EOs are secondary metabolites synthesized by plants. As many other secondary metabolites, they possess different bioactivities that have been employed for centuries by utilizing the whole plant or by the application of the EOs previously extracted.

- food waste

- packaging

- circular economy

1. Introduction

Traditionally, they have been used mostly for pharmacological, medicinal, aromatic or cosmetic purposes. However, from the 19th century, their application has been wider in the nutritional field [10][1]. Many different EOs have been characterized, even though the chemical profile depends on the species, the collection area and season or the extraction solvents and techniques. Their physical properties prompt their use in the food industry since they contain volatile aroma compounds, they are commonly liquid and colorless at room temperature, they are lipophilic and they can create emulsions with hydrophilic solvents. Further, they possess several bioactivities, such as antimicrobial, antifungal, antioxidant, antiviral, antiparasitic or insecticidal. Thus, these compounds have been used in the food industry as aroma and flavor ingredients, but also for preservative purposes [11–14][2][3][4][5]. The possibility of developing active packaging systems containing natural bioactive compounds such as EOs is a promising alternative since it can reduce food safety risks associated with chemically synthetized additives [1][6].

Currently, EOs application in active food packaging are strongly linked to their incorporation into biodegradable films in combination with another polysaccharide-protein- or lipid-based edible film [15][7]. Another recent approach is the development of composite films or multicomponent films to take advantage of their main beneficial properties [16][8].

Hence, the incorporation of EOs is increasingly common, because they can enhance antimicrobial and antioxidant activity, among others, or reduce water vapor permeability [17][9]. Particularly, when producing biofilms, hydrophilic matrices are usually used (for increasing water vapor permeability), formed by protein or polysaccharides polymers that serve as a base on which to incorporate other substances such as lipid components [18][10]. Ideally, for this purpose, the chosen materials should be of low viscosity, with high hygroscopicity and emulsifying capacity, low reactivity, low cost and with no effect on organoleptic properties of the processed food [19,20][11][12]. Specifically, lipophilic substances, such as EOs, incorporated into hydrophilic materials is performed by the application of emulsification or homogenization [21][13]. Thus, the association of EOs and biodegradable films is gaining more attention, especially by the active food packaging industry.

2. Application of Essential Oils in Food Preservation and Packaging Sector

Most of the permitted food additives are applied for their preservation properties, attributed to their recognized bioactivities. Additives with antimicrobial properties can control food spoilage and/or prevent contamination by foodborne pathogens, in-cluding acetic, malic, lactic, benzoic, sorbic and propionic acids, potassium and calci-um acetates, carbon dioxide, benzoates, sorbates, propionates, nitrites, nitrates or parabens. The most used additives that prevent food browning, caused by chemical or enzymatic reactions, are sulfites. Even though all these compounds are permitted to be used in the food industry, the current trend is replacing chemically synthesized com-pounds for natural ones. In this sense, the use of EOs is considered as an alternative to the use of synthetic additives [3,22][14].

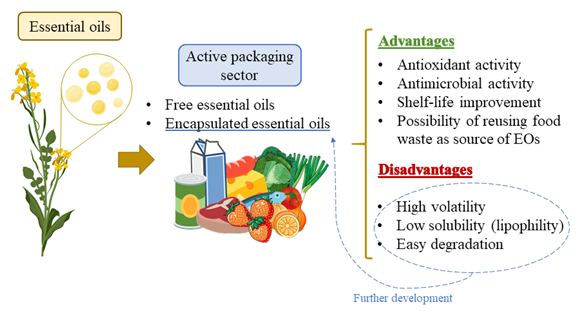

In active packaging, the packaging materials can incorporate components with biological properties destined to be slowly released into the food [3][15] (Figure 1). The use of EOs in appropriate amounts may improve the water vapor barrier property and also provide antioxidant and antimicrobial activity to the packaging films.

Figure 1. Essential oils (EOs) application strategies in the food active packaging sector: advantages and disadvantages.

2.1. Free EOs Combined with Packaging Materials

Free EOs have been combined with different biodegradable materials, such as paper or edible films. Cardboard and paper have been traditionally used as packaging material but new packaging systems such as active cardboard tray coated with emulsions including encapsulated EOs are continuously being developed. These are widely used as food and vegetables packaging material (with waterproof layers) and are considered as an alternative to the high use of plastics by the packaging sector [38,39][16][17]. However, due to the water vapor permeability of these materials, it is convenient and necessary to apply a layer of some material that makes them resistant to the presence of water, vapors and gases. EOs are an attractive alternative for the creation of such films, due to their waterproofing properties and biological activities, turning packaging into an active material and increasing its value. For example, eugenol (a common component of EOs) was linked to cellulose by polycarboxylic acid to create a paper-based active packaging. This new material was used to pack wheat flour and other grain foods and prevented water absorption similarly to typical packaging paper and preserved the mechanical properties of the grain products, although ductility and tensile strength were reduced. Besides, it significantly provided insecticide and insectifuge capacities, which extended the product shelf life without compromising its original flavor, taste and odor [40][18].

Regarding edible films, EOs are added into a hydrophilic matrix resulting in an aqueous dispersion. In this way, the lipid droplets become embedded in the matrix once the film is subjected to a drying process causing structural reorganizations of the hydrophilic components [41,42][19][20]. For instance, in a study performed on a chitosan-based film, as the formed dispersion loses water through drying, the concentration of lipid particles increases, which also increases the risk of emulsion phases separation, flocculation or loss of EOs. In particular, the stability of the film microstructure can be improved by application of microfluidization which entails a reduction of the droplet size and the viscosity of the aqueous phase, also resulting in an increase of the ζ-potential, which indicates that the emulsion can be stable against aggregation events [43][21]. Few studies have displayed the advantages of using EOs as an additional ingredient directly added to the edible films or biodegradable trays to enhance their packaging properties. Syzygium aromaticum EOs were incorporated into two kinds of edible films, one elaborated with gelatin and other with a mixture of gelatin and chitosan. Both materials containing the EOs showed significant anti-bacterial activity, especially against Gram-negative bacteria, when tested in chilled fish samples [44][22]. Another work used cassava bagasse and polyvinyl alcohol to create biodegradable trays containing EOs from Origanum vulgare or Eugenia caryophyllata (Syzygium aromaticum). The EOs were incorporated into the trays in two ways: directly, by adding them into the mixture of ingredients or by coating the surfaces with EOs. The best results were achieved when trays were coated with the highest amount of EOs, showing inhibitory effects against different bacterial and fungi species [45][23]. Other biodegradable films containing EOs have been tested in different food matrices such as fruits (i.e., strawberries), prolonging their shelf-life but also preventing or reducing the growth of bacterial colonies and acting as fungicides [46][24]. Additionally, the active biodegradable films containing encapsulated EOs showed no cytotoxicity while they permitted to maintain the sensorial properties of the food products during storage [47][25].

2.2. Encapsulation of EOs

Encapsulation is an affordable and ideal technique to protect EOs from limiting factors, including oxidative processes, photodegradation, thermal conditions or high relative humidity. Encapsulation also provides a controlled release of the EO from the capsule which can last up to 45 days [48]. Encapsulation also favors the incorporation of fats in the different matrices utilized for creating packaging materials, since it reduces the negative interactions between the lipid phase and the matrix, whose nature is normally hydrophilic. Therefore, the use of encapsulated lipophilic molecules prevents the alteration of the properties of the final structure of the packaged product [49][26]. In addition, this technique is useful to prevent changes in the organoleptic properties of the food product caused by EOs and other lipids [39,50][27].

Basically, capsules can be classified into three large groups according to their size: macrocapsules, microcapsules and nanocapsules. The latter present a diameter between 0.05 and 1 µm, although the most common average measure is between 0.1 and 0.5 µm [51][28]. The use of capsules with diameters in the nanoscale range is more convenient since the particle size is inversely proportional to the stability, that is, the smaller the diameter of the capsules, the greater the stability during incorporation into the matrices. Likewise, a better control of its availability and release is also achieved, favoring the creation of active packaging systems that prolong food shelf-life. Active packaging can be developed by the direct incorporation of the nanocapsules into the matrix of the packaging material or they can be emulsified in an aqueous base to make a waterproofing barrier to cover the package [22,52–54][29][30][31].

Several studies have assessed the suitability of EOs’ encapsulation and different encapsulation materials. For instance, rosemary EO was successfully encapsulated in a benzoic acid–chitosan nanogel that was lately included in the starch–carboxy methyl cellulose film [55][32]. Other study used zein to synthesize a film containing microencapsulated rose hip seed EOs and the protective properties of this material were evaluated in bananas and cumquats. Negative controls, in both kinds of fruit, showed discoloration and signs of rotting with storage time, but when packaged in zein-rose hip EO film, spoilage slowed down [56][33]. Lectin was employed to encapsulate different concentrations of Thymus zygis EO (0.25 to 0.5 g/g polymer) to optimize the EO retention. The best approach provides a 45–55% of EO retention which improved the antifungal activity of the film, its water barrier capacity, gloss and resistance [57][34]. Cyclodextrins, which have been extensively studied in recent years, have been used to encapsulate EOs. A work presented a successful solution for the encapsulation of EOs extracted from coriander by combining them with cyclodextrins. This mixture allowed the encapsulation of the coriander EO, which becomes further stabilized by their inclusion in dextrin-derived nanosponges. This final product permitted the development of a controlled release mechanism stable at high temperature. Thus, the encapsulation of the EO allowed extending the action time of the bioactivities associated to the major biocompounds present in coriander [58]. Another study analyzed the encapsulation efficiency of different concentrations of cinnamon EO (0.5 to 3 g) and β-cyclodextrin (1 to 3 g). Then, an electro spun nanofibrous film was developed using the electrospinning polyvinyl alcohol to which it was added β-cyclodextrin and cinnamon EO. When this film was tested with strawberries showed a prolonged shelf-life of the product while maintaining its sensorial properties during storage. The shelf-life of strawberries was similar to that achieved with common plastic film but the nanofibrous film presented two additional features: it was non-toxic and biodegradable [46][35]. EOs are a current field of study in the food packaging sector that could compete with the actual materials of food packaging for its enormous versatility and possibilities that need to be more explored.

Conserving the bioactivities of EOs presents a challenge that needs to be addressed. The concentration of EOs extracts needed to maintain their bioactivities in the food could alter the organoleptic characteristics of the food making it less attractive to the consumer. This makes the use of EOs at industrial scale difficult. Furthermore, the use of encapsulated EOs has shown some physical modifications such as plasticizing effect or tensile and color properties variations [3,59–61][36][37][38].

3. Current Trends on the Application of EOs in the Food Industry

Currently there is a growing interest in the production of active packaging using renewable and environmentally friendly materials [62][39]. Innovative active packaging has been shown to extend the shelf life of food products and reduce the growth rate of certain microorganisms. These improvements can be achieved through the formation of biocomposite systems based on natural biopolymers or synthetic materials.

Some articles have stated that edible packaging has gained popularity within consumers, since an edible film or coating, apart from prolonging the shelf-life of the food product, can also be consumed together with the food [26][40]. On the other hand, other studies have highlighted that few cases of films can be really eaten (whereas others can only be more easily degraded) and that consumers will only accept edible films if they feel them as safe [63][41]. These packaging systems can incorporate components intended to be immobilized at the film, released into food or able to absorb substances responsible for spoilage [64][42]. Among other things, packaging protects food from dehydration and acts as a gas barrier from the surrounding media. Edible films can serve as carriers of active compounds such as antimicrobials, antioxidants, texture enhancers or key nutrients, among others [65][43]. Furthermore, these properties can be enhanced by incorporating active substances to the films such as EOs.

EOs can be incorporated in food and beverage packaging systems (edible films) as an additional ingredient directly added to edible films or encapsulated into the edible films. For instance, different amounts of EOs from Origanum vulgare and Eugenia caryophyllata were incorporated into cassava bagasse–polyvinyl alcohol-based trays. EOs were incorporated into the trays in two ways, directly by adding them into the mixture of ingredients at proportions 6.5, 8.5 and 10.0% (w/w) or by coating the surface with EOs at concentrations 2.5, 5.0 and 7.5 g oil/100 g tray. The best results were achieved when trays were coated with the highest amounts of EOs, especially for O. vulgare that displayed total inhibition of molds, yeasts and few Gram-positive and negative bacteria, showing total inhibition or important reduction of the bacterial viability [45][23].

Hence, EOs exhibit antimicrobial and antioxidant characteristics while they are compatible with several types of food, contributing to the increase of food products shelf life or enhancing their organoleptic properties [10,43][1]. In the United States, several EOs that have already been used in food packaging have been recognized as safe ingredients and included in the Generally Recognized as Safe (GRAS) category established by the Food and Drug Administration (FDA) [17][9]. However, it must also be considered that they are chemically unstable and easily oxidized, being sensitive to light, oxygen and temperature changes. In this sense, nanoencapsulation techniques can be used to improve EOs chemical stability and enhance their physicochemical capabilities, thus allowing their use in food packaging [66]. For example, fish oil was encapsulated by emulsion electrospinning into polyvinyl alcohol nanofibers. The encapsulation efficiency for high omega-3 fatty acids (92.4 ± 2.3%) provided an oil load capacity of 11.3 ± 0.3% and thus, an even distribution of oil into the fibers and fortification of the food matrix with less amounts of PUFAs [67][44]. The type and amount of EOs incorporated into the packaging material will provide specific biological activity [68][45].

Some of the most commonly EOs used in packaging systems have been extracted from jasmine, rosemary, peppermint, cinnamon, oregano, thyme, cumin, eucalyptus, rosewood, clove, tea tree, palmarosa, geranium, lavender, lemongrass, mandarin, bergamot or lemon. With respect to the food matrixes on which packaging systems with EOs have been used, different food products such as fresh meat, butter, fresh octopus, ham and fish can be found [3][15]. Regarding their major identified components, they belong to the hydrocarbon monoterpenes, such as α-pinene, β-pinene, α-selinene and p-cymene, or to the oxygenated monoterpenes group, such as thymol, carvacrol, geraniol, borneol, eugenol, linalool, terpineol-4-ol, 1,8-cineole, α-terpinyl acetate and camphor [13–15,49][26]. Another study evaluated variable concentrations of some major hydrocarbon and oxygenated monoterpenes present in EOs. These compounds applied at a concentration of 0.2 µg/mL and a pH 4.0 showed antibacterial effect against E. coli and L. monocytogenes. This work underlined that oxygenated monoterpenes exerted more effective antimicrobial effect than hydrocarbon ones. In fact, the efficiency of these molecules was evaluated in orange or apple juice in combination with heat treatments and displayed synergistic lethal effect against E. coli. [14][46].

References

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods—A review. Int. J. Food Microbiol. 2004, 94, 223–253.

- Hyldgaard, M.; Mygind, T.; Meyer, R. Essential Oils in Food Preservation: Mode of Action, Synergies, and Interactions with Food Matrix Components. Front. Microbiol. 2012, 3, 12.

- Falleh, H.; Ben Jemaa, M.; Saada, M.; Ksouri, R. Essential oils: A promising eco-friendly food preservative. Food Chem. 2020, 330, 127268.

- Rota, M.C.; Herrera, A.; Martínez, R.M.; Sotomayor, J.A.; Jordán, M.J. Antimicrobial activity and chemical composition of Thymus vulgaris, Thymus zygis and Thymus hyemalis essential oils. Food Control 2008, 19, 681–687.

- Ait-Ouazzou, A.; Cherrat, L.; Espina, L.; Lorán, S.; Rota, C.; Pagán, R. The antimicrobial activity of hydrophobic essential oil constituents acting alone or in combined processes of food preservation. Innov. Food Sci. Emerg. Technol. 2011, 12, 320–329.

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential oils as additives in active food packaging. Food Chem. 2020, 343, 128403.

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Polysaccharides, Protein and Lipid-Based Natural Edible Films in Food Packaging: A Review. Carbohydr. Polym. 2020, 238, 116178.

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2018, 109, 1095–1107.

- Kouhi, M.; Prabhakaran, M.P.; Ramakrishna, S. Edible polymers: An insight into its application in food, biomedicine and cosmetics. Trends Food Sci. Technol. 2020, 103, 248–263.

- Atarés, L.; Chiralt, A. Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci. Technol. 2016, 48, 51–62.

- Blanco-Padilla, A.; Soto, K.M.; Hernández Iturriaga, M.; Mendoza, S. Food antimicrobials nanocarriers. Sci. World J. 2014, 2014, 1–11.

- Zhu, G.; Xiao, Z.; Zhou, R.; Yi, F. Fragrance and flavor microencapsulation technology. Adv. Mater. Res. 2012, 2, 440–445.

- Burgos, N.; Mellinas, A.C.; García-Serna, E.; Jiménez, A. Nanoencapsulation of Flavor and Aromas in Food Packaging; Elsevier Inc.: Philadelphia, PA, USA, 2017.

- Carocho, M.; Barreiro, M.F.; Morales, P.; Ferreira, I.C.F.R. Adding molecules to food, pros and cons: A review on synthetic and natural food additives. Compr. Rev. Food Sci. Food Saf. 2014, 13, 377–399.

- Ribeiro-Santos, R.; Andrade, M.; de Melo, N.R.; Sanches-Silva, A. Use of essential oils in active food packaging: Recent advances and future trends. Trends Food Sci. Technol. 2017, 61, 132–140.

- Robertson, T.R.; Hamza, M.F. Paper Products: Food Packages. Ref. Modul. Mater. Sci. Mater. Eng. 2016.

- Buendía-Moreno, L.; Soto-Jover, S.; Ros-Chumillas, M.; Antolinos, V.; Navarro-Segura, L.; Sánchez-Martínez, M.J.; Martínez-Hernández, G.B.; López-Gómez, A. Innovative cardboard active packaging with a coating including encapsulated essential oils to extend cherry tomato shelf life. LWT 2019, 116, 108584.

- Muratore, F.; Barbosa, S.E.; Martini, R.E. Development of bioactive paper packaging for grain-based food products. Food Packag. Shelf Life 2019, 20, 100317.

- Sánchez-González, L.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Physical properties of edible chitosan films containing bergamot essential oil and their inhibitory action on Penicillium italicum. Carbohydr. Polym. 2010, 82, 277–283.

- Sánchez-González, L.; Chiralt, A.; González-Martínez, C.; Cháfer, M. Effect of essential oils on properties of film forming emulsions and films based on hydroxypropylmethylcellulose and chitosan. J. Food Eng. 2011, 105, 246–253.

- Bonilla, J.; Atarés, L.; Vargas, M.; Chiralt, A. Effect of essential oils and homogenization conditions on properties of chitosan-based films. Food Hydrocoll. 2012, 26, 9–16.

- Gómez-Estaca, J.; de Lacey López, A.; López-Caballero, M.E.; Gómez-Guillén, M.C.; Montero, P. Biodegradable gelatin–chitosan films incorporated with essential oils as antimicrobial agents for fish preservation. Food Microbiol. 2010, 27, 889–896.

- Debiagi, F.; Kobayashi, R.K.T.; Nakazato, G.; Panagio, L.A.; Mali, S. Biodegradable active packaging based on cassava bagasse, polyvinyl alcohol and essential oils. Ind. Crops Prod. 2014, 52, 664–670.

- Wen, P.; Zhu, D.-H.; Wu, H.; Zong, M.-H.; Jing, Y.-R.; Han, S.-Y. Encapsulation of cinnamon essential oil in electrospun nanofibrous film for active food packaging. Food Control 2016, 59, 366–376.

- Zhou, Y.; Miao, X.; Lan, X.; Luo, J.; Luo, T.; Zhong, Z.; Gao, X.; Mafang, Z.; Ji, J.; Wang, H.; et al. Angelica Essential Oil Loaded Electrospun Gelatin Nanofibers for Active Food Packaging Application. Polymers 2020, 12, 299.

- Joven, R.; Garcia, A.; Arias, A.; Medina, J. Development of an active thermoplastic film with oxygen scavengers made of activated carbon and sodium erythorbate. Packag. Technol. Sci. 2015, 28, 113–121.

- Ribeiro-Santos, R.; Andrade, M.; Sanches-Silva, A. Application of encapsulated essential oils as antimicrobial agents in food packaging. Curr. Opin. Food Sci. 2017, 14, 78–84.

- Pathak, C.; Vaidya, F.U.; Pandey, S.M. Mechanism for Development of Nanobased Drug Delivery System. In Applications of Targeted Nano Drugs and Delivery Systems; Elsevier: Amsterdam, The Netherlands, 2019; pp. 35–67.

- Mohammadi, A.; Jafari, S.M.; Esfanjani, A.F.; Akhavan, S. Application of nano-encapsulated olive leaf extract in controlling the oxidative stability of soybean oil. Food Chem. 2016, 190, 513–519.

- Peng, X.Q.; Wei, M.J.; Wang, L.; Gu, L.P. Study on microcrystalline chitin cinnamon nanoemulsion. Appl. Mech. Mater. 2014, 525, 53–57.

- Severino, R.; Ferrari, G.; Vu, K.D.; Donsì, F.; Salmieri, S.; Lacroix, M. Antimicrobial effects of modified chitosan based coating containing nanoemulsion of essential oils, modified atmosphere packaging and gamma irradiation against Escherichia coli O157:H7 and Salmonella Typhimurium on green beans. Food Control 2015, 50, 215–222.

- Mohsenabadi, N.; Rajaei, A.; Tabatabaei, M.; Mohsenifar, A. Physical and antimicrobial properties of starch-carboxy methyl cellulose film containing rosemary essential oils encapsulated in chitosan nanogel. Int. J. Biol. Macromol. 2018, 112, 148–155.

- Yao, Z.-C.; Chang, M.-W.; Ahmad, Z.; Li, J.-S. Encapsulation of rose hip seed oil into fibrous zein films for ambient and on demand food preservation via coaxial electrospinning. J. Food Eng. 2016, 191, 115–123.

- Sapper, M.; Wilcaso, P.; Santamarina, M.P.; Roselló, J.; Chiralt, A. Antifungal and functional properties of starch-gellan films containing thyme (Thymus zygis) essential oil. Food Control 2018, 92, 505–515.

- Wen, P.; Zhu, D.-H.; Wu, H.; Zong, M.-H.; Jing, Y.-R.; Han, S.-Y. Encapsulation of cinnamon essential oil in electrospun nanofibrous film for active food packaging. Food Control 2016, 59, 366–376.

- Zinoviadou, K.G.; Koutsoumanis, K.P.; Biliaderis, C.G. Physico-chemical properties of whey protein isolate films containing oregano oil and their antimicrobial action against spoilage flora of fresh beef. Meat Sci. 2009, 82, 338–345.

- Negi, P.S. Plant extracts for the control of bacterial growth: Efficacy, stability and safety issues for food application. Int. J. Food Microbiol. 2012, 156, 7–17.

- Goñi, P.; López, P.; Sánchez, C.; Gómez-Lus, R.; Becerril, R.; Nerín, C. Antimicrobial activity in the vapour phase of a combination of cinnamon and clove essential oils. Food Chem. 2009, 116, 982–989.

- Coelho, P.M.; Corona, B.; ten Klooster, R.; Worrell, E. Sustainability of reusable packaging—Current situation and trends. Resour. Conserv. Recycl. X 2020, 6, 100037.

- Jugreet, B.S.; Suroowan, S.; Rengasamy, R.R.K.; Mahomoodally, M.F. Chemistry, bioactivities, mode of action and industrial applications of essential oils. Trends Food Sci. Technol. 2020, 101, 89–105.

- Jeya Jeevahan, J.; Chandrasekaran, M.; Venkatesan, S.P.; Sriram, V.; Britto Joseph, G.; Mageshwaran, G.; Durairaj, R.B. Scaling up difficulties and commercial aspects of edible films for food packaging: A review. Trends Food Sci. Technol. 2020, 100, 210–222.

- European Commission. Regulation (EC) No 450/2009 of 29 May 2009 on active and intelligent materials and articles intended to come into contact with food. Off. J. Eur. Commun. 2009, 135, 3–11.

- Acevedo-Fani, A.; Salvia-Trujillo, L.; Rojas-Graü, M.A.; Martín-Belloso, O. Edible films from essential-oil-loaded nanoemulsions: Physicochemical characterization and antimicrobial properties. Food Hydrocoll. 2015, 47, 168–177.

- García-Moreno, P.J.; Stephansen, K.; van der Kruijs, J.; Guadix, A.; Guadix, E.M.; Chronakis, I.S.; Jacobsen, C. Encapsulation of fish oil in nanofibers by emulsion electrospinning: Physical characterization and oxidative stability. J. Food Eng. 2016, 183, 39–49.

- Adel, A.M.; Ibrahim, A.A.; El-Shafei, A.M.; Al-Shemy, M.T. Inclusion complex of clove oil with chitosan/β-cyclodextrin citrate/oxidized nanocellulose biocomposite for active food packaging. Food Packag. Shelf Life 2019, 20, 100307.

- Ait-Ouazzou, A.; Cherrat, L.; Espina, L.; Lorán, S.; Rota, C.; Pagán, R. The antimicrobial activity of hydrophobic essential oil constituents acting alone or in combined processes of food preservation. Innov. Food Sci. Emerg. Technol. 2011, 12, 320–329.