Precision livestock farming (PLF) has developed and concerned the whole sector: from cattle to pigs, to poultry, achieving the best results in cattle farms, especially in dairy farms. The technology that is affecting various aspects of dairy cattle breeding is certainly near infrared spectroscopy (NIRS) which is versatile and can be used on line/in line to evaluate and control the critical points of the production process by entering the PAT (process analytical technology). In the barn, NIRS currently can obtain information on the chemical-physical composition of raw materials, total mixed ration (TMR), feces and digestibility, chemical and technological analysis of milk. All this in a short time by eliminating the waiting times for analysis response and costs, allowing an improvement of livestock management. Many studies affirm the validity of NIRS as a reliable and predictive technology against multiple relevant parameters in matrices such as raw feed, TMR, feces, and milk.

- near infrared spectroscopy

- NIRS

- portable NIRS

- dairy cow

- feeding

- in-farm analysis

1. Introduction

Undoubtedly, dairy cattle breeding is one of the most affected by PLF, since it is possible to obtain greater profitability and improvement of animal welfare [1]. Moreover, the adoption of PLF techniques allows to produce safety food with a reduced environmental impact [2].

Results of scientific research have clearly showed that improving animal welfare is an effective tool to increase profits by reducing costs related to poor animal health [3]. Furthermore, consumers are becoming more and more focused to purchase and even spending more for animal products obtained through the satisfaction of animal welfare and protection of the environment.

The main technological innovations have to take into account all aspects related to dairy farm, starting from the housing structures, environmental control, removal, treatment, and storage of livestock effluents, milking, individual milk yield and quality controls, up to the identification of individual animals. All these aspects are checked through sensors designed to acquire the ‘raw’ data of interest, which have to be managed and stored to be accessible. Currently, the challenge is to be able to get the largest amount of data automatically, quickly, and accurately and use machine learning (ML) or deep learning (DL), both based on the development of artificial neural networks (ANN), classification algorithms to have increasingly automatic, precise, and accurate farm management.

Precision feeding (PF) is an important part of PLF. Control and a more detailed knowledge of feeding is a very essential aspect, considering it represents more than half of the milk production costs for dairy cattle farms.

The 2019 data stated [4] that the estimated feeding costs to produce 100 kg of milk represents more than 45% of the total production costs, with a wide variability between the years due to the availability of raw materials. As an example, a peak of 60% of total expenses was reached in 2012–2013 (data referring to US companies). Recently, the volatility of the prices of concentrates has been recurrent in world markets [5]. Therefore, it is very important to avoid mistakes both in the formulation and in the distribution of the ration, since they may involve: digestive process inefficiency, production losses, worsening production quality, reduction of reproductive performance, increase of production costs, greater waste and environmental impact, animal health problems, worsening of well-being, and greater drug consumption.

2. The Use of Near Infrared Spectroscopy (NIRS) on Farms for the Management of Dairy Cows

Near infrared spectroscopy (NIRS) could be used on the farm in a PF system. It could be an economically viable system to provide the right amount of daily nutrients with fewer metabolic alterations by aiming for high efficiency of feed use [6]. Near infrared spectroscopy portable tools can be used on the barn directly, in “on-line” and “on-live” mode, allowing to obtain information in real-time avoiding the long waiting times for laboratory analysis responses, allowing a timely intervention of prevention and/or correction, as well as carrying out countless self-control analyzes.

Near infrared spectroscopy on the farm could be used to design, analyze, and control production processes/products based on continuous measurements over time, of critical quality and performance attributes of raw materials to ensure an acceptable quality of the final product. In this perspective, NIRS can be defined as an innovative process/product analytical technology, that can positively affect the ‘production process’ improving farm performances and then farmer welfare and income. According to the classification proposed by Knight et al. [7], who classified the sensors used in dairy cattle breeding in three categories, NIRS applied at the barn level is part of sensors defined as “Near Cow” and “From Cow”.

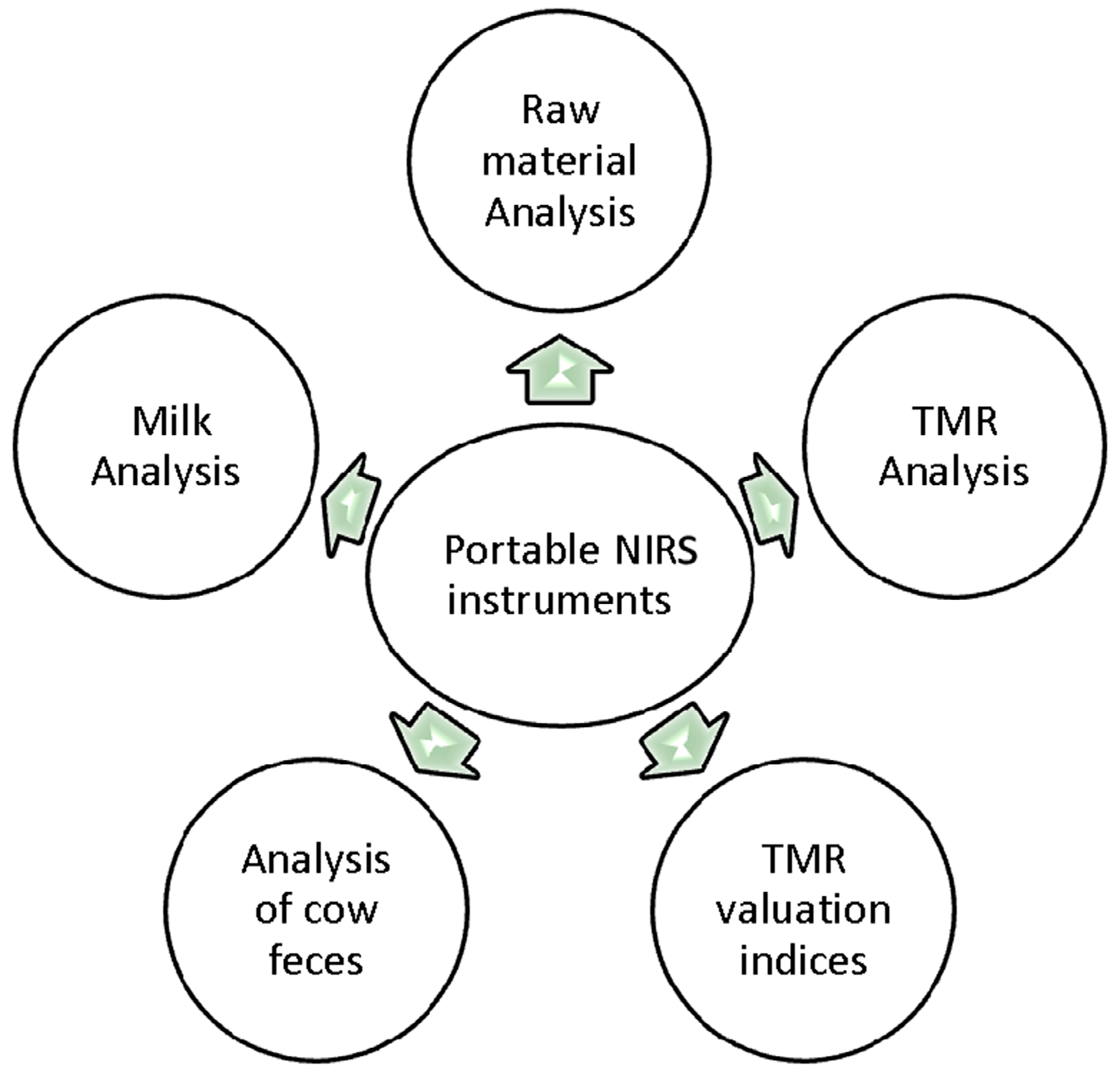

Currently, portable NIRS instruments are used for (Figure 1):

Figure 1. Schematic representation of portable NIRS instruments use in dairy farms.

Figure 1. Schematic representation of portable NIRS instruments use in dairy farms.

-

analysis of chemical composition of raw materials both in the field and in the loading phase of the mixer wagon;

-

analysis of chemical and physical constituents of the TMR;

-

analysis of TMR evaluation indices (homogeneity and selection);

-

analysis of chemical composition of feces, slurry, and manure;

-

on-line analysis of milk quality (total and individual) in the milking parlor.

Among the many PF technologies, the declination of NIRS to dairy cow feeding management, is undoubtedly one of the most promising. The use of portable NIR spectrophotometers to evaluate the physio-chemical composition of TMR and manure represent a recently introduced technology. Its application on raw materials, TMR, and feces can obtain, or derive, values and indices, that guide dairy farmer decisions to rapidly implement corrective or preventive actions for improving, or in any case keeping constant over time, the management of dairy farm. The reviewed literature showed that the use on barn NIRS, through appropriate calibrations, is a rapid and accurate analytical technique. The potential benefits, as widely discussed, are enormous.

The new solutions proposed for the control and management of TMR is the use of NIRS systems directly on the mixer wagon. Another advantage, which can be obtained using this tool, is the knowledge of the physical structure of TMR to estimate a homogeneity of distribution and selection index to optimize ruminal efficiency. Additionally, the determination in the barn of the chemical characteristics of feces may allow the estimation of diet digestibility. Moreover, spectroscopic analysis of milk in the milking parlor demonstrates to be a valid means to improve management on several aspects inherent to dairy cattle farming. In particular, the detection of some parameters in milk—such as progesterone, SCC, fat, proteins, etc.—during milking allows to monitor health, physiological, and reproductive status at the herd level or for individual cows, as well as to check milk chemical-bromatological and technological characteristics. Furthermore, the application of NIRS on AMS could be a valuable aid for a more specific control of individual cows, at each individual milking. The spread of AMS is therefore a useful means of improving milk-based controls at the individual level. So, NIRS instrumentation would be extremely useful to analyze all the critical control points in the management of dairy cattle allowing to improve animal welfare, production, reproduction, and sustainability; as well as the farmer’s income.

Limitations to the spread of these technologies in the contest of commercial farms includes the investment cost and the difficult amortization for the purchase of technologies, especially in small and medium farms where basic technologies are generally lacking. In addition, the advanced age of the breeders and the low rate of digital tech usage in agriculture sector compared to other sectors should be considered. Another limit is the need for calibration procedures, the management and interpretation of the data. It is therefore advisable to trust on specialized personnel. Therefore, assistance to the breeder is essential for the correct use of these new technologies and will be important for increasing on-farm use of NIRS techniques.

Further research should be carried out to open other fields of NIRS application that are not currently considered. Moreover, NIRS is being developed to be used on farm via smartphone with special apps to have “the technology at hand”.

References

- Mipaaf. Available online: (accessed on 25 October 2020).

- Berckmans, D. General introduction to precision livestock farming. Anim. Front. 2017, 7, 6–11.

- Cozzi, G.; Brscic, M.; Gottardo, F. Animal welfare as a pillar of a sustainable farm animal production. Acta Agric. 2008, 2, 23–31.

- Teseo. Available online: (accessed on 15 December 2020).

- De la Roza-Delgado, B.; Garrido-Varo, A.; Soldado, A.; Gonz’alezArrojo, A.; Cuevas Vald´es, M.; Maroto, F.; Pérez-Marínb, D. Matching portable NIRS instruments for in situ monitoring indicators of milk composition. Food Control 2017, 76, 74–81.

- Piccioli-Cappelli, F.; Calegari, F.; Calamari, L.; Bani, P.; Minuti, A. Application of a NIR device for precision feeding in dairy farms: Effect on metabolic conditions and milk production. Ital. J. Anim. Sci. 2019, 18, 1–12.

- Knight, C.H. Review: Sensor techniques in ruminants: More than fitness trackers. Animal 2020, 14, 187–195.