The importance of energy demands that have increased exponentially over the past century has led to the sourcing of other ideal power solutions as the potential replacement alternative to the conventional fossil fuel. However, the utilisation of fossil fuel has created severe environmental issues. The identification of other renewable sources is beneficial to replace the energy utilisation globally. Biomass is a highly favourable sustainable alternative to renewable resources that can produce cleaner, cheaper, and readily available energy sources in the future. The palm oil industry is essentially ideal for the availability of abundant biomass resources, where the multifaceted residues are vital for energy production through the conversion of biomass waste into value-added products simultaneously. This article discusses the utilisation of palm oil and its residues in the energy and transportation sector. Assessment and evaluation on the feasibility of palm oil and its residues were made on the current valorisation methods such as thermochemical and biochemical techniques. Their potential as transportation fuels were concurrently reviewed. This is followed by a discussion on future challenges of palm oil industries that will take place globally, including the prospects from government and non-government organisations for the development of palm oil as a sustainable alternative replacement to fossil fuel. Hence, this review aims to provide further insight into the possibilities of palm oil and its residues towards sustainable development with reduced environmental-related issues.

- biofuel

- bioenergy

- oil palm residues

- renewable energy

- thermochemical process

- biochemical process

- pyrolysis

- direct combustion

- anaerobic digestion

- gasification

- agropolitics

1. Introduction

The estimated extinction of fossil fuel has led to challenges in the energy industry in sourcing other powerful, yet environmentally friendly, potions with lower emission and abundant in nature to be equally standing on the world energy platform. According to the International Energy Agency (IEA), the global oil price has shot up to $80/barrel in 2018, yet the global energy demand is expected to increase up to 25% between 2017 and 2040, subsequently raising CO2 emission by 1.6% in the year 2017, which were flat for the previous three consecutive years [1]. Globally, greenhouse gas emissions (GHG) have increased from extreme human exploitation in finding ways to cope with the ever-increasing energy demand day by day due to the population growth and other human activities. The various sectors demanding energy are transportation, residential, commercial, industries, and agricultural practices, which indicate a heavy requirement for a sustainable fuel alternative.

Following the era of rapid development and advancement, the research effort and attention should be diverted to the discovery of renewable and sustainable fuel resources. The employment of biofuels in the energy and transportation sector should receive high research interest due to their several advantages such as cheaper production cost, cleaner production method, and reduced environmental issues [2]. Biofuel has been perceived as a highly preferable replacement alternative to conventional fossil fuels. It is strongly favourable in the industries for their functionalities and advantages, which are comparable and compatible with fossil derived fuels. Notably, the distinguished advantage for biofuel is the abundance of available resources that are renewable and more sustainable in comparison to fossil fuel sources that are utilised until extinction. In addition, biofuel has shown its environmental friendliness as an alternative fuel with reduced environmental impacts, leading to the development of a greener environment.

Scholars and researchers in recent decades have selected biomass as a potential alternative fuel in the world. Biomass is primarily found in the form of living matters or recently living plants, as well as in waste. The term feedstock refers to whatever type of organic material that could be used to produce energy. Different feedstocks have different physical compositions, but generally, all feedstocks include varying amounts of carbon, water, and organic volatiles for energy production. This biomass feedstock is classified as “theoretically carbon neutral”. This is because the plants that change into biomass feedstock use carbon dioxide during the growing stage and repel the same amount of carbon to the atmosphere when they are incinerated. Sulaiman et al. [3] revealed in their recent studies that the amount of CO2 could be reduced by up to 0.8888% in 27 EU countries by an increment of 1% of wood biomass utilization. This statement is further substantiated by Gwan Seon Kim, Sun Ki Choi, and Jun Ho Seok [4], revealing that an increase of 1% per capita biomass fuel reduces 0.65% emission of CO2 per capita. Biomass has been readily used as an efficient fuel substance, which has varying benefits as well.

There are abundant biomass sources to be employed as fuel in the world. The biomass sources quality and characteristics vary regionally and are controlled by multidimensional components mechanism and drivers [5], such as water, soil, climate, and agricultural science for sustainable farming practices [6]. Palm oil is a potential biomass source abundantly available in Asia region, in which it requires less fertilizers and pesticides in comparison to other oil seeds [7] and can even be grown in peat soil [8] with less water needed for the cultivation. In addition, the palm oil tree utilizes nine times less land compared to any other oil crops [9] and is disease-free with the recent discovery of GanoCare to cure Ganoderma disease [10]. Nevertheless, these elements have made palm oil, and the generated oil palm residues to become sustainable replacements of fossil fuels. However, the origin and characteristic, current utilisation, and environmental impact of palm oil industries in the world should be further investigated.

Therefore, a review on oil palm residues and their suitability as an alternative fuel is vital for a sustainable environmental prospect. Thus, this review focuses on the assessment and evaluation of palm oil and the usage of its agro-industrial residues as biofuel, bioenergy, and in the transportation sector. This is followed by an investigation of the possibilities of palm oil and its residues for sustainable development with reduced environmental-related issues. Thus, this review targets selected palm oil as a fossil fuel replacement to provide further insight into the current development in the palm oil industry. This development is achieved with the rapid advancement of both palm oil and palm residues conversion techniques and approaches, including the production of value-added products from the industries.

2. Palm Oil Origin, Products and By-Products with Their Characteristics and Current Utilisation

Palm oil is one of the major ingredients in up to 50% of all daily-used products, everything from cosmetics, such as lipsticks, shampoo, and deodorants, to food ingredients, like margarine, chocolate, pastries, and baby food, including instant noodles, mentioned as either hydrogenated vegetable fats or plant fats. Palm oil (Elaeis guinneensis) [6] is considered as a versatile oil crop as palm oil trees are highly productive and have multiple uses in each different tree parts, from the fruits to the oil palm residues, including the ability to produce bioenergy or biofuels [11].

Palm oil originating from West Africa, Malaysia, and Indonesia with conducive tropical climate contributes to potentially healthy growth of palm oil trees, substantially making these countries the prime producers of palm oil in the world [12]. Initially, the palm oil production was led by Malaysia until the end of 2007; it was then led by Indonesia in the beginning of 2008 with sturdy growth until the present time [13]. In 2019, the Malaysian Palm Oil Council (MPOC) [13] reported that Malaysia has exported 18.47 million metric tonnes of palm oil, while Indonesia has exported 29.52 million metric tonnes, making Malaysia the leading secondary palm oil producers in the world. The world’s third-largest palm oil producers include Colombia, Thailand, and Nigeria, with a total production of 7% in the world [14].

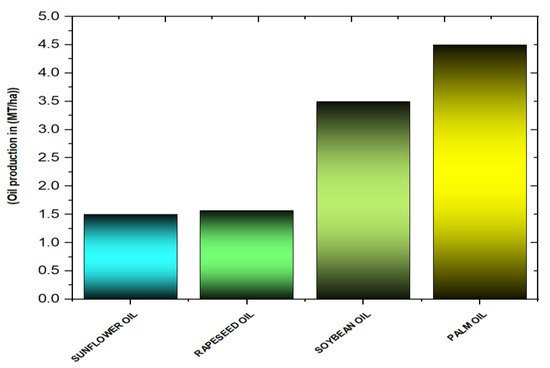

The oil demand has bloomed, outracing the productivity of the significant oil crop market over the past decades, which is in parallel with the human population growth. Palm oil seems to surpass other major oil-producing commodities such as sunflower oil and soybean oil with an average consumption of 71.48 million metric tonnes a year [15], mainly due to the high-yield factors of palm oil in contrast to other oil-producing crops. Palm oil could yield about an average of 4 to 4.5 tonnes of oil per hectare [15], which is the highest in comparison to soybean oil yield of only about 1.5 to 3.5 tonnes/ha, 1 to 1.5 tonnes/ha oil from sunflower seeds, and about 1.57 tonnes/ha oil from rapeseed oil [16] as shown in Figure 1. It is also anticipated that the breakthrough via microbial oil production and palm oil species could also increase the palm oil industry’s yield [17]. In addition, the demand for palm oil has increased due to its affordable price compared to other plant-based alternatives and is free from genetically modified organisms (GMO) or trans-fatty acids (TFA) [18]. Despite the proportional demand for palm oil for its reasonable price, unintended rapid economic growth, alongside the elevation of biodiesel production and labour cost, has massively increased the palm oil price in recent years [19].

Figure 1. Illustrated significant plant-based oil yields per hectares.

The primary global consumer of palm oil is India, which was expected to consumed nearly 9.3 million tonnes from 2016 to 2017, and the consumption is expected to increase by two-fold by 2030, followed by Europe and China with the consumption of 6.7 and 5 million tonnes, respectively [20]. Apart from that, the Balkans (Bulgaria, Croatia, Greece, and etc.) have also shown an increase in demand for edible oil consumption especially palm oil from the year 2010 to 2016, Kalsom et al. [21]. It has been discovered that these regions have also imported palm oil from nonpalm oil producers such as the Netherlands, Germany, and Italy, aside from the prime palm oil producers like Malaysia and Indonesia [21].

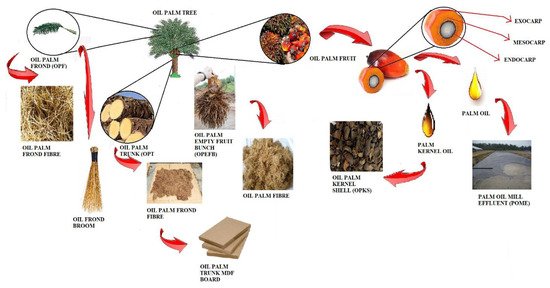

Palm oil fruit is unique in comparison to other vegetable oil producers worldwide as it could grow up to 25 m tall, produce fruit throughout the year, and expire after 25 years [22]. After the oil is squeezed out, the leftover mesocarp fibre from it is a lignocellulosic material, which consists of exocarp (the outer layer of the fruit), mesocarp (the inner layer of the fruit), and endocarp (seed cap of the fruit), as shown in Figure 2. The volume of oil obtained from the inner, middle, and outer layers of palm oil fruits vary from 14.2% to 46.9% [23]. Additionally, both parthenocarpy fruit and fruits’ oil compositions are indistinguishable in terms of palmitic acid, oleic, linoleic acid, and linolenic [23].

Figure 2. Palm oil fruits and their processed residues.

Various usages or applications of palm oil fruits and its processed residues can be seen in several industries such as pastries, confectioneries, medicines, and supplements for general health. The debate against the consumption of palm oil is always a matter of discussion among researchers and scientists. It was also reported that heart-related disease contributors might be due to the unhealthy diet commonly practiced in the western countries with less vegetable oil consumption [24]. Furthermore, Zhang et al. [25] have illustrated that palm oil intake is proven to reduce cholesterol level in comparison to lard fats or other vegetable oil (soybean and peanut) intake. In addition, palm oil utilization is quite prominent even in nonfood applications, which were proven to be about 20% of the overall palm oil usage [26]. Table 1 shows the common usage of palm oil in food industries, medical industries, and other industries.

Table 1. Palm oil utilization in various industries.

| Confectionery, Baking, and Food |

|---|

| 0.09 | ||||||

| 0.09 | ||||||

| 0.08 | ||||||

| 0.90 | 0.29 | |||||

| Proximate Analysis (%) | M | 10.10 | 7.30 | 4.90 | 2.10 | 6.15 |

| VM | 74.90 | 82.40 | 75.40 | 76.70 | 80.55 | |

| AC | 5.60 | 7.51 | 8.70 | 4.30 | 3.02 | |

| FC | 9.40 | 10.09 | 15.90 | 16.90 | 16.43 | |

| HHV (MJ/kg) | 17.15 | 16.9 | 19.5 | 17.2 | 17.00 | |

| Ref. | [64] | [57] | [57] | [65] | [66] | |

| Usage | Year | References |

| Baking fats | 2020 | Meng, Xiaoyu, et al. [27], |

| Shortening | 2019 | Goh et al. [28] |

| Imitation meat emulsifier | 2013 | Rafidah Abd Hamid [29] |

| Fat substitution in a chicken nugget | 2009 | Alina et al. [30] |

| Margarine | 2019 | Makeri, Mohammad, et al. [31] |

| Medicinal properties | ||

| Replacement of Vitamin E (α−tocotrienol) | 2010, 2015 | Sen et.al [32], Ali and Woodman [33] |

| Lubricant in human joints | 2019 | Sapawe, Norzahir, Muhammad Farhan Hanafi, and Syahrullail Samion [34] |

| Suppression of cancer cell | 2013 | Loganathan et al. [35] |

| Antioxidant for diabetes mellitus | 2020 | Alabi, Olabiyi, and Oguntibeju [36] |

| Industries | ||

| Hydrogenated biofuel | 2020 | Boonrod, Bulin, et al. [37], |

| Mix biodiesel | 2017, 2018 | Khalil et al. [38], Cordero-Ravelo and Schallenberg-Rodriguez [39]. |

The oil palm residues come in different sizes and forms: oil palm trunk (OPT) and oil palm frond (OPF) are two lignocellulosic materials available right after replanting and pruning of the palm oil trees. These OPFs and OPTs can be used in various industries such as broom from palm fronds [40] and compressed medium density fibreboard (MDF) from OPT [41], whereas oil palm empty fruit bunches (OPEFB) are being utilized widely as a mulch for palm oil trees or processed fertilizer to promote soil fertility [42]. The lignocellulosic characteristic of oil palm residues such as (OPEFB) can be a good source of polymer reinforcement material, petrochemical-based matter as a building buffer creating thermal equilibrium [43][44] and reinforcing broom frond fibre from palm oil with concrete, which is economical and eco-friendly for building construction. In addition, processed palm kernel cake has been commonly used for animal feed given to cattle and chicken [45][46]. Feeding livestock with oil palm residues, especially palm kernel expeller, could be more economical and highly nutritious and produce fatless meat, which carries 75.8% of total digestible nutrients and 11.13 MJ/kg−1 of metabolizable energy [47]. The accumulation of palm oil mill effluent (POME) throughout the production needs further treatment. It can later be utilized for other energy backup purposes.

Structural and Chemical Properties

The chemical composition oil palm residues such as oil palm mesocarp fibre (OPMF), OPEFB, oil palm kernel shell (OPKS), OPT, and OPF were outlined by previous studies as illustrated in Table 1. Overall, the cellulose content is quite prominent in comparison to the lignin and hemicellulose contents from oil palm residue. Another chemical substance present in oil palm residues apart from these two components is ash [48]. The cellulose, hemicellulose, and lignin of oil palm residues were compared with other biomasses such as banana pseudostem, corn straw, rice husk, sugarcane bagasse, and jatropha based on prevalent literature. The cellulose content of oil palm residues, especially OPF, has a higher percentage of cellulose in contrast with corn straw (31.7%) [49] and rice husk (37.1%) [50], respectively. Besides that, the lignin content of oil palm residues, ranging from 12 to 50% is significantly high, especially in OPKS as compared to banana pseudostem (17.26%) [51], sugarcane bagasse (20%) [52], jatropha (29.6%) [53], and other oil palm residues. The removal of lignin content can contribute to value-added fuels or chemicals in a later stage of fuel production [54].

Table 1. Composition of oil palm residues.

| Composition | Cellulose | Hemicellulose | Lignin | Ash | Ref. |

|---|

| Ultimate Analysis (%) | Materials | |||||

|---|---|---|---|---|---|---|

| I | II | III | IV | V | ||

| C | 43.17 | 42.80 | 50.29 | 41.60 | 42.60 | |

| H | 6.09 | 6.20 | 6.35 | 6.80 | 5.71 | |

| O | 49.75 | 50.44 | 42.82 | 50.40 | 51.00 | |

| N | 0.90 | 0.47 | 0.48 | 0.40 | 0.42 | |

| S | ||||||

| I (%) | 25.0 ± 1.7 | 25.7 ± 3.3 | 25.5 ± 0.5 | 5.8 ± 0.2 | [55] |

| II (%) | 34.4 ± 0.7 | 26.7 ± 0.2 | 12.45 ± 0.45 | 4.85 ± 0.15 | [56] |

| III (%) | 20.7 | 23.3 | 49.5 | [57] | |

| IV (%) | 34.5 | 31.8 | 25.7 | 4.3 | [58] |

| V (%) | 40.7 | 26.1 | 26.2 | [59] |

Note: I (OPMF), II (OPEFB), III (OPKS), IV (OPT), V (OPF), M (moisture content), VM (volatile matter), AC (ash content), and FC (fixed carbon).

The possible utilization of multiple agricultural solid biomass feedstocks as an energy substitution has been evaluated through energy content, proximate and ultimate analysis, as well as associating with the characteristic requirement to run optimal operation for thermochemical processes [60]. The principal constituents of oil palm residues in the ultimate analysis are carbon, hydrogen, oxygen, nitrogen, chlorine, and sulphur. The volatile matter, moisture content, ash content, and fixed carbon of the feedstocks which are known as proximate analysis has been illustrated in Table 2. The higher percentage of moisture content in both OPMF and OPEFB resulted in low bulk density and transportation difficulties, which could be altered by pretreatment methods and stretches the feedstock’s usability and market value [61]. However, OPEFB still has proven to produce approximately one third of the power from the direct combustion system as compared to a similar amount of methane used to produce electricity [62]. The application of OPKS and OPMF in thermochemical processes is relatively significant in comparison with OPEFB due to its low moisture and high nutrient content as well as possessing the value-added potential for other material production [63].

Table 3. Proximate and ultimate analysis.

Note: I (OPMF), II (OPEFB), III (OPKS), IV (OPT), V (OPF), M (moisture content), VM (volatile matter), AC (ash content), and FC (fixed carbon).

Moreover, the presence of higher carbon (43.17–50.29%) and hydrogen (6.09–6.35%) of both OPKS and OPMF along with a higher calorific value than the average lignocellulosic feedstock residues available in the market makes both of these materials readily available for thermochemical processes [62]. Mahmood et al. [67] discovered that OPKS and OPEFB appeared to be the right candidate for biochar production with 81% and 75% of carbon percentages, respectively, even though OPF produces a better yield of carbon at 91%. The percentage of nitrogen and sulphur is less than 1% of each oil palm residue, which is negligible.

3. Palm Oil and Its Residues for Sustainable Biofuel and Bioenergy Production

As in the palm oil industry, the consumption of palm oil has increased nearly two-fold over the past 20 years from the initial introduction of the oil into the world market. However, this issue has increased the accumulation of oil palm residue in both processing and transportation. Even though the palm oil industry satisfies the world’s needs, it negatively impacts the environment with the residues accumulated on the field and palm oil mills over the years of production. The oil palm residues are a definite matter of concern in the palm oil industry, whereby with every 10% of oil generated, approximately 90% [68] remains as a waste biomass material. The waste comes in various form and shapes such as pressed fruit fibres (PFF), OPEFB, OPKS, palm oil mill effluent (POME), and it never stops, as the quantity of the waste produced by the trees is higher when they accomplish the optimal monetary lifespan through the OPT and OPF.Today, the palm oil businesses are still rehearsing the conventional waste administration, with just little improvement. Back then, the disposal of palm oil fibre, mostly the OPEFB, is burnt in incinerators or discarded as mulch back to palm oil plants, creating environmental polluted emissions problems from the incineration and landfill gases. Currently, the typical disposal route of direct incineration has been announced illegal by the Malaysian government and found that no energy is recovered through this disposal mode. Indeed, some other defined route must be created and developed over the years of research to find the best suitable ways to dispose the oil palm residues, serving in energy reservation and eventually equipping the nation financially and environmentally.Energy has been a vital concern over the years, and the development of energy versatility promising better energy with lower production prices is always be a topic of discussion among investors. Access to energy has been fundamental, reshaping billions of people’s daily life routines from lighting our homes to online transactions to even travelling, which relies on energy. According to a recent poll conducted by the United Nations on the Sustainable Development Goal (SDG), it was reported that almost 789 million people worldwide still lack electricity access. SDG further added that more affordable and reliable electricity is needed with the recent Covid-19 pandemic implication, especially in healthcare services. The solution to the above world scenarios can be performed in various ways, and oil palm residues can be used for a versatile energy generation. It is estimated that about 2400–7460 MW of potential installed capacity could be yielded from OPKS, OPEFB, and OPMF, whereas about 410–483 MW power could be produced from POME biogas with 7200hr/year of operating hours [69]. Of all the different types of processes available globally, only two main methods are well known for their complete usability to transform waste into energy (WtE), such as thermochemical processes (gasification, pyrolysis, and direct combustion) and biochemical processes (anaerobic digestion, aerobic digestion) to produce solid, liquid, and gaseous biofuels.

3.1. Palm Oil as a Biofuel (Transportation)

The advanced technology has brought advancement in transportations (sea ships, aeroplanes, trains, cars, motorbike, and others), making movement possible with ease expeditiously for multiple facets, such as transferring of goods from one continental to another, travelling, and others. All these vehicles need fuel primarily derived from fossil fuel such as crude oil and natural gas. In some other cases, secondary fuel may be needed to run smoothly and efficiently, such as gasoline and diesel.

The main concern of transportation industries has corresponded to a long-term environmental impact and health issues through toxic emissions such as carbon monoxide (CO), carbon dioxide (CO2), particulate matter (PM), hydrocarbon, and nitrogen oxides (NOX) [70]. Considerable study has been done and is still ongoing in search for the reduction of environmental impact by introducing the intelligent transport system (ITS) [71] to track fuel consumption and emission estimation. However, fuel consumption is still primarily related to the type of vehicles used and the parameters of vehicles running on the road based on velocity, road condition, and volume of traffic and weather conditions [72]. Therefore, it is crucial to find a potential alternative with similar power for vehicle engine start-up that also contributes to lesser pollution.

The fossil-fuel implications have made biofuel production an alternative fuel for mitigating crude-oil life-cycle emission. Mathew and Ardiyanto

estimated that about 43.95% of greenhouse gas emissions could be restored in biodiesel production, and this greenhouse gas emission can be further recovered to 66.95% through methane capturing and flaring improvement. The counterattack created by MTBE addition in gasoline was entirely banned in 1996, and “zero” sulphur content and group of benzene in biodiesel

have initiated vigorous biofuel modification and substitution as a vehicle’s fuel. Biofuels can be divided into first generation (food crops: sugar cane and soybean), second generation (waste and lignocellulosic crop waste), third generation (algae), and fourth generation based on their origin of biomasses

. Apart from no engine modification needed in utilizing biofuel, biofuel reduces the dependency on oil imports and eventually increases the region’s economy.

Statistically over the decades, biofuel demand has grown substantially, and countries like Canada, U.S., Brazil, France, India, Malaysia, Indonesia, and Australia, were identified to be among the world’s largest biodiesel producers [76]. These countries have proclaimed some major strategies through policies to expand their contribution of biodiesel globally. In line with biodiesel’s higher production by palm oil utilization, Malaysia is one of the countries that has taken the initial steps since late 2014 by mandating B7 to be implemented across the nation (Peninsular Malaysia and planning towards B10 implementation soon after the success of B7) [77]. Indonesia has followed Malaysia’s footsteps in promoting B10 in biodiesel and E3 in ethanol production. Apart from these two producers, Canada has imparted a percentage of 5% ethanol in gasoline mix (E5) and 2% biodiesel in diesel and distillate oil production (B2) [78][79]. Whereas the European Union has made it compulsory to substitute 5.75% and move towards 10% mixing by 2020 [80].

The production of biodiesel through a series of reactions transforming triglycerides into fatty acids (ethyl or methyl esters) in the presence of methanol or ethanol with the catalyst is called the “transesterification process” [81]. Transesterification process depends on the alcohol and glycerine used with catalyst (acid, enzymes, or alkaline) to promote biodiesel production. A catalyst such as sulphonated graphite [82], hydrated lime-derived [83], pig bone (hydroxyapatite) [84], and enzymes such as lipase [85] has been used in recent timeline with palm oil-based biodiesel. All these catalysts used in the experiments provide benefits in various ways, such as shortening the reaction time, and no alteration was found throughout the process of reusing the catalyst [82]. In the alkaline-based catalyst reaction, the higher surface area created with the lower calcining temperature, higher reaction hours, and higher catalyst reused time has been identified [83]. Among all these catalysts, pig bone has shown the highest recycling time even after eight recycling rounds with a biodiesel yield of about 90% [84]. Whereas in the presence of an enzyme, alternating the temperature to 40 °C with the molar ratio of 3:1 (palm oil:enzyme) or equalizing both palm oil and enzyme molar ratio to (1:1) at 30 °C yields biodiesel in the range of 89–95% [85].

The higher blending biodiesel could result in a drawback on the vehicle’s brake power. Nahian [86] identified that an increase from 10 to 20% blending of palm oil biodiesel has shown a significant drop in vehicle’s brake performance, such as brake efficiency drop to less than 1% for B10 and 0.070 kg/kW/h more fuel consumed in comparison to 100% diesel with the same engine load. Moreover, a higher blending ratio of biodiesel exhibits a significant drop in the oxidative stability of the fuel, which results in sediment deposition at the bottom of storage tank, reduces the life cycle of engine fuel delivery components, and increases the viscosity of the fuel [87][88]. J. Pullen and K. Saeed [87] have used the Rancimat induction period (RIP) method twice for a period of 3 weeks apart from different biodiesel blends such as B2, B5, and B7 and found the RIP percentage decreases from 12.59, 12.39, and 8.13%, respectively. In addition, biodiesel with a higher than 40% blending ratio exhibits power loss due to a lower calorific value [89]. However, Vieira da Silva et al. [90] encountered a significant drop of NOx emission through an experiment conducted between palm-based biodiesel within the blending ratios of 20 to 50% compared to waste cooking oil. Moreover, the NOx emission is interrelated with the experimental setup, biodiesel content, type of engine, and operating conditions [91]. The hydrocarbon emission in biodiesel was found to be slightly lower than fossil-fuel diesel.

Although biodiesel has brought several benefits in bringing down the emission and rising the economic prospects, the debate between food versus fuel and the challenges of the production cost within specific limitations are still significant factors influencing the biodiesel industry [92]. According to Acevedo et al. [93], the main contributor in the production cost would be the feedstock, which carries about three quarters of the overall production cost, followed by supply cost of about one quarter, and finally with the maintenance cost of less than 1%. However, the study mentioned that biodiesel production is still a profitable feasible option for about 22% of the overall production cost. Nevertheless, utilizing edible oil in biodiesel production has been the main factor contributing to the world’s food price increments, which is still a presumption [92] as Malaysia and Indonesia have proved otherwise. Both leading producers have set a limitation towards the production of palm-based biodiesel, and the exportation of palm oil has been used widely in food production rather than biodiesel production in import countries.

3.2. Oil Palm Residues Valorisation into Biofuel and Bioenergy Production

A comparatively sufficient productivity of palm oil biomass is a significant non-conventional energy reserve compared to other renewable option such as hydropower, wind power, and solar energy. A wide range of by-products can be yielded through biomass waste to energy valorisation technologies. Different approaches to biomass waste valorisation have been used in converting waste into value-added products [94] such as solid biofuel, gaseous biofuel, and liquid biofuel with respect to biochemical or thermochemical processes. In direct combustion, heat is generated (exothermic) to produce electricity, whereas in gasification and pyrolysis, heat is used (exothermic) in an oxygen-lean environment to produce bio-oil, char, chemical, and syngas, and in an anaerobic environment, digestion, biogas, and bioethanol are produced [94].

In various scales, combustion can be used to obtain heat or electricity from oil palm residues even if the energy efficiency of the conversion is poor. Moreover, the lower calorific value, higher moisture content, and lower density of oil palm residues compared to conventional fuel have also contributed significant drawbacks in utilizing these biomass materials in biomass boiler. The introduction of solid-biomass densification techniques such as briquetting, pelletisation, etc., is discussed in upcoming sections of this manuscript. Additionally, the cocombustion of OPEFB and coal is an attractive method to mitigate the inefficiency of biomass fuel [95]. Even though the energy-via-biomass boiler produces less emissions than conventional fossil-fuel boilers, the formation of crinkle and emission such as sulphur oxides (SOx), nitrogen oxides (NOx), hydrochloric acid, and particulate matter (PM) could still set other operational and maintenance-related issues due to the formation of fouling and slagging in biomass boiler [96]. Lee et al. [97] discovered that a mixing ratio of 1:3 of PKS with coal in cofiring compensates the formation of both CO and SOx, ultimately produces a higher amount of NOX. Lee et al. [97] have further identified that reducing SOx formation would be possible by reducing PKS mass from 10–15%. In addition, Hawari et al. [98] have reviewed that PM could be further reduced by a few mechanical and instrument modifications in biomass boilers such as cyclone and multicyclone systems. Suheri and Kuprianov [99] found that the overall usage of oil palm residue in generating electricity through direct combustion is still considered to be sustainable in terms of low emission. Furthermore, the by-product from this incineration can be reused to fertilize palm oil trees due to the higher potassium content found in the ash produced.

3.2.1. The Production of Solid Biofuel (Densification)

The considerable amount of processed waste from palm oil industries in the form of OPMF and other oil palm residues such as OPKS and OPEFB could be potentially harmful to the environmental deterioration over time if left untreated [100]. Apart from that, high moisture content of up to 37% from OPKS and OPEFB incorporates high relative moisture content causing difficulties in both transportation and particle-size alteration [100]. Furthermore, oil palm residues are lower in density than coal, which has further substantiated a pretreatment to increase the higher end utilization functionality. Sabil et al. [100] have also stated that apart from being tough to grind, a higher loading rate is needed to produce the same amount of energy comparatively with coal due to the low carbon content and low energy density with a higher O/C ratio straining its fuel utilization. Several alternative possibilities (torrefaction, briquetting, and pelletisation) could attempt to compensate for the biomass material’s flaws.

In most of the torrefaction process, the end torrefied biomass feedstock could gain thermal efficiency benefits and increase the overall calorific value. Torrefied biomass feedstock can be used for the pelletisation process as well where the advantages are compressibility strength and improved adhesiveness of the material, but with the drawback of low calorific value due to the presence of higher binding element [101]. In most of the torrefaction process, the end torrefied biomass feedstock could gain thermal efficiency benefits and increase the overall calorific value. In addition to torrefied biomass, especially OPEFB, a higher yield of lignin (28%) with higher extractive concentration (22.65%) is produced and only starts to disintegrate after reaching a maximum temperature of 300 °C [102]. Moreover, it has been suggested by Nurdiawati et al. [103] that wet torrefaction followed by densification could be a potential future innovation in preparing palm oil-based biomass fuels to compensate for the booming energy demands.

Pretreatment can be categorized under several groups such as physical, thermal, chemical, biological, and combinatorial methods determined by the characteristic of the biomass residues and the characteristic of product yield. In a recent study by Wattana et al. [104], it was discovered that mixed biomass pellets from oil palm residues (palm leaves and OPF) with rubber tree branches and leaves improve the feedstock’s combustion characteristic. Wattana et al. [104] further discovered that the ultimate pelletisation mixing of palm leaves and rubber leaves shows a significant drop in ash percentage of 7.18% compared to pure palm leaves where the ash content is 9.64%. Furthermore, self-produced electricity has proven to be efficient through polygeneration in palm oil mills using the pelletisation method [105].

The low energy density of oil palm residues has made possible today’s advancement in the briquetting process to produce better fuel for future power generation. Even though the briquetting has been commonly used in the power generation field, these briquettes are commonly used to replace firewood or coal for heat generation purposes, too [106][107]. Briquettes are better than pellets in various ways, such as no preprocessing needed, lower price value, and correlative production location, such as palm mills (production decentralization). However, higher moisture content and smaller particle size of the biomass feedstock could lower mechanical strength and lower energy density [108]. Therefore, fundamental presetting factors such as an additional binder, feedstock mixing ratios, and ultimate pressure and temperature setting are essential to produce a better briquette pellet. Oke et al. [109] have discovered particle size of less than 0.6 mm causes a significant drop in calorific value by approximately 6.18% of briquette made from PKS compared to the average calorific value of 18.41 MJ/kg with the particle size ranges in between 0.6 to 4.76 mm. Sing and Aris [110] found that 60% of PKS with 40% of OPF and additional paper binder would produce a better briquette with higher calorific value as compared to other ratio’s binder. In addition, oil palm residue could be mixed with other biomass material to produce higher strength hybrid briquette. Kpalo et al. [111] mixed corn cobs with OPT under low-pressure densification of less than 7 MPa and found that the hybrid briquette has better compressibility strength and exhibited lower moisture content, lower ash content, and prevents agglomeration with the addition of paper pulp as a binder.

3.2.2. The Production of Liquid Biofuel

The adaptability of modern applications in power generation, liquid fuel production, and chemical production from biomass is possible today by converting biodegradable material into liquid fuel. Pyrolysis has been one way to convert biomass material thermochemically to produce the end product consisting of liquid biofuel, char, and biogas. Unlike direct combustion and gasification, pyrolysis is an endothermic process in the absence of oxygen with relatively low temperatures. The variation of the end product depends on the prepyrolytic condition such as pyrolysis mechanism (percentage of lignin, cellulose, and hemicellulose), type of feedstocks, pretreatment (physical, thermal, and biological), and condition of reactions (heating rate and residence time) [112]. In fast pyrolysis, it is proven that char, tar, and gas production depend on the reduction and increment of both lignin and cellulose content [113]. Moreover, the pyrolysis rate slows down with the increase of lignin and a decrease in cellulose content of any biomass material [113].

Pyrolysis of oil palm residues can be conducted using the proven feasible microwave technique by Abas et al. [114] which yields a pyrolysis liquid oil of OPMF via a catalytic base through microwave heating. However, the percentage of biochar and pyrolytic liquid oil contributed mainly to the percentage of lignin, cellulose, and hemicellulose contents in the biomass feedstock. According to Safana et al. [57] and Lee et al. [97], the percentage of char yield is quite prominent in feedstock which contains a higher amount of lignin as compared to the cellulose and hemicellulose content, and it is vice-versa for a higher yield of pyrolytic liquid, which is proven by Sukiran et al. [115]. Their experiment reported that OPEFB has the highest yield of pyrolytic oil (47 wt.%), and OPKS has the highest yield of char (55 wt.%) in comparison to other palm oil biomasses [115]. Apart from that, a higher percentage of ash yield as contaminants during fast pyrolysis reduced the produced bio-oil [116]. Therefore, water-prewashed OPEFB resulted in the reduction of ash to 2.39% from the initial percentage of 5.9%, with the overall bio-oil yield in between the range of about 28 to 48.4% and decreased for higher reaction temperature, which was produced through an experiment conducted by Yoo et al. [116]. The yield of either char or bio-liquid through a pyrolysis process is also determined by the application of prewashing methods. OPEFB treated with sulphuric acid produces the highest yield of pyrolytic oil of about 56% due to a decrease in the ash content of up to 56% with the highest fixed carbon percentage of 0.51% and with the highest calorific value of 18.14 MJ/kg contrary from OPEFB treated with distilled water and sodium hydroxide [117]. Overall, fast pyrolysis has been selected as an efficient method with few drawbacks by most scholars and researchers, which produces better bio-oil yield than slow and flash pyrolysis. However, this depends solely on the overall production cost with the type of prewashed method employed for the maximum yield of pyrolytic liquid.

3.2.3. The Production of Gaseous Biofuel

In palm oil mills, for every ton of processed fresh fruit bunches, it produces 0.7 m3 of POME [118] and is kept either in a ponding system or tank system as a final treatment before dischargement to a nearby water source. Palm oil mill effluent (POME) still causes a principal amount of pollution to the surrounding from its final discharge to natural water sources, which can be life-threatening to the aquatic life ecosystem as it halts the dissolved oxygen [119]. Besides that, POME can produce an enormous amount of methane gas by almost 600 million m3 per year, which could contribute to global warming up to 25 times more than carbon dioxide [120]. There are two types of biochemical digestion practiced widely in palm oil mills, such as aerobic digestion (open lagoon) and anaerobic digestion (closed with high-density polyethylene, HDPE).

In anaerobic digestion, the resulting gas consists mainly of 55–77% methane (CH4), 30–45% carbon dioxide (CO2), a small number of other gases such as 1–2% of hydrogen sulphide (H2S), 0–1% of nitrogen (N2), and 0–1% of hydrogen (H2), and traces of carbon monoxide (CO) and oxygen (O2) [121]. Even though anaerobic digestion is suggested to be the most fundamental method due to the high volume of carbon content in the palm oil mill effluent, this factor could lead to unstable C/N ratio in anaerobic digestion as the optimal C/N ratio should be in the range of 20–30/1 [74], [122]. Irregularity in C/N ratios resulted in a more significant release of total ammonia nitrogen or high build-up of volatile fatty acids (VFA), which also inhibits the AD processes [123]. Besides that, some other factors could still halt the overall reaction and reduce biogas production efficiencies, such as pH, organic loading rate (OLR), ambient temperature, and hydraulic retention time (HRT) [74]. These problems were addressed by Shakib and Rashid [120] in an experimental analysis between all these three elements, in which it was discovered that the optimum pH of 6.9 with 30/1 C/N ratio and 6 g/L.d VSS is needed to produce 3.8L/d of biogas.

There are four different stages of anaerobic digestion (AD) (hydrolysis, acidogenesis, acetogenesis, and methanogenesis) associated with the presence of multicomplex microorganisms to break down complex biomass material into the end product of biogas. The growth of these microbes depends on the pH, temperature, agitation ratio, and HRT. These complex conditions and factors inhibit microorganisms’ growth rate, causing separation of acidogenesis and methanogenesis to ease the microbial conversion activities in later years [124]. In all of these stages, methanogenesis is the most sensitive to temperature alteration and is the most time-consuming process. There are two types of temperature conditions present in the methanogenesis stage: thermophilic (50-60 °C) and mesophilic (25–40 °C) [118]. According to Trisakti et al. [125], an increase in temperature raises the microbial activity of microorganisms in both mesophilic and thermophilic conditions in POME, which significantly maximizes the yield of biogas, CO2, and methane production, as well as reduces the maximum HRT. Trisakti et al. [125] have further stated that an increase in temperature reduces the chemical oxygen demand (COD) and volatile solid (VS) in a thermophilic condition, which differs slightly in mesophilic condition [125].

Nevertheless, a further increase of temperature of more than 60 °C eventually alleviates the microorganism’s microbial activity in less than six days [126]. In addition, the presence of higher volatile fatty acids in the digester would reduce pH, which eventually inhibits the growth of methanogenesis microbes and leads to an overall decrease of methane gas production in both ultrasonic and normal POME [126]. Wong et al. [127] further added that pH of (6.8–7.8) would be important for the overall production of biogas in AD and suggested stretching HRT to 20 days and adding calcium carbonate CaCO3 to neutralize the VFA acidity and facilitate the production of methane. Suksong et al. [123] discovered that the yield of methane from POME could be enhanced by mixing sewage sludge. They yielded the highest methane of 56 mL CH4 g−1 VS through mixing ratios of 99:1 from codigestion POME and sewage chemical sludge [123]. Suksong et al. [123] further added that the methane yield from liquid AD is 20–25 times higher than solid AD due to lower water content inhibiting the microbial conversion.

In general, biogas produced via POME could be utilized in many ways: heat, electricity, or both. However, the principal matter that constrain the production is the complexity of the overall production, which elevates the cost of the biogas. Hosseini et al. [128] introduced H2 with POME biogas, which visibly stretches the formation of flame and improved the low calorific biogas nature by increasing the percentage of H2 from 5 to 10%. The only drawback of this method is that it produces NOX, enhanced via the temperature [128]. Bukhari et al. identified that cofiring of biogas in palm oil mill boilers could potentially reduce the formation of PM by up to 50% and provide fuel saving by up to 80–90% [129]. Of all these significant contributions of POME, the most prominent and essential aspect is the economic analysis. A typical biogas plant’s overall installation is estimated at around RM 4–6 million, subjected to the mill’s capacity [130]. The return on investment (ROI) would be fruitful after completing 2–4 years with revenues from grid-connected electricity generation and reduced diesel usage [130]. Biogas from POME could be a solution for both environments and generate income in rural or remote areas whereby natural gas infrastructure does not reach.

With the types of valorisation used like thermochemical and biochemical processes and factors affecting the biofuel yield production and bioenergy production, it was concluded that all these processes (e.g., combustion, gasification, pyrolysis, and anaerobic digestion) contributed to different benefits in the form of solid, liquid, and gaseous biofuel production from various types of palm oil feedstocks. Therefore, it is essential to perform further research on the employment of different processes in the optimisation and advancement of biofuel or bioenergy production in a cost-effective way.

4. Major Challenges, Perspectives, and a Future Sustainable Approach

Entering 2020, palm oil is the cheapest vegetable oil to be produced. It is a multi-billion-dollar industry with a pretty bad reputation that has been blamed, among other things, for wiping out rainforests and pushing animals towards extinction, especially the orangutans, and disrupting the world ecosystem [131]. However, the palm oil industry might not be the only cause of orangutan extinction, as stated by the International Union for Conservation of Nature (IUCN) [132]. It has been reported that the Borneo orangutan has been classified as an endangered species of up to 75% declination in the year 2016 due to the combinational cause of wildlife trafficking and wild meat trading, and other secondary causes [133]. In Malaysia, palm oil may not be the driver of deforestation as palm oil plantations made use of present deforested land as revealed by The Ministry of Land and Development Sarawak and chief executive of Malaysian Palm Oil Council [134]. According to the Food and Agriculture Organization of the United Nations (FAO), recent forest estimation in Malaysia has increased by 0.88% from 2010 to 2017 with an implied emission factor of CO2 reduced from 1.8883 to 0.0147 tonnes/ha [135]. The rise of harvested land for palm oil crops has shown only the slightest increase of 2.44% from 2010 to 2018, about 0.31% increase for each year, thereby proving the above Malaysian’s forest conservation statement [135]. Thornton implied that crop production’s burgeoning would be in situ with the yield increase as compared to the area stretching where it is vice-versa in the livestock industry requiring almost three-fold of land for crop production [136].

Human land exploitation expansion for agricultural purposes has been going on since the early 1980s, especially in the subtropic region. In the early 1980s, the land that was previously used astoundingly for cocoa and rubber production purposes has been subjected to palm oil production right after unprecedented price collapse for both commodities and the invasion of a pest-related issue in cocoa production called “cocoa-pod borer” [137]. The lower land price has also contributed to the land facelift possible for palm oil production today, causing much debate with regards to greenhouse gas emissions and other social-related issues. Therefore, land-use change analysis (LUCA) has been implemented in estimating the overall palm oil expansion corresponding to the new planting procedure (NPP 2015) on a year-to-year basis. However, due to the costly procedure and expertise-based farmland image (satellite image) interpretation needs, it is not favourable, especially for the small palm oil holders to inaugurate it [138]. Nevertheless, this unfavourable issue unacknowledged by NPP even for small farmers or alter the LUCA procedure to fit current users will be unreliable and unrealistic to track farmland [138]. On the other hand, engaging with LUCA would help small farmers improve production, enabling them to ditch the old and turn to the more lucrative crop options in the future instead [139].

Meanwhile, in the year 2019 and 2020, it is forecasted that the production of palm oil (CPO) exceeds 1.5% from the previous year, which has elevated labour needs where Malaysian Ministry of Primary Industries and the Ministry of Human Resources assured the intake of foreign workers that have faced shortfalls in recent years [140]. It has been estimated that there are about 15,000 workers fewer than the previous year of 50,000 workers by the Malaysian Palm Association (MPO). Consequently, the surge of foreign workers in the palm oil industry has created social conflict among societies that have contributed to significant drawbacks to the export countries. Malaysia has encountered multiple issues pertinent to the labour shortage. It brings other social-related issues such as drug trafficking, rising sex trades, sabotage, robbery, and competition among local workers in bringing an enormous number of foreign workers to work in palm oil farms [141]. This labour shortage significantly intensified the palm oil harvesting process’s implication, resulting in the FFB rotting and an overall yield reduction [141].

4.1. Agropolitical Issues

In developing countries such as Malaysia and Indonesia, clearing the farmland after accomplishing the full harvesting period of palm oil trees causes environmental devastation. The emission of CO2 through total forest fires for both years in 2001 and 2013 was approximated at 2270 Gt yearly [142]. The approximation of tree cover loss area has reduced significantly to 58.14%, with a 63.57% reduction in CO2 emission from 2013 to 2014 in Malaysia [142]. However, the result is generally different due to the clouds covering above those areas, discarded from the potentially deforested land that was never accounted for in the calculation [142]. Moreover, clearing peatland causes more destruction than typical land rejuvenation. The carbon bank underlying the peatland forest is a vast carbon bank that releases an enormous amount of carbon once cleared, and in the worst-case scenario of firing, it emits a considerable amount of carbon. [143]. The seeded clouds have been implemented above the fire by the neighbouring countries such as Singapore and Malaysia, hoping to bring rain to drench fires smouldering created through the transboundary haze of forests’ fire in Indonesia [144].

Nevertheless, Indonesia is blamed for their incompetencies in tackling transboundary haze by the Malaysian government. It is estimated that Malaysia has created a socio-economy and political relationship with Indonesia to invest in the palm oil expansion in the region [145]. It is approximated that about 162 plantations in Indonesia have shares held by well-established Malaysian companies [146], indirectly proving Malaysia as one of the most prominent foreign investors in Indonesia’s palm oil businesses [147]. In the long run, deforestation also causes water-source contamination and health deterioration [148], upsetting the economic activities and the tourism industry [149]. Nevertheless, this is the only traditional, shortest, fastest, and economical route to convince small palm oil holders to clear the land and control the pest problem for sanitizing reasons and improve soil fertility for the next cultivation purposes.

The burning method of oil palm residues, including post-deforestation trunks of palm oil trees, has been replaced with the zero-burning policy in recent days. Malaysia has entirely banned open-firing farm-clearing methods since 1987, and Indonesia carried out immediate action towards a sustainable approach coupled with a government act to decrease environmental pollution in the palm oil industry in 2014. Ever since the mission has been introduced in Malaysia, the giant industrialist tycoon Sime Darby Corporation has pledge with “zero-burning replanting technique” to commercially adopt this method before 1987 and has proven to be environment-friendly in the reawakening of an industrial standard of palm oil replanting technique. These zero-burning techniques have aggravated many small farmers’ problems and eventually caused the world’s palm oil production decline due to almost 40.8% of the total palm oil land in Indonesia being owned by these small farmers [150]. Instead, scholars such as Murniati and Surharti have reported that incentive schemes and stakeholders play a vital role in successfully inducing small farmers to adopt a zero-burning policy. Murniati and Surharti added that the government should be more lenient in allowing reasonable fire methods to clear the land and differentiate between bottom-feeders and sincere farmers [151].

On the broader approach, being the world’s prime palm oil producers, Malaysia and Indonesia have a massive responsibility in making the palm oil business as sustainable as possible. In Malaysia, palm oil plantation expansion has been halted since the day when palm oil was introduced as an agricultural crop following the new regulations concerning the ecosystem’s disruption with the government’s pledge to keep 50% of its forest [152]. However, restriction upon the expansion of palm oil farms would not be an excellent solution for the world forest conservation issues. This included palm oil, which is not a sole oil-producing crop destroying forest land and peatland. According to Taheripour et al. [153], the palm oil percentage only amounted to 10% (20Mha) out of 200.5 million hectares in 2016, whereas soybean covered more than half or approximately 61% (121Mha) of the total land. In contrast to palm oil farming, deforestation was caused by road construction, inefficient timber harvesting, and energy-wood harvesting [154]. Limiting the overall consumption or usage of palm oil in the world would not be the only sensible option or driver to tackle the deforestation issue; it would also open potential platforms for other oil crops to grow on the reserved land or even forest land replacing the palm oil plantation.

4.2. World Players in Sustainable Palm Oil Goal

In response to the never-ending issues related in the palm oil industry, and to put a full-stop to the unsustainable palm oil trade practices, the world’s most prominent players in this area such as Roundtable on Sustainable Palm Oil (RSPO), a non-profit organization established in 2004, have brought awareness of choosing sustainable palm oil and palm oil products through a certified sustainable palm oil (CSPO) certification. This CSPO certification has ensured that 95% of palm oil in the products with the RSPO trademark are certified and traceable in its entire supply chain. RSPO has pursued a wide range of steps in eradicating palm oil crops’ environmental impact, such as in the recent Amsterdam Declaration, to issue 100% sustainable palm oil usage by 2020 in all over Europe [155]. In the year 2019, RSPO has announced that over 4500 new members have registered and over 4.2 Mha of palm oil has been certified on the same course [150].

Additionally, due to the pandemic, a group of smallholder credits scheme in Central Kalimantan Indonesia has helped many families in need at a region via premium returned from RSPO [156]. RSPO has also helped small farmers conduct LUCA following the stated NPP and ensuring no child labour [137].

Besides RSPO, several local organizations in export countries such as Indonesia Sustainable Palm Oil (ISPO), Malaysia Palm Oil Board (MPOB), and Malaysia Biomass Industries Confederation (MBIC) have multifaceted plans, creating a mandatory standard in the palm oil industry to be engaged with the Sustainable Development Goals (SDG) set by the United Nation (UN). In particular, MPOB goes hand in hand with the Department of Environment (DOE) to mitigate all the palm-oil environmental-related issues, brainstorming by organizing surveys, verifying technology, and revising the regulation contemplating current environmental terms and conditions [157]. MPOB has paved the road for producing sustainable palm oil through palm oil marketing and educating by fostering small palm oil stakeholders to come forward and register online with a very low membership fee of seventy-five Malaysian Ringgit. This act could equip both parties with benefits from various categories in fostering a sustainable palm oil industry. MPOB further spread its wings through seminars, online research journal libraries such as e-books, journals, and newsletters, and bulletins to educate people in the palm oil industry and society.

The European Renewable Energy Directive (RED) has, in view of all these government and nongovernment entities, filled in the blanks to fix problems not covered by the RSPO. In RSPO-RED, additional conditions have been applied to the accomplished RED specifications required to help generate bioenergy fuel from palm oil in the European Union [158]. However, in Germany, the international sustainable and carbon certification (ISCC 2018) contributed a significant role in the palm oil certification [159]. Under the leadership of RSPO members, optional standards called RSPO-NEXT may be used to extend their credentials. The additional emphasis of RSPO-NEXT is on the attributes of deforestation, zero burning, no peat planting, GHG emission reduction, and respect for human rights and accountability [159].

Apart from the aforementioned challenges and land-use issues, the sustainability issues of the palm oil industry are the most significant. As for the importance of sustainability demonstration, life-cycle assessment (LCA) is one of the sustainability assessment tools applied to evaluate the environmental sustainability of the oil palm industry. Furthermore, LCA is an assessment technique on the environmental impacts associated with all the stages of a commercial product, process, or service. Essentially, the palm oil industry involves several important processes, including plantation, collection of oil dates, oil production, and valorisation of by-products and wastes. The application of LCA is an essential technique for the evaluation of the entire life cycle in the palm oil industry, which involves the conversion of palm oil fruit into palm oil and the remaining biowastes.

Several studies have been performed on LCA in the palm-oil-related industry. Archer et al. [160], conducted an in-depth exploration on the variation of different LCA’s of palm oil biodiesel, assembling the comparison inventory of quantities, energy, and carbon equivalent analyses on the environmental performance of biofuels. In the research by Yung et al. [161], a gate-to-gate LCA production for palm biodiesel was performed with the impact assessment demonstrating the replacement of fossil-based methanol with bio-methanol resulted in 63% of reduced usage of fossil sources and a 22% reduction in global warming. Meanwhile, a review study was performed on the implementation of LCA for biodiesel production from palm oil in Indonesia. The robust life-cycle inventory in a wider range (e.g., cradle to grave) was applied, which was important in presenting the palm oil industry in a global forum. These LCA-based studies were conducted in line with the environmental issues raised by the palm oil industry in Indonesia Siregar et al. [162]. Additionally, LCA was also applied in the production of bioenergy via thermochemical processes, specifically pyrolysis with OPEFB. This LCA was used to evaluate the environmental impact related to greenhouse gases emissions and air pollutant gases with the aid of Simapro 8.5 software Darojat, Hadi, and Rahayu [163]. Apart from biofuel production, LCA was likewise applied to the palm oil production process. A study reported on LCA evaluation, specifically the environmental impacts of the crude palm oil production system at Sumatera Island using the Eco-indicator 99, Andarani et al. [164]. Another study presented the environmental sustainability approach for palm oil production in Malaysia Yahya et al. [165].

4.3. Goals and Sustainable Palm Oil Approach

“Misguided perceptions might turn into conviction” legitimization has its vulnerability, whereby this is the issue related to the palm oil industry. In recent years, public finances are already being used to fund biofuel projects in several European nations. Most of these proposals had triggered an enormous backlash, leading to politicians’ humiliation when it emerged that there were no legitimate grounds for suggesting that these publicly funded biofuel projects were environmentally friendly or substantially contributing to tackling the issue. In addition, large-scale deforestation would have long-term environmental implications for the coastal climate, which would only become apparent later. Whether or not palm oil becomes a significant feedstock for biofuel producers in Europe depends on the European Union’s future decisions. In January 2018, the European Parliament suggested that the public subsidies towards the application of biodiesel from palm oil in 2021 should end. However, later in June 2018, the Commission, the EU Council, and the EU Parliament withdrew and came to an agreement on a final EU statute whereby the final legislation does not terminate palm oil biofuel application by 2021, instead to promise to phase out totally by 2030 [166]. However, this would not contribute to massive impact on palm oil industry expansion, as the prime consumers of palm oil are situated in the Asia region and out of 100% of palm oil production: only 10% has been utilized for biofuel production globally [167].

However, utilization of the palm oil biofuels evolution would be “quid pro quo” in palm oil price hike if the entire demand surpasses the productivity, and the consequences need to be faced by the exporting countries in terms of export earnings increase and food price mark-up in both good and bad ways. The export earnings of palm oil can be seen in various global government approaches, which contributed to palm oil price rises such as biofuel blend mandates by Indonesia and Malaysia (B20 to B30), France tax exemption, global sulphur cap implementation by the International Maritime organization for marine fuels, aviation enacts to carbonless fuel from 2020, and trade war implication in between China and U.S [168]. In addition, palm oil exporting countries have significantly owned domestic earning if the per capita consumption increases in the near future collectively with the rising contribution of 15.22% towards population growth in the low- and middle-income (Asia) developing countries over the next two decades [169]. Nonetheless, it is only possible if these related countries expected the achievement of highest per capita income growth soon, whereby it transposed into palm oil productivity increment and started the whole process of palm oil expansion again from where it stopped.

It would be senseless to boycott the entire palm oil industry to deal with the complete environmental devastation as the expansion of palm oil is not strictly dependent on land use. It would benefit the region’s environment and economy if the overall yield could be increased and shifting palm oil could be readily depleted or in low-yielding pasturelands. According to Murphy, palm oil has become more productive by up to more than 6.5 times in terms of the overall oil yield per hectare than the average combined yields of temperate oilseed crops in recent years [170]. Murphy further added that provided the plausible possibilities for further improvements in palm oil yield over the next couple of years, the expansion of palm oil plantations would eventually decrease. The outlook of palm oil as a global crop of vegetable oil over the near future seems much more optimistic in parallel with the elevation of income status across the developing nations [170].

The future goal in making the palm oil industry sustainable and less harmful would become a reality by introducing current genetically modified (GM) palm oil using transgenic palm oil to yield more than the conventional tree, which indirectly increases the content of oleate and lauric acid in palm oil production [171]. In addition, the propagation of palm oil via in vitro indirect somatic embryogenesis is a method to maintain high-grade seedlings with agronomic features [172]. However, due to the high research and development costs, GM produced oil crop growth with traits with a guaranteed agronomic and commercial potential, and GM faced a backlash disputatious from many anti-GM groups and activists, especially in Europe.

It is advisable to initiate more research to reduce deforestation methods to make it a more sustainable approach redeemed through smart-farming techniques such as artificial-intelligence (AI) farming techniques, automated drone tracking system to view the entire farmland, and an automated watering system. Sustainable farming practices can be launched by reducing land erosion and leaching, which has been proven feasible through leguminous crops (Mucuna bracteate), thereby increasing the ground moisture content by preventing evaporation and soil improvement via organic matter disintegration even on the hilly farmland [173]. It is also found that primary carbon leaching is attributed to the soil’s dryness underneath the tree, which decreases with the rise in soil moisture, addressing the central question behind land transforming sustainability for palm land [174]. In addition, preventing palm oil farming on the hilly lands is vital in preventing soil erosion and promotes sustainable farming practices in palm oil production. Apart from that, the judicious application of controlled-release fertilizers has promising outcomes in preventing nutrient leaching, especially on the hilly land when promoting the sustainable palm oil approach [175]. Additionally, frequent switching of land uses needed to be monitored, resulting in long-term organic carbon stock reduction [139].

5. Conclusions

In recent advancements, substantial improvements could be achieved by converting oil-palm-related agricultural residues into more environmentally friendly products by implementing sustainable approaches. Scientists, stakeholders, and societies agree that the production of biofuel from the palm oil industry should be conducted in a more sustainable way to manage environmental degradation. In this review, the palm oil and its residues origin, characteristics, production methods for heat/power generation, production of biofuel, the related challenges, and prospects on the sustainable approach in the palm oil industry were discussed. Several approaches could be applied for heat and power generation from palm oil and its derivatives, such as thermochemical processes and biochemical processes. In regard to the importance and essential functionalities of the production of palm oil and its biowastes, the sustainability demonstration holds the highest importance for the selection as a potential replacement to fossil fuel.

References

- IEA. International Energy Agency, World Energy Outlook 2018: Highlights; IEA: Paris, France, 2018; Available online: https://www.iea.org/reports/world-energy-outlook-2018/electricity (accessed on 20 July 2020).

- Gomiero, T. Are biofuels an effective and viable energy strategy for industrialized societies? A reasoned overview of potentials and limits. Sustainability 2015, 7, 8491–8521.

- Sulaiman, C.; Abdul-Rahim, A.S.; Ofozor, C.A. Does wood biomass energy use reduce CO2 emissions in European Union member countries? Evidence from 27 members. J. Clean. Prod. 2020, 253, 119996.

- Kim, G.; Choi, S.-K.; Seok, J.H. Does +9biomass energy consumption reduce total energy CO2 emissions in the US? J. Policy Model. 2020, 42, 953–967.

- Walters, J.P.; Archer, D.W.; Sassenrath, G.F.; Hendrickson, J.R.; Hanson, J.D.; Halloran, J.M.; Vadas, P.; Alarcon, V.J. Exploring agricultural production systems and their fundamental components with system dynamics modelling. Ecol. Model. 2016, 333, 51–65.

- Mba, O.I.; Dumont, M.J.; Ngadi, M. Palm oil: Processing, characterization and utilization in the food industry—A review. Food Biosci. 2015, 10, 26–41.

- Dumelin, E.E. The Environmental Impact of Palm Oil and Other Vegetable Oils. Fuel Chem. 2009, 13, 420–427.

- Othman, H.; Darus, F.M.; Nor, M.H.M.; Amit, S. Re-evaluation of nutrients requirement for oil palm planting on peat soil. Plants 2014, 90, 161–177.

- Fong, L. Palm Oil Alternatives Use More Land, Produce less Yield. Malaysiakini. Available online: https://www.malaysiakini.com/letters/468459 (accessed on 24 July 2020).

- Rebitanim, N.A.; Hanafi, M.M.; Idris, A.S.; Abdullah, S.N.A.; Mohidin, H.; Rebitanim, N.Z. GanoCare® Improves Oil Palm Growth and Resistance against Ganoderma Basal Stem Rot Disease in Nursery and Field Trials. Biomed Res. Int. 2020, 2020, 1–16.

- Versatility and Technical Advantages of Palm Oil. Available online: http://www.arabis.org/index.php/articles/articles/marketing/versatility-and-technical-advantages-of-palm-oil (accessed on 15 February 2021).

- Barcelos, E.; Rios, S.D.A.; Cunha, R.N.; Lopes, R.; Motoike, S.Y.; Babiychuk, E.; Skirycz, A.; Kushnir, S. Oil palm natural diversity and the potential for yield improvement. Front. Plant Sci. 2015, 6, 190.

- Monthly Palm Oil Trade Statistics: January–December 2019, M.P.O.C. Available online: http://mpoc.org.my/monthly-palm-oil-trade-statistics-2019/ (accessed on 29 July 2020).

- Yusoff, M.N.A.M.; Zulkifli, N.W.M.; Sukiman, N.L.; Chyuan, O.H.; Hassan, M.H.; Hasnul, M.H.; Zulkifli, M.S.A.; Abbas, M.M.; Zakaria, M.Z. Sustainability of Palm Biodiesel in Transportation: A Review on Biofuel Standard, Policy and International Collaboration Between Malaysia and Colombia. Bioenergy Res. 2020, 236, 155–163.

- Mutsaers, H. The challenge of the oil palm: Using degraded land for its cultivation. Outlook Agric. 2019, 48, 190–197.

- Global Palm Oil Demand to Fall by 4% on Pandemic Impact. The Malaysian Reserve. Available online: https://themalaysianreserve.com/2020/11/11/global-palm-oil-demand-to-fall-by-4-on-pandemic-impact/ (accessed on 7 January 2021).

- Ahmad, F.B.; Zhang, Z.; Doherty, W.O.S.; O’Hara, I.M. Evaluation of oil production from oil palm empty fruit bunch by oleaginous micro-organisms. Biofuels Bioprod. Biorefining 2016, 10, 378–392.

- Singh, R.P. Cost effectiveness of palm oil in comparison to other oils and fats in the country with special emphasis on lower income group. Indian J. Community Health 2014, 26, 37–44.

- Megashah, L.N.; Ariffin, H.; Zakaria, M.R.; Hassan, M.A. Properties of Cellulose Extract from Different Types of Oil Palm Biomass. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012049.

- Sagar, H.S.S.C.; Mabano, A.; Roopa, R.; Sharmin, M.; Richard, F.-J.; Clause, J. India in the Oil Palm Era: Describing India’s Dependence on Palm Oil, Recommendations for Sustainable Production, and Opportunities to Become an Influential Consumer. Trop. Conserv. Sci. 2019, 12, 1–9.

- Zakaria, K.; Kunchu, J.A.B.; Salleh, K.M.; Nambiappan, B.; Hassan, N.A.M.; Azam, A.H.M. Demand for Palm Oil in the Balkans using Autoregressive Distributed Lag (ARDL) (Permintaan Minyak Sawit di Balkan menggunakan Lat Tertabur Autoregresif). J. Ekon. Malays. 2019, 53, 145–152.

- Tengku, Z.; Abdul, W.A. An overview of the palm oil sector: Countries and companies. Glob. Palm Oil Conf. 2015, 1, 1–20.

- Sujadi, S.; Hasibuan, H.A.; Rivani, M.; Purba, A.R. Oil Content and Chemical Composition in the Parts of Oil Palm Fruit from 8 IOPRI Varieties. J. Penelit. Kelapa Sawit 2016, 24, 67–76.

- Boateng, L.; Ansong, R.; Owusu, W.B.; Steiner-Asiedu, M. Coconut oil and palm oil’s role in nutrition, health and national development: A review. Ghana Med. J. 2016, 50, 189–196.

- Zhang, J.; Wang, C.-R.; Xue, A.-N.; Ge, K.-Y. Effects of red palm oil on serum lipids and plasma carotenoids level in Chinese male adults. Biomed. Environ. Sci. 2003, 16, 348–354.

- Kushairi, A.; Loh, S.K.; Azman, I.; Hishamuddin, E.; Ong-Abdullah, M.; Izuddin, Z.B.M.N.; Razmah, G.; Sundram, S.; Parveez, G.K.A. Oil palm economic performance in Malaysia and R&D progress in 2017—Review Article. J. Oil Palm Res. 2018, 30, 163–195.

- Meng, X.; Liu, C.; Cao, C.; Zheng, Z.; Su, Q.; Liu, Y. L-ascorbyl palmitate modify the crystallization behavior of palm oil: Mechanism and application. LWT 2020, 1089, 12299.

- Goh, K.M.; Wong, Y.H.; Abas, F.; Lai, O.M.; Cheong, L.Z.; Wang, Y.; Wang, Y.; Tan, C.P. Effects of shortening and baking temperature on quality, MCPD ester and glycidyl ester content of conventional baked cake. LWT 2019, 116, 108553.

- Hamid, R.A. Application of Palm Emulsion in Vegetarian Nuggets. In Malaysian Palm Oil Board Inf Ser. (MPOB TT.541); June 2013. Available online: http://palmoilis.mpob.gov.my/publications/TOT/TT541.pdf (accessed on 20 July 2020).

- Alina, A.R.; Babji, A.S.; Affandi, S. Nutritional quality of palm fat substituted chicken nuggets. Nutr. Food Sci. 2009, 39, 181–188.

- Makeri, M.; Sahri, M.M.; Ghazali, H.M.; Ahmad, K.; Muhammad, K. Polymorphism, textural and crystallization properties of winged bean (Psophocarpus tetragonolobus, D.C) oil-based trans-fatty acids free ternary margarine blends. LWT 2019, 100, 158–166.

- Sen, C.K.; Rink, C.; Khanna, S. Palm oil–derived natural vitamin e α-tocotrienol in brain health and disease. J. Am. Coll. Nutr. 2010, 29, 314S–323S.

- Ali, S.F.; Woodman, O.L. Tocotrienol Rich Palm Oil Extract Is More Effective Than Pure Tocotrienols at Improving Endothelium-Dependent Relaxation in the Presence of Oxidative Stress. Oxidative Med. Cell. Longev. 2015, 2015, 1–10.

- Sapawe, N.; Hanafi, M.F.; Samion, S. The Use of Palm Oil as New Alternative Biolubricant for Improving Anti-Friction and Anti-Wear Properties. Mater. Today Proc. 1126, 2019, 19–1135.

- Loganathan, R.; Selvaduray, K.R.; Nesaretnam, K.; Radhakrishnan, A.K. Differential and antagonistic effects of palm tocotrienols and other phytonutrients (carotenoids, squalene and coenzyme Q10) on breast cancer cells in vitro. J. Oil Palm Res. 2013, 25, 208–215.

- Alabi, T.D.; Olabiyi, F.A.; Oguntibeju, O.O. Palm oil: Its antioxidant potential in diabetes mellitus. In Diabetes; Academic Press: Cambridage, UK, 2020; pp. 285–291.

- Boonrod, B.; Prapainainar, P.; Varabuntoonvit, V.; Sudsakorn, K.; Prapainainar, C. Environmental impact assessment of bio-hydrogenated diesel from hydrogen and co-product of palm oil industry. Int. J. Hydrogen Energy 2020, 46, 10570–10585.

- Khalil, I.; Aziz, A.R.A.; Yusup, S.; Heikal, M.; El-Adawy, M. Response surface methodology for the optimization of the production of rubber seed/palm oil biodiesel, IDI diesel engine performance, and emissions. Biomass Convers. Biorefinery 2017, 7, 37–49.

- Cordero-Ravelo, V.; Schallenberg-Rodriguez, J. Biodiesel production as a solution to waste cooking oil (WCO) disposal. Will any type of WCO do for a transesterification process? A quality assessment. J. Environ. Manag. 2018, 228, 117–129.

- Nwankwojike, B.N. Development of Abrasive Selection Model/Chart for Palm Frond Broom Peeling Machine Design. Int. J. Eng. Res. Appl. 2014, 4, 84–90.

- Ibrahim, Z.; Aziz, A.A.; Ramli, R.; Mokhtar, A.; Omar, R.; Lee, S. Production of Medium Density Fibreboard (MDF) from Oil Palm Trunk (OPT). J. Appl. Sci. 1174, 2014, 14–1179.

- Deka, D.; Tayung, K.; Jha, D.K. Harnessing Fungal Endophytes for Plant and Human Health. In Sustainable Development and Biodiversity 15: Endophytes: Biology and Biotechnology, 1st ed.; Maheshwari, D.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 67–82.

- Fabiani, C.; Pisello, A.L.; Barbanera, M.; Cabeza, L.F. Palm oil-based bio-PCM for energy efficient building applications: Multipurpose thermal investigation and life cycle assessment. J. Energy Storage 2020, 28, 101129.

- Momoh, E.O.; Osofero, A.I. Recent developments in the application of oil palm fibers in cement composites. Front. Struct. Civ. Eng. 2020, 14, 94–108.

- Ishak, F.A.; Jamil, M.H.; Abd Razak, A.S.; Zamani, N.H.A.; Ab Hamid, M.R. Development of Animal Feed from Waste to Wealth using Napier Grass and Palm Acid Oil (PAO) from Palm Oil Mill Effluent (POME). Mater. Today Proc. 1618, 2019, 19–1627.

- Halim, R.M.; Ramli, R.; Che Mat, C.M.; Hadi, N.A.; Abu Bakar, N.; Aziz, A.A.; Highly Digestible Palm Kernel Cake (PKC) For Animal Feed. Malaysian Palm Oil Board. 2017. Available online: http://palmoilis.mpob.gov.my/publications/TOT/tot2017/TT619-Rohaya.pdf (accessed on 25 July 2020).

- Kum, W.H.; Zahari, M.W. Utilisation of Oil Palm By-Products as Ruminant Feed in Malaysia. J. Oil Palm Res. 1029, 2011, 23–1035.

- Nadlene, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Yusriah, L. A Review on Roselle Fiber and Its Composites. J. Nat. Fibers 2016, 13, 10–41.

- Liu, Z.; Li, L.; Liu, C.; Xu, A. Pretreatment of corn straw using the alkaline solution of ionic liquids. Bioresour. Technol. 2018, 260, 417–420.

- Kalita, E.; Nath, B.K.; Deb, P.; Agan, F.; Islam, M.R.; Saikia, K. High quality fluorescent cellulose nanofibers from endemic rice husk: Isolation and characterization. Carbohydr. Polym. 2015, 122, 308–313.