Nanomaterials and nanotechnology will undoubtedly become core materials and technologies in advanced materials and technologies. In recent years, nanomaterials and nanotechnology have been widely used in environmental restoration due to their low cost, high efficiency, and other advantages. In this study, the high-performance poand mulyurethane/rare earth (PU/RE) tifuntional composite nanomaterials were fabricated via electrospinning. The electrospun nanomaterials for adsorption of volatile organic compounds (VOCs) in air was tand harmful heavy metal ions in waste water was thoroughly investigated. The PU nanofiber containing 50 wt. % RE powder had the smallest fiber diameter of 356 nm; itIn addition, the electrospun nanomaterials also showed the highest VOC absorption capacity compared with other composite membranes, having an absorption capacity about three times greater than pure PU nanofibersdemonstrated excellent antimicrobial activity on Gram-negative Escherichia coli and Gram-positive Staphylococcus aureus bacteria.

- Electrospinning

- Nanocomposites

- Volatile organic compounds

- Polyurethane

- Fly ash

- Polyacrylonitrile

- Silver nitrate

1. Introduction

Volatil The organic compounds (VOCs) are numerous, varied, and ubiquitous, and they are one of the sources of air pollution. VOCs can be categorized according to their chemical structures: alkanes, aromaticharmfuel emissions emitted from theconventional cars mainly include carbon monoxide (CO), hydrocarbons, esters, aldehydes, alcohols, ethers, and amides [1]. There (HC), NOx and PM, as well as a smarell about 300 different kinds of VOCs; most day-to-day activities lead to the production of VOCs, mount of volatile organic compounds (VOCs) such as driving, cooking, building, decorating, paintingbenzen and aldehydes, polycyclic aromatic hydrocarbons (PAHs), and even face-paintingsome harmful trace heavy metals. Especially for [2][3][4].some Aold high concentration of VOCs can easily lead to acute poisoning, lightheadedness, headache, dizziness, coughing, nausea, vomiting, and liver poisoning, and can even induce a comavehicles, their emissions are huge due to poorly maintained and designed, which may contribute disproportionately to total emissions. Benzene and formaldehyde are the most common carcinogenic and highly toxic pollutants in VOCs and they can quickly damage the human respiratory system [1]. Therefore,In it is important to effectively reduce the content of VOCs in the air, and finding a way to control and reduce the content of VOCs in air has attracted attention for a long time.

Electrospaddition, with sufficient illuminning is a fiber production method that provides a straightforward yet versatile approach for the convenient preparation of continuous fibers [5][6][7][8]. Ition, aphotochemical reaction bet has bween widely applied to various fields, such as artificial skin, bandages, bulletproof clothing, battery electrolytes, sensors, and hierarchically structured fibrous composites [9][10][11][12]. RaVOCs and NOx produces ozone, which also thre earth (RE) materials, ‘the Vitamins of Modern Industry’, play an important role in industrial development. Smelting and separation of RE raw materials can be accomplished and used for energetic materials, luminescent materials, grinding materials, environmental protection materials, and permanent magnetic materialtens human health as well as that of animals and plants [13].

Therefore, in this study, we investigated the combined characteristics of RE and polyurethane (PU) and their VOC adsorption capacity using the electrospinning technique. The morphology and components and mechanical properties were thoroughly investigated. A certain amount (up to 50 wt. % compared to PU pellets) of RE nanoparticles (NPs) could be loaded on/into PU fibers.

2. Experimental Details

2.1 Materials

Polyuretha's very important to find a new and efficiene (PU) pellets (Estan te® Skytchane® X595A-11) were purchased from Lubrizol Advanced Materials, Inc., Cleveland, OH, USA, and were used as the polymeric matrix. RE powder were purchased from ZIBO WEIJIE RARE EARTH CO., LTD, Zibo, China. N,N-Dimeogy to conthylformamide (DMF) was purchased from Showa Chemical Co., Ltd., Tokyo, Japan. Extra pure methyl ethyl ketone (MEK, 2-butanone) was purchased from Junsei Chemical Co., Ltd, Tokyo, Japan. In VOCs absorption experiments, five different kinds of gases (styrene, xylene, chloroform, benzene, and toluene) (purity 99.9%, AR grade) were analyzedol these pollutants.

2.2 Fabrication of Composite Nanofibrous Membranes

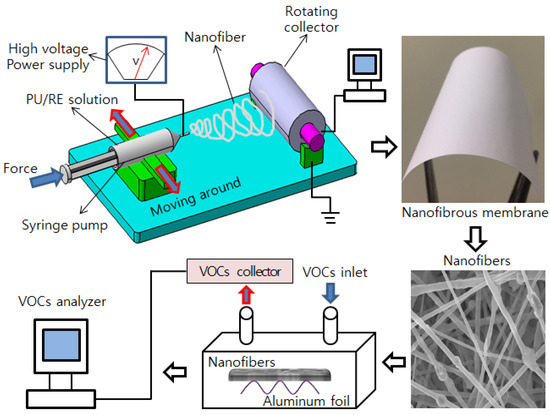

The fabrpplication process of PU/RE nanofibrous membranes is given as follows. First, the PU pellets were dried (constant temperature: 80 °C) for about 3 h in a dry oven before dissolving them in the solvent. Second, 10 wt. % PU pellets were dissolved in a DMF/MEK (50:50 by weight) mixing solution, using a magnetic stirrer dissolved for 12 h at room temperature. Then 0, 10, 30, and 50 wt. % (compared to PU pellets) RE powders were added into above the solution as electrospun precursors via ultrasonication for 2 h. The process of electrospinning is shown in Figure 1. The electrospun temperature and relative humidity are constantly controlled at 23 ± 2 °C and 40%–50%, respectively. All PU/RE spinning solutions were elof nanomaterials has become more and more widespread with the rapid development of science and technology. Electrospun at 15 kV of high-voltage electricity with an 18 cm tip-to-collector distance, the rotating speedinning, as one of the rotating collector was 650 rpm, and the solution feed rate was 1 mL/h.

Figure 1. Schematic diagram of the electrospinning setup and volatile organic compounds (VOCs) absorption experiment.

3. Results and Discussion

3.1 Physical Properties of Spinning Solutions and Properties of PU/RE Fiber

The electrospinning eftechnologies fect and VOC adsorption capacity of the PU/RE nanofibrous membranes were determined by the physical properties of the spinning solutions and the properties of the PU/RE composite nanofibers. The specific surface area was measured by the N2 preparing nanomaterials, has the adsorption-desorption isotherms test via the Brunauer–Emmett–Teller (BET) method. It was found that the viscosity, conductivity and specific surface area increased by increasing the amount of RE powder in the spinning solution. However, the fiber diameter first increased from 489 nm to 524 nm and then decreased from 524 nm to 356 nm when the relative content of the RE powder reached 50 wt. %. The PU nanofiber containing 50 wt. % of the RE powder had the smallest fiber diameter, which was 356 nmantages of simple equipment and easy manipulation.

3.2 Morphological Characteristics of the PU/RE Nanofibrous Membranes

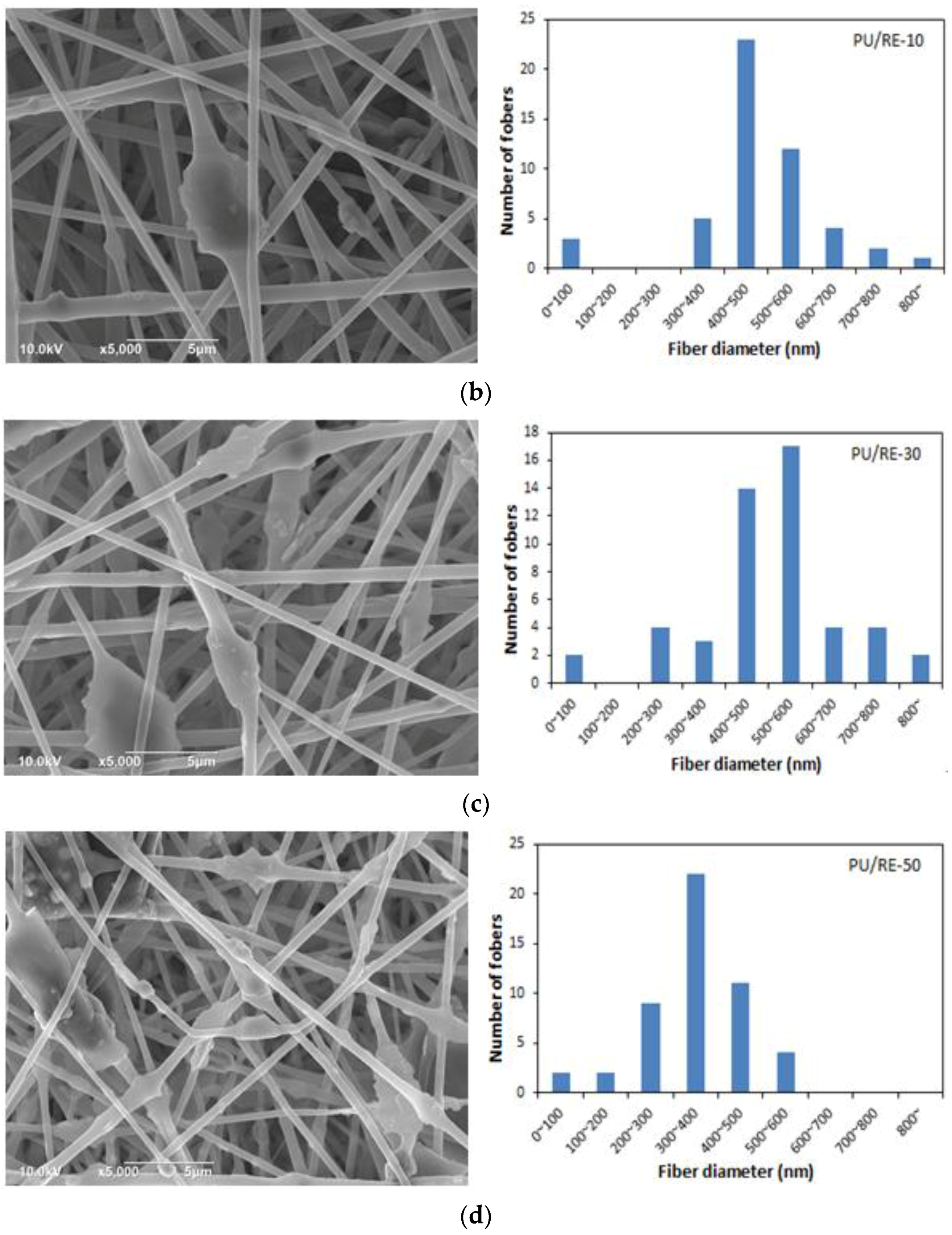

Figure 2 shows the morphology aInd the fiber diameter distribution of the composite PU/RE nanofibrous membranes. From Fig. 2a–d, it was observed that the changes of the fiber morphology and fiber diameter distribution correlated very closely with the increasing amounts of RE powder in the PU fibers. The pristine PU fibers had smooth surfaces and an average fiber diameter of 489 nm. However, it was found that there were a lot of RE NPs embedded in the PU fibers, and the number of RE NPs increased with an increased concentration of RE powder (Fig. 2b–d). In addition, some particle agglomeration existed in Fig. 2d because higher concentrations of RE powder cannot be completely dispersed into the spinning this study, fly ash (FA), polyacrylonitrile (PAN), and silver nitrate (AgNO3) were melted in a N,N-dimethylformamide (DMF) solution. Fig. 2e–h show the average fiber diameters of the PU, PU/RE-10, PU/RE-30 and PU/RE-50 nanofibrous membranes, which were 489, 513, 524 and 356 nm, respectively. Each of the reported PU/RE nanofibers’ diameters represents an average of 50 random fibers. The fiber diameters increased slightly as the amount of RE powder increased from 0 to 30 wt. % according to a certain ratio, and then showed a marked decrease when the relative amount of RE powder was 50 wt. %. The PU/RE-50 possessed the smallest average diameter of 356 nm.

Figure 2. FE-SEM images and diameter distributions of (a) polyurethane (PU); (b) PU/RE-10; (c) PU/RE-30 and (d) PU/RE-50.

3.3 Absorption Characteristics of the Composite PU/RE Nanofibrous Membranes

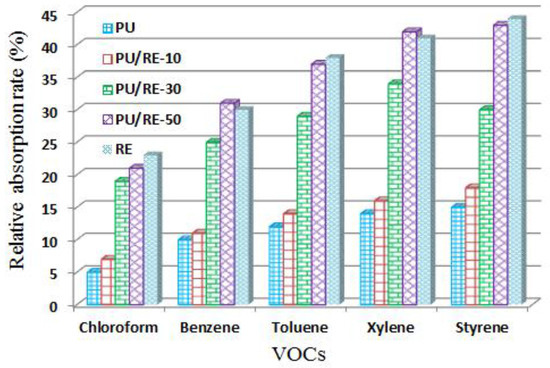

The VOC absorpwere spun into a multifunction characteristics of the PU l nanofibers containing different amounts of RE powder (0 wt. %, 10 wt. %, 30 wt. %, 50 wt. %) are shown in Figure 3. As shown in Fig. 3, it can be seen that the pure PU nanofibrous membrane had a weak VOC absorption capacity (about 10%), while the pure RE powder had a better VOC absorption capacity compared with the pure PU nanofibrous membrane. However, the RE powder will limit its usability. To integrate the merit and eliminate the defect of both PU and RE, the RE-incorporated PU fibers were electrospun before the VOC absorption experiment materials, which had the ability to adsorb VOCs in air and heavy metal ions in waste water. The VOC absorption capacability of the composite PU/RE nanofibrous membranes increased as the amount of RE powder in the PU fibers increased. The PU nanofiber containing 50 wt. % RE powder had the highest VOC absorption capacityheavy metal ions. In addition, the absorption capacity of the PU nanofiber containing 50 wt. % RE powder increased by 320%, 210%, 208% and 187% compared with that of the pure PU nanofibrous membrane during the absorption of styrene, xylene, toluene, benzene and chloroform, respectively. This may be due to the decreasing fiber diameter of the PU/RE composite fibers as the amount of RE powder increased, which subsequently increased the surface area of the composite fiber, producing a high physical absorption capacity. Furthermore, the higher BET surface area of the PU nanofiber containing 50 wt. % RE powder is 1.64 times greater than the pure PU nanofiber.

Figure 3. VOC absorption capacity of different nanofibrous mats.

Figure 3. VOC absorption capacity of different nanofibrous mats.

4. Conclusions

In summary also showed excellent antimicrobial activity, a series of PU nanofibers containing different amounts of RE powder (0 wt. %, 10 wt. %, 30 wt. %, 50 wt. %) with a high VOC absorption capacity can be successfully produced via electrospinning. At RE powder concentrations greater than 50 wt. %, however, the electrospinning nozzle will be seriously blocked. The PU/RE-50 fiber had the smallest fiber diameter, with an average fiber diameter of 356 nm. In addition, this fiber also had outstanding mechanical properties, with an average tensile strength of 8.28 MPa and a percentage strain that was above 700%. Most importantly, it had the highest VOC absorption capacity, more than three times that of the pure PU nanofiber. In addition, the composite PU/RE nanofibrous membranes most easily absorbed styrene, followed by xylene, toluene, benzene and chloroformon Gram-negative Escherichia coli (E. coli) (ATCC 52922) and Gram-positive Staphylococcus aureus (S. aureus) (ATCC 29231) bacteria.