Twinning-induced plasticity (TWIP) steel is a second-generation advanced high strength steel grade developed for automotive applications. TWIP steels exhibit an excellent combination of strength and ductility, mainly originating from the activation of deformation twinning.

- TWIP

- yield strength

- strengthening mechanism

1. Introduction

High Mn twinning-induced plasticity (TWIP) steel is a second-generation advanced high strength steel grade developed for automotive applications. TWIP steels are characterized by high Mn content ranging from 12 to 30 wt.%, and their main alloying elements besides Mn include C, Al, Si, etc. TWIP steels exhibit an excellent combination of strength and ductility due to the superior strain hardening behavior originating from the activation of deformation twinning [1][2]. The use of TWIP steels can result in a considerable weight reduction of steel components and a reduction of material use [3]. Further, the high energy-absorption capacity of TWIP steels is suitable for applications of crash relevant components in automobiles. However, TWIP steels generally have a relatively low yield strength (YS), which limits their practical applications. For example, the crash performance of TWIP steels can be outperformed by dual phase (DP) steels of the equal ultimate tensile strength (UTS) due to higher YS of the latter [4]. Considerable research has been conducted to tackle the issue of low YS of TWIP steels [5][6][7].

High Mn twinning-induced plasticity (TWIP) steel is a second-generation advanced high strength steel grade developed for automotive applications. TWIP steels are characterized by high Mn content ranging from 12 to 30 wt.%, and their main alloying elements besides Mn include C, Al, Si, etc. TWIP steels exhibit an excellent combination of strength and ductility due to the superior strain hardening behavior originating from the activation of deformation twinning [1,2]. The use of TWIP steels can result in a considerable weight reduction of steel components and a reduction of material use [3]. Further, the high energy-absorption capacity of TWIP steels is suitable for applications of crash relevant components in automobiles. However, TWIP steels generally have a relatively low yield strength (YS), which limits their practical applications. For example, the crash performance of TWIP steels can be outperformed by dual phase (DP) steels of the equal ultimate tensile strength (UTS) due to higher YS of the latter [4]. Considerable research has been conducted to tackle the issue of low YS of TWIP steels [5,6,7].

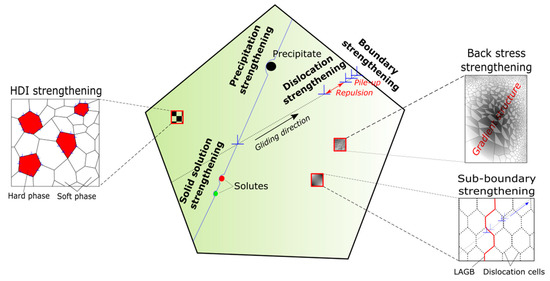

Classical strengthening mechanisms of metals include grain boundary strengthening [8], precipitation strengthening [9], solid solution strengthening [10], and work hardening [11]. Materials with high strength generally show ductility loss [12]. Various processing methods have been proposed to overcome the strength-ductility trade-off, which can be mainly divided into two directions: (1) Control of the thermomechanical processing [13][14][15]; (2) Application of novel processing methods to activate multiple strengthening effects [7][16][17].

Classical strengthening mechanisms of metals include grain boundary strengthening [8], precipitation strengthening [9], solid solution strengthening [10], and work hardening [11]. Materials with high strength generally show ductility loss [12]. Various processing methods have been proposed to overcome the strength-ductility trade-off, which can be mainly divided into two directions: (1) Control of the thermomechanical processing [13,14,15]; (2) Application of novel processing methods to activate multiple strengthening effects [7,16,17].

The present work summarizes representative research works on the improvement of YS in TWIP steels by activation of multiple strengthening mechanisms as illustrated in

. With regards to novel processing methods, TWIP steels with high YS without losing ductility have been reported. For instance, dislocation cell structure [16], multi-phase structure [17], and gradient structure [

] lead to the effective strengthening of TWIP steels without significant loss of ductility.

Figure 1. Classical and novel strengthening mechanisms operative in TWIP steels. (LAGB: Low angle grain boundary, HDI: Hetero deformation induced).

2. Novel Processes to Improve the Yield Strength

This section will focus on novel processes to improve the YS without ductility degradation in TWIP steels. Hamada et al. [16] developed a TWIP steel with a dense dislocation cell structure by using cyclic pre-straining, which showed a superior strength-ductility combination (YS of ~1 GPa, TE of ~50%). The dislocation cell structures are reported to play a unique role in strengthening mechanisms, which can act as stable and penetrable barriers to glide of dislocations and result in an increase in both YS and ductility [18][19].

ε

-martensite could be simply achieved by a combination of cold rolling and annealing of the low SFE TWIP/TRIP steels since the low-SFE alloys exhibit an intrinsic shape memory effect of reversible γ and ε-martensite [20][21]. The Fe-Mn alloys which have a dual-phase microstructure consisting of γ and ε-martensite generally show good ductility due to the activation of intrinsic deformation mechanisms of ε martensite such as <c>-component dislocations [22]. Li et al. [17]developed a multi-phase hetero-structured Fe-18Mn-0.4C-3Cr-6Si-0.1Ni-1.6Mo-0.2Cu TWIP/TRIP steel with the microstructure consisting of fine and coarse austenitic grains with a few fine ferritic grains, which showed a YS of 1.2 GPa with a TE of 30%. Such a high YS was originated from the combination of the hard phase and hetero-structured matrix, leading to the hetero-deformation induced strengthening. TRIP and TWIP effect activated during deformation could contribute to the strain hardening of the material.

Gradient microstructures could be utilized to enhance the balance between strength and ductility of TWIP steels. Conventionally, the gradient structure provides an extra strain hardening by the geometrically necessary dislocations caused by strain gradient [15][23][24]. Kalsar et al. [7] reported that the gradient structure in Fe-10Mn-0.5C-3Ni TWIP steel generated by surface mechanical attrition treatment (SMAT) could increase the YS from 400 MPa for the annealed starting material to 550MPa with maintaining an excellent ductility (TE of ~52%). Kim et al. [25] reported a gradient structured Fe-15Mn-0.6C-1.2Al TWIP steel processed by ultrasonic nanocrystalline surface modification. The material showed an excellent strength-ductility combination (YS of ~800 MPa, TE of ~50%) due to the grain refinement and additional back-stress hardening.

Severe plastic deformation was also utilized to increase the YS of TWIP steels. The combination of severe plastic deformation using equal-channel angular pressing (ECAP, at 300 ℃) and recovery annealing was introduced by Haase et al. [26]. The material showed an ultrahigh YS of 1077 MPa and TE of 12.3%. The ultrahigh YS was originated from the nanocrystalline grains (<100 nm) and remained deformation twins generated during the ECAP process. In addition, the decrease of dislocation density upon recovery annealing slightly recovered strain hardening and ductility. Wang et al. [27] also reported for Fe-20Mn-0.5C-1.2Si-1.7Al TWIP steel that the combination of ECAP and annealing at 300 °C could result in excellent mechanical properties with YS of 1150 MPa and TE of 19%.

) and recovery annealing was introduced by Haase et al. [62]. The material showed an ultrahigh YS of 1077 MPa and TE of 12.3%. The ultrahigh YS was originated from the nanocrystalline grains (<100 nm) and remained deformation twins generated during the ECAP process. In addition, the decrease of dislocation density upon recovery annealing slightly recovered strain hardening and ductility. Wang et al. [63] also reported for Fe-20Mn-0.5C-1.2Si-1.7Al TWIP steel that the combination of ECAP and annealing at 300 °C could result in excellent mechanical properties with YS of 1150 MPa and TE of 19%.