2. Vertical Type High Speed Twin Roll Caster

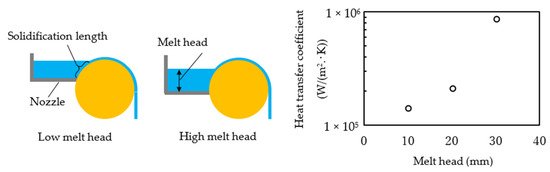

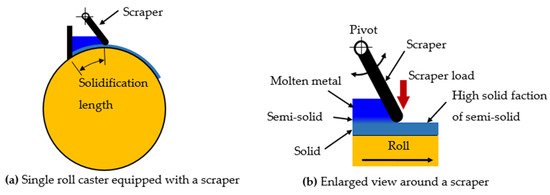

The effect of the melt head on the heat transfer coefficient between the molten metal (or solidification layer) and the roll was investigated using a melt-drag single-roll caster and Al-12 mass% Si. When the melt head was changed, the solidification length was kept constant by adjusting the position of the nozzle, as shown in

[13]. The heat transfer coefficient was calculated from the strip thickness and solidification time using the one-dimensional finite differential method. The heat transfer coefficient increased as the molten melt head became higher as shown in . The cooling rate increased as the heat transfer coefficient increased. The higher cooling rate is useful, for example, to make fine eutectic Si and the inter metallic compound included as impurities.

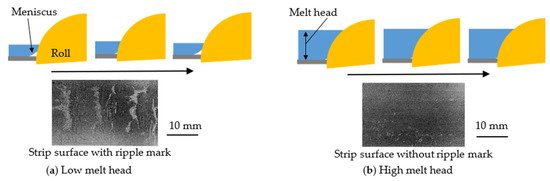

shows the effect of the melt head on the stability of the meniscus of molten metal and influence of the stability of the meniscus on ripple mark on the strip surface [13][14]. When the melt head is lower than the sufficient height, as shown in

shows the effect of the melt head on the stability of the meniscus of molten metal and influence of the stability of the meniscus on ripple mark on the strip surface [13,14]. When the melt head is lower than the sufficient height, as shown in a, the meniscus of the molten metal at the tip of the nozzle is unstable. The instability of the meniscus becomes worse as the roll speed becomes higher. The instability of the meniscus causes a ripple mark on the strip surface. When the melt head is sufficient height, the instability of the meniscus is suppressed by the hydrostatic pressure of the molten metal as shown in

b. As a result, the ripple mark was reduced, and the strip surface is improved greatly. A vertical type high speed twin roll caster (VHSTRC) was designed based on this these results shown in

and

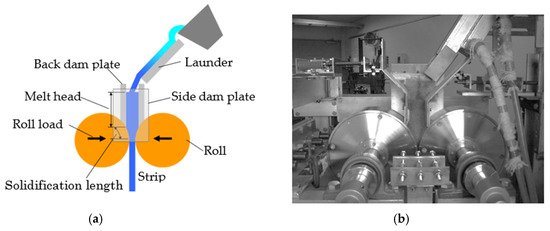

A schematic diagram of a VHSTRC and a close-up photograph near rolls are shown in

. The rolls of the CTRCA are made of steel for hot working. In the VHSTRC, rolls made of copper alloy are used. The thermal conductivity of the copper alloy is approximately seven times larger than that of the steel for hot working. Molten metal can be more rapidly solidified by the copper alloy roll as compared to the steel roll. Therefore, the roll speed can be increased. In the CTRCA, parting material is sprayed on the steel roll in order to prevent sticking of the strip to the roll. The parting material becomes heat resistance between the molten metal and the roll. The parting material decreases the heat transfer from the molten metal (or solidification layer) to the roll. As a result, the roll speed becomes low. In the VHSTRC, parting material is not used because the strip does not stick to the copper alloy roll [16]. The temperature of the surface of the copper alloy roll does not increase to the temperature at which fusion occurs as a result of the effect of the higher thermal conductivity. Non-use of the parting material is beneficial in terms of the rapid solidification of the molten metal. The strength of the copper alloy is lower than that of steel used for hot working. Therefore, the roll load of the VHSTRC is much smaller than that of the CTRCA. However, the VHSTRC can cast the strip without a higher roll load because the solidification layer is rapidly cooled using a copper alloy roll and non-use of a parting material. A small roll load is effective to prevent adhesion of the strip to the roll.

The back dam and side dam plates are essential to make melt pool and to use hydrostatic pressure in order to make the meniscus stable. The back dam plate has another important role. The back dam plate is useful to make the solidification length constant. A constant solidification length is needed to make strip thickness constant. When the back dam plate is not used, the surface position of molten metal must be controlled to be constant in order to keep the solidification length constant. It is not easy to keep the surface position constant. When the surface position changes, the solidification is kept constant if a back dam plate is used.

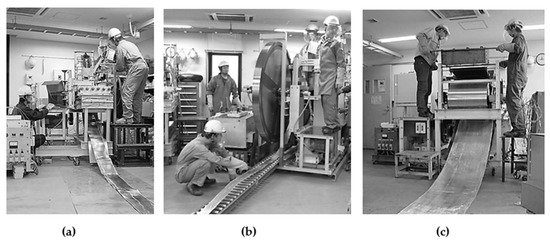

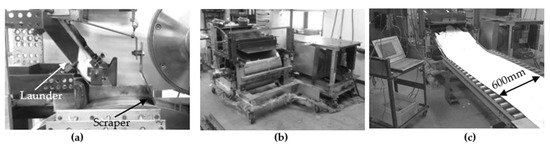

Photographs of casting being conducted using a VHSTRC of laboratory size are shown in

.

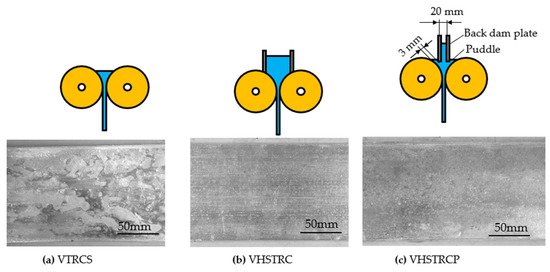

The effect of the back dam plate on the surface of the aluminum alloy strip is shown in

. In

a, the back dam plate is not used, and this is a vertical-type twin-roll caster for steel (VTRCS) [15]. b shows the VHSTRC. A mottled pattern existed on the strip surface cast using the VTRCS. A unique pattern did not appear on the strip surface cast using the VHSTRC. The back dam plate is useful to make the strip surface sound. In

c, the back dam plate does not contact the roll surface. The clearance between the tip of the back dam plate and the roll surface is approximately 3 mm to 5 mm. A puddle of molten metal exists between the roll surface and the outside of the back dam plate. The twin-roll caster of

c is a vertical-type high-speed twin-roll caster with puddle (VHSTRCP). The surface of the strip cast using the VHSTRCP was different from the surfaces of the strips cast using the VTRCS and the VHSTRC. The surface of the strip cast using the VHSTRCP is better than that cast using the VTRCS. In the surface of the strip cast using the VHSTRCP, there was no effect of the hydrostatic pressure by the molten metal on the meniscus at the contact starting point between the molten metal and the roll. In the VHSTRCP, when the clearance between the back plate and the roll surface was wider than 6 mm, the strip surface was near the strip surface cast using the VTRCS. This means that the narrow clearance between the tip of the back dam plate and the roll surface affected the contact condition between the molten metal and the roll surface. The contact-start point of the molten metal to the roll may be below the tip of the back dam plate. Some aluminum alloys were cast using the VHSTRC to test the ability of the VHSTRC, for example 3xxx, 5xxx, 6xxx, A356, A383 and Al-25%Si [16][17][18][19][20][21][22][23]. The VHSTRC could cast the strip of a magnesium alloy [24].

c is a vertical-type high-speed twin-roll caster with puddle (VHSTRCP). The surface of the strip cast using the VHSTRCP was different from the surfaces of the strips cast using the VTRCS and the VHSTRC. The surface of the strip cast using the VHSTRCP is better than that cast using the VTRCS. In the surface of the strip cast using the VHSTRCP, there was no effect of the hydrostatic pressure by the molten metal on the meniscus at the contact starting point between the molten metal and the roll. In the VHSTRCP, when the clearance between the back plate and the roll surface was wider than 6 mm, the strip surface was near the strip surface cast using the VTRCS. This means that the narrow clearance between the tip of the back dam plate and the roll surface affected the contact condition between the molten metal and the roll surface. The contact-start point of the molten metal to the roll may be below the tip of the back dam plate. Some aluminum alloys were cast using the VHSTRC to test the ability of the VHSTRC, for example 3xxx, 5xxx, 6xxx, A356, A383 and Al-25%Si [16,17,18,19,20,21,22,23]. The VHSTRC could cast the strip of a magnesium alloy [24].

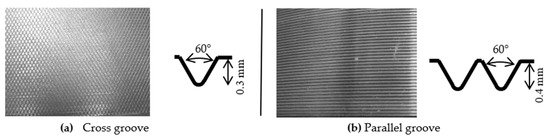

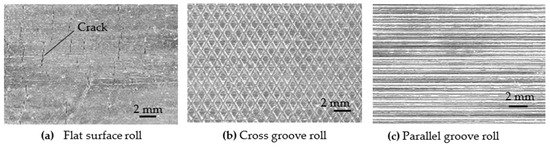

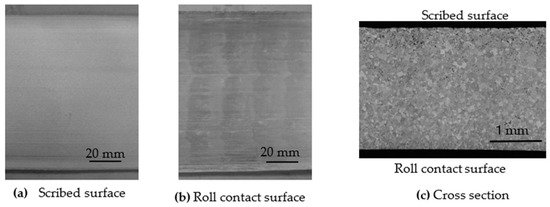

Effect of the condition of the roll surface on the crack at the strip surface was investigated [25]. The roll surface is usually flat. Casting of the strip using the rolls, which had the orientations shown in , was investigated. The orientations were cross groove and parallel groove. The surfaces of the strips cast using the rolls of

are shown in

. When a flat roll was used and 6061 aluminum alloy strip was cast, cracks occurred at the surface. It is estimated that the contact condition between the molten metal and the roll surface was not uniform, and cracks occurred at the solidification delay part by solidification shrinkage. When rolls with cross groove or parallel groove orientations were used for strip casting, cracking did not occur. The contact condition between the molten metal and the roll surface became uniform, and solidification delay did not occur. As a result, cracking did not occur.

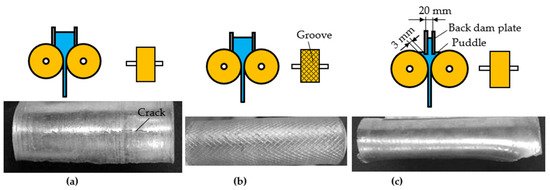

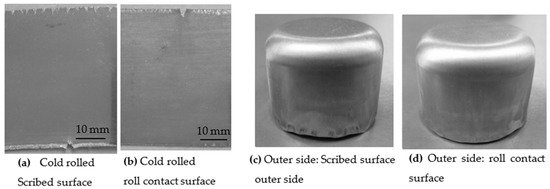

As-cast strips were bent, and the outer surfaces of the bent strip are shown in

. The crack did not occur at the surface of the 6022 strip cast using the VHSTRC, as in the 6061 strip shown in

a. However, in the 6022 strip with a radius of curvature of 10 mm, cracking occurred at the outer surface as shown in

a. On the other hand, for the 6022 strips cast using the VHSTRC with the cross groove roll and the VHSTRCP with the flat surface roll, cracking did not occur at the outer surface of the bent as-cast strip. Cracking occurred in an area of lower strength. In

b,c, the contact condition between the roll surface and the molten metal was uniform, and the microstructure near surface was constant. As a result, the strength is constant. Therefore, cracking did not occur under the conditions in

b,c. Convex strip surfaces shown in

b,c and

b were flattened by the cold rolling.

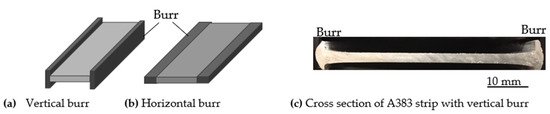

Burrs occur at the edges of strips cast using a twin-roll caster equipped with side dam plates [26][27]. Schematic illustration of a typical burr of the as-cast strip is shown in

Burrs occur at the edges of strips cast using a twin-roll caster equipped with side dam plates [26,27]. Schematic illustration of a typical burr of the as-cast strip is shown in a. The burr became smaller as the roll speed increased. The lower the flow ability in the semisolid condition of an aluminum alloy, the smaller the burr. The burr in

a is perpendicular to the strip. This type of burr is called a vertical burr. The vertical burr becomes an obstacle in coiling of the strip and becomes the origin of edge-cracking upon cold rolling. In the worst case, the burr sometimes destroys the side dam plate. The vertical burr is changed to have the same thickness as the strip, as shown in

b. This type of burr is called a horizontal burr.

c shows the cross section of a strip with a vertical burr.

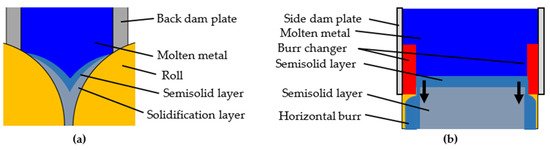

A cross section vertical to the roll shaft near the center of the roll is shown in

a. Semisolid metal exists on the solidification layer. This semisolid metal is squeezed toward to the side plate, and this semisolid metal enters between the side dam pale and the side surface of the roll. As a result, inserted semisolid metal solidifies and becomes a vertical burr. The proposed method, which changes a vertical burr to a horizontal burr, is shown in

b, a plate, which is called a burr changer, is attached to the inside of the side dam plate. The lowest position of the burr changer is lower than the position at which the semisolid metal is squeezed and becomes vertically burry. The semisolid metal is squeezed between the burr changer and the strip. The squeezed semisolid metal was rolled and solidified and becomes a horizontal burr. The thickness of the horizontal burr was as same as the strip. The burr changer did not affect the strip surface.

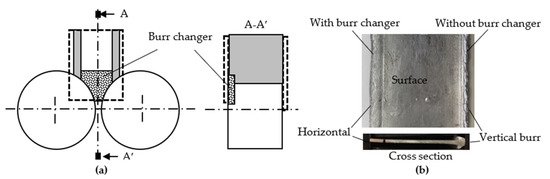

The burr changer was attached to only one side dam plate of the VHSTRC as shown in

a and the casting was conducted. The surface and cross section of the strip cast using the this VHSTRC is shown in

b. The edge of the strip corresponding to the side dam plate without burr changer had the vertical burr. On the other hand, the edge of the strip corresponding to the side dam plate with burr changer had not the vertical burr but the horizontal burr.

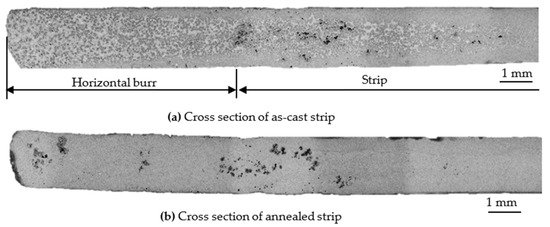

The cross section of the horizontal burr of A383 strip is shown in

. The eutectic crystal was squeezed and became a horizontal burr, as shown in

a. The microstructure of the horizontal burr was different from that of the strip in the as-cast condition. The microstructures of the horizontal burr and the strip became uniform after annealing, as show in

b. According to this result, the horizontal burr is estimated to be part of the strip.

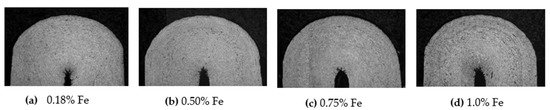

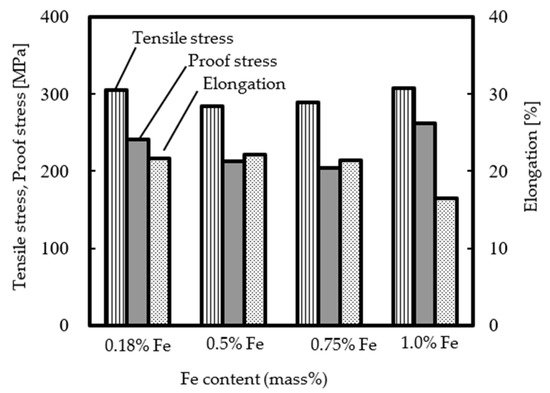

The cooling rate of the strip cast using the VHSTRC was estimated from DAS, 4000 K/s near surface region of the strip, and 500/s at mid-thickness region [29]. It is very difficult to estimate the cooling rate from the DAS as the microstructure at mid-thickness region is not dendrite but globular structure [30]. Actually, the cooling rate of the mid-thickness region may be faster. The high cooling ability of the VHSTRC is suitable for the improvement of the decreased mechanical property of recycled aluminum alloy [31][32][33][34][35][36]. Iron was added to 6016 aluminum alloy as a model of recycled aluminum alloy [33]. 6016 aluminum alloy is usually used for body sheet of the automobile. The content of the Fe increases by recycling. The Fe content of the 6016 was 0.18%, and the Fe content was increased up to 1.0%. The 6016 and Fe-added 6016 was roll-cast using the VHSTRC at a speed of 60 m/min, and as-cast strip was cold rolled down to 1 mm and annealed. The results of full bending and a tension test are shown in

The cooling rate of the strip cast using the VHSTRC was estimated from DAS, 4000 K/s near surface region of the strip, and 500/s at mid-thickness region [29]. It is very difficult to estimate the cooling rate from the DAS as the microstructure at mid-thickness region is not dendrite but globular structure [30]. Actually, the cooling rate of the mid-thickness region may be faster. The high cooling ability of the VHSTRC is suitable for the improvement of the decreased mechanical property of recycled aluminum alloy [31,32,33,34,35,36]. Iron was added to 6016 aluminum alloy as a model of recycled aluminum alloy [33]. 6016 aluminum alloy is usually used for body sheet of the automobile. The content of the Fe increases by recycling. The Fe content of the 6016 was 0.18%, and the Fe content was increased up to 1.0%. The 6016 and Fe-added 6016 was roll-cast using the VHSTRC at a speed of 60 m/min, and as-cast strip was cold rolled down to 1 mm and annealed. The results of full bending and a tension test are shown in and

, respectively. Cracking did not occur at the outer surface, even for the case in which the Fe content was 1.0, as shown in

. Based on the results of the tension test, the tensile stress, the proof stress, and the elongation were not strongly influenced by the increase of the Fe content up to 0.75%. However, when the Fe content was 1.0%, the elongation decreased. These results show that detoxification of increased Fe was attained up until 0.75% Fe. The AlFeSi intermetallic compound became fine by the effect of rapid solidification by the VHSTRC, and the AlFeSi was detoxified.

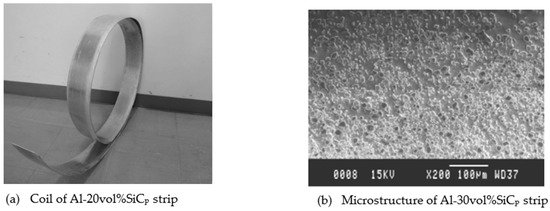

The VHSTRC can be used for strip casting of a particle-dispersed composite, such as Al-SiCp [23]. shows a coil of Al-20vol%SiCp strip and the microstructure of Al-30vol%SiCp strip. The matrix of these Al-SiCp strips is Al-Si alloy. The eutectic Si of Al-Si matrix became fine as a result of the effect of rapid solidification of the VHSTRC, and Al-SiCp strip had ductility. Therefore, Al-20vol%SiCp could be coiled. The SiC particle uniformly dispersed and the agglomeration of SiC particles did not occur because the crystal became fine by the effect of rapid solidification of the VHSTRC.

The crystallization position and formation mechanism of globular crystals at the center area in the thickness direction of aluminum alloy strips cast by a high-speed twin roll caster was investigated. It was demonstrated that globular crystals at the center area of the thickness direction were formed by dendrite-arm-dividing at the roll gap by the strip casting clad strip [30]. Experiments by semisolid-strip casting with the cooling slope showed that globular crystals in the molten metal existed in the solidification layers.

3. Unequal Diameter Twin Roll Caster

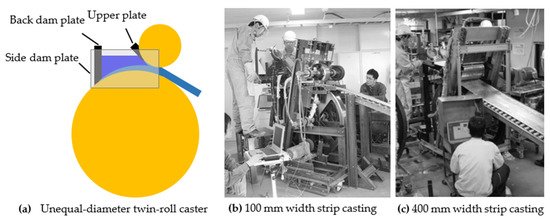

A schematic diagram of an unequal-diameter twin-roll caster (UDTRC) and a photograph of casting procedure are shown in

[37]. The lower roll is larger than the upper roll. The molten metal is poured on the lower roll. A molten metal pool is made by side dam plates, a back dam plate, and an upper plate on the lower roll. The UDTRC equips copper alloy rolls or mild steel rolls with a thin shell thinner than 6 mm, and a parting material is not used on the roll. Therefore, the UDTRC can cast strip at a speed higher than that of the CTRCA. The casting speed of the UDTRC is up to 60 m/min when the copper alloy rolls are used. The casting speed of the UDTRC is lower than that of the VHSTRC. However, the UDTRC has some advantages. For example, conveyance of the cast strip is easier because the strip is not bent below the rolls, as is the case for the VHSTRC. The strip, which is a semisolid inside, can be conveyed without being broken. This means that the UDTRC can cast strip at a smaller roll load than the VHSTRC without the strip being broken. This is very useful for an inline hot rolling. The UDTRC can cast thicker strip at lower speeds than the VHSTRC (down to 5 m/min). The solidification layer cast by the lower roll is thicker than that cast by the upper roll. Therefore, the microstructure of the strip cast by the UDTRC is not symmetric. This becomes either an advantage or a disadvantage, depending on use. The UDTRC can cast wrought aluminum alloy strip [37][38]. The high cooling ability of the UDTRC is suitable for the improvement of the decreased mechanical property of recycled aluminum alloy [39]. Hyper-eutectic Al-Si and Al-40%Sn-1%Cu have very wide solidification temperature, and the UDTRC can cast the strips of these alloys by the high cooling ability [40][41].

[37]. The lower roll is larger than the upper roll. The molten metal is poured on the lower roll. A molten metal pool is made by side dam plates, a back dam plate, and an upper plate on the lower roll. The UDTRC equips copper alloy rolls or mild steel rolls with a thin shell thinner than 6 mm, and a parting material is not used on the roll. Therefore, the UDTRC can cast strip at a speed higher than that of the CTRCA. The casting speed of the UDTRC is up to 60 m/min when the copper alloy rolls are used. The casting speed of the UDTRC is lower than that of the VHSTRC. However, the UDTRC has some advantages. For example, conveyance of the cast strip is easier because the strip is not bent below the rolls, as is the case for the VHSTRC. The strip, which is a semisolid inside, can be conveyed without being broken. This means that the UDTRC can cast strip at a smaller roll load than the VHSTRC without the strip being broken. This is very useful for an inline hot rolling. The UDTRC can cast thicker strip at lower speeds than the VHSTRC (down to 5 m/min). The solidification layer cast by the lower roll is thicker than that cast by the upper roll. Therefore, the microstructure of the strip cast by the UDTRC is not symmetric. This becomes either an advantage or a disadvantage, depending on use. The UDTRC can cast wrought aluminum alloy strip [37,38]. The high cooling ability of the UDTRC is suitable for the improvement of the decreased mechanical property of recycled aluminum alloy [39]. Hyper-eutectic Al-Si and Al-40%Sn-1%Cu have very wide solidification temperature, and the UDTRC can cast the strips of these alloys by the high cooling ability [40,41].

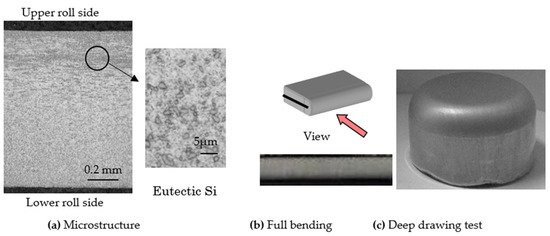

The A356 was aluminum alloy for casting. Therefore, the A356 is suitable for roll casting as well [42]. The properties of the roll cast A356 strip are shown in . A cross section of cold-rolled 1-mm-thick A356 strip and its eutectic Si is shown in

a. The eutectic Si was fine and globular as a result of the effect of rapid solidification. The as-cast strip can be cold rolled down to 1 mm without breaking, despite having an Si content of 6.5%, and being annealed. A full bending test and a deep drawing test were conducted using a cold-rolled and annealed strip. Cracking did not occur at the outer surface of the bent strip. A 32-mm diameter punch was used for the deep drawing test. The limiting drawing ratio (LDR) was 1.8. The results of the full bending test and the deep drawing test are shown in

b,c, respectively. A356 is an aluminum alloy for casting and has an Si content that is much higher than that of wrought aluminum alloy. However, strip cast using the VHSTRC had good ductility and formability for fine globular eutectic Si obtained by rapid solidification. A356 strip cast using the VHSTRC may be used for sheet forming.

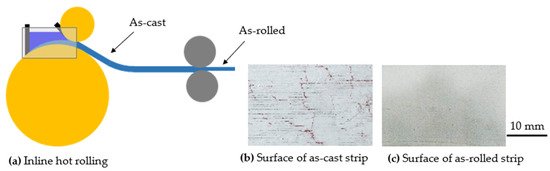

Surface cracking and center-line segregation occur in Al-Mg strip cast using the high-speed twin-roll caster. A molten-metal pouring method to reduce the surface cracking was proposed [43]. However, the reduction of the center-line segregation is difficult. The center-line segregation of the strip cast using the VHSTRC or the UDTRC is milder than that cast using the CTRCA. Inline hot rolling was proposed in order to reduce these defects. Inline hot rolling was performed using the UDTRC. Schematic diagrams of inline hot rolling and the surfaces of Al-4.8Mg strip under as-cast and as-rolled conditions are shown in . The casting speed of Al-4.8Mg strip was 60 m/min, and the temperature of the inline hot rolling was 450 °C. The reduction in the inline hot rolling was 40%. A color check was conducted on the surfaces of the as-cast strip and the inline hot-rolled strip in order to investigate surface cracks. Cracks existed on the as-cast strip. These cracks did not exist on the inline hot-rolled strip. The center-line segregation was reduced by inline hot rolling as well.

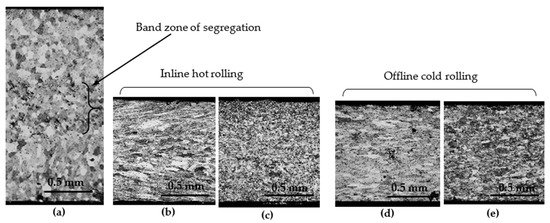

The microstructures of the as-cast strip, the inline hot-rolled strip, and the offline cold-rolled strip are shown in

. The microstructures of annealed strips of the inline hot-rolled strip and offline cold-rolled strip are also shown. A band zone of the segregation existed in the middle of the thickness direction in the as-cast strip, as shown in

a. The as-cast strip was inline hot rolled down to 1.1 mm in one pass. The structure of the cross section became a typical rolled structure after inline hot rolling, and the segregation was reduced, as shown in

b. The structure of the inline hot-rolled strip became fine and globular after annealing, as shown in

c. The structure became remarkably fine near the strip surface because the induction of strain was greater and cooling was more rapid around the surface in the case of inline hot rolling. In offline cold rolling, the as-cast strip was cold rolled down to 1.1 mm by a number of passes. Therefore, the structure of the cross section of the offline cold-rolled strip was different from that of the inline hot-rolled strip, as shown in

d. A cross section of annealed offline cold-rolled strip is shown in

e, and the grain of this strip was larger than that of the annealed inline hot-rolled strip.