- stress induced transformations

- strain induced transformations

- transformation induced plasticity

- displacive transformations

- bainite

- martensite

1. Introduction

Displacive stress induced transformations (SIT) and strain/deformation induced transformations (DIT) include the transformations from austenite (γ), which has a face-centered cubic (fcc) structure, to either martensite or bainitic ferrite, promoted by the application of elastic stress or plastic strain, respectively [1][2][3][4]. This type of transformations can happen from the austenite in microstructures in which the austenite is the only phase [5][6][7][8][9][10][11], which are called fully austenitic microstructures, from now on. They can also occur from the retained austenite in microstructures which consist of different phases [1][4][12][13][14][15][16][17][18][19], which are named multiphase microstructures, from now on. Some examples of multiphase microstructures are microstructures consisting of allotriomorphic ferrite, martensite, bainitic ferrite, and retained austenite [20], bainitic microstructures with retained austenite [21] or microstructures obtained by a quenching and partitioning (Q&P) treatment with retained austenite [22]. The SIT/DIT can happen while a microstructure is subjected to a mechanical test or in a thermomechanical treatment by which a certain final microstructure is aimed.

With respect to the first scenario (SIT/DIT in mechanical tests), the former research on displacive SIT and DIT has mainly focused on the martensite transformation induced plasticity (TRIP) effect at room temperature, which can happen in austenitic or in multiphase microstructures. The TRIP effect refers to the effect by which a SIT/DIT may lead to improved mechanical properties, as these transformations are associated to an increase of volume, i.e., an increase of elongation and an increase of the dislocation density. However, the optimization of the mechanical properties by TRIP effect is not straightforward. The effect of the stress or strain induced martensite on the mechanical properties can vary depending on several factors, such as the thermal or mechanical austenite stability [23][24] and the product phase [25]. In addition, the complexity of the initial microstructure can also have other effects on these transformations, such as the effect of the matrix in multiphase steels [26][27][28]. Oppositely to the wide knowledge about martensite TRIP effect, the bainite TRIP effect has not been so studied. Although this transformation has been detected in multiphase steels deformed above room temperature [2][3][4][19][29], its effect on the mechanical properties and its differences with respect to the martensite TRIP effect have not been assessed yet.

Concerning the second case (SIT/DIT happening in thermomechanical treatments), there are many scenarios that have not received much attention, especially the ones involving the formation of bainite. For instance, although the bainite SIT/DIT has been studied under constant stress [30][31][32][33][34], the formation of bainite while straining fully austenitized steels [35][36] has not been deeply assessed.

2. Metastable Phases Formed by Stress and Strain Induced Transformations

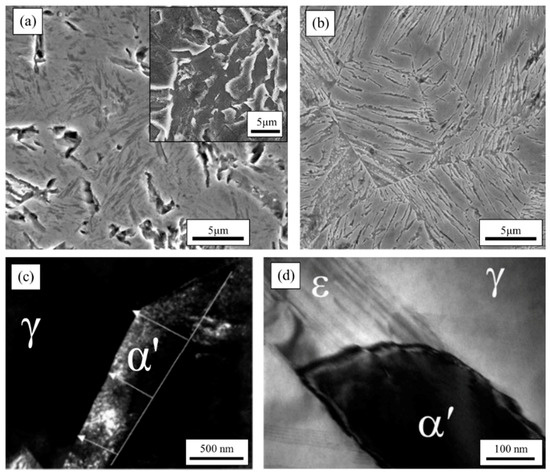

As mentioned, the product of SIT and DIT include martensite and bainitic ferrite. The structure of the bainitic ferrite (αB

) is always either body-centered cubic (bcc) or body centered tetragonal (bct) and it has morphology of plate or lath. Depending on the chemical composition of the steel, a bainitic microstructure can contain cementite, martensite, and/or retained austenite, apart from αB

. a,b show two micrographs showing the granular bainite and plate-like bainite microstructures that were formed in a medium carbon high silicon steel by a DIT at 520 °C and 400 °C, respectively [35].

Figure 1.

a

b

c

d

However, the structure of martensite is not always the same. In many cases, two different types of martensite are detected: α′-martensite and ε-martensite. The former one is the most common type of martensite, with a bcc or bct structure and whose nucleation is associated with dislocation pile-ups on the active slip plane of γ [39]. On the other hand, ε-martensite, which has a hexagonal close-packed (hcp) structure, is less common. ε-martensite has been mainly studied in high manganese steels or in austenitic steels (>12 wt. %) [39][40][41][42][43][44][45][46], although it has also been observed in a low fraction in low-alloy steels [47]. Its nucleation occurs from randomly spaced overlapping γ stacking faults formed at grain boundaries [39] and, in many occasions, it is an intermediate phase during the α′-martensite, i.e., the martensitic transformation follows the sequence γ→ ε →α′ [48]. Whereas

However, the structure of martensite is not always the same. In many cases, two different types of martensite are detected: α′-martensite and ε-martensite. The former one is the most common type of martensite, with a bcc or bct structure and whose nucleation is associated with dislocation pile-ups on the active slip plane of γ [39]. On the other hand, ε-martensite, which has a hexagonal close-packed (hcp) structure, is less common. ε-martensite has been mainly studied in high manganese steels or in austenitic steels (>12 wt. %) [39,40,41,42,43,44,45,46], although it has also been observed in a low fraction in low-alloy steels [47]. Its nucleation occurs from randomly spaced overlapping γ stacking faults formed at grain boundaries [39] and, in many occasions, it is an intermediate phase during the α′-martensite, i.e., the martensitic transformation follows the sequence γ→ ε →α′ [48]. Whereas c is an example of a direct γ →α′ transformation observed while straining a 304 stainless steel at −32 °C, d is an example of a γ→ ε →α′ transformation in a 304L steel deformed at −196 °C, as in the micrograph one can see a α′ embryo on a band of ε. In multiphase structures, the transformation process is usually γ →α′, where the transformation γ→ ε is only sporadically reported [47].The appearance of the metastable phases named in this section as a product of SIT/DIT mainly depends on the chemical composition of the steel and on the deformation temperature. Hence, whereas the formation of stress or strain induced α′ is very common in many different microstructures [23][25][35][49][50][51][52][53][54][55][56], ε is mainly found in austenitic steels [23][25][39][48][52], although it has been sporadically detected in multiphase steels [47]. The formation of α

The appearance of the metastable phases named in this section as a product of SIT/DIT mainly depends on the chemical composition of the steel and on the deformation temperature. Hence, whereas the formation of stress or strain induced α′ is very common in many different microstructures [23,25,35,49,50,51,52,53,54,55,56], ε is mainly found in austenitic steels [23,25,39,48,52], although it has been sporadically detected in multiphase steels [47]. The formation of αB has not been reported, to the authors’ knowledge, at room temperature, although it has been found in fully austenitized steels [35] and in multiphase steels [1][3][57] deformed at high temperatures.

has not been reported, to the authors’ knowledge, at room temperature, although it has been found in fully austenitized steels [35] and in multiphase steels [1,3,57] deformed at high temperatures.3. Resultant Microstructures of Stress and Strain Induced Transformations and Their Strain Hardening Capacity

In this section, the characteristics of α′/ε/αB

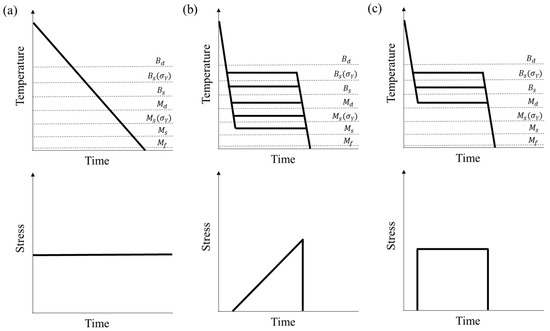

SIT and DIT are described. These transformations can be obtained by different routes that are detailed next. The most common scenarios are shown in . Note that the deformation temperatures could be reached in b,c by heating, instead of cooling, depending on the chemical composition of the steel and on whether an initial fully austenitic or multiphase microstructure is aimed. In those cases, the microstructure may need a previous austenitization or a previous heat-treatment, respectively. The characteristics of the SIT/DIT taking place during the mentioned treatments would only be expected to vary significantly depending on the initial structure and not on how the initial structure was obtained.

Figure 4.

a

b

c

3.1. Stress or Strain Induced Martensite Transformations

3.1.1. Continuous Cooling Treatments under Constant Stress

σ

Figure 4a. Usually, the initial structure is fully austenitic, either because the steel of study is austenitic or because it has been previously austenitized (high temperature deformation). In this case, if the cooling rate was high enough to avoid ferritic/pearlitic/bainitic transformations, a martensite transformation would happen [49][58][59]. The transformation would be athermal, it would start at a temperature

Ms(σ)

Ms if the deformation mode was uniaxial tension, uniaxial compression or torsion [49][58][59][60][61][62]. In addition, in cases in which the

Mα′f

σY) the increase in nucleation sites [49]. In cases in which no plastic deformation was introduced, the addition of the mechanical driving force would not only affect the start of the α′ transformation, but also the selection of specific crystallographic variants [63][64][65][66], especially during the first stages of the transformation [66]. The selected variants would have the highest total driving force in absolute value, as

ΔGmech is a function of the position of the habit plane [63][64][65]. Variant selection in α′ has also been reported in transformations on continuous cooling under stresses higher than the

σY by Liu et al. and it has been associated to the application of stress rather than to the introduction of dislocations [49]. This assumption would follow the same line of thought of Tamura, who suggested that the strain-induced transformations can be understood only in terms of the applied stress [50][67] or of Chatterjee and Bhadeshia, who reached the same conclusion later [68]. Regarding the martensite scale, Liu et al. reported that, the α′ microstructure obtained by applying 70 MPa to an austenitized medium carbon steel during continuous cooling was more refined than the stress-free α′ microstructure obtained by a continuous cooling. They attributed this refinement to the small applied plastic deformation (<5%), which led to the recrystallization of some prior austenite grains at high temperature and to a dislocation density increase in the non-recrystallized grains. The scale of the α′ strain-induced laths/plates has not been reported in any other study, to the authors’ knowledge.

3.1.2. Deformation at a Constant Temperature

Md

Figure 4b. When martensite is induced during straining in austenite structures, it is possible that the transformation process is γ→ ε, γ→ ε →α′, or γ →α′ [25], depending on the applied strain and the deformation temperature [25], where the formation of ε is always preceded by the formation of stacking faults [39]. In addition, the application of stress can also lead to the coalescence of α′ or ε, as previously reported [69][70][71][72].

Regarding variant selection, stress/strain induced α′ [23][50][51][52][73], and ε [23][48][52] present this phenomenon. Even when the transformation happens from a fully austenitic structure, there is no agreement about the reasons of the variant selection phenomenon. While some authors claim that variant selection in transformations from a fully austenitic structure may be explained by the mechanical driving force criterion [48][50][51][52], other authors suggest that some transformation sequences lead to local stress fields which make the analysis more complex [23]. The rules governing variant selection in TRIP transformations in multiphase structures—i.e., formation of stress or strain induced phases from retained austenite—have not been deeply studied. Yamashita et al. studied this phenomenon in a microstructure consisting of ferrite, bainitic ferrite, and retained austenite which was subjected to tensile tests. The retained austenite transformed to α′, always governed by variant selection, although the explanation for this variant selection was not always based on the mechanical driving force, but depended on the location of the retained austenite (at the ferrite grain boundaries or inside the ferrite matrix) [73]. The effect of other types of matrices on the selection of variants of α′ formed by TRIP effect in multiphase microstructures is still unclear.

σY

σcrit−SIT

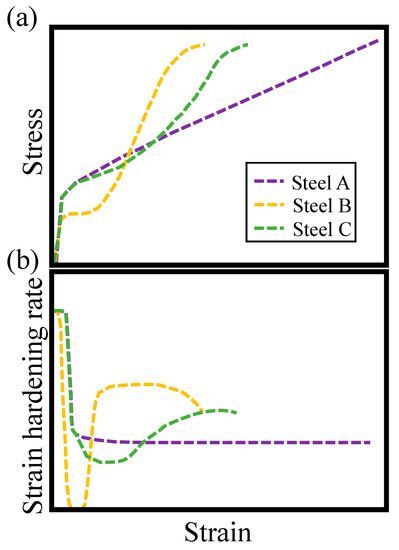

σcrit−DIT, a SIT/DIT starts and the stress–strain behavior is no longer as would expected. From this point onwards, the martensite fraction increases as the stress to which the austenite is subjected is higher [67][74][75], mainly as a function of the strain and not of the temperature [76], until it reaches a limit, see

Figure 5b. The first of them is called dynamic softening and it is a product of the transformation working as a competing deformation mechanism. It is associated with the fact that the SIT/DIT transformation strain contributes to the total strain, while the stress increases more slowly [77][78] and it usually predominates at low strain values [10]. In some cases, this phenomenon has also been associated to the formation of ε in the early stages [79], as this phase has been proved to be almost ideally plastic [80]. Dynamic softening is characterized by a rapid decrease of the strain hardening rate, as happens for steels B and C in

Figure 5b at low strain values. For higher strains, one can observe that the second effect, called static hardening, is predominant. Static hardening is characterized by a strong increase of the strain hardening rate due to the presence of martensite which acts as a reinforcing phase [77][78]. It has been previously reported that, during the static hardening effect, the martensite volume fraction can increase up to a given amount, called percolation threshold [81], and that, up to this point, the austenite stress level is similar to the macroscopic stress [82]. Once the martensite volume fraction is higher than the percolation threshold, the martensite forms a percolating cluster which extends through the whole structure [81]. In this stage, the strain hardening rate further increases until it reaches its maximum value and the austenite stress level deviates from the macroscopic stress level, suggesting that the material is acting as a composite [10][82]. Finally, once the volume fraction of martensite is close to the unity, the material behavior starts to resemble the martensite behavior and, hence, the strain hardening rate starts to decrease [82]. This final hardening has also been attributed to the activation of strain hardening mechanisms which involve a high dislocation density or a complex state of stress, among others [10]. Note that, although all the mentioned effects are predominant at different stages, it could be possible that some of them were not noticeable during the deformation process. These concepts can be extrapolated to the mechanical behavior of a multiphase structure if one understands that the initial microstructure has already a composite-like behavior [26], as would happen for an austenite structure in which α′ has formed by TRIP effect in a high fraction, i.e., after the percolation threshold has been overcome. However, in this case, the retained austenite may be more stable against deformation depending on several factors: (a) its chemical stability, which depends on its chemical composition [83]; (b) in the case that the matrix phase has formed by a displacive transformation, the stability of the retained austenite increases because of the hydrostatic stresses that the matrix exerts on this retained austenite, as reported in

B, the amount of dislocations introduced during the transformation in the retained austenite mechanically stabilize it [84].

Figure 5.

a

b

σY

Therefore, if one wants to control the mechanical properties of a microstructure which contains retained austenite or that is fully austenitic and that is expected to undergo TRIP effect, one must control several factors. First, as mentioned, the austenite stability is one of the most important factors controlling the mechanical properties of these structures. If the austenite stability is low, a SIT or DIT starts at very low strain values and the material yield strength and elongation are lower, although their ultimate tensile strength is high [23][24][85]. If the austenite is too stable, the TRIP effect may never occur, hence, its benefits cannot be exploited [85]. If the austenite stability is high enough, the ultimate tensile strength of the material is not so high, although its elongation is higher [24]. In addition, it has been reported that, in an austenitic steel with rather stable austenite, the formation of martensite—specially α′, rather than ε—during straining leads to higher uniform elongations [25] because of the suppression or delay of the necking phenomenon [86]. Previous studies have shown that the uniform elongation can be maximized if it is made sure that the induced transformation continues until the latter stage of deformation or the onset of necking [67][76][87] and that the transformation rate is slow, as the dislocations have time to be accommodated and the local stresses can be suppressed [23][76]. The combination of high strength and high ductility can be obtained at temperatures close to

Md at which the DIT starts for high strains, before the necking effect takes place, enabling its suppression [24]. A similar effect has been reported in multiphase microstructures [88][89][90].

Second, the strain rate can also affect the mechanical behavior, depending on whether the specimen is deformed under isothermal or under adiabatic conditions, on the product phase and on the deformation temperature. Generally, under isothermal conditions, an increase of the strain rate leads to an increase of the final fraction of stress or strain induced martensite [6][91]. However, if the strain rate is too high, there is a transition from isothermal to adiabatic material behavior, which makes the SFE increase [9][81][91][92] and the driving force for the transformation decrease (in absolute value) [93]. Therefore, using higher strain rates would decrease the volume fraction of stress/strain induced martensite as the strain rate is higher [9][93][94][95][96]. In multiphase microstructures, the effect of the strain rate follows similar trends [97][98][99].

3.2. Stress or Strain Induced Bainite Transformations

B

B transformation [30][31][32][33][34], provided that the stress is not very low (few MPa) [33], attributed to the increase of driving force (in absolute value). The kinetics of the transformation were also shown to be accelerated when plastic uniaxial deformation was applied during the isothermal holding [31][100][101][102][103] as a result of the increase in nucleation sites (defects) [31]. Regarding the α

B

σ

σY in a Fe-0.45C2.08Si-2.69Mn (wt %) steel [32]. If higher stresses are applied, the effect on the volume fraction of α

B

B or α′ transformation [104][105][106], theoretically, the addition of the mechanical driving force would shift the T

0

B

B decreased with respect to the one obtained by the standard treatment if the steel carbon content was above 0.86 wt %, while it increased with respect to the one obtained by the standard treatment for a steel with carbon content of 0.43 wt % [101]. The application of stress has also been shown to lead to transformation plasticity strains, i.e., anisotropic portion of the transformation strains: the changes in length due to the α

B transformation are not the same along all axes [32][33][34][107][108]. This transformation plasticity is due to variant selection effects driven by the same mechanisms that drive the α′ transformations during continuous cooling under constant stresses, i.e., variants which are preferentially promoted by the applied stress (those whose habit plane lies at about 45° with respect to the deformation direction) tend to form first and their fraction tends to be the highest [30][33][34][64][108][109][110]. Variant selection affects the microstructure, which becomes much more organized after transformation under stress, i.e., in each PAG, there are fewer sheaves which are bigger than the ones obtained by stress-free transformation. The reduction of sheaves affects the number of blocks of austenite that are present in the microstructure, i.e., microstructures show less blocky γ if they have been transformed under the effect of stress [110]. To the best knowledge of the authors, the effect of the stress on the thickness of the α

B has not been assessed, although it would be expected that microstructures are refined because of the increase of driving force [111][112][113],

σY

σY is overcome) [111][112][113], and transformation kinetics [114]. It has been reported, though, that applying stress while a specimen is isothermally treated promoted the coalescence of α

B plates [115]. Nevertheless, further research is needed.

B SIT/DIT happening while straining a fully austenitic structure is not very common, only reported in [35][36] to the authors’ knowledge. In multiphase structures, the α

B SIT/DIT at temperatures higher than room temperature have been reported in few studies [2][3][4][19][29], although their effect on the mechanical properties or the differences with respect to the SIT/DIT taking place in fully austenitic structures has not been discussed. Further research would be needed in order to know if the conclusions made with the α′ and ε transformations could be extrapolated to α

B

B after a plate/lath is fully grown, which is expected to increase the SFE [116][117] and the driving force for the transformation [114], inhibiting the SIT/DIT in a higher extent as the transformation progresses [118]; (c) bainitic ferrite may not be as hard as martensite because of their different carbon contents, hence, the α

B