Flexible electronics is a rapidly growing technology for a multitude of applications. Wearables and flexible displays are some application examples.

- flexible electronics

- flexible substrates

- applications of flexible electronics

1. Introduction

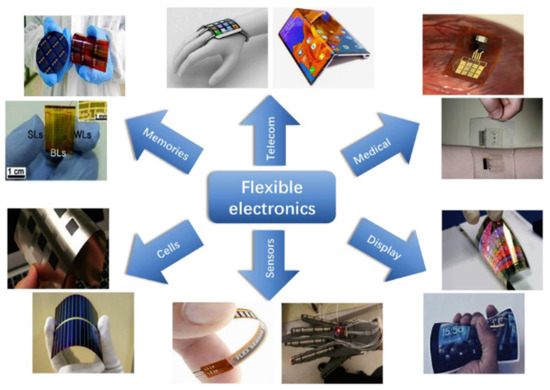

The market for flexible electronics is growing steadily [1][2][3][1,2,3]. Reasons for the growing numbers of flexible electronics used include mechanical flexibility, high scalability, low weight, and, last but not least, large-area production compatibility [4][5][6][4,5,6]. Because of these advantages, flexible electronics find more applications and use in the industry in many sectors [6]. It is estimated that the global market for flexible electronics will be around 87.21 billion USD in 2024. In the Asia Pacific region alone, the market is expected to grow from about 5 billion USD in 2013 to 30 billion USD in 2024 [7]. Furthermore, according to a study by IDTechEx, the global demand for flexible hybrid electronics will reach a value of over $3 billion in 2030 [8]. Applications of flexible electronics include consumer electronics [9][10][9,10], industry technology [11][12][13][14][11,12,13,14], healthcare [15][16][17][15,16,17], automotive technology [4][18][4,18], and aerospace technology [18][19] [18,19] (Figure 1). These sectors drive the growth of the market for flexible electronics. Related to flexible electronics, there is also a trend to foldable and stretchable electronic systems, which can be used in applications such as wearable and implantable electronics in healthcare, displays in consumer electronics, and robotic skin in industry applications [20].

Established semiconductor technologies can be integrated into flexible electronics, so that this combination has the ability to be bendable, deformed into irregular shapes, or even stretched [15][21][15,21]. Flexible electronics consist of electronic components, such as surface-mounted devices (SMDs) or ultra-thin chips on flexible substrates [22][23][22,23]. The electronic components are not flexible by nature but are as thin as possible to provide flexibility as a complete system when integrating onto or in flexible substrates [23][24][23,24]. Bending strain is one of the main movements inducing cracks and leading to the malfunction of flexible structures [20]. The mechanical reliability of these flexible electronics is very important to ensure the growing market demand for those systems. Furthermore, the robustness of the components and their integration should be optimized [25][26][25,26]. Ultra-thin chips are very common in flexible electronics and therefore need to be strong enough to withstand the tension that occurs during production and handling [12]. The integration of these ultra-thin and bendable integrated circuits in roll-to-roll processes enables the development of cheap, mechanically flexible electronics. To make these systems reliable, detailed investigations of both the strength and the deformation of the layers of thin components have to be performed. Once these properties are known, individual technology steps can be characterized and optimized in the best possible way [27].

Flexible electronics must be able to deform and at the same time, both the functional properties and the electronic parameters must remain unaffected by bending during application [19]. Moreover, with growing demands on the reliability of flexible systems, the need for characterization of the mechanical stability of the components also increases. [28]. Therefore, the testing of their reliability under mechanical bending is essential [29][30][29,30]. The goals of the bending test are to understand the behavior of flexible systems under bending and their fatigue stability.

The failures associated with bending strongly influence the reliability of the components. This failure is mainly caused by the forces generated due to bending or vibration of the circuit carriers [31].

2. Substrates for Flexible Electronics

Flexible systems require mechanically compliant substrates that adapt to soft and irregularly shaped surfaces. Furthermore, large area compatibility, chemical stability, process-compatible melting and glass transition temperatures, outgassing rates as well as low surface roughness are very desirable properties for flexible systems [19][32][19,32]. Table 1 gives an overview of the most used substrates in flexible electronics and some useful properties.

Table 1. Overview of the most used plastic substrates for flexible electronics and some of their properties.

| Material | Polyethylene Naphthalate (PEN) |

Polyethylene Terephthalate (PET) |

Liquid-Crystal Polymer (LCP) |

Polydimethyl-Siloxane (PDMS) | Polyimide (PI) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Density (g/cm | 3 | ) | 1.39 | 1.39 [33] | 1.41 | 1.41 [33] | 1.38–1.95 | 1.38–1.95 [34] | 0.95–1.08 | 0.95–1.08 [34] | 1.06–1.45 | 1.06–1.45 [34] |

| Young’s modulus (MPa) | 2000 | 2000 [33] | 1700 | 1700 [33] | 5000–20,000 | 5000–20,000 [34] | 0.36–0.87 | 0.36–0.87 [34] | 1800–15,000 | 1800–15,000 [34] | ||

| Poisson ratio | 0.3–0.4 | 0.3–0.4 [2] | 0.3–0.4 | 0.3–0.4 [2] | 0.4 | 0.4 [35] | 0.5 | 0.5 [2] | 0.34 | 0.34 [2,36,37] | ||

| Glass transmission temperature (°C) | 116–120 | 116–120 [33] | 68–114 | 68–114 [33] | 82–280 | 82–280 [34] | −125 | −125 [34] | 290–430 | 290–430 [34] | ||

| Coefficient of thermal expansion (CTE) at 20 °C (ppm/K) | 10–14 | 10–14 [2] | 40–50 | 40–50 [2] | 4–38 | 4–38 [34] | 180–450 | 180–450 [34] | 3–50 | 3–50 [34,36] | ||

| Moisture absorption (%) | 0.3 | 0.3 [38] | 0.4 | 0.4 [38] | 0.02–0.04 | 0.02–0.04 [34] | 0.1–1.3 | 0.1–1.3 [34] | 2–4 | 2–4 [34] | ||

| Challenges | Lower thermal stability | Lower thermal stability [26] | Lower thermal stability | Lower thermal stability [26] | Lack of self-adhesion to metal | Lack of self-adhesion to metal [12,34] | High gas permeability | High gas permeability [34,39] | High moisture-uptake, short of rigidity | High moisture-uptake, short of rigidity [34,40] |

3. Application of Flexible Electronics

3.1. Wearables and E-Textiles

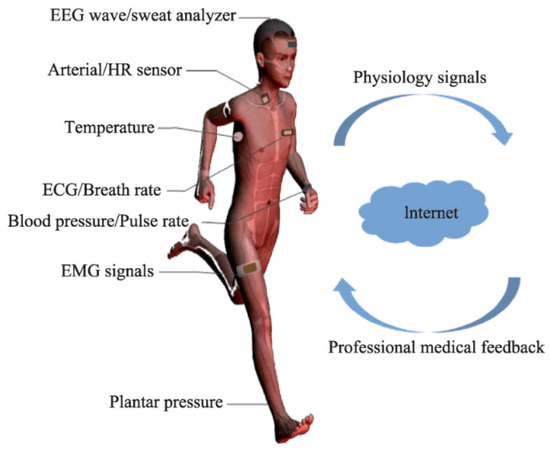

Flexible electronics are increasingly used in wearables and smart medical applications. Medical resources are reaching their limits when it comes to providing for our ageing society. Traditional medical methods cannot meet the needs of patients in time. Flexible and portable health monitoring, on the other hand, offers a completely new technology and alternative to traditional diagnostic methods. At the same time, health care will be portable and timely [41]. Figure 2 illustrates some physiological signals, which can be measured using wearable flexible sensors and then remotely evaluated.

Figure 2. Monitoring of some physiological signals using flexible sensors and diagnosis and evaluation per remote medicine. Adapted from [41]. The abbreviations EEG, HR, ECG, and EMG stand for electroencephalogram, heart rate, electrocardiogram, and electromyogram, respectively.

Someya et al. [9] [9] developed an electronic artificial skin based on large-area flexible pressure sensors with field-effect transistors built on a flexible substrate. Lumelsky et al. [42] [42] worked on a large-area, flexible array of sensors, consisting of LEDs and detectors, which can cover the entire surface of the human body or a machine and has the ability to detect many signals such as pressure, temperature, or even touch. Similar to Lumelsky, Manssfeld et al. [43] [43] published a paper on an electronic system using large arrays of capacitive pressure sensors with excellent sensitivity and very short response times on a flexible and stretchable polydimethylsiloxane (PDMS) substrate.

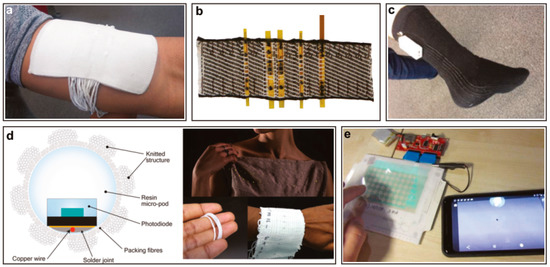

Compared to polymer foils, textile structures have additional potential for being stretched and deformed, while also allowing for a degree of breathability. For this reason, they can adapt well to the shape of the body. By integrating flexible sensors in textiles, namely, e-textiles, numerous applications can be realized, especially in the healthcare sector [32]. A market study by IDTechEx has predicted that the market for e-textiles will be worth over $1.4 billion by 2030 [44].

Figure 3 shows some examples of integrated flexible sensors in textiles and yarns. With the help of these sensors, vital parameters of the human body can be measured and further evaluated remotely.

Figure 3. Examples for smart textiles and their applications [32]. (a) Temperature sensing yarns in a textile for health monitoring [45]. (b) Optoelectronic near-infrared spectroscopy smart textile for measuring the blood oxygenation levels in health care [46]. (c) A temperature-sensing sock for fitness and health care [47]. (d) Embedded photodiodes in textile for health-monitoring [48]. (e) Tactile-sensing fabric for applications in human-machine interfaces (HMIs), smartphones, and Internet of Things (IoT) devices [49].

An et al. [50] [50] reported on the fabrication and characterization of a transparent and flexible fingerprint sensor array with multiplexed detection of tactile pressure and skin temperature for mobile devices and smartwatches. The sensor is built based on a silver nanofiber and fine silver nanowires (AgNWs) on a flexible polyimide substrate [50].

3.2. Flexible Displays

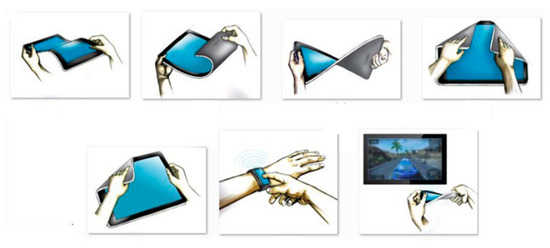

Optimization of organic light-emitting diodes (OLEDs) leads towards mechanical flexible displays when integrated on plastics. This is possible due to the unique properties of OLEDs, including their ultra-thin and simple structure and low-temperature manufacturing process [51]. Forrest [52] [52] reviewed the organic semiconductors used to fabricate flexible displays. Moreover, he covered the technologies for the deposition of polymer thin films. To reduce costs in the production of large-area flexible displays, Gelinck et al. [53] [53] demonstrated the use of organic transistors on flexible substrates for the development of flexible active-matrix monochrome electrophoretic displays. Figure 4 demonstrates the possible handling of flexible displays.

Im et al. [55] [55] reported on a process chain for fabricating a mechanically flexible OLED on flexible plastic substrate. A high performance conductive film with an embedded transparent conductive electrode of copper nanowires was used [55]. An attractive application for flexible displays is their integration into clothing and textiles. Ivanov et al. [56] [56] have investigated the use of light-emitting diodes (LEDs) and printed electroluminescent elements to fabricate flexible displays for integration into textiles. Huang et al. [57] [57] also reported on the integration of flexible displays into textiles.

3.3. Diagnostics and Healthcare

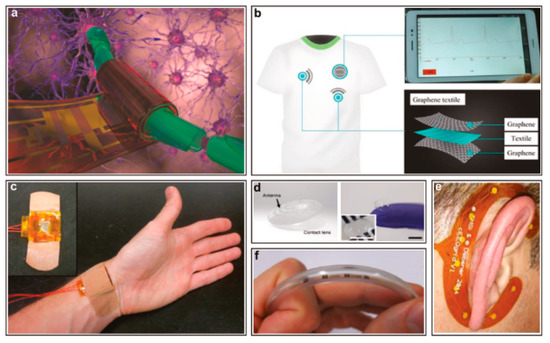

Flexible electronics gain more interest in medical sectors because they offer more comfort, while being in contact with patients [58]. In the early 2000s, Nathan et al. [59] [59] already reported on the use of large-area flexible electronics for large area X-ray imaging. They produced thin-film electronics on flexible polymer substrates. Both Jin et al. [60] [60] and Ko et al. [61] [61] published papers on the fabrication of electronic eye cameras on flexible polymer substrates. Figure 5 shows some applications for flexible electronics in the healthcare sector.

Figure 5. Applications for bio-monitoring, diagnosis, and hazards prevention [9]. (a) Flexible electronics for regenerative neuronal cuff implants [62]. (b) Flexible graphene wearable electrodes for dynamic ECG sensing [63]. (c) Flexible polymer transistors for application in electronic skin and health monitoring [64]. (d) Contact lens with ocular diagnostics of detecting the glucose levels in tears in diabetes patients [65]. (e) Ambulatory and wearable EEG sensor around the ear [66]. (f) Electronic nose on a flexible substrate for detecting hazardous gases [67].

An interesting approach for health monitoring and, for example, the realization of an e-skin, is the fabrication of active-matrix pressure sensors. These consist of integrated arrays of graphene transistors and can measure pressure up to higher-pressure ranges up to 3 MPa [68]. Other new research in medicine and electronics is the use of virtual reality (VR). Li et al. [41] [41] provided an overview of the use of flexible sensors for health monitoring in virtual reality. This trend in the use of flexible sensors is revolutionizing medicine and especially telemedicine. Flexible sensors can be applied to the skin, enabling personalized medicine by collecting important parameter data from the human body, and capturing meaningful changes in health status [69]. Gao et al. [69], Khan et al. [70], and Wang et al. [71] [71] reviewed the current researches and applications of flexible sensors to measure the vital signs of the human body.