classified into two groups: (i) techniques based on the bending characteristics of the stalk, such as the bending force, bending stress and Young’s modulus, and (ii) techniques based on the shear characteristics, such as the shear force, shear strength and shear energy.

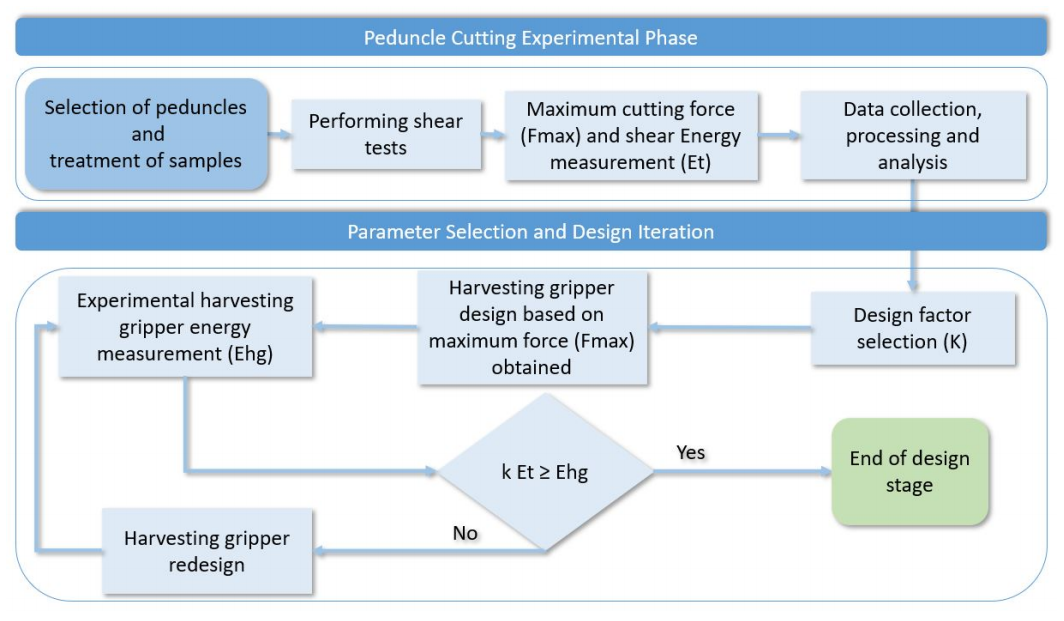

The proposed protocol brings together the knowledge and methods used by other authors for the study of the shear characteristics in agricultural applications. Furthermore, this protocol provides a design guide for cutting tools based on energy consumption minimization. Additionally, the protocol can be used as a classification framework based on its suitability for the crop to be harvested and can contribute to the advancement of the state of art in achieving more energy-efficient devices and classification methods. To summarize, this methodology is shown in

Figure 14 and listed as follows:

and listed as follows:

- First, the process begins with the definition of the fruit to be harvested. In this part, there must be certainty that the fruit cannot be harvested by another of the methods mentioned above, such as the indirect movement of the fruit through the plant or the direct movement of the fruit by pulling, bending or twisting. It has to be the case that the crop can be harvested by the cutting method. In this case, apart from the energy criterion, other criteria, such as not damaging the fruit or a post-processing criterion to remove the stalk, must be taken into account [21].

- Then, in the second step, relevant samples of the fruit peduncles are obtained, which must be collected and tested within a short period of time after they have been cut since it has been demonstrated that the moisture content directly affects the values obtained in the test, such as the peak load and the cutting energy [49].

- In the third step, the experiment of cutting the peduncles is carried out, following the protocol detailed in this article, which includes the experiences learned by other authors.

- In the fourth step, the maximum forces are obtained along with the shear energy, which can be estimated by applying the obtained measurements in the equations. After analysis of the data and verification of their homogeneity, a mathematical model can be found to fit the data obtained. Typically, the relationship between the shear energy and a section of the peduncle can provide an almost linear model. The task to select a design factor (\( k \)) applied to the minimum cutting energy (\( E_t \)Et) for the efficient design of the cutting tool will be left to the designer. An indicative criterion for the selection of this parameter is the one used in those plants in which the stems can be divided into nodes and internodes. In these cases, the design of the tool must be based on the maximum force (\( F_{max} \)) required to cut the largest node portion of the plant. This approach is reported to work well for the entire stalk, as it already includes the variation arising from the material (internode) and the size [50].

- Once the experimental model of the cutting gripper is obtained, the energy consumption of the harvesting gripper (\( E_{hg} \)) is measured and compared with \( E_t \) obtained from the performed cutting experiments; it is known that \( E_t \) can never be reached because the harvesting tool will be affected by factors such as friction between parts, the efficiency of the mechanism, and the performance of the electric motor or other electronic elements used to control it. If \( E_{hg} \) is greater than \( k*E_t \), the cutting gripper must be redesigned, taking into account the factors mentioned above.

- When a balance between the energy consumed and the cut-off energy determined by the design factor is achieved, the design stage based on the energy criteria is completed.

-

First, the process begins with the definition of the fruit to be harvested. In this part, there must be certainty that the fruit cannot be harvested by another of the methods mentioned above, such as the indirect movement of the fruit through the plant or the direct movement of the fruit by pulling, bending or twisting. It has to be the case that the crop can be harvested by the cutting method. In this case, apart from the energy criterion, other criteria, such as not damaging the fruit or a post-processing criterion to remove the stalk, must be taken into account [21].

-

Then, in the second step, relevant samples of the fruit peduncles are obtained, which must be collected and tested within a short period of time after they have been cut since it has been demonstrated that the moisture content directly affects the values obtained in the test, such as the peak load and the cutting energy[49].

-

In the third step, the experiment of cutting the peduncles is carried out, following the protocol detailed in this article, which includes the experiences learned by other authors.

-

In the fourth step, the maximum forces are obtained along with the shear energy, which can be estimated by applying the obtained measurements in the equations. After analysis of the data and verification of their homogeneity, a mathematical model can be found to fit the data obtained. Typically, the relationship between the shear energy and a section of the peduncle can provide an almost linear model. The task to select a design factor (k) applied to the minimum cutting energy (Et) for the efficient design of the cutting tool will be left to the designer. An indicative criterion for the selection of this parameter is the one used in those plants in which the stems can be divided into nodes and internodes. In these cases, the design of the tool must be based on the maximum force (Fmax) required to cut the largest node portion of the plant. This approach is reported to work well for the entire stalk, as it already includes the variation arising from the material (internode) and the size (Fmax).

-

Once the experimental model of the cutting gripper is obtained, the energy consumption of the harvesting gripper (Ehg) is measured and compared with Et obtained from the performed cutting experiments; it is known that Et can never be reached because the harvesting tool will be affected by factors such as friction between parts, the efficiency of the mechanism, and the performance of the electric motor or other electronic elements used to control it. If\( E_{hg} \) is greater than\( k*E_t \), the cutting gripper must be redesigned, taking into account the factors mentioned above.

-

When a balance between the energy consumed and the cut-off energy determined by the design factor is achieved, the design stage based on the energy criteria is completed.

Therefore, this study has focused on the cutting tools that are implemented in harvesting robots since until now, there has been no design methodology for these types of tools. The proposed design criterion can be crucial for reducing the energy consumption of these tools and for increasing the efficiency of harvesting robots.

On the other hand, this study could also contribute to realistically estimating the environmental footprint. In the manufacturing sector, the environmental footprint is calculated based on average energy consumption and is reflected in environmental impact databases. As a result, these values are highly inaccurate and give distorted figures to life cycle assessment practitioners .

On the other hand, this study could also contribute to realistically estimating the environmental footprint. In the manufacturing sector, the environmental footprint is calculated based on average energy consumption and is reflected in environmental impact databases. As a result, these values are highly inaccurate and give distorted figures to life cycle assessment practitioners.

Finally, the proposed protocol is intended to be a guide for the designers of robotic cutting end-effectors and cutting tools for harvesting, as well as a way to determine the suitability of the cutting tools for the plants to be harvested.

References

- Roemi Fernández; Héctor Montes; Carlota Salinas; Javier Sarria; Manuel Armada; Combination of RGB and Multispectral Imagery for Discrimination of Cabernet Sauvignon Grapevine Elements. Sensors 2013, 13, 7838-7859, 10.3390/s130607838.

- Roemi Fernández; Carlota Salinas; Héctor Montes; Javier Sarria; Multisensory System for Fruit Harvesting Robots. Experimental Testing in Natural Scenarios and with Different Kinds of Crops. Sensors 2014, 14, 23885-23904, 10.3390/s141223885.

- Roemi Fernández; Héctor Montes; Carlota Salinas; VIS-NIR, SWIR and LWIR Imagery for Estimation of Ground Bearing Capacity. Sensors 2015, 15, 13994-14015, 10.3390/s150613994.

- Carlota Salinas; Roemi Fernández; Héctor Montes; Manuel Armada; A New Approach for Combining Time-of-Flight and RGB Cameras Based on Depth-Dependent Planar Projective Transformations. Sensors 2015, 15, 24615-24643, 10.3390/s150924615.

- Davinia Font; Tomàs Pallejà; Marcel Tresanchez; David Runcan; Javier Moreno; Dani Martínez; Mercè Teixidó; Jordi Palacín; A Proposal for Automatic Fruit Harvesting by Combining a Low Cost Stereovision Camera and a Robotic Arm. Sensors 2014, 14, 11557-11579, 10.3390/s140711557.

- S. S. Mehta; T. F. Burks; Vision-based control of robotic manipulator for citrus harvesting. Computers and Electronics in Agriculture 2014, 102, 146-158, 10.1016/j.compag.2014.01.003.

- Sergio Cubero; Maria Paz Diago; José Blasco; Javier Tardáguila; Borja Millán; Nuria Aleixos; A new method for pedicel/peduncle detection and size assessment of grapevine berries and other fruits by image analysis. Biosystems Engineering 2014, 117, 62-72, 10.1016/j.biosystemseng.2013.06.007.

- Sepúlveda D., Fernández R., Navas E., González-de-Santos P., Armada M. (2020) ROS Framework for Perception and Dual-Arm Manipulation in Unstructured Environments. In: Silva M., Luís Lima J., Reis L., Sanfeliu A., Tardioli D. (eds) Robot 2019: Fourth Iberian Robotics Conference. ROBOT 2019. Advances in Intelligent Systems and Computing, vol 1093. Springer, Cham. https://doi.org/10.1007/978-3-030-36150-1_12

- Rubens A Tabile; Eduardo P Godoy; Robson R. D Pereira; Giovana T Tangerino; Arthur J. V Porto; Ricardo Y Inamasu; Design and development of the architecture of an agricultural mobile robot. Engenharia Agrícola 2011, 31, 130-142, 10.1590/s0100-69162011000100013.

- Alejandro Agostini; Guillem Alenyà; Andreas Fischbach; Hanno Scharr; Florentin Wörgötter; Carme Torras; A cognitive architecture for automatic gardening. Computers and Electronics in Agriculture 2017, 138, 69-79, 10.1016/j.compag.2017.04.015.

- B. Zion; M. Mann; D. Levin; A. Shilo; D. Rubinstein; I. Shmulevich; Harvest-order planning for a multiarm robotic harvester. Computers and Electronics in Agriculture 2014, 103, 75-81, 10.1016/j.compag.2014.02.008.

- Pablo Gonzalez-De-Santos; Roemi Fernández; Delia Sepúlveda; Eduardo Navas; Luis Emmi; Manuel Armada; Field Robots for Intelligent Farms—Inhering Features from Industry. Agronomy 2020, 10, 1638, 10.3390/agronomy10111638.

- Ya Xiong; Yuanyue Ge; Lars Grimstad; Pål J. From; An autonomous strawberry‐harvesting robot: Design, development, integration, and field evaluation. Journal of Field Robotics 2019, 37, 202-224, 10.1002/rob.21889.

- R. Fernández; R. Aracil; M. Armada; Control de Tracción en Robots Móviles con Ruedas. Revista Iberoamericana de Automática e Informática industrial 2012, 9, 393-405, 10.1016/j.riai.2012.09.008.

- Navas E., Fernández R., Sepúlveda D., Armada M., Gonzalez-de-Santos P. (2020) Modular Dual-Arm Robot for Precision Harvesting. In: Silva M., Luís Lima J., Reis L., Sanfeliu A., Tardioli D. (eds) Robot 2019: Fourth Iberian Robotics Conference. ROBOT 2019. Advances in Intelligent Systems and Computing, vol 1093. Springer, Cham. https://doi.org/10.1007/978-3-030-36150-1_13

- Eduardo Navas; Roemi Fernández; Delia Sepúlveda; Manuel Armada; Pablo Gonzalez-De-Santos; Soft Grippers for Automatic Crop Harvesting: A Review. Sensors 2021, 21, 2689, 10.3390/s21082689.

- Yanbin Hua; Nairu Zhang; Xin Yuan; Lichun Quan; Jiangang Yang; Ken Nagasaka; Xin-Gen Zhou; Recent Advances in Intelligent Automated Fruit Harvesting Robots. The Open Agriculture Journal 2019, 13, 101-106, 10.2174/1874331501913010101.

- Delia Sepulveda; Roemi Fernandez; Eduardo Navas; Manuel Armada; Pablo Gonzalez-De-Santos; Robotic Aubergine Harvesting Using Dual-Arm Manipulation. IEEE Access 2020, 8, 121889-121904, 10.1109/access.2020.3006919.

- Nasini, L.; Proietti, P. Olive harvesting. In The Extra-Virgin Olive Oil Handbook; Wiley: Hoboken, NJ, USA, 2014; pp. 87–105.

- Polat, R.; Guner, M.; Dursun, E.; Erdogan, D.; Gezer, I.; Bilim, H.C. Mechanical harvesting of almond with an inertia type limb shaker. Asian J. Plant Sci. 2007, 6, 528–532.

- Polat, R.; Gezer, I.; Guner, M.; Dursun, E.; Erdogan, D.; Bilim, H.C. Mechanical harvesting of pistachio nuts. J. Food Eng. 2007, 79, 1131–1135.

- Fotios Dimeas; Dhionis V. Sako; Vassilis C. Moulianitis; Nikos A. Aspragathos; Design and fuzzy control of a robotic gripper for efficient strawberry harvesting. Robotica 2014, 33, 1085-1098, 10.1017/s0263574714001155.

- Shigehiko Hayashi; Kenta Shigematsu; Satoshi Yamamoto; Ken Kobayashi; Yasushi Kohno; Junzo Kamata; Mitsutaka Kurita; Evaluation of a strawberry-harvesting robot in a field test. Biosystems Engineering 2010, 105, 160-171, 10.1016/j.biosystemseng.2009.09.011.

- Zhao De-An; Lv Jidong; Ji Wei; Zhang Ying; Chen Yu; Design and control of an apple harvesting robot. Biosystems Engineering 2011, 110, 112-122, 10.1016/j.biosystemseng.2011.07.005.

- Baeten J., Donné K., Boedrij S., Beckers W., Claesen E. (2008) Autonomous Fruit Picking Machine: A Robotic Apple Harvester. In: Laugier C., Siegwart R. (eds) Field and Service Robotics. Springer Tracts in Advanced Robotics, vol 42. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-75404-6_51

- Jun Li; Manoj Karkee; Qin Zhang; Kehui Xiao; Tao Feng; Characterizing apple picking patterns for robotic harvesting. Computers and Electronics in Agriculture 2016, 127, 633-640, 10.1016/j.compag.2016.07.024.

- Davidson, J.R.; Silwal, A.; Hohimer, C.J.; Karkee, M.; Mo, C.; Zhang, Q. Proof-of-concept of a robotic apple harvester. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 634–639.

- Monta M., Kondo N., Ting K.C. (1998) End-Effectors for Tomato Harvesting Robot. In: Panigrahi S., Ting K.C. (eds) Artificial Intelligence for Biology and Agriculture. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-5048-4_1

- Yaguchi, H.; Nagahama, K.; Hasegawa, T.; Inaba, M. Development of an autonomous tomato harvesting robot with rotational plucking gripper. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 652–657.

- Zhiguo Li; Pingping Li; Hongling Yang; Yuqing Wang; Stability tests of two-finger tomato grasping for harvesting robots. Biosystems Engineering 2013, 116, 163-170, 10.1016/j.biosystemseng.2013.07.017.

- Yuanshen Zhao; Liang Gong; Chengliang Liu; Yixiang Huang; Dual-arm Robot Design and Testing for Harvesting Tomato in Greenhouse. IFAC-PapersOnLine 2016, 49, 161-165, 10.1016/j.ifacol.2016.10.030.

- Shigehiko Hayashi; Katsunobu Ganno; Yukitsugu Ishii; Itsuo Tanaka; Robotic Harvesting System for Eggplants. Japan Agricultural Research Quarterly: JARQ 2002, 36, 163-168, 10.6090/jarq.36.163.

- Yael Edan; D. Rogozin; T. Flash; G. E. Miles; Robotic melon harvesting. IEEE Transactions on Robotics and Automation 2000, 16, 831-835, 10.1109/70.897793.

- Giovanni Muscato; Michele Prestifilippo; Nunzio Abbate; Ivan Rizzuto; A prototype of an orange picking robot: past history, the new robot and experimental results. Industrial Robot: An International Journal 2005, 32, 128-138, 10.1108/01439910510582255.

- E.J. Van Henten; J. Hemming; B.A.J. Van Tuijl; J.G. Kornet; J. Meuleman; J. Bontsema; E.A. Van Os; An Autonomous Robot for Harvesting Cucumbers in Greenhouses. Autonomous Robots 2002, 13, 241-258, 10.1023/A:1020568125418.

- Roemi Fernández; Héctor Montes; Jelena Surdilovic; Dragojlub Surdilovic; Pablo Gonzalez-De-Santos; Manuel Armada; Dragoljub Surdilovic; Automatic Detection of Field-Grown Cucumbers for Robotic Harvesting. IEEE Access 2018, 6, 35512-35527, 10.1109/access.2018.2851376.

- C. Wouter Bac; Jochen Hemming; B.A.J. Van Tuijl; Ruud Barth; Ehud Wais; Eldert J. Van Henten; Performance Evaluation of a Harvesting Robot for Sweet Pepper. Journal of Field Robotics 2017, 34, 1123-1139, 10.1002/rob.21709.

- Christopher F. Lehnert; Andrew English; Christopher McCool; Adam W. Tow; Tristan Perez; Autonomous Sweet Pepper Harvesting for Protected Cropping Systems. IEEE Robotics and Automation Letters 2017, 2, 872-879, 10.1109/lra.2017.2655622.

- Marco Ceccarelli; Giorgio Figliolini; Erika Ottaviano; Antonio Simon Mata; Emilio Jimenez Criado; Designing a robotic gripper for harvesting horticulture products. Robotica 2000, 18, 105-111, 10.1017/s026357479900226x.

- E.J. Van Henten; B.A.J. Van Tuijl; J. Hemming; J.G. Kornet; J. Bontsema; E.A. Van Os; Field Test of an Autonomous Cucumber Picking Robot. Biosystems Engineering 2003, 86, 305-313, 10.1016/j.biosystemseng.2003.08.002.

- G. Mattiazzo; S. Mauro; T. Raparelli; M. Velardocchia; A fuzzy controlled pneumatic gripper for asparagus harvesting. Control Engineering Practice 1995, 3, 1563-1570, 10.1016/0967-0661(95)00166-r.

- Irie, N.; Taguchi, N.; Horie, T.; Ishimatsu, T. Asparagus harvesting robot coordinated with 3-D vision sensor. In Proceedings of the 2009 IEEE International Conference on Industrial Technology, Gippsland, VIC, Australia, 10–13 February 2009.

- Chatzimichali, A.P.; Georgilas, I.P.; Tourassis, V.D. Design of an advanced prototype robot for white asparagus harvesting. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 887–892.

- Pellenc, R. Trigger-Operated Portable Electric Tool. U.S. Patent 8,813,370, 26 August 2014.

- Schmid, A.E. Power Pruning Shears. U.S. Patent 3,178,816, 20 April 1965.

- Dongdong, D. Research on mechanics properties of crop stalks: A review. Int. J. Agric. Biol. Eng. 2016, 9, 10–19.

- Womac, A.; Yu, M.; Igathinathane, C.; Ye, P.; Hayes, D.; Narayan, S.; Sokhansanj, S.; Wright, L. Shearing characteristics of biomass for size reduction. ASAE Pap. 2005, 56058, 2–8.

- Hao Gan; Sunil Mathanker; Abdul Momin; Brendan Kuhns; Neal Stoffel; Alan Hansen; Tony Grift; Effects of three cutting blade designs on energy consumption during mowing-conditioning of Miscanthus Giganteus. Biomass and Bioenergy 2018, 109, 166-171, 10.1016/j.biombioe.2017.12.033.

- Ying Chen; Jean Louis Gratton; Jude Liu; Power Requirements of Hemp Cutting and Conditioning. Biosystems Engineering 2004, 87, 417-424, 10.1016/j.biosystemseng.2003.12.012.

- C. Igathinathane; A.R. Womac; S. Sokhansanj; Corn stalk orientation effect on mechanical cutting. Biosystems Engineering 2010, 107, 97-106, 10.1016/j.biosystemseng.2010.07.005.