Total Petroleum Hydrocarbons (TPH) is a term used to represent petroleum (crude oil) that consists of a blend of thousands of compounds. They are referred to as hydrocarbons because almost all consist of hydrogen and carbon. A crude oil spill is a common issue during offshore oil drilling, transport and transfer to onshore. Second, the production of petroleum refinery effluent is known to cause pollution due to its toxic effluent discharge. Sea habitats and onshore soil biota are affected by TPH as a pollutant in their natural environment. Crude oil pollution in seawater, estuaries and beaches requires an efficient process of cleaning. To remove crude oil pollutants from seawater, various physico-chemical and biological treatment methods have been applied worldwide. A biological treatment method using bacteria, fungi and algae has recently gained a lot of attention due to its efficiency and lower cost.

- oil spill treatment

- crude oil

- petroleum products

1. Petroleum Hydrocarbons

TPH referred to as hydrocarbons because almost all consist of hydrogen and carbon. Petroleum hydrocarbons account for 50–98% of crude oil and are considered an important component depending on the source of petroleum [1]. The main composition of crude oil is illustrated in Table 1.

Elemental composition of crude oil.

| Sr.No. | Elements | Percentage (%) |

|---|

| 1. | Carbon | 85 – 90 |

| 2. | Hydrogen | 10 – 14 |

| 3. | Sulfur | 0.2 – 3 |

| 4. | Nitrogen | <0.1 – 2 |

| 5. | Oxygen | 1 – 1.5 |

| 6. | Metals * | <1 |

* Hg, Au, Cu, Al, Ca, Co, K, Mg, Si, Sr, Mo, Ti, Mn, Li, Se, Rb, Ag, Ba, Pb, As, Cd, Cr, Fe, Ni, V, Zn.

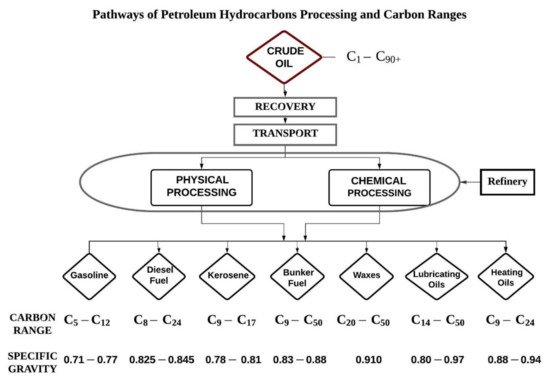

Crude oil is extracted from offshore oil rigs in seawater and transported to the shore. Crude oil recovered from the sub surface is of no use directly, for this reason it must undergo refining for a variety of applications. In a petroleum oil refinery crude oil undergoes processes. The oil refinery methods and processes refine products like petrol, gasoline, diesel, jet fuel, asphalt, wax, lubricating oil, tar, kerosene, and liquefied petroleum gas (LPG), etc. The petroleum industry supplies a substantial quantity of world’s energy demands in addition to popular petro-chemical intermediates required for production of extensive range of goods viz. solvents, dye stuffs, pharmaceuticals, polymers, and new chemicals etc. All these goods generate environmental pollution when discharged in the environment [2][3]. Figure 1 show the different products obtained from the petroleum hydrocarbon refinery with their molecular carbon ranges. Carbon ranges illustrated may differ from state to state. These ranges mentioned are the most common.

The stability and behavior of petroleum in seawater depends on its relative density (the relationship between the density of petroleum and pure water) and the distillation characteristics (definition of volatility, large quantities of resin, asphalt, wax, etc. reduces the volatility of oil), viscosity (flow resistance that varies with temperature) and point of pour [4]. Due to the formation of water or gas, or liquids and chemicals extracted during operations, inorganic salts like sodium chloride, magnesium chloride and other inorganic salts often follow crude oil from wells. Heavy crude oils produce large quantities of difficult to process complex hydrocarbons, such as polynuclear aromatic compounds (PNA), PAHs, alkyl aromatic compounds, heteroatoms, and metal materials. Sulphur, oxygen, nitrogen, and metal atoms are typical heteroatoms in hydrocarbons [5].

2. Sources of Petroleum Hydrocarbons Intrusion

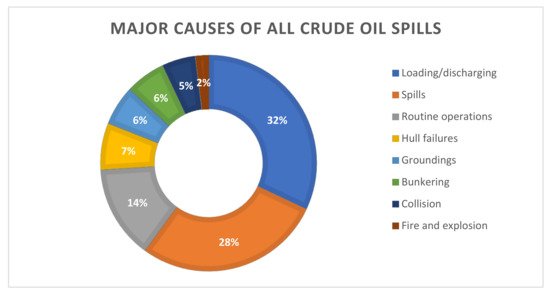

TPH is released to the environment through oil spill incidents, industrial releases or by-products of private or commercial uses [6]. Crude oil spill in coastal waters is mainly the result of ship operations, tanker accidents, oil exploration and production. The main causes of all the spills are illustrated in Figure 2. In the previous half century, the statistics on the incidence of oil spills have shown a marked downward trend, but still the volume of oil spills is of concern for the environment. More than 7 million tons of hydrocarbon oil from over 140 major spills have been released into the environment [7]. The estimated amount of petroleum hydrocarbon oil lost from tanker discharges alone in 2020 was around 1000 tons [8]. That is the same amount as in the year 2012 and 2019. The list of global oil spills and current spills reveals more than 200 of these incidences in last 50 years on both the offshore and inland waters [9]. In addition to the occurrence of anthropogenic oil spills, millions of tons of petroleum enter the marine environment every year from natural seepages [10].

3. Properties of Crude Oil

Crude oil is primarily a natural, sticky and flammable liquid. The crude oils vary greatly in chemical composition. It is usually dark brown or black (though it may be yellow or green in color). From an engineering point of view, crude oils are usually classified according to their sources, gravity of the American Petroleum Institute (API) and amount of Sulphur (S). Crude oil is considered “light” when its density is low and “heavy” when it is dense. Crude oils with relatively low sulphur content are called “mild” crudes, while those containing significant amounts of sulphur are called “acid” crudes. Crude oil is a blend of various organic substances, mostly hydrocarbons, organic compound [12]. Petroleum components are divided into four main groups according to their different solubility’s in organic solvents [13][14]. The chemical composition of the crude oil contains the following four main compounds saturated, aromatics, resins and asphaltenes [15]. This is also named SARA [16][17]. Saturated hydrocarbons are regular and branched alkanes with CnH2n+2 (aliphatic) structure. It contains cyclic alkanes (chain lengths of 1 to 40 or more carbons). Saturated hydrocarbons are the most prevalent constituents of crude oil. Aromatic hydrocarbons are aromatic monocyclic compounds (benzene, toluene, xylene, etc.) and PAHs (naphthalene, anthracene, phenanthrene, etc.). Resins include nitrogen, sulphur, and oxygen-containing polar compounds (for example, pyridine and thiophene). Finally, asphaltenes are poorly polymerized compounds and of high molecular weight. Asphaltenes are poorly characterized hydrocarbons, metals such as nickel, vanadium, and iron also relate to asphalt.

4. Toxicity of Petroleum Hydrocarbons

Many factors affect the health effects of exposure to TPH. This involve the form of organic compounds in the TPH, the duration of exposure and the number of chemical substances in contact. Figure 3 illustrate few impacted areas due to petroleum oil spills in the marine environment.

Figure 3. Few impacts of oil spills in the marine environment.

4.1. Effects on Marine Organisms

The petroleum hydrocarbons oil spill disaster has an impact on the marine environment and ecosystem [18][19]. As TPH is discharged directly into water bodies by oil spills, petroleum hydrocarbons float on the surface of water and establish thin oily layer. Figure 4 illustrates a few ways a petroleum oil spill can affect organisms in the marine environment.

Figure 4. Oil spill in marine environment and ways to affect organisms.

In situations where the exposure fills the organism’s body with petroleum hydrocarbon oil, direct toxicity is attained and death by smothering takes place [20]. The shallow coral reefs are significant habitat that has been affected by petroleum hydrocarbon oil spills. Coral damage and death following petroleum hydrocarbon oil exposure have been seen extensively [21]. The species have decreased resistance to other environmental stresses, such as variations in temperature, infectious diseases and other pollutants because of petroleum oil that covers the mammals and birds [20].

Seabirds are particularly vulnerable because oil contact inhibits the ability to fly. The resulting intake of infected food, inhalation, and repeated encounters with the interface of the oil water result in severe personal poisoning with high mortality rates [21]. Ingested or dissolved oil in the body via membranes, e.g., gill surfaces cause direct lethal toxicity, sublethal effects and marine organisms reproductive failure [20]. Turtles trapped in oil spills are exposed to prolonged physical contact with both floating oils, largely petroleum-saturated respiration air, and the ingestion of food polluted by oil or tar balls. Old and young tortoises were found to be starving to death, as petroleum hydrocarbons blocked their esophagus [21].

The loss of economic capital due to direct mortality, loss of habitat, and restrictions on harvesting and fisheries closures affects the commercial and aquaculture industries [21]. There are negative effects on marketing of commercially valuable species in the aquaculture industry. Similarly, oil taint makes products not suitable for market. Another problem is high concentrations of petroleum oil chemicals of concern for human health in products make then unacceptable for the market [20].

4.2. Impacts on Humans

First and foremost, in any accident involving petroleum oil spills in the aquatic environment, it is imperative to prevent, if necessary, and reduce the loss of human life and the detrimental effects on human health of the response and clean-up staff and any nearby people and human communities [20][21]. The TPH released on the soil flows into the groundwater through the surface. Some of these chemicals are volatile and evaporate in the air. A few dissolve into the groundwater and move away from the spill area. Most substances bind with soil particles and remain in the soil for a long time, while microbes that are present in the soil break down some hydrocarbons. Secondly, contact may occur via dermal constant contact, inhalation, and ingestion, depending on the properties of the chemical or media (i.e., air, water, soil, food) in which human activity in and around that material [21]. Figure 5 show the population affected by an oil spill accident.

Figure 5. Population of people affected due to oil spill.

The damage caused by contact to petroleum hydrocarbons can be cancerous, or temporary, or permanently non-cancerous [22]. The numerous chemicals used in dispersants and crude oils poses some documented and alleged health risks [21][23]. Compounds of various fractions of TPH influence the body in different ways. TPH compounds, especially smaller compounds such as benzene, toluene and xylene (which are present in gasoline), can affect the human central nervous system [21][24][25]. Death can occur if exposures are high enough. Breathing toluene at concentrations greater than 100 parts per million (100 ppm) for more than a few hours may induce fatigue, headache, nausea and drowsiness [25]. When the exposure stops, the symptoms will go away. However, if anyone is exposed for a long time, irreversible damage to the central nervous system can result. One TPH compound (n-hexane) can have a distinct effect on the central nervous system, inducing a nervous disease termed “peripheral neuropathy” marked by numbness of the feet and legs and, in extreme cases, paralysis [25]. Swallowing certain petroleum products such as diesel and kerosene causes inflammation of the mouth and stomach, weakness of the central nervous system, trouble coughing, and pneumonia from breathing the fumes of the liquid into the lungs [25]. Compounds in certain TPH fractions may also affect the blood, immune system, liver, spleen, kidneys, developing foetuses, and lungs [25]. Many TPH compounds can be harmful to the skin and eyes. TPH products such as certain mineral oils are not very harmful and are used in food [21][25].

Researchers analyzed the effect of crude oil, dispersants on epithelial cells of human airways and identified similar pathological modes of action for the development of various lung diseases. Their research indicates synergistic effects of crude oil and dispersants important for understanding physical health outcomes and the importance of respiratory safety for particular clean-up crews operating immediately after a spill [24][26]. Other researchers studied the influence of Deep water Horizon (DWH) oil, dispersed mixtures on rodent health in a laboratory setting, with results showing increased influence of the mixture on modifying white blood cells and platelet counts, and affecting liver and kidney function [24][27]. Researchers have reported the acute human health effects among the first responders to the 2007 Hebei Spirit oil spill off the Yellow Sea Coast of South Korea, dumping 12,547 kiloliters of crude oil polluted with 167 km of shoreline and 13,978 hectares of fishery and aquaculture infrastructure, and involving 563,761 clean-up duties [28]. Another study shows that about 442 of the most impacted first responders to the original exposure symptoms were analyzed 1 year later to determine the durability of the toxic effects. Decreased periods of symptoms recorded were eye symptoms (average 9.7 months), headaches (average 8.4 months), skin symptoms (average 8.3 months), neuro-vestibular structures (average 6.9 months), respiratory symptoms (average 2.1 months) and back pain (average 1.8 months) [29]. They further reported that it is important to remember that the statistics are merely observational, and some of those who come into contact with volatile compounds during the cleaning operation appear to suffer from these supposed effects after 12 months, with headaches, eye symptoms, neuro-vestibular symptoms, respiratory symptoms, skin symptoms, and back pain in that order.

5. Petroleum Hydrocarbon Treatments

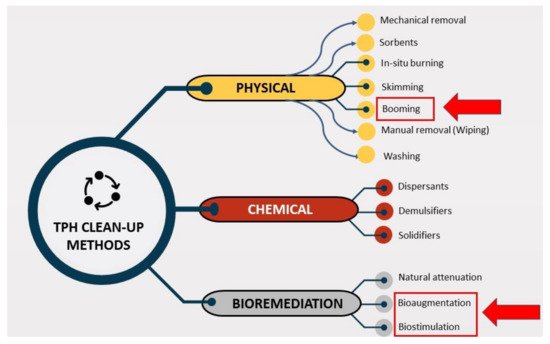

Clean-up techniques of hazardous materials are highly influenced by a number of factors such as oil content, oil spill site characteristics and even political considerations [30]. A variety of methods to control oil spills in marine shorelines and freshwater ecosystems have been established but still the problem exists. These methods were closely researched and outlined in several technical documents [30][31][32][33][34][35][36][37]. Floating booms and barriers, oil collection materials, oil collection vessels, absorbing materials, chemical dispersants, surfactants, physical degradation, biodegradation and on-site oil combustion are the most common methods and techniques for oil containment and removal at sea [31]. Clean-up oil is mechanically extracted in significant time using physical techniques. The in-situ burning method will contribute to air pollution and, when used with the combustion system, worsen the ambient air quality. Secondly, shoreline vegetation deteriorates as many people manually collect oil and no more than 10–15% of oil recovery take place after a major spill [30][38][39]. The chemical methods of oil removal are faster than physical ones and include toxic chemicals in most situations. Oil spill treatment additives like chemical surfactants are most often harmful rather than oil itself [39][40][41]. Oil spill response workers (OSRWs) are exposed to those operating in the post-emergency process onshore for the purpose of cleaning of oil. OSRWs may be highly exposed to oil spill chemicals by dermal routes and inhalation unless protected and procedures are not followed [42]. Most of the techniques for the recovery or removal of the spilled oil in the water are physical and chemical methods. Oil spill cleaning techniques such as mechanical skimming, sorbents, dispersants, controlled combustion, high-pressure hosing, etc. are quite effective in cleaning up the maximum amount of oil spilled in seawater, but these techniques are not capable of removing emulsified oil left over after physicochemical techniques have been applied.

The treatment steps are discussed in later sections. Figure 6 show the proposed protocol to treat or clean oil spills. Figure 7 show the recent methods used to treat or clean oil spills.

At present, one of the greatest challenges to the application of oil bioremediation in marine water is the lack of guidance about when and how to use this technology [30]. A positive and beneficial aspect is that bioremediation methods may be used in situations where there is less movement of water in the enclosed environment. This form of condition can be created by placing oil containment booms known as booming (Figure 7) on the surface of the water, which are typically used to contain oil spills in moving water and limit movements of moving water with oil spills resulting in an enclosed environment. Floating booms and barriers as the best form of containment for oil spills, followed by oil collection of materials and vessels, have been tested in most cases [31]. The use of oil spill booms as floating barriers should comply with environmental, mechanical and operational constraints. Numerical boom behavior modelling methods may be used to prepare or verify booming strategies that meet these limitations [43]. The residual oil (pollutant) concentration after physicochemical treatment in seawater can be determined by onsite TPH analyzers [18]. Researchers can select an appropriate study from review article [44], considering local conditions such as availability of culture of micro-organisms, biostimulants (agro-industrial waste, surfactants etc.), type of TPH pollutants and time to complete bioremediation work.

In several of the studies mentioned in review [44], micro-organisms are either isolated from seawater or enhanced in seawater so that they can be used effectively in their natural environment. Researchers have reported several laboratory scale studies using bioaugmentation (BA), biostimulation (BS) or both methods combined (BA-BS) in aqueous media studies that can be applied on site even after considering the problem due to poor bioavailability of pollutants, protozoan predation or competition from native microbiota, etc. Bioremediation is commonly used as a polishing stage following the application of traditional mechanical clean-up options and is often started from weeks to months following the oil spill [30]. In bioremediation, there is minimal physical damage and short-lived detrimental effects, helping to eliminate certain hazardous elements, a simpler and more rigorous approach, a lower labor intensity and a lower cost [39][19]. Some of the benefits of using bioremediation techniques like BA, BS or both methods combined (BA-BS) are that harmful petroleum hydrocarbons mixtures or combinations are eliminated instead of merely transferred to another nearby environment. Complex processes not applicable in all pollution situations cannot produce substantial short-term outcome and should not be adapted individually to each polluted site as a protective first measures if high concentrations of oil is present [39]. When correctly used in certain oil-contaminated environments, bioremediation has proved to be a cost-effective treatment technique [30][45]. After its successful application in the Exxon Valdez 1989 oil spill, bioremediation has been among the most promising secondary treatment options for oil removal [30][45]. The decision to bioremediate a site depends on the objectives and on all factors, which are present that influence its performance, including clean-up, rejuvenation and habitat preservation.

References

- Al-Dhabaan, F.A. Morphological, biochemical and molecular identification of petroleum hydrocarbons biodegradation bacteria isolated from oil polluted soil in Dhahran, Saud Arabia. Saudi journal of biological sciences 2019, 26, 1247-1252.

- Zhang, B.; Matchinski, E.J.; Chen, B.; Ye, X.; Jing, L.; Lee, K. Marine Oil Spills—Oil Pollution, Sources and Effects. In World Seas: An Environmental Evaluation; Sheppard, C., Ed.; Elsevier: London, UK, 2019; pp. 391–406.

- De la Huz, R.; Lastra, M.; López, J. Other Environmental Health Issues: Oil Spill. In Encyclopedia of Environmental Health; Nriagu, J.O., Ed.; Elsevier: Burlington, NJ, USA, 2018; pp. 251–255.

- Nriagu, J. Encyclopedia of Environmental Health; Nriagu, J.O., Ed.; Elsevier: Burlington, NJ, USA, 2019.

- Al-Sayegh, A.; Al-Wahaibi, Y.; Joshi, S.; Al-Bahry, S.; Elshafie, A.; Al-Bemani, A. Bioremediation of Heavy Crude Oil Contamination. Open Biotechnol. J. 2016, 10, 301–311.

- Cai, Y.; Wang, R.; Rao, P.; Wu, B.; Yan, L.; Hu, L.; Park, S.; Ryu, M.; Zhou, X. Bioremediation of Petroleum Hydrocarbons Using Acinetobacter sp. SCYY-5 Isolated from Contaminated Oil Sludge: Strategy and Effectiveness Study. Int. J. Environ. Res. Public Health 2021, 18, 819.

- Li, P.; Cai, Q.; Lin, W.; Chen, B.; Zhang, B. Offshore oil spill response practices and emerging challenges. Mar. Pollut. Bull. 2016, 110, 6–27.

- ITOPF. Oil Tanker Spill Statistics. 2020. Available online: (accessed on 28 January 2021).

- Wikipedia. List of Oil Spills. Available online: (accessed on 27 January 2020).

- Speight, J.G. Biological Transformation. In Reaction Mechanisms in Environmental Engineering: Analysis and Prediction; Butterworth-Heinemann: Waltham, MA, USA, 2018.

- Amin, S. Environmental Safety of Petroleum Refinery Operation: Malaysian Case Studies; University of Malaya: Kuala Lumpur, Malaysia, 2006.

- Varjani, S.J.; Upasani, V.N. A new look on factors affecting microbial degradation of petroleum hydrocarbon pollutants. Int. Biodeterior. Biodegrad. 2017, 120, 71–83.

- Venosa, A.D.; Zhu, X. Guidance for the bioremediation of oil–contaminated wetlands, marshes and marine shorelines. Bioremediation of Aquatic Terrestrial Ecosystems. Science Publishers. UK 2002, 142-171.

- Fingerman, M. Guidance for the bioremediation of oil–contaminated wetlands, marshes and marine shorelines. In Bioremediation of Aquatic and Terrestrial Ecosystems; CRC Press: Boca Raton, FL, USA, 2016; p. 141.

- Al-Hawash, A.B.; Dragh, M.A.; Li, S.; Alhujaily, A.; Abbood, H.A.; Zhang, X.; Ma, F. Principles of microbial degradation of petroleum hydrocarbons in the environment. Egypt. J. Aquat. Res. 2018, 44, 71–76.

- McGenity, T.J. Hydrocarbon biodegradation in intertidal wetland sediments. Curr. Opin. Biotechnol. 2014, 27, 46–54.

- Santos, J.M.; Vetere, A.; Wisniewski, J.A.; Eberlin, M.N.; Schrader, W. Comparing Crude Oils with Different API Gravities on a Molecular Level Using Mass Spectrometric Analysis. Part 2: Resins and Asphaltenes. Energies 2018, 11, 2767.

- Fingas, M.. Marine Oil Spills; Fingas, M., Eds.; MDPI: Basel, Switzerland, 2019; pp. 1-288.

- Hyeonuk Kim; Yunseon Choe; Cheol Huh; Estimation of a Mechanical Recovery System’s Oil Recovery Capacity by Considering Boom Loss. Journal of Marine Science and Engineering 2019, 7, 458, 10.3390/jmse7120458.

- John W. Farrington; Oil Pollution in the Marine Environment II: Fates and Effects of Oil Spills. Environment: Science and Policy for Sustainable Development 2014, 56, 16-31, 10.1080/00139157.2014.922382.

- Zhang, B.; Matchinski, E.J.; Chen, B.; Ye, X.; Jing, L.; Lee, K.. In World seas: an environmental evaluation (Marine oil spills—Oil pollution, sources and effects); Sheppard, C., Eds.; Elsevier: London,UK, 2019; pp. 391-406.

- Tanu Altomare; Patrick M. Tarwater; Alesia C. Ferguson; Helena M. Solo-Gabriele; Kristina D. Mena; Estimating Health Risks to Children Associated with Recreational Play on Oil Spill-Contaminated Beaches. International Journal of Environmental Research and Public Health 2020, 18, 126, 10.3390/ijerph18010126.

- Alesia Ferguson; Helena Solo-Gabriele; Kristina Mena; Assessment for oil spill chemicals: Current knowledge, data gaps, and uncertainties addressing human physical health risk. Marine Pollution Bulletin 2020, 150, 110746, 10.1016/j.marpolbul.2019.110746.

- Ellen Cristina Souza; Thereza Christina Vessoni-Penna; Ricardo Pinheiro De Souza Oliveira; Biosurfactant-enhanced hydrocarbon bioremediation: An overview. International Biodeterioration & Biodegradation 2014, 89, 88-94, 10.1016/j.ibiod.2014.01.007.

- G daneil Todd; Robert L Chessin; Joan Colman. TOXICOLOGICAL PROFILE FOR TOTAL PETROLEUM HYDROCARBONS (TPH). U.S Department of Health and Human Services: USA, 1999; pp 1-225.

- Yao-Zhong Liu; Astrid M. Roy-Engel; Melody C. Baddoo; Erik K. Flemington; Guangdi Wang; He Wang; The impact of oil spill to lung health—Insights from an RNA-seq study of human airway epithelial cells. Gene 2016, 578, 38-51, 10.1016/j.gene.2015.12.016.

- Sindhu Ramesh; Dwipayan Bhattacharya; Mohammed Majrashi; Marlee Morgan; T. Prabhakar Clement; Muralikrishnan Dhanasekaran; Evaluation of behavioral parameters, hematological markers, liver and kidney functions in rodents exposed to Deepwater Horizon crude oil and Corexit. Life Sciences 2018, 199, 34-40, 10.1016/j.lfs.2018.02.028.

- Moonkoo Kim; Sang Hee Hong; Jongho Won; Un Hyuk Yim; Jee-Hyun Jung; Sung Yong Ha; Joon Geon An; Changkyu Joo; Eunsic Kim; Gi Myung Han; et al.Seongho BaekHyun-Woo ChoiWon Joon Shim Petroleum hydrocarbon contaminations in the intertidal seawater after the Hebei Spirit oil spill – Effect of tidal cycle on the TPH concentrations and the chromatographic characterization of seawater extracts. Water Research 2013, 47, 758-768, 10.1016/j.watres.2012.10.050.

- Ji Ung Na; Min Seob Sim; Ik Joon Jo; Hyoung Gon Song; The duration of acute health problems in people involved with the cleanup operation of the Hebei Spirit oil spill. Marine Pollution Bulletin 2012, 64, 1246-1251, 10.1016/j.marpolbul.2012.03.013.

- Farrington, J.W. Oil Pollution in the Marine Environment II: Fates and Effects of Oil Spills. Environ. Sci. Policy Sustain. Dev. 2014, 56, 16–31.

- Mapelli, F.; Scoma, A.; Michoud, G.; Aulenta, F.; Boon, N.; Borin, S.; Kalogerakis, N.; Daffonchio, D. Biotechnologies for Marine Oil Spill Cleanup: Indissoluble Ties with Microorganisms. Trends Biotechnol. 2017, 35, 860–870.

- Karlapudi, A.P.; Venkateswarulu, T.; Tammineedi, J.; Kanumuri, L.; Ravuru, B.K.; Dirisala, V.R.; Kodali, V.P. Role of biosurfactants in bioremediation of oil pollution—A review. Petroleum 2018, 4, 241–249.

- Serrano, R.; Lastra, M.; Lopez, J. Oil Spills. In Encyclopedia of Environmental Health; Elsevier: Amsterdam, The Netherlands, 2011; pp. 251–255.

- Mercer, K.; Trevors, J.T. Remediation of oil spills in temperate and tropical coastal marine environments. Environmentalist 2011, 31, 338–347.

- Zafirakou, A.; Themeli, S.; Tsami, E.; Aretoulis, G. Multi-Criteria Analysis of Different Approaches to Protect the Marine and Coastal Environment from Oil Spills. J. Mar. Sci. Eng. 2018, 6, 125.

- Gogoi, B.; Dutta, N.; Goswami, P.; Mohan, T.K. A case study of bioremediation of petroleum-hydrocarbon contaminated soil at a crude oil spill site. Adv. Environ. Res. 2003, 7, 767–782.

- Darmayati, Y. Efficacy of Bioremediation Methods for oil Contaminated Sandy Beach in Cilacap, Central Java, Indonesia; Marine science major; Bogor Agricultural University: Bogor, Indonesia, 2016.

- Shany, A.; Ur, B.; Greenberg, H. Rapid-Deployment Oil Spill Containment Boom and Method of Deployment. U.S. Patent 9,739,023, 22 August 2017.

- Wang, Q.; Zhang, S.; Li, Y.; Klassen, W. Potential Approaches to Improving Biodegradation of Hydrocarbons for Bioremediation of Crude Oil Pollution. J. Environ. Prot. 2011, 2, 47–55.

- Muttin, F.; Campbell, R.; Ouansafi, A.; Benelmostafa, Y. Numerical modelling and full-scale exercise of oil-spill containment boom on Galician coast. Int. J. Comput. Methods Exp. Meas. 2017, 5, 760–770.

- Wilks Enterprise Inc. InfraCal® TOG/TPH Analyzer, Model HATR-T2 and CH User’s Guide; Wilks Enterprise Inc., Ed.; Wilks Enterprise Inc.: East Norwalk, CT, USA, 2009.

- Prince, R.C.; Clark, J.R. Bioremediation of marine oil spills. In Studies in Surface Science and Catalysis; Vazquez-Duhalt, R., Quintero-Ramirez, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2004; Volume 151, pp. 495–512.

- Fingas, M.. Marine Oil Spills; Fingas, M., Eds.; MDPI: Basel, Switzerland, 2019; pp. 1-288.

- Khalid Sayed; Lavania Baloo; Naresh Sharma; Bioremediation of Total Petroleum Hydrocarbons (TPH) by Bioaugmentation and Biostimulation in Water with Floating Oil Spill Containment Booms as Bioreactor Basin. International Journal of Environmental Research and Public Health 2021, 18, 2226, 10.3390/ijerph18052226.

- Xueqing Zhu, A.D.V.; Makram, T.; Lee, S.K. Guidelines for the Bioremediation of Marine Shorelines and Freshwater Wetlands; 23; U.S. Environmental Protection Agency: Cincinnati, OH, USA, 2001.