Growing concern over the hazardous effect of radionuclides on the environment is driving research on mitigation and deposition strategies for radioactive waste management. Currently, there are many techniques used for radionuclides separation from the environment such as ion exchange, solvent extraction, chemical precipitation and adsorption. Adsorbents are the leading area of research and many useful materials are being discovered in this category of radionuclide ion separation. The adsorption technologies lack the ability of selective removal of metal ions from solution. This drawback is eliminated by the use of ion-imprinted polymers, these materials having targeted binding sites for specific ions in the media.

- ion-imprinted polymers

1. Introduction

Spent nuclear fuel (SNF) and high-level radioactive waste (HLRW) are generated during nuclear power reactor operation and decommissioning of nuclear facilities, respectively. There are 62 different radionuclides (RNs) formed from ²³⁵U fission, which due to their instability, are subject to radioactive transformation. About 200 different radioisotopes are observed during the nuclear reactor operation, mainly in the core. Nuclear power plants around the world are the major producers of SNF and HLRW. Situated on the territory of the Slovak republic are in Jaslovské Bohunice (Bohunice 4 and 3—reactor units in operation; Bohunice 2, 1 and A1—in the decommissioning process) and Mochovce (Mochovce 1 and 2—reactor units in operation; Mochovce 3 and 4—reactors units under construction).Slovak legislation on SNF and radioactive waste (RW) management fully correspond to international legislation and regulations. Requirements for the management of SNF and RW have been regulated in the Act No. 541/2004 Collection on the peaceful use of nuclear energy (Atomic Act) and in its implementing regulation and the Act No. 308/2018 Collection on the National Nuclear Fund and amending the Atomic Act. The Atomic Act defines RW as any unusable material in gaseous, liquid, or solid form, which cannot be released into the environment due to the content of RNs or the level of RN contamination. Details on the requirements for the management of nuclear materials, RW, and SNF are also defined by the Decree of the Nuclear Regulatory Authority of the Slovak Republic No. 30/2012 Collection. It is assumed that the individual units of nuclear power plants in Slovakia will produce 2500 tons of SNF and 3700 tons of HLRW during their operation period. Produced SNF can be considered either as a usable source of energy and RNs and can be reprocessed or can be destined for final disposal if it is considered as RW.By ²³⁵U fission two main groups of RNs are created:

- (1)

-

Fission products (FPs): formed by the fission of fuel nuclei by neutrons. These are highly active RNs; whose half-life ranges from a few seconds to thousands of years:

-

-volatile substances (⁹⁹Tc, ¹⁰³,¹⁰⁶Ru, ¹³¹,¹³³,¹³⁵I, ¹³⁴,¹³⁵,¹³⁷Cs, …),

-

-non-volatile substances (⁹⁰Sr, ¹⁴⁰La, ¹⁴¹,¹⁴⁴Ce, …),

-

-noble gases (⁸⁵Kr, ¹³¹,¹³³,¹³⁵Xe), tritium (³H).

-

-

(2)

-

Activation products (APs): formed by the interactions of neutrons with inactive nuclides of the coolant, moderator, or reactor construction materials, respectively. By activating the reactor construction materials, the following main activation corrosion and erosion products are formed:

-

-steel: ⁵¹Cr, ⁵⁴Mn, ⁶⁰Co, ⁶³Ni, ⁵⁹Fe, ⁹³Mo, ⁹⁴Nb, ¹⁰⁸ᵐ

,

¹¹⁰ᵐAg, ¹²⁴

,

¹²⁵Sb, ¹⁵²Eu, ¹⁶⁶ᵐHo,

-

-concrete: ³⁶Cl, ⁴¹Ca, ⁴⁶Sc, ⁵¹Cr, ⁵⁹Fe, ⁵⁹, ⁶³Ni, ⁶⁰Co, ⁶⁵Zn, ⁸⁵Sr, ¹²⁴Sb, ¹³¹Cs, ¹⁵²,¹⁵⁴,¹⁵⁵Eu, ¹⁶⁰Tb, ¹⁸¹Hf, ¹⁸²Ta.

-

The gradual capture of neutrons by fuel nuclei and their subsequent radioactive transformations produce transuranic elements. The most commonly used source nuclides of transuranic elements are ²³⁸U, ²³⁷,²³⁹Np, ²³⁸,²⁴²Pu, ²⁴¹,²⁴³Am, ²⁴²,²⁴⁴Cm. The RNs with a half-life longer than >200,000 years, such as: ⁷⁹Se, ⁹³Zr, ⁹⁹Tc, ¹⁰⁷Pd, ¹²⁶Sn, ¹²⁹I, ¹³⁵Cs which are difficult to measure, play significant roles in the separation processes. However, there are also other problematically detected RNs with shorter half-life < 200,000 are i.e., ⁵⁹,⁶³Ni, ⁷⁹Sc, ¹⁴⁶Sm, and actinide ²³⁶U.Uranium is the most significant metal for energy production and also the primary waste generated from nuclear reactor operation. Uranium is known for its toxicity, apart from the fact that ingestion of uranium can damage the liver and cause acute renal failure in humans [1]. The uranyl ion (UO₂⁺) occurs in oxidation state 6+ and is the most stable form of uranium in an aqueous solution [2][3][4]. According to safety regulations, uranium consumption in drinking water should be less than 0.015 mg/L [5]. Thorium is a metallic element of the actinides. For energy generation, thorium is a better choice than uranium due to its abundance on Earth, and the relatively less radioactive waste generated from its operation in a nuclear reactor. More than 99.99% of natural thorium is ²³²Th, the rest being represented by ²³⁰Th and ²²⁸Th. Thorium metal occurs naturally in the environment. The increasing release of these metals has spiked due to mining activity, e.g., milling, and processing operation, coal production, and phosphate production for fertilizers. Besides its attractive properties for nuclear energy generation, it is toxic element for human health, as a potentially carcinogenic substance. Thorium exposure is primarily due to inhalation, intravenous injection, ingestion and absorption through the skin [6]. The dispersion of thorium in the environment, mainly in water bodies, creates great concern to humans and ecological life forms [7][8]. Cesium-137 and Strontium-90 are isotopes produced during a nuclear power plant’s operation by ²³⁵U fission and are the most harmful RNs due to their strong beta emission properties and long half-life (30 years, and 29 years, respectively). The nuclear accidents in Chernobyl and the Fukushima Daiichi released large amounts of cesium isotopes (¹³⁴Cs, ¹³⁷Cs) into the surroundings [9]. These radionuclides are highly soluble and mobile in water. ⁹⁰Sr can accumulate in human organs, mostly in the liver, lungs, and kidneys of animals, and causes diseases and damage [10][11]. Cerium-144 (half-life 284.91 days) is formed by the fission of uranium and accumulates in the human body leading to acute myocardial infarction, leukemia, and imbalance in blood biochemistry. It also causes a toxic effect damaging the cell membranes in marine life, consequently damaging the nervous system and reproduction system in organisms [12][13]. The nuclear power generation from uranium generates a significant amount (≈6.05%) of Technetium-99, which as a FP is highly toxic due to its high mobility in water and a half-life of 2.11 × 105 years [14]. Lanthanum-140 (half-life 1.68 days) occurs as a FP of uranium; it has no biological role and is considered an environmental threat due to its radioactivity [15]. Chromium-51 (half-life 27.70 days) is an AP and can be used as a radioactive tracer in isotope dilution analysis. Chromium is needed in trace amounts for the proper functioning of the human body, but its excess can cause carcinogenic effects [16]. Nickel-59, 63 are isotopes generated in the nuclear reactor as APs [17]. ⁵⁹Ni and ⁶³Ni have a half-life of 76,000 and 101.2 years, respectively [18]. Nickel is responsible for various health effects on humans, depending on the route of exposure and dosage. It can cause cardiovascular diseases, skin diseases, nose and lung cancer [19]. Cobalt-60 is generated in the nuclear power plant. ⁶⁰Co is the source of high gamma radiation and has a half-life of 5.27 years. The presence of cobalt in the environment, considering its radioactivity, can cause detrimental effects on ecology and human health [20].For the mitigation of radionuclides’ environmental impact, various methods have been used to date such as phytoremediation [21], ion-exchange [22], chemical precipitation [23], solvent extraction [24], reverse osmosis [25], electrochemical purification [26], membrane separation [27] and adsorption [28]. The adsorption method is the most reliable method for toxic radionuclide removal and has been widely used. Numerous materials can be utilized for adsorption purposes such as inorganic sorbents [29], oxides [29][30][31], carbon materials [32], organic-inorganic hybrid materials [33], metal-organic frameworks [34] and porous organic polymers [35]. Although the adsorbents used in nuclear waste management, e.g., ion exchangers and inorganic materials are constantly improving over the time in their structural, physical, and chemical aspects [36], these materials also have disadvantages, e.g., rapid saturation, etc.The Department of Nuclear Chemistry, Faculty of Natural Sciences, Comenius University in Bratislava, has long been dedicated to the development and research on various highly selective and radiation-stable sorbents, which are used:

-

-as a component in a multibarrier system for the safe storage and final disposal of SNFs and RWs, respectively,

-

-as a separation component for RN isolation from RN mixtures, mainly for further use, or in radiochemical analysis for target radionuclide separation and subsequent qualitative and quantitative determination.

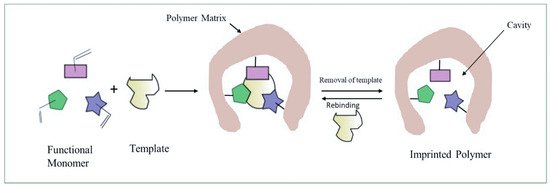

Ion-imprinted polymers (IIPs) can solve this issue and are widely used for in radionuclide adsorption or removal processes [37]. IIPs are sorbents with various application possibilities, e.g., extraction, filtration, solid and liquid media purification [38]. These materials are crosslinked polymers with pores and binding sites for the targeted ions and negatively or positively charged molecules [39]. IIPs are generally prepared from a reaction mixture composed of a functional monomer, a crosslinker, an initiator and a template [40]. Imprinting of the template ions in a polymer matrix can be achieved by using different strategies and are discussed further in detail. IIPs are developed in a similar way to imitate key and lock mechanisms (Figure 1) for recognition and removal of the targeted ions. Thus, IIPs offer excellent selectivity and specific affinity for a given ion. Contaminants present at low concentrations can be removed selectively by IIPs, which was not effectively achieved before by other methods [41]. IIPs are similar to molecularly imprinted polymers (MIPs) which are developed to imitate the interactions between enzymes and antibodies. The difference between IIPs and MIPs lies in the type of recognition substance which can be ions or molecules. Figure 1. Schematic presentation of the procedure for the preparation of imprinted polymers.MIP and IIP preparation differ in the type of interaction between the monomers or ligands (MIPs) and ions (IIPs), i.e., covalent or noncovalent interactions. The covalent molecular imprinting technique method developed by Wulff et al. [42], involves reversible covalent binding between monomers and the templates. This approach provides greater stability and consistent recognition sites compared to the non-covalent approach. In the non-covalent method, the non-covalent bonds such as H-bonds, ionic bonds, van der Waals interactions, etc. are used by monomers to self-assemble around the template. The template is then removed from the material after polymerization. Mosbach et al. [43] developed the non-covalent method, which is an effective way to form cavities with the template’s shape and charge memory effects, responsible for the selective recognition of analytes. The non-covalent method is easy to use and has the option to choose from a range of different monomers. IIPs exhibit similar virtues as MIPs, the only difference being the specific recognition of inorganic ions after the imprinting process [44][45]. The first IIP preparation was achieved using poly(vinyl pyridine) crosslinked with 1,4-dibromobutane in the presence of metal ions [46]. Saunders et al. [47] used 2-chloroacrylic acid and ethylene glycol dimethacrylate (EGDMA) with a uranyl ion-imprinted co-polymer after removal of the template. This material selectively extracts uranium from dilute aqueous solutions. He et al. [48] synthesized a new functional monomer—N-(o-carboxyphenyl) maleamic acid (CPMA)—for Th(IV) ion separation. This adsorbent was made of a silica gel surface coating with a thin IIP layer.

Figure 1. Schematic presentation of the procedure for the preparation of imprinted polymers.MIP and IIP preparation differ in the type of interaction between the monomers or ligands (MIPs) and ions (IIPs), i.e., covalent or noncovalent interactions. The covalent molecular imprinting technique method developed by Wulff et al. [42], involves reversible covalent binding between monomers and the templates. This approach provides greater stability and consistent recognition sites compared to the non-covalent approach. In the non-covalent method, the non-covalent bonds such as H-bonds, ionic bonds, van der Waals interactions, etc. are used by monomers to self-assemble around the template. The template is then removed from the material after polymerization. Mosbach et al. [43] developed the non-covalent method, which is an effective way to form cavities with the template’s shape and charge memory effects, responsible for the selective recognition of analytes. The non-covalent method is easy to use and has the option to choose from a range of different monomers. IIPs exhibit similar virtues as MIPs, the only difference being the specific recognition of inorganic ions after the imprinting process [44][45]. The first IIP preparation was achieved using poly(vinyl pyridine) crosslinked with 1,4-dibromobutane in the presence of metal ions [46]. Saunders et al. [47] used 2-chloroacrylic acid and ethylene glycol dimethacrylate (EGDMA) with a uranyl ion-imprinted co-polymer after removal of the template. This material selectively extracts uranium from dilute aqueous solutions. He et al. [48] synthesized a new functional monomer—N-(o-carboxyphenyl) maleamic acid (CPMA)—for Th(IV) ion separation. This adsorbent was made of a silica gel surface coating with a thin IIP layer.

2. Fundamentals of IIPs Synthesis for Radionuclides Adsorption

The synthesis of IIPs is commonly carried out in the following way: First, monomers containing functional groups are mixed with template ions, whereupon the monomers self-assemble around the ions. Second, a crosslinker is used to polymerize the monomers by using a photo- or thermal polymerization technique. Third, template ions are removed from the polymers, consequently generating specific binding sites that can capture target ionic species [49]. IIPs shows excellent ion selectivity due to their recognizable binding sites for a particular ion’s size and charge. The adsorption capacity of the IIPs is influenced by certain factors, such as their ligands’ ability to bind with metal ions, ionic charge, the size of ions, and the electronic configuration of the metals such as coordination number or oxidation states [50][51]. The IIPs are stable against pH, temperature, and pressure which is almost impossible to achieve in natural molecular recognition systems [52].

2.1. Principles and Basic Components for the Synthesis of IIPs

One of the most crucial criteria for the effective binding and selectivity of the metal ion to the imprinted material is the interaction of the functional groups of monomers with the template [53]. The template interaction depends upon the type of bonding present with monomers. Two approaches, as mentioned earlier, are used: the covalent approach and the non-covalent approach. The IIPs are developed using a template, functional monomers, crosslinkers, porogens, and initiators. The ratio and the selection of these components are essential for better selectivity and binding capacity and affect the ultimate physical and chemical properties of the IIPs.

2.1.1. Templates

The selection of templates is a crucial requirement for IIP development. The templates’ chemical and physical properties are analyzed for their selection. The basic requirements for choosing a template are as follows:

-

The template should be inert, it should not affect the cross-linking and polymerization of the monomer, e.g., the functional moieties shouldn’t interfere with the polymerization by acting as inhibitors or reacting with the monomer.

-

The template should be cost-effective.

-

The template should be stable at the polymerization or crosslinking temperature or exposure to UV radiation.

2.1.2. Monomers and Crosslinkers

In order to prepare recognition sites in a polymer matrix monomer should have functional groups that will bind with the analytes. Monomer selection is an important factor for the design of IIPs. To prepare imprinted polymers a free radical polymerization (FRP) method is used since it is easy to execute and offers a wide range of monomer selection. Generally, in radical polymerization (RP) of IIPs vinyl monomers are used, e.g., methacrylic acid [54], acrylamide [55], styrene [56], 4-vinylpyridine [57], etc. The monomers are crosslinked using di-, tri-, or tetrafunctional vinylated crosslinkers. Crosslinkers are useful for improving the mechanical properties of the material such as strength and tolerance to the solvent and different pH values. They also help the morphology of the material and adjusting the monomer–crosslinker ratio affects the materials’ porosity. Commonly used crosslinkers for free radical polymerization are ethylene glycol dimethacrylate (EGDMA) [58], divinylbenzene (DVB) [59], or trimethylolpropane trimethacrylate (TRIM) [60]. The ratio of the template to monomer is crucial. The compatibility ratio for the adsorption of UO₂⁺ ion was found to be 1:4 template to monomer, and exceeding the ratio will cause reduced interaction with the template [61]. The abovementioned monomers’ binding capacity is relatively weaker; they carry a single functionality for interaction. The dependence on a metal ion’s characteristics such as shape, oxidation, and chemical structure and surroundings play an important role in its effective binding [62]. To improve the binding performance of the materials, various ligands were prepared for effective binding with selective ions. Fasihi et al. [63] synthesized a 1-hydroxy-2-(prop-2′-enyl)-9,10-anthraquinone ligand to prepare uranyl IIPs. Zulfikar et al. [64] prepared 5,7-dichloroquinoline-8-ol and 4-vinylpyridine-based IIPs for the adsorption of yttrium. Macromolecular monomers such as chitosan and, sodium alginate are also widely used to remove radionuclides from the environment [65][66]. Chitosan has NH₂ and -OH groups that will donate to the metals and be useful for chelation and crosslinking [67]. Sodium alginate contains -COOH and -OH groups, which helps provide the necessary binding sites for the preparation of IIPs [68].

2.1.3. Porogens (Solvents)

The purpose of the solvent in the polymerization is to solubilize the components of the reaction mixture such as monomers, templates, and crosslinkers. It helps in pore formation in a material, which improves the material’s adsorption properties [69]. The solvent choice depends on the reaction system interactions. In the case the system consists of organic molecules that contain hydrogen atoms, for that purpose nonpolar solvents such as toluene can be used, and for polar systems, water or other polar solvents have been used [70].

2.1.4. Initiators

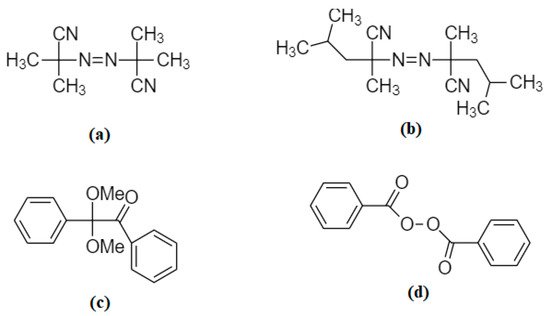

The initiator is responsible for the activation of free radical polymerization in monomers. The initiator selection depends on the template ion’s stability and electrostatic interactions with the monomers, mainly for complex formation. If initiators are thermally activated, thermal stability of the template is also required. If the monomers form a complex with the template ions by hydrogen bond formation, then it is not appropriate to use a thermal method. However, a photochemically activated initiator is more reliable for using such a low stability template and its interactions. The initiator concentration is directly related to the generation of radicals in the system, which increases the particle size of the IIPs

[71]

. Some of the initiators used are shown in

. Figure 2. Commonly used initiators: (a) azobisisobutyronitrile (AIBN), (b) azobisdimethylvaleronitrile (ABDV), (c) benzildimethyl acetal, (d) benzoyl peroxide (BPO).

Figure 2. Commonly used initiators: (a) azobisisobutyronitrile (AIBN), (b) azobisdimethylvaleronitrile (ABDV), (c) benzildimethyl acetal, (d) benzoyl peroxide (BPO).

2.2. Imprinting Strategy for the IIPs Synthesis

The preparation of IIPs can be performed in several ways using multiple preparation methods. In this section, the most commonly used type of polymerization or imprinting strategies are described. The simplest method for IIP synthesis is radical polymerization (RP). Radical polymerization can be divided into bulk polymerization [72], emulsion polymerization [73], solution polymerization [74], precipitation polymerization [75] and reversible addition-fragmentation techniques (RAFT) polymerization [76]. In the living free radical polymerization method (for e.g., RAFT) the desired polymer morphologies can be achieved [77]. RP also provides significantly faster polymerization rates compared to the condensation polymerization method. The system in RP contains the monomer, initiator and crosslinker, if required. Another common method for making crosslinked structures is the condensation method, which includes sol-gel and co-condensation polymerization. Chitosan is a functional group-carrying polymer with -NH2 and -OH groups which can be modified with other compounds, in order to form a dendritic structure or crosslinked networks. For the preparation of crosslinked structures chitosan can be crosslinked with various difunctional molecules such as glutaraldehyde [78], epichlorohydrin, etc. In another study, Gao et al. [79] used 3-glycidoxypropyltrimethoxysilane (GPTMS) for crosslinking chitosan or silane coupling agents. Imprinting metal ions on the materials’ surface solves certain drawbacks associated with the use of IIPs, such as poor mass transfer and binding kinetics. The surface of imprinted polymers can improve the selectivity and specificity of the materials’ surface, which is not found in general IIPs [80].

References

- Keith, S.; Faroon, O.; Roney, N.; Scinicariello, F.; Wilbur, S.; Ingerman, L.; Llados, F.; Plewak, D.; Wohlers, D.; Diamond, G. Toxicological Profile for Uranium; Agency for Toxic Substances and Disease Registry: Atlanta, GA, USA, 2013.

- Horne, G.P.; Zarzana, C.A.; Grimes, T.S.; Rae, C.; Ceder, J.; Mezyk, S.P.; Mincher, B.J.; Charbonnel, M.-C.; Guilbaud, P.; Saint-Louis, G. Effect of Chemical Environment on the Radiation Chemistry of N, N-Di-(2-Ethylhexyl) Butyramide (DEHBA) and Plutonium Retention. Dalton Trans. 2019, 48, 14450–14460.

- Augustine, S.; Gagnaire, B.; Adam-Guillermin, C.; Kooijman, S.A.L.M. Effects of Uranium on the Metabolism of Zebrafish, Danio Rerio. Aquat. Toxicol. 2012, 118, 9–26.

- Manaka, M.; Seki, Y.; Okuzawa, K.; Watanabe, Y. Uranium Sorption onto Natural Sediments within a Small Stream in Central Japan. Limnology 2008, 9, 173–183.

- Nordberg, G.F.; Fowler, B.A.; Nordberg, M.; Friberg, L. Handbook on the Toxicology of Metals; Academic Press: Amsterdam, The Netherlands, 2007; p. 1024.

- Keith, S.; Wohlers, D.; Ingerman, L. Toxicological Profile for Thorium; Agency for Toxic Substances and Disease Registry: Atlanta, GA, USA, 2019.

- Ding, H.; Zhang, X.; Yang, H.; Luo, X.; Lin, X. Highly Efficient Extraction of Thorium from Aqueous Solution by Fungal Mycelium-Based Microspheres Fabricated via Immobilization. Chem. Eng. J. 2019, 368, 37–50.

- Morsy, A.M.A. Performance of Magnetic Talc Titanium Oxide Composite for Thorium Ions Adsorption from Acidic Solution. Environ. Technol. Innov. 2017, 8, 399–410.

- Igarashi, Y.; Kogure, T.; Kurihara, Y.; Miura, H.; Okumura, T.; Satou, Y.; Takahashi, Y.; Yamaguchi, N. A Review of Cs-Bearing Microparticles in the Environment Emitted by the Fukushima Dai-Ichi Nuclear Power Plant Accident. J. Environ. Radioact. 2019, 205, 101–118.

- Ma, B.; Oh, S.; Shin, W.S.; Choi, S.-J. Removal of Co2+, Sr2+ and Cs+ from Aqueous Solution by Phosphate-Modified Montmorillonite (PMM). Desalination 2011, 276, 336–346.

- Li, Q.; Liu, H.; Liu, T.; Guo, M.; Qing, B.; Ye, X.; Wu, Z. Strontium and Calcium Ion Adsorption by Molecularly Imprinted Hybrid Gel. Chem. Eng. J. 2010, 157, 401–407.

- Guo, Y.; Zhang, S.; Lai, L.; Wang, G. Rare Earth Elements in Oolong Tea and Their Human Health Risks Associated with Drinking Tea. J. Food Compos. Anal. 2015, 44, 122–127.

- Li, Y.; Li, P.; Yu, H.; Bian, Y. Recent Advances (2010–2015) in Studies of Cerium Oxide Nanoparticles’ Health Effects. Environ. Toxicol. Pharmacol. 2016, 44, 25–29.

- Colton, R. The Chemistry of Rhenium and Technetium; Interscience Publishers: London, UK; New York, NY, USA, 1965.

- Iannicelli-Zubiani, E.M.; Stampino, P.G.; Cristiani, C.; Dotelli, G. Enhanced Lanthanum Adsorption by Amine Modified Activated Carbon. Chem. Eng. J. 2018, 341, 75–82.

- Boffetta, P.; Cardis, E.; Vainio, H.; Coleman, M.P.; Kogevinas, M.; Nordberg, G.; Parkin, D.M.; Partensky, C.; Shuker, D.; Tomatis, L. Cancer Risks Related to Electricity Production. Eur. J. Cancer Clin. Oncol. 1991, 27, 1504–1519.

- Fišera, O.; Šebesta, F. Determination of 59Ni in Radioactive Waste. J. Radioanal. Nucl. Chem. 2010, 286, 713–717.

- Mudipalli, A.; Zelikoff, J.T. Essential and Non-Essential Metals; Humana Press: Totowa, NJ, USA, 2017.

- Taddei, M.H.T.; Macacini, J.F.; Vicente, R.; Marumo, J.T.; Sakata, S.K.; Terremoto, L.A.A. Determination of 63Ni and 59Ni in Spent Ion-Exchange Resin and Activated Charcoal from the IEA-R1 Nuclear Research Reactor. Appl. Radiat. Isot. 2013, 77, 50–55.

- Gault, N.; Sandre, C.; Poncy, J.-L.; Moulin, C.; Lefaix, J.-L.; Bresson, C. Cobalt Toxicity: Chemical and Radiological Combined Effects on HaCaT Keratinocyte Cell Line. Toxicol. Vitr. 2010, 24, 92–98.

- Mahar, A.; Wang, P.; Ali, A.; Awasthi, M.K.; Lahori, A.H.; Wang, Q.; Li, R.; Zhang, Z. Challenges and Opportunities in the Phytoremediation of Heavy Metals Contaminated Soils: A Review. Ecotoxicol. Environ. Saf. 2016, 126, 111–121.

- Kononova, O.N.; Bryuzgina, G.L.; Apchitaeva, O.V.; Kononov, Y.S. Ion Exchange Recovery of Chromium (VI) and Manganese (II) from Aqueous Solutions. Arab. J. Chem. 2019, 12, 2713–2720.

- Mollah, A.; Begum, A.; Rahman, M. Removal of Radionuclides from Low Level Radioactive Liquid Waste by Precipitation. J. Radioanal. Nucl. Chem. 1998, 229, 187–189.

- Khani, M.H.; Keshtkar, A.R.; Ghannadi, M.; Pahlavanzadeh, H. Equilibrium, Kinetic and Thermodynamic Study of the Biosorption of Uranium onto Cystoseria Indica Algae. J. Hazard. Mater. 2008, 150, 612–618.

- Montaña, M.; Camacho, A.; Serrano, I.; Devesa, R.; Matia, L.; Vallés, I. Removal of Radionuclides in Drinking Water by Membrane Treatment Using Ultrafiltration, Reverse Osmosis and Electrodialysis Reversal. J. Environ. Radioact. 2013, 125, 86–92.

- Abdi, S.; Nasiri, M.; Mesbahi, A.; Khani, M.H. Investigation of Uranium (VI) Adsorption by Polypyrrole. J. Hazard. Mater. 2017, 332, 132–139.

- Wang, J.; Zhuang, S. Removal of Various Pollutants from Water and Wastewater by Modified Chitosan Adsorbents. Crit. Rev. Environ. Sci. Technol. 2017, 47, 2331–2386.

- Wang, G.; Liu, J.; Wang, X.; Xie, Z.; Deng, N. Adsorption of Uranium (VI) from Aqueous Solution onto Cross-Linked Chitosan. J. Hazard. Mater. 2009, 168, 1053–1058.

- Galamboš, M.; Suchánek, P.; Rosskopfová, O. Sorption of Anthropogenic Radionuclides on Natural and Synthetic Inorganic Sorbents. J. Radioanal. Nucl. Chem. 2012, 293, 613–633.

- Means, J.L.; Crerar, D.A.; Borcsik, M.P.; Duguid, J.O. Radionuclide Adsorption by Manganese Oxides and Implications for Radioactive Waste Disposal. Nature 1978, 274, 44–47.

- Musić, S.; Ristić, M. Adsorption of Trace Elements or Radionuclides on Hydrous Iron Oxides. J. Radioanal. Nucl. Chem. 1988, 120, 289–304.

- Lu, S.; Sun, Y.; Chen, C. Adsorption of Radionuclides on Carbon-Based Nanomaterials. In Interface Science and Technology; Elsevier: Amsterdam, The Netherlands, 2019; Volume 29, pp. 141–215.

- Claverie, M.; Garcia, J.; Prevost, T.; Brendlé, J.; Limousy, L. Inorganic and Hybrid (Organic–Inorganic) Lamellar Materials for Heavy Metals and Radionuclides Capture in Energy Wastes Management—A Review. Materials 2019, 12, 1399.

- Naeimi, S.; Faghihian, H. Performance of Novel Adsorbent Prepared by Magnetic Metal-Organic Framework (MOF) Modified by Potassium Nickel Hexacyanoferrate for Removal of Cs+ from Aqueous Solution. Sep. Purif. Technol. 2017, 175, 255–265.

- Sun, Q.; Aguila, B.; Ma, S. Opportunities of Porous Organic Polymers for Radionuclide Sequestration. Trends Chem. 2019, 1, 292–303.

- Vellingiri, K.; Kim, K.-H.; Pournara, A.; Deep, A. Towards High-Efficiency Sorptive Capture of Radionuclides in Solution and Gas. Prog. Mater. Sci. 2018, 94, 1–67.

- Chen, L.; Xu, S.; Li, J. Recent Advances in Molecular Imprinting Technology: Current Status, Challenges and Highlighted Applications. Chem. Soc. Rev. 2011, 40, 2922–2942.

- Haupt, K. Imprinted Polymers—Tailor-Made Mimics of Antibodies and Receptors. Chem. Commun. 2003, 171–178.

- Tarley, C.R.T.; Corazza, M.Z.; Somera, B.F.; Segatelli, M.G. Preparation of New Ion-Selective Cross-Linked Poly (Vinylimidazole-Co-Ethylene Glycol Dimethacrylate) Using a Double-Imprinting Process for the Preconcentration of Pb2+ Ions. J. Colloid Interface Sci. 2015, 450, 254–263.

- Mahony, J.O.; Nolan, K.; Smyth, M.R.; Mizaikoff, B. Molecularly Imprinted Polymers—Potential and Challenges in Analytical Chemistry. Anal. Chim. Acta 2005, 534, 31–39.

- Rao, T.P.; Daniel, S.; Gladis, J.M. Tailored Materials for Preconcentration or Separation of Metals by Ion-Imprinted Polymers for Solid-Phase Extraction (IIP-SPE). TrAC Trends Anal. Chem. 2004, 23, 28–35.

- Wulff, G. Molecular Imprinting in Cross-linked Materials with the Aid of Molecular Templates—A Way towards Artificial Antibodies. Angew. Chem. Int. Ed. Engl. 1995, 34, 1812–1832.

- Haupt, K.; Mosbach, K. Molecularly Imprinted Polymers and Their Use in Biomimetic Sensors. Chem. Rev. 2000, 100, 2495–2504.

- Fu, J.; Chen, L.; Li, J.; Zhang, Z. Current Status and Challenges of Ion Imprinting. J. Mater. Chem. A 2015, 3, 13598–13627.

- Metilda, P.; Gladis, J.M.; Rao, T.P. Influence of Binary/Ternary Complex of Imprint Ion on the Preconcentration of Uranium (VI) Using Ion Imprinted Polymer Materials. Anal. Chim. Acta 2004, 512, 63–73.

- Nishide, H.; Deguchi, J.; Tsuchida, E. Selective Adsorption of Metal Ions on Crosslinked Poly (Vinylpyridine) Resin Prepared with a Metal Ion as a Template. Chem. Lett. 1976, 5, 169–174.

- Saunders, G.D.; Foxon, S.P.; Walton, P.H.; Joyce, M.J.; Port, S.N. A Selective Uranium Extraction Agent Prepared by Polymer ImprintingS. N. Port, MJ Joyce, PH Walton and GD Saunders, UK Pat. Appl., 979946.7, 1997; Int. Pat., WO 99/15707, 1998. Chem. Commun. 2000, 273–274.

- He, Q.; Chang, X.; Wu, Q.; Huang, X.; Hu, Z.; Zhai, Y. Synthesis and Applications of Surface-Grafted Th (IV)-Imprinted Polymers for Selective Solid-Phase Extraction of Thorium (IV). Anal. Chim. Acta 2007, 605, 192–197.

- Say, R.; Birlik, E.; Ersöz, A.; Yılmaz, F.; Gedikbey, T.; Denizli, A. Preconcentration of Copper on Ion-Selective Imprinted Polymer Microbeads. Anal. Chim. Acta 2003, 480, 251–258.

- Nicholls, I.A.; Adbo, K.; Andersson, H.S.; Andersson, P.O.; Ankarloo, J.; Hedin-Dahlström, J.; Jokela, P.; Karlsson, J.G.; Olofsson, L.; Rosengren, J.; et al. Can We Rationally Design Molecularly Imprinted Polymers? Anal. Chim. Acta 2001, 435, 9–18.

- Laatikainen, K.; Udomsap, D.; Siren, H.; Brisset, H.; Sainio, T.; Branger, C. Effect of Template Ion–Ligand Complex Stoichiometry on Selectivity of Ion-Imprinted Polymers. Talanta 2015, 134, 538–545.

- Özkara, S.; Andaç, M.; Karakoç, V.; Say, R.; Denizli, A. Ion-imprinted PHEMA Based Monolith for the Removal of Fe3+ Ions from Aqueous Solutions. J. Appl. Polym. Sci. 2011, 120, 1829–1836.

- Sharma, G.; Kandasubramanian, B. Molecularly Imprinted Polymers for Selective Recognition and Extraction of Heavy Metal Ions and Toxic Dyes. J. Chem. Eng. Data 2020, 65, 396–418.

- Meng, H.; Li, Z.; Ma, F.; Jia, L.; Wang, X.; Zhou, W.; Zhang, L. Preparation and Characterization of Surface Imprinted Polymer for Selective Sorption of Uranium (VI). J. Radioanal. Nucl. Chem. 2015, 306, 139–146.

- Germiniano, T.O.; Corazza, M.Z.; Segatelli, M.G.; Ribeiro, E.S.; Yabe, M.J.S.; Galunin, E.; Tarley, C.R.T. Synthesis of Novel Copper Ion-Selective Material Based on Hierarchically Imprinted Cross-Linked Poly (Acrylamide-Co-Ethylene Glycol Dimethacrylate). React. Funct. Polym. 2014, 82, 72–80.

- Mafu, L.D.; Mamba, B.B.; Msagati, T.A.M. Synthesis and Characterization of Ion Imprinted Polymeric Adsorbents for the Selective Recognition and Removal of Arsenic and Selenium in Wastewater Samples. J. Saudi Chem. Soc. 2016, 20, 594–605.

- Cai, X.; Li, J.; Zhang, Z.; Yang, F.; Dong, R.; Chen, L. Novel Pb2+ Ion Imprinted Polymers Based on Ionic Interaction via Synergy of Dual Functional Monomers for Selective Solid-Phase Extraction of Pb2+ in Water Samples. ACS Appl. Mater. Interfaces 2014, 6, 305–313.

- Rodríguez-Fernández, R.; Peña-Vázquez, E.; Bermejo-Barrera, P. Synthesis of an Imprinted Polymer for the Determination of Methylmercury in Marine Products. Talanta 2015, 144, 636–641.

- Jinadasa, K.K.; Peña-Vázquez, E.; Bermejo-Barrera, P.; Moreda-Piñeiro, A. Ionic Imprinted Polymer Solid-Phase Extraction for Inorganic Arsenic Selective Pre-Concentration in Fishery Products before High-Performance Liquid Chromatography–Inductively Coupled Plasma-Mass Spectrometry Speciation. J. Chromatogr. A 2020, 1619, 460973.

- Yordanova, T.; Dakova, I.; Balashev, K.; Karadjova, I. Polymeric Ion-Imprinted Nanoparticles for Mercury Speciation in Surface Waters. Microchem. J. 2014, 113, 42–47.

- Anirudhan, T.S.; Nima, J.; Divya, P.L. Adsorption and Separation Behavior of Uranium (VI) by 4-Vinylpyridine-Grafted-Vinyltriethoxysilane-Cellulose Ion Imprinted Polymer. J. Environ. Chem. Eng. 2015, 3, 1267–1276.

- Comba, P.; Schiek, W. Fit and Misfit between Ligands and Metal Ions. Coord. Chem. Rev. 2003, 238, 21–29.

- Fasihi, J.; Alahyari, S.A.; Shamsipur, M.; Sharghi, H.; Charkhi, A. Adsorption of Uranyl Ion onto an Anthraquinone Based Ion-Imprinted Copolymer. React. Funct. Polym. 2011, 71, 803–808.

- Zulfikar, M.A.; Zarlina, R.; Handayani, N.; Alni, A.; Wahyuningrum, D. Separation of Yttrium from Aqueous Solution Using Ionic Imprinted Polymers. Russ. J. Non-Ferrous Met. 2017, 58, 614–624.

- Muzzarelli, R.A.A. Potential of Chitin/Chitosan-Bearing Materials for Uranium Recovery: An Interdisciplinary Review. Carbohydr. Polym. 2011, 84, 54–63.

- Monier, M.; Abdel-Latif, D.A.; Mohammed, H.A. Synthesis and Characterization of Uranyl Ion-Imprinted Microspheres Based on Amidoximated Modified Alginate. Int. J. Biol. Macromol. 2015, 75, 354–363.

- Ngah, W.S.W.; Teong, L.C.; Hanafiah, M.A.K.M. Adsorption of Dyes and Heavy Metal Ions by Chitosan Composites: A Review. Carbohydr. Polym. 2011, 83, 1446–1456.

- Özkahraman, B.; Özbaş, Z.; Öztürk, A.B. Synthesis of Ion-Imprinted Alginate Based Beads: Selective Adsorption Behavior of Nickel (II) Ions. J. Polym. Environ. 2018, 26, 4303–4310.

- Okay, O. Macroporous Copolymer Networks. Prog. Polym. Sci. 2000, 25, 711–779.

- Yoshizako, K.; Hosoya, K.; Iwakoshi, Y.; Kimata, K.; Tanaka, N. Porogen Imprinting Effects. Anal. Chem. 1998, 70, 386–389.

- Rammika, M.; Darko, G.; Torto, N. Optimal Synthesis of a Ni (II)-Dimethylglyoxime Ion-Imprinted Polymer for the Enrichment of Ni (II) Ions in Water, Soil and Mine Tailing Samples. Water SA 2012, 38, 261–268.

- Lin, C.; Wang, H.; Wang, Y.; Zhou, L.; Liang, J. Selective Preconcentration of Trace Thorium from Aqueous Solutions with Th (IV)-Imprinted Polymers Prepared by a Surface-Grafted Technique. Int. J. Environ. Anal. Chem. 2011, 91, 1050–1061.

- Monier, M.; Abdel-Latif, D.A. Synthesis and Characterization of Ion-Imprinted Resin Based on Carboxymethyl Cellulose for Selective Removal of UO22+. Carbohydr. Polym. 2013, 97, 743–752.

- Ji, X.Z.; Liu, H.J.; Wang, L.L.; Sun, Y.K.; Wu, Y.W. Study on Adsorption of Th (IV) Using Surface Modified Dibenzoylmethane Molecular Imprinted Polymer. J. Radioanal. Nucl. Chem. 2013, 295, 265–270.

- Chen, J.; Bai, H.; Xia, J.; Liu, X.; Liu, Y. Trace Detection of Ce3+ by Adsorption Strip Voltammetry at a Carbon Paste Electrode Modified with Ion Imprinted Polymers. J. Rare Earths 2018, 36, 1121–1126.

- Liu, Y.; Meng, X.; Luo, M.; Meng, M.; Ni, L.; Qiu, J.; Hu, Z.; Liu, F.; Zhong, G.; Liu, Z. Synthesis of Hydrophilic Surface Ion-Imprinted Polymer Based on Graphene Oxide for Removal of Strontium from Aqueous Solution. J. Mater. Chem. A 2015, 3, 1287–1297.

- Salian, V.D.; Byrne, M.E. Living Radical Polymerization and Molecular Imprinting: Improving Polymer Morphology in Imprinted Polymers. Macromol. Mater. Eng. 2013, 298, 379–390.

- Chen, Y.; Wang, J. Removal of Radionuclide Sr2+ Ions from Aqueous Solution Using Synthesized Magnetic Chitosan Beads. Nucl. Eng. Des. 2012, 242, 445–451.

- Gao, M.; Zhu, G.; Gao, C. A Review: Adsorption Materials for the Removal and Recovery of Uranium from Aqueous Solutions. Energy Environ. Focus 2014, 3, 219–226.

- Gao, D.; Zhang, Z.; Wu, M.; Xie, C.; Guan, G.; Wang, D. A Surface Functional Monomer-Directing Strategy for Highly Dense Imprinting of TNT at Surface of Silica Nanoparticles. J. Am. Chem. Soc. 2007, 129, 7859–7866.