The use of corrosion inhibitors is an important method to retard the process of metallic attack by corrosion. The construction of mathematical models from theoretical-computational and experimental data obtained for different molecules is one of the most attractive alternatives in the analysis of corrosion prevention, whose objective is to define those molecular characteristics that are common in high-performance corrosion inhibitors.

- corrosion inhibition

- organic inhibitors

- theoretical studies

- molecular descriptors

- mathematical models

1. Introduction

Corrosion is defined as the destructive attack of a material by reaction with its environment. This process is a worldwide, significant problem because of the economic damage and safety loss it may lead to. The losses originating from corrosion can be categorized as direct and indirect, and the latter includes economic losses caused by plant shutdowns, efficiency reduction, costly maintenance, and contamination of products whose overall impact will ultimately require over-design. The direct losses include the cost of replacing corroded structures, fixing damaged machinery, and substituting some of its components.

Corrosion control can be achieved by recognizing and understanding the mechanisms associated with this process. It is possible to prevent corrosion by using corrosion-resistant materials and protective systems.

The selection of materials; which can be metallic, non-metallic or alloys, is a key factor in the prevention of corrosion processes, as well as the consideration of the temperature, the type of environment and the general conditions to which the material is subjected. In such selection, both the mechanical and physical analyses of the materials’ properties play a very important role. However, such selection is limited by the availability and cost of materials. This limitation forces the industry to resort to the corrosion protection offered by metallic or non-metallic coatings and anodic or cathodic processes for metal protection, as well as to carefully select the appropriate geometrical configurations to prevent corrosive conditions and to avoid the use of bimetallic couples, which can be responsible for favoring the corrosion process. Corrosion protection can also be achieved by promoting the formation of Ni and Cr protective barriers or by protecting a substrate (steel) with sacrificing materials such as Zn, Al or Cd [1].

The environments to which metals are exposed make them prone to corrosion. A less aggressive environment can be obtained by removing constituents that facilitate corrosion, modifying the temperature, dehumidifying the air, removing dissolved O2 or solid particles, controlling the pH or adding corrosion inhibitors. The usage of inhibitors is one of the most practical methods for protection against corrosion in acidic, alkaline, saline, and other aggressive environments.

The following sections include:

- The definition of a corrosion inhibitor and the structural characteristics associated with an inhibitor molecule; a brief mention is made of the techniques that allow evaluating the performance of corrosion inhibitors in the protection of metal surfaces exposed to aggressive environments.

- The factors that increase the corrosion process and those that can be modified to prevent this phenomenon are briefly mentioned.

- The most important data such as molecules and inhibition efficiencies obtained by different techniques and experimental conditions have been summarized, taking into account the functional group of greatest interest to the study authors. Information related to the descriptors used in the theoretical analysis of corrosion inhibitors has been collected.

- Finally, a table has been generated with examples of some mathematical models obtained to evaluate corrosion inhibitor molecules, in which it is possible to observe the most common descriptors to predict the corrosion phenomenon.

2. Corrosion Inhibitors

Corrosion inhibitors are chemical substances that are added to aggressive environments in small concentrations to decrease the corrosion rate. These substances can react with either a metal surface or its surroundings providing protection to the surface, although it has been observed that corrosion inhibitors generally work by forming an adsorbed film. Corrosion inhibitors are an appropriate option for metal protection when these are exposed to aggressive media, such as, acidic solutions (widely employed for industrial cleaning), oil well acidification, and petrochemical processes [2]. Corrosion inhibitors can be introduced into the aggressive environment in a single application or continuously by gradual and controlled additions. The single addition is possible in static systems at low temperature and where friction is negligible. Gradual addition is necessary for systems where variation in flow and temperature degrade the integrity of the protective film formed on the metal surface, either by physisorption or chemisorption. The stability of the corrosion inhibitor films can be compromised by the concentration levels of the inhibitor in the medium [2]. Comparative studies performed to determine inhibition effects are generally performed without shaking. Therefore, the existence of a significant effect of immersion time on the quality of the formed film of an inhibitor is reasonable.

An important number of compounds have been used for the corrosion protection of metals exposed to aggressive media. Their effectiveness is associated to their chemical composition, molecular structure, alkyl chain length (or molecular volume), planarity, presence of lone pairs of electrons in heteroatoms (e.g., S, N, O, P), affinity for the metallic surface, dipole moment, presence of π-electrons (unsaturation or aromatic ring) and energy of frontier molecular orbitals. The efficiency (E%) of corrosion inhibitors is measured by applying the Equation (1) to experimental data obtained by techniques such as weight loss (WL), potentiodynamic polarization (PP), and electrochemical impedance spectroscopy (EIS):

\( E\% = \frac{{\left( {C{R_u} - C{R_i}} \right)}}{{C{R_u}}} \times 100 \). Equation (1)

where CRu is the corrosion rate of the uninhibited system and CRi is the rate of the inhibited system.

The mechanisms through which corrosion inhibitors can be bounded to the metal or the metal oxide surface may be physisorption, chemisorption, complexation or precipitation. The film formed by corrosion inhibitors prevents the access of oxygen to the cathode and the diffusion of hydrogen away from it, or simply inhibits metal dissolution (anodic inhibitors). Inhibition efficiency can be altered by modifying the system parameters such as pH, temperature, metal composition, type of inhibitor and molecular structure of the corrosion inhibitor [3]. An important factor associated with the corrosion process is surface roughness. The increase in the surface roughness of alloys (magnesium, titanium-based), stainless steels, copper, and aluminum increases the pitting susceptibility and the corrosion rate [4].

Corrosion inhibitors can act by stimulating anodic or cathodic polarization, reducing the transport of ions towards the metallic surface and increasing the electrical resistance of a metallic material. These compounds can be classified according to their functionality (anodic, cathodic, organic and precipitation-inducing inhibitors). Anodic inhibitors are molecules that cause a large anodic shift of the corrosion potential and by this means they are able to generate the passivation of the metal surface. On the other hand, cathodic inhibitors either slow the cathodic reaction or selectively precipitate on cathodic areas increasing the surface impedance and reducing the diffusion of species. Some cathodic inhibitors may precipitate as oxides building a protective layer on the metallic surface. Organic inhibitors can be classified as another type of inhibitor. These substances can be associated with anodic and cathodic effects; they generally protect the metallic surface by creating a film whose function consists in isolating the metal from corrosion. Finally, precipitation-inducing inhibitors are compounds responsible for the formation of precipitates on the metallic surface which protect it from the corrosion process . In the study of amino acids carried out by Aouniti et al. [10][3], it was demonstrated by the analysis of cathodic and anodic potentiodynamic polarisation curves, that these compounds act as cathodic inhibiting only the cathodic process. In the analysis, before recording the cathodic polarisation curves, the electrode was polarised at −800 mV/SCE (saturated calomel electrode) for 10 min, while for the anodic curves, the potential electrode was swept from its corrosion potential (maintained 30 min) to positive values. No changes were observed in the anodic curves.

3. N-Containing Corrosion Inhibitors

An important number of molecules evaluated as corrosion inhibitors in acidic media contain N-atoms and the structural properties that are characteristic of high-performance corrosion inhibitors. Table 1 shows some examples of the N-containing corrosion inhibitors evaluated by different researchers. The Table indicates which corrosion inhibitors have been theoretically analyzed.

Table 1. N-containing corrosion inhibitors

Example |

Corrosion Inhibitor |

EfWL/EfPP/EfEIS |

Ref |

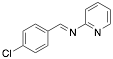

|

(4-Chloro-benzylidene-pyridine-2-yl-amine) |

99.5/99.6/99.6 |

[5] |

Exp. C. NCI: 3, Met: mild steel, Media: HCl 1.0 M, Co: 2×10−4–1×10−2 M, t: 24 h (WL), T: 25 °C, TA: A |

|||

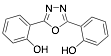

|

|

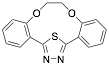

2,5-bis(2-hydroxyphenyl)-1,3,4-oxadiazole |

98.2/94.7/99.1 |

[6] |

Exp. C. NCI: 2, Met: mild steel, Media: HCl 1.0 M, 0.5 M H2SO4, Co: 20–80 mg•L−1, t: 24 h (WL), 20 h (EIS), T: 30 °C, TA: NA |

|||

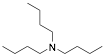

|

Tributylamine |

97.8/-/- |

[7] |

Exp. C. NCI: 23, Met: 13% Cr steel, Media: HCl (15%w/v), Co: 2%w/v inhibitor and 0.6% w/v formaldehyde (used to minimize hydrogen penetration), t: 3 h, T.: 60 °C, TA: A |

|||

|

1,2-bisbenzylbenzimidazole |

96 |

[8] |

Exp. C. NCI: 11, Met: iron, Media: HCl 1.0 M. The analysis technique and the rest of the experimental conditions are not specified. TA: A |

|||

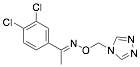

|

3,4-Dichloro-acetophenone-O-1′-(1′.3′.4′-triazolyl)-metheneoxime (DATM) |

92.8/98.7/98.7 |

[9] |

Exp. C. NCI: 3, Met: mild steel, Media: HCl 1.0 M, Co:1×10−5–1×10−3 M, t: 3 h (WL), 30 min (PP), T: 25 °C, TA: A |

|||

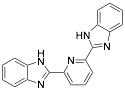

|

* 2,6-bis-(2-benzimidazolyl) pyridine |

-/94–96/97.0 |

[10] |

Exp. C. NCI: 4, Met: mild steel, Media: HCl 1.0 M, Co: 0.1–1.0 mM, t: 1–96 h (WL), 45 min (PP), T.: 30 °C, TA: NA |

|||

|

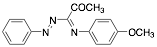

1-(4-Methyloxyphenylimino)-1-(phenylhydrazono)-propan-2-one |

-/95.9/96.2 |

[11] |

Exp. C. NCI: 5, Met: mild steel, Media: HCl 1.0 M, Co: 5×10−6–7.5×10−5 M, t: 30 min, T: 25 °C, TA: NA |

|||

|

1-Butyl-2-propylene-2-imidazoline |

95.1/-/- |

[12] |

Exp. C. NCI: 34, Met: stainless steel, Media: HCl 5%, Co: ≈0.1 M, t: 48 h, T: TR (room temperature), TA: A |

|||

|

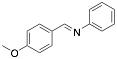

Aniline, N-(p-methoxybenzylidene) |

-/94.0/- |

[13] |

Exp. C. NCI: 4, Met: aluminium, Media: HCl 2.0 N, Co: 10−5–10−2 M, t:-, T: 30 °C, TA: NA |

|||

|

Cyclohexanone oxime |

93.9/98.4/95.2 |

[14] |

Exp. C. NCI: 3, Met: aluminium, Media: HCl 1.0 M, Co: 0.2–2.0 mM, t: 2 h, T: 20–50 °C, TA: NA |

|||

|

6-Bromo-1H-benzimidazole |

-/-/89.4 |

[15] |

Exp. C. NCI: 15, Met: carbon steel, Media: HCl 1.0 M, Co:0.1–10 mM, t: 30 min, T: TR, TA: A |

|||

|

2-Mercaptobenzimidazole |

-/88.7/90.4 |

[2] |

Exp. C. NCI: 3, Met: mild steel, Media: HCl 1.0 M, Co: 50–250 ppm, t: 30 min, T: 25 °C, TA: NA |

|||

|

2-Chloromethylbenzimidazole |

-/-/69.7 |

[16] |

Exp. C. NCI: 6, Met: carbon steel, Media: HCl 1.0 M, Co: 1×10−3 M, t: -, T: TR, TA: A |

|||

|

2,4-Dimercaptopyrimidine |

43.0/-/- |

[3] [17] |

Exp. C. NCI: 14, Met: Aramco iron, Media: HCl 2.0 M, Co: 1×10−3 M, t: 1 h, T: 40 °C, TA: A |

|||

Simbology: TA: theoretical analysis, A: applied, NA: not applied, Exp. C.: experimental conditions; NCI: number of corrosion inhibitors, Co: inhibitor concentration, t: exposure time, T: temperature, EfWL/EfPP/EfEIS: corrosion inhibition efficiencies obtained by weight loss (WL), potentiodynamic polarization (PP), and electrochemical impedance spectroscopy (EIS), respectively. |

|||

Table 2. S-containing corrosion inhibitors

Example |

Corrosion Inhibitor |

EfWL/EfPP/EfEIS |

Ref |

|

1-Phenyl thiosemicarbazide |

-/100.0/- |

[18] |

Exp. C. NCI: 10, Met: mild steel, Media: H2SO4, Co: 1 mM

|

|||

|

Phenylthiourea (PTU) |

-/-/97.2 |

[19] |

Exp. C. NCI: 3, Met: mild steel, Media: H2SO4 0.1 M, Co: 1–10 mM, t:1 h, T: TR, TA: NA |

|||

|

2-Mercaptobenzothiazole |

-/97/- |

[20] |

Exp. C. NCI: 1, Met: Steel (API 5L X52), Media: H2SO4 1.0 M, Co: 10−4-–10−3 M, t: 30 min, T: 25 °C, TA: A |

|||

|

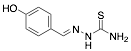

4-Hydroxybenzaldehyde thiosemicarbazone |

-/97.0/90.0 |

[21] |

Exp. C. NCI: 6, Met: carbon steel, Media: HCl 1.0 M, Co: 10−4–10−2 M, t: 30 min, T: 25 °C, TA: NA |

|||

|

2-Mercapto-1-methylimidazole |

90.4 /95.5/- |

[22] |

Exp. C. NCI: 1, Met: carbon steel, Media: HClO4 1.0 M, Co: 7.5

|

|||

Simbology: TA: theoretical analysis, A: applied, NA: not applied, Exp. C.: experimental conditions; NCI: number of corrosion inhibitors, Co: inhibitor concentration, t: exposure time, T: temperature, EfWL/EfPP/EfEIS: corrosion inhibition efficiencies obtained by weight loss (WL), potentiodynamic polarization (PP), and electrochemical impedance spectroscopy (EIS), respectively. |

|||

Table 3. O-containing corrosion inhibitors

Example |

Corrosion Inhibitor |

EfWL/EfPP/EfEIS |

Ref |

|

2-(4-Methylbenzylidene)-3-oxo-2,3-dihydro-1H-indene-1-carboxylic acid |

92.0/93.9/92.6 |

[23] |

Exp. C. NCI: 3, Met: mild steel, Media: HCl 1.0 M, Co: 10−6–10−3 M, t: 6 h, T: 30 °C, TA: NA |

|||

|

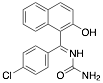

1-((4-Chlorophenyl)(2-hydroxynaphtalen-1-yl)(phenyl) methyl)urea (CPHU) |

90/92.0/- |

[24] |

Exp. C. NCI: 3, Met: mild steel, Media: H2SO4 0.5 M, Co: 2–10 ppm, t: 24 h (WL) and 30 min (PP), T: 20 °C, TA:A |

|||

|

1,3-Dibromo-5,5-dimethylhydantoin |

-/89.8/91.4 |

[25] |

Exp. C. NCI: 6, Met: mild steel, Media: HCl 0.5 M, Co: 10–50 ppm, t: 30 min, T: 30 °C, TA:A |

|||

|

L-ascorbic acid |

69.0/-/- |

[26] |

Exp. C. NCI: 1, Met: mild steel, Media: H2SO4 0.01 M, Co: 10−7–10−3 M, t: -, T: TR, TA: NA |

|||

Simbology: TA: theoretical analysis, A: applied, NA: not applied, Exp. C.: experimental conditions; NCI: number of corrosion inhibitors, Co: inhibitor concentration, t: exposure time, T: temperature, EfWL/EfPP/EfEIS: corrosion inhibition efficiencies obtained by weight loss (WL), potentiodynamic polarization (PP), and electrochemical impedance spectroscopy (EIS), respectively. |

|||

Table 4. Multi-heteroatom containing corrosion inhibitors

Example |

Corrosion Inhibitor |

EfWL/EfPP/EfEIS |

Ref |

|

(2,3,8,9-Dibenzo-4,7-dioxa-13-thia-11,12-diazabicyclo[8.2.1]trideca-10,12-diene (1-MCTH) |

97.7/-/- |

[27] |

Exp. C. NCI: 5, Met: mild steel, Media: 1.0 M HCl, Co: 1

|

|||

|

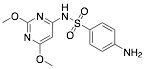

Sulphadimethoxine |

93.8/84.0/92.1 |

[28] |

Exp. C. NCI: 5, Met: mild steel, Media:1.0 M HCl, Co: 1–5

|

|||

|

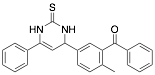

5-Benzoyl-4-tolyl-6-phenyl-1,2,3,4-tetrahydro-2-thioxopyrimidine |

-/93.0/93.0 |

[29] [30] |

Exp. C. NCI: 2, Met: stainless steel, Media:1.0 M HCl, Co:1

|

|||

|

L-Cysteine |

82.2/-/- |

|

Exp. C. NCI: 4, Met: mild steel, Media:0.1 M HCl, Co: 0.1–0.5 g

|

|||

|

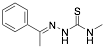

(E)-N-methyl-2-(1-phenylethylidene)hydrazinecarbothioamide PHCARB |

80.7/-/- |

[31] |

Exp. C. NCI: 4, Met: mild steel, Media:0.1 M HCl, Co: 1–5

|

|||

|

Methionine |

72.7/84.6/85.8 |

|

Exp. C. NCI: 16, Met: Armco iron, Media: HCl 1.0 M, Co: 10−3 M, et: 6 h (WL), 10 y 30 min (PP), T: 35 °C, TA: A |

|||

Simbology: TA: theoretical analysis, A: applied, NA: not applied, Exp. C.: experimental conditions; NCI: number of corrosion inhibitors. Co: inhibitor concentration, t: exposure time, T: temperature, EfWL/EfPP/EfEIS: corrosion inhibition efficiencies obtained by weight loss (WL), potentiodynamic polarization (PP), and electrochemical impedance spectroscopy (EIS), respectively. |

|||

Table 5. Examples of descriptors used in the theoretical analysis of corrosion inhibitors.

Quantum Descriptor |

Symbol |

Description |

Reference |

Energy of the highest occupied molecular orbital |

EHOMO |

Associated with the electron-donating ability of a molecule. |

[5] |

Energy of the lowest unoccupied molecular orbital |

ELUMO |

Indicates the ability of the molecule to accept electrons. |

[22] |

Ionization potential |

IP |

It is a descriptor of the chemical reactivity of atoms and molecules. IP is the minimum energy required to remove an electron from an atom. |

[30] |

Electron affinity |

A |

It is a property that determines how susceptible a molecule is towards the attack of a nucleophile. |

[32] |

Dipole moment |

μD |

The dipole moment is considered a measure of the stability of the formed complex on a metal surface. It is an indicator of the asymmetry in the molecular charge distribution. It is related to the hydrophobic character of the molecules. |

[24] [33] [34] |

Energy gap |

ΔE |

ΔE= EHOMO − ELUMOIt has been mentioned that the successful adsorption and proper efficiency of an inhibitor have been characterized by a high EHOMO, a low ELUMO, and a small energy gap. The lower the ΔE is, the higher the stability of the metal-inhibitor interaction. |

[10] [33] [35] |

Fraction of electron transferred |

ΔN |

If ΔN > 3.6, the inhibition efficiency increases |

[10] |

Global hardness |

η |

It is a parameter associated with the resistance of an atom to transfer its charge. |

[10] |

Softness |

σ |

The σ shows the reactivity of the inhibitor molecules in terms of charge transfer. |

[10] |

Electronegativity |

χ |

The electronegativity measures the power of a group of atoms to attract electrons towards itself. |

[10] |

Electrophilicity index |

ω |

It is a reactivity descriptor that allows the quantitative classification of the global electrophilic nature of a molecule. This descriptor has been proposed as a measure of energy lowering due to maximal electron flow between donor and acceptor. |

[9] |

Electrodonating power |

ω- |

A descriptor associated with the ability of a species to donate electrons. |

[36] |

Electroaccepting power |

ω+ |

A descriptor associated with the ability of a species to accept electrons. |

[36] |

Dipole polarizability |

α |

α is a measure of the mean polarizability. Higher values of α enable a strong adsorption process. |

[9] |

Fukui functions |

fk+, fk - |

These functions indicate the part of the molecule where nucleophilic, electrophilic, and radical attack is most likely to occur. |

[32] |

Partition coefficient |

Log P |

Log P is a hydrophobic parameter of a molecule. |

[37] |

Table 6. Examples of mathematical models generated for corrosion analysis.

Molecules Evaluated |

Theoretical Calculation |

Mathematical Model |

R2 |

Ref. |

Schiff base |

AM1 semi-empirical method |

\( {\small I{E_{exp}}\left( \% \right) = 2.084{E_{HOMO}} - 3.041{E_{LUMO}} + 115.772 } \) |

1.00 |

[5] |

| \( {\small IE_{Theor}=\frac{\left(-604.90E_{HOMO}+5864.86E_{LUMO}+1190.06\mu_D-642.67\right)C}{\left[1+\left(-604.90E_{HOMO}+5864.86E_{LUMO}+1190.06\mu_D-642.67\right)C\right]} } \) |

0.98 |

|||

Amines, thioureas, acetylenic alcohols |

AM1 methodology was used for most descriptors, PC model provided the volume calculations |

\( {\small \begin{matrix}lnK_{ads}=-0.93N-7.64P+6.74C-2.27C_{12}+0.94C_{13}-1.06C_1\\-7.22C_2-2.17E_{HOMO}-1.17DP+7.45V-1.15A_1\\-1.81A_2+7.12NCS-1.869NOH-1.085NCR\\\end{matrix} } \) |

0.98 |

[7] |

| \( {\small lnK_{ads}=1.52M-0.79P+0.53C_{12}+0.80NT-0.66NOH } \) |

0.86 |

|||

| \( {\small \begin{array}{*{20}{c}} {{\rm{ ln}}{{\rm{K}}_{{\rm{ads}}}}{\rm{ = }}}&{ - 2.688 \times {{10}^{ - 2}}{A_1} + 0.115{A_2} + 4.530 \times {{10}^{ - 2}}{A_3} + 8.762 \times {{10}^{ - 2}}NB - 1.305 \times {{10}^{ - 2}}NC}\\ {}&{ + 0.102NCS - 4.518 \times {{10}^{ - 2}}NT - 5.172 \times {{10}^{ - 2}}NOH - 1.099 \times {{10}^{ - 3}}NCR + 4.996 \times {{10}^{ - 2}}NR}\\ {}&{ - 6.338 \times {{10}^{ - 2}}N - 0.114ED + 0.184M + 0.180P - 6.838 \times {{10}^{ - 2}}C + 8.092 \times {{10}^{ - 2}}{C_{12}}}\\ {}&{ - 4.783 \times {{10}^{ - 2}}{C_{13}} - 1.130 \times {{10}^{ - 2}}{C_{14}} - 0.167{C_1} - 0.152{C_2} - 0.122{E_{HOMO}}}\\ {}&{{\rm{ - 7.838}} \times {\rm{1}}{{\rm{0}}^{ - 2}}{{\rm{E}}_{{\rm{LUMO}}}}{\rm{ - 7.004}} \times {\rm{1}}{{\rm{0}}^{ - 3}}\Delta {\rm{E + 0.109}}\mu {\rm{ + 0.141V}}} \end{array} } \) |

0.85 |

|||

Triazole derivatives |

Density Functional Theory (DFT), B3LYP/6-31G |

\( {\small IE_{Theor}=\frac{\left(18.38E_{HOMO}-7.28E_{LUMO}-0.012V+123.36\right)C}{\left[1+\left(18.38E_{HOMO}-7.28E_{LUMO}-0.012V+123.36\right)C\right]} } \) Derived QSAR equation in gas phase |

0.94 |

[9] |

|

\( {\small IE_{Theor}=\frac{\left(-2.19E_{HOMO}-1.24E_{LUMO}-0.014V-10.94\right)C}{\left[1+\left(-2.19E_{HOMO}-1.24E_{LUMO}-0.014V-10.94\right)C\right]} } \) Derived QSAR equation in aqueous phase |

0.95 |

|||

Imidazole derivatives |

Restricted Hartree–Fock level (RHF) using MINDO/3, MNDO, PM3 and AM1 semi-empirical SCF-MO methods. |

\( {\small I{E_{exp}}\left( \% \right) = 1174.95 + 214.612{E_{HOMO}} - 16.793{E_{LUMO}} } \) Gas phase (series 1) |

0.90 |

[8] |

|

\( {\small I{E_{exp}}\left( \% \right) = 517.7 + 53.8{E_{HOMO}} - 1.97{E_{LUMO}} } \) Aqueous phase (series 1) |

0.82 |

|||

|

\( {\small I{E_{exp}}\left( \% \right) = 2420.86 + 295.67{E_{HOMO}} - 30.08{E_{LUMO}} } \) Gas phase (series 2) |

0.97 |

|||

|

\( {\small I{E_{exp}}\left( \% \right) = 601.53 + 63.07{E_{HOMO}} - 1.405{E_{LUMO}} } \) Aqueous phase (series 2) |

0.99 |

|||

Imidazole and benzimidazole derivatives |

--- | \( {\small I{E_{exp}}\left( \% \right) = 38.47 + 20.21n\left( N \right) - 7.98N\left( {O + N{H_2}} \right) + 14.94{\eta ^ + } - 17.93{\eta ^ - } } \) |

0.97 |

[12] |

Indole derivatives |

DFT, B3LYP functional and 6-31G(2d,2p) basis |

\( {\small R_{ct}=150+\left(-359539E_{HOMO}+1585825E_{LUMO}\right)C } \) |

0.97 |

[27] |

| \( {\small R_{ct}=150+\left(-402535E_{HOMO}+960146E_{LUMO}\right)C } \) |

0.97 |

|||

Imidazole and benzimidazole derivatives |

DFT: PBE/6-311++G ** |

\( {\small {E_{exp}}\left( \% \right) = 5130.95 - 32.03\chi + 533.4b{q^{ISO}} + 0.37V + 1433.78{q_{N1}} } \) |

0.92 |

[38] |

Imidazole, benzimidazole and pyridine derivatives |

DFT: PBE/B3LYP/M06, using the orbital basis 6-31G* and 6-311++G** |

\( {\small I{E_{exp}}\left( \% \right) = 92.965 + 0.152V + 35.337{\omega ^ - } + 3.592b{q_{ANS}} } \) |

0.75 |

[15] |

Pyrimidine derivatives |

DFT BLYP/DNP |

\( {\small I{E_{exp}}\left( \% \right) = - 4.324\mu - 46.527{\rm{\Delta }}E + 376.48{q_{N1}} } \) |

0.98 |

[17] |

Thiosemicarbazides |

PM3 and MNDO method. |

\( {\small IE_{Theor}=\frac{\left(-6.7E_{HOMO}-5.9E_{LUMO}-3.5\mu-43.7\right)C}{\left[1+\left(-6.7E_{HOMO}-5.9E_{LUMO}-3.5\mu-43.7\right)C\right]}\times100 } \) |

0.84 |

|

| \( {\small IE_{Theor}=\frac{\left(227.2+23.5E_{HOMO}-3.8\mu\right)C}{\left[1+\left(227.2+23.5E_{HOMO}-3.8\mu\right)C\right]}\times100 } \) |

0.92 |

|||

Thiosemicarbazides/ Thiosemicarbazones |

Data obtained from literature |

\( {\small IE_{exp}=\frac{e^{-2.5219E_{HOMO}-0.5119\mu_D-18.1761}C}{\left(1+e^{-2.5219E_{HOMO}-0.5119\mu_D-18.1761}C\right)} } \) |

0.89 |

[18] |

| \( {\small {\rm{I}}{{\rm{E}}_{{\rm{exp}}}}{\rm{ = }}\frac{{{{\rm{e}}^{{\rm{263.12}}\Delta {\rm{E - 17.26}}\Delta {\rm{E2 - 999.22}}}}{\rm{C}}}}{{{\rm{1 + }}{{\rm{e}}^{{\rm{263.12}}\Delta {\rm{E - 17.26}}\Delta {\rm{E2 - 999.22}}}}}} } \) |

0.88 |

|||

2-Mercaptobenzothiazole |

DFT: B3LYP/6-31+G* |

\( {\small I{E_{Theor}} = \frac{{\left( {2.23{E_{HOMO}} - 8.37{E_{LUMO}} + 5.47\Delta E + 1.76\Delta N + 6.47\mu + 119.8V + 2.07} \right)C}}{{\left[ {1 + \left( {2.23{E_{HOMO}} - 8.37{E_{LUMO}} + 5.47\Delta E + 1.76\Delta N + 6.47\mu + 119.8V + 2.07} \right)C} \right]}} \times 100 } \) |

0.96 |

[20] |

Urea derivatives |

DFT: B3LYP/6-31G |

\( {\small ∆E=-0.0024IEexp-4.3145} \) |

0.95 |

[24] |

| \( {\small {E_{HOMO}} = - 0.0107I{E_{\exp }} - 4.88596 } \) |

0.93 |

|||

Hydantoin derivatives |

DFT: B3LYP/6-31G+(d,p) |

\( {\small IE_{Theor}=129.054-0.181Mwt-6.550∆E-174.884∆N+0.484BE } \) |

1.00 |

[25] |

| \( {\small I{E_{Theor}} = \frac{{\left( {9.1 \times {{10}^{13}}Mwt + 4.9 \times {{10}^{14}}\Delta N + 9.7 \times {{10}^{13}}\Delta E + 2.4 \times {{10}^{13}}BE - 5.9 \times {{10}^{13}}} \right)}}{{\left( {1 + 1.8 \times {{10}^{13}}Mwt + 1.8 \times {{10}^{16}}\Delta N + 8.1 \times {{10}^{14}}\Delta E - 1.2 \times {{10}^{13}}BE - 7.2 \times {{10}^{15}}} \right)}} } \) |

0.99 |

|||

Polyether compounds |

DFT B3LYP/6-31G(d,p) |

\( {\small R_t=5+\left(2.710^7E_{HOMO}-7.610^7E_{LUMO}+3.910^6\mu\right)C } \) |

0.81 |

[27] |

Sulphonamide derivatives |

DFT: B3LYP/6-311+G(d,p) |

\( {\small I{E_{\exp }}\left( \% \right) = \frac{{\left( {2.47\omega + 8.56 \times {{10}^{ - 2}}{E_{LUMO}} - 5.27 \times {{10}^{ - 2}}\mu + 6.20\eta - 4.11 \times {{10}^{ - 2}}LogP - 21.81} \right) * 5000}}{{\left( {1 + \left( {2.47\omega + 8.56 \times {{10}^{ - 2}}{E_{LUMO}} - 5.27 \times {{10}^{ - 2}}\mu + 6.20\eta - 4.11 \times {{10}^{ - 2}}LogP - 21.81} \right) * 50} \right)}} } \) |

1.00 |

[28] |

| \( {\small I{E_{\exp }}\left( \% \right) = \frac{{\left( { - 1.44\Delta E + 3.48{E_{LUMO}} - 3.50{E_{HOMO}} + 1.07\eta + 1.75{\omega ^ + } - 17.85} \right)*5000}}{{\left( {1 + \left( { - 1.44\Delta E + 3.48{E_{LUMO}} - 3.50{E_{HOMO}} + 1.07\eta + 1.75{\omega ^ + } - 17.85} \right)*50} \right)}} } \) |

0.99 |

|||

Pyrimidine compounds |

B3LYP/6-311++G(d,p) |

\( {\small I{E_{Theor}}\left( \% \right) = 9.255 \times {10^1} - 3.213 \times {10^{ - 3}}\frac{\chi }{{{C_1}}} + 3.432 \times {10^{ - 7}}\frac{\mu }{{C_2^2}} - 1.768 \times {10^{ - 10}}\frac{{\Delta E}}{{C_3^3}} - 5.859\frac{{{E_{HOMO}}}}{{C_4^4}} } \) * equation for BTPTT, phase gas |

0.98 |

[29] |

| \( {\small I{E_{Theor}}\left( \% \right) = 9.326 \times {10^1} + 6.249 \times {10^{ - 4}}\frac{{{E_{HOMO}}}}{{{C_1}}} - 1.093 \times {10^{ - 7}}\frac{{{E_{LUMO}}}}{{C_2^2}} } \) |

0.99 |

|||

Amino acids |

PM6, PM3, MNDO and RM1 for semi-empirical studies. DFT. Local selectivity |

\( {\small IE_{exp}=125.80E_{HOMO}-121.83E_{LUMO}+1402.96 } \) PM6 Hamiltonian |

0.93 |

[30] |

|

\( {\small I{E_{Theor}} = \frac{{\left( {1.085{E_{HOMO}} + 1.114{E_{LUMO}} + \Delta E + 4.128\mu } \right)C}}{{\left[ {1 + \left( {1.085{E_{HOMO}} + 1.114{E_{LUMO}} + \Delta E + 4.128\mu } \right)C} \right]}} \times 100 } \) AM1 Hamiltonian, gas phase |

0.86 |

|||

|

\( {\small I{E_{Theor}} = \frac{{\left( {0.896{E_{HOMO}} + 1.38{E_{LUMO}} + \Delta E + \mu + 1.694{E_{diel}} + 18.38} \right)C}}{{\left[ {1 + \left( {0.896{E_{HOMO}} + 1.38{E_{LUMO}} + \Delta E + \mu + 1.694{E_{diel}} + 18.38} \right)C} \right]}} \times 100 } \) RM1 Hamiltonian, aqueous phase |

0.96 |

|||

Carbozones |

AM1, PM6, PM3, MNDO and RM1 Hamiltonians. Correlation MP2, basis STO-3G |

\( {\small I{E_{exp}}\left( \% \right) = - 14.686{E_{HOMO}} - 48.966 } \) |

0.94 |

[31] |

| \( {\small I{E_{Theor}} = \frac{{\left( {1.0176{E_{HOMO}} + 0.9743{E_{LUMO}} + 1.0351\Delta E + \cos A + \cos V + 428.6731} \right)C}}{{\left[ {1 + \left( {1.0176{E_{HOMO}} + 0.9743{E_{LUMO}} + 1.0351\Delta E + \cos A + \cos V + 428.6731} \right)C} \right]}} } \) |

0.83 |

|||

Simbology

|

||||

|

|

|

|

||

References

- Rosa L. Camacho-Mendoza; Evelin Gutiérrez-Moreno; Edmundo Guzmán-Percástegui; Eliazar Aquino-Torres; Julián Cruz-Borbolla; José A. Rodríguez-Ávila; José G. Alvarado-Rodríguez; Oscar Olvera-Neria; Pandiyan Thangarasu; José L. Medina-Franco; et al. Density Functional Theory and Electrochemical Studies: Structure–Efficiency Relationship on Corrosion Inhibition. Journal of Chemical Information and Modeling 2015, 55, 2391-2402, 10.1021/acs.jcim.5b00385.

- L. A. Godinez; Y. Meas; R. Ortega-Borges; A. Corona; Los inhibidores de corrosión. Revista de Metalurgia 2003, 39, 140-158, 10.3989/revmetalm.2003.v39.i2.325.

- Aouniti, A.; Khaled, K.F.; Hammouti, B.; Correlation Between Inhibition Efficiency and Chemical Structure of Some Amino Acids on the Corrosion of Armco Iron in Molar HCl. Int. J. Electrochem. Sci. 2013, 8, 5925–5943.

dm−3, t: -, T: 30 °C. TA: A

dm−3, t: -, T: 30 °C. TA: A 10−5–2.5

10−5–2.5