Ballasted railway tracks constitute the major transportation grids in many countries across the globe; they convey commuters, as well as freight and bulk cargoes, between cities, mines, farmlands, and ports . The railtrack structure can be categorised into two groups: the substructure and the superstructure. The substructure comprises the subgrade, the sub-ballast, and the ballast, while the superstructure encompasses the sleepers (timber or concrete), the fastening mechanism, and the steel rails.

- railway

- ballast

- fouling

- degradation

- ballast breakage

1. Introduction

Ballast materials form a layer which encases the sleepers to provide both vertical and transversal stability to rail tracks. In the classical (conventional) design of railway tracks, the ballast is often considered as a flexible medium to simplify behavioural simulations during track analysis; as such, its continuous deterioration and accompanying plastic deformation are often disregarded. These issues result from the inadequate understanding of the complicacy of ballast particle rupture and other fouling mechanisms, as well as the lack of a properly definitive model. These have been consequential in the adoption of basic empirical methods in the planning and assemblage of railway track substructures, which often further require repetitive remedial operations and cost-intensive maintenance. The points at which the ballast particles interact with each other are the locations where load transfer occurs between adjacent particles. These tiny positions of contact continually and considerably deform with loading cycles while providing the requisite magnitude of resilience [5,6][1][2]. The high recurring loads concentrated on micro contact areas result in the wearing effect at contact points and, subsequently, fragmentation of the materials, with applied pressures exceeding the material’s bearing capacity [7][3]. The most commonly utilised materials for railway ballasts are described in Table 1.

Table 1. Description of commonly utilised ballast bed materials [8,9][4][5].

|

Material |

Geology |

Gradation |

Remarks |

|

Crushed stone |

Sedimentary rocks: basalt, porphyry, gneiss, granite, sandstone, limestone, etc. |

30–60 mm for main lines, 20–40 mm for switch and crossings |

Highly favourable in terms of strength and toughness; however, can be susceptible to weathering and fouling. Basalt offers higher resistance to fragmentation compared to limestone |

|

Gravel |

Collected from rivers |

20–50 mm |

Usually hard, but possesses rounded particles offering less internal friction |

|

Crushed gravel |

Obtained by crushing larger masses of gravel |

20–40 mm |

Offers greater shearing resistance compared to normal gravel |

|

Moorum |

Decomposed lateritic rocks |

– |

Requires the presence of laterite stones; can be used as underlying layers for ballast |

2. Ballast Contamination (Fouling)

A major reason for railway track maintenance is the accrual of contaminants in the voids between ballast aggregates. The deterioration of large ballast materials under loading further leads to the formation of fouling materials (particles ≤1.2 cm) [19][6]. Fouling influences the performance of tracks by altering the strength characteristics of substructure components via reduced durability, mud-hole formations, reduced permeability (drainage), reduced vertical, transverse, and longitudinal stability, and increased permanent deformation rates [22–27][7][8][9][10][11][12]. Railway maintenance frequency is linked to ballast quality, which constantly varies as a result of the intrusion and generation of fouling materials [1,7,19][6].

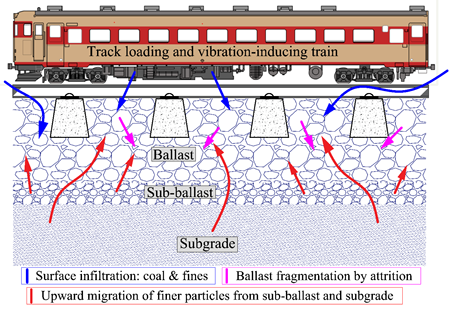

As reported in past studies, ballast fouling may occur as a result of one or the combination of five different mechanisms which include fragmentation of ballast (76%), migration of underlying sub-ballast materials (13%), surface infiltration of weathered particles and coal droplets (7%), upward migration of fines from subgrade formations (3%), and sleeper wearing (1%) [19,28,29][13][14]. Ballast fragmentation accounts for a significant fraction of commonly recorded contaminations, especially in the United States (US), and it has also been observed to be the most critical to track stability [19,30–32][15][16][17]. On the contrary, in the United Kingdom (UK), the main source of fouling observed is surface weathering [33][18]. As such, railway researchers have, over the decades, concluded that fouling significantly alters railway track deformational performance. [19,28][13]. However, Sussman et al. [5][1] argued that, except under high saturation levels, the high plasticity of clays causes it to stick and, as such, prevents the material from pumping into higher ballast layers. Rather, ballast materials often settle into the subgrade, thereby resulting in fouling [5][1]. Figure 1 illustrates the mechanisms of ballast fouling.

Figure 1. Ballast fouling mechanisms.

3. Ballast Degradation and Durability

Ballast durability is, in many cases, influenced by edge abrasion and fragmentation under loading cycles. Makarov, Ermakov, and Ekimov [69][19] reported the degradation of ballast aggregates with the use of a combined Los Angeles Abrasion (LAA) test and 3D laser method. Wnek et al. [21][20] assessed ballast durability and contamination by performing LAA tests at 400 and 1000 revolutions. Qian et al. [70][21] further appraised ballast degradation by analysing the aggregate images before and after LAA tests. Okonta [71][22] correlated and established relationships between the shape characteristics and abrasion index of abraded ballast aggregates via LAA experimentation. Additionally, Sun et al. [72][23] found different vices for assessing ballast performance under recurrent train loadings and a wide range of speeds. It was noticed that degradation increased at higher speeds [72][23]. Nevertheless, Indraratna et al. [73][24] made a comparison of the performance of dissimilar ballast aggregate gradations under a cyclic drained triaxial test. Furthermore, Koohmishi and Palassi [18][25] evaluated the impacts of dissimilar gradation and subgrade situations on the degradation and durability of ballasts under impact loadings.

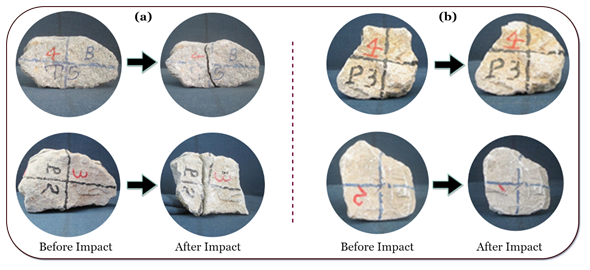

Tracks are often subjected to impact loads as a result of the inconsistencies in component geometry resulting from sudden changes in formation rigidity at transition points between ballasted and non-ballasted track structures, as well as rail/wheel-associated anomalies or corrugation of rails [74][26]. These continuous loadings are consequential in the rapid deterioration of ballast particles and development of mineral contaminants. In response to this issue, Kaewunruen and Remennikov [4] studied the projection of dynamic cracks from prestressed concrete tie beams to underlying ballast layers under impact loadings. Nimbalkar et al. [75][27] discussed the prospects of utilising shock mats in improving ballast durability performance. This was achieved by developing and performing extensive impact tests on ballast aggregates. Likewise, Aikawa [76][28] identified the role of ballast particles in the reduction of the criticality of induced impact loadings via in situ experimentations of the ballast layer’s dynamic reactions under moving traffic loads. Furthermore, Nimbalkar and Indraratna [77][29] conducted field investigations to assess the impacts of rubber shock mats and geosynthetics on the degradation and durability of ballast aggregates. It was observed that, at transition points, the insertion of shock mats between the concrete slab and the ballast layer results in a substantial decrease in the degradation of the ballast. Figure 9 shows ballast degradation by fragmentation and attrition after impact loading.

From the preceding summary of past ballast degradation studies, it is clear that the influence of ballast characterisation, loading situation, rock geological history, and operating climatic conditions (especially in tropical regions) on the durability and degradation of ballasts subjected to impact loading is yet to be well understood. As such, there is a need for further research focused on evaluating the durability of ballast materials in the tropical climates of Africa.

Figure 92. Comparison of ballast degradation patterns: (a) fragmentation; (b) abrasion [18][25].

4. Ballast Microstructure

Most studies on coarse aggregate and rock microscopy or microstructural assessment across the globe over the years focused on practicality in concrete [104–106][30][31][32]. As such, there is insufficient existing literature describing the microstructural properties and requirements of ballasts. Microstructural analysis incorporates quantitative and qualitative evaluations often with the use of energy-dispersive X-ray (EDX) and scanning electron microscopic (SEM) analyses, respectively [107][33]. Chen, Qi, Wang, and Cui [108][34] conducted experimental assessments on the microscopy and hydraulic characteristics of coarse aggregates utilised in high-speed railway substructures at varying degrees of compaction. In this study, a mercury intrusion porosimeter and a scanning electron microscope (SEM) were adopted. The outcomes revealed the presence of two variations of typical pores: micropores with diameters less than 12.1 µm and macropores greater than or equal to 12.1 µm. The micropores were further observed to considerably influence the hydraulic properties of the aggregates [108][34].

References

- Sussmann, T.R.; Ruel, M.; Chrismer, S.M. Source of Ballast Fouling and Influence Considerations for Condition Assessment Criteria. Transp. Res. Rec. J. Transp. Res. Board 2012, 87–94. [Google Scholar] [CrossRef]

- Agarana, M.C.; Ede, A.N. Application of differential transform method to vibration analysis of damped railway bridge on pasternak foundation under moving train. In Proceedings of the World Congress on Engineering 2016, London, UK, 29 June–1 July 2016; Volume 2, pp. 1177–1179. [Google Scholar]

- Koohmishi, M.; Azarhoosh, A. Assessment of Drainage and Filtration of Sub-ballast Course Considering Effect of Aggregate Gradation and Subgrade Condition. Transp. Geotech. 2020, 24, 100378. [Google Scholar] [CrossRef]

- Esveld, C. Modern Railway Track, 2nd ed.; Nieuwenhuizen, D.Z., Ed.; MRT-Productions: Zaltbommel, The Netherlands, 2001; ISBN 9080032433. [Google Scholar]

- Geological Society London Railway track ballast. Eng. Geol. Spec. Publ. 2001, 17, 285–289.

- Ebrahimi, A.; Tinjum, J.M.; Edil, T.B. Deformational behavior of fouled railway ballast. Can. Geotech. J. 2015, 52, 344–355. [Google Scholar] [CrossRef]

- Sadeghi, J.; Motieyan-Najar, M.E.; Zakeri, J.A.; Yousefi, B.; Mollazadeh, M. Improvement of railway ballast maintenance approach, incorporating ballast geometry and fouling conditions. J. Appl. Geophys. 2018, 151, 263–273. [Google Scholar] [CrossRef]

- Rampersad, A.; George, T.B.; Mokoena, R.; Mgangira, M.B.; Gräbe, P.J. The Influence of Ballast Fouling on Track Settlememt. In Proceedings of the 2018 37th Southern African Transport Conference, Pretoria, South Africa, 9–12 July 2018. [Google Scholar]

- Tutumluer, E.; Ahuja, N.; Hart, J.M.; Moaveni, M.; Huang, H.; Zhao, Z.; Shah, S. Field Evaluation of Ballast Fouling Conditions Using Machine Vision; Safaty IDEA Program Project Final Report; Transportation Research Board: Washington, DC, USA, 2017. [Google Scholar]

- De Paiva, C.E.L.; Pereira, M.L.; Pimentel, L.L. Study of Railway Ballast Fouling by Abrasion-Originated Particles. Railw. Eng. 2017. [Google Scholar] [CrossRef]

- Huang, H.; Liu, S.; Qiu, T. Identification of railroad ballast fouling through particle movements. J. Geotech. Geoenvironmental Eng. 2018, 144, 6016001. [Google Scholar] [CrossRef]

- U.S. Department of Transportation. Ballast Fouling Measurement Tool: Phase 1; U.S. Department of Transportation: Washington, DC, USA, 2018.

- Selig, E.; Waters, J. Track Geotechnology and Substructure Management; Thomas Telford Services Ltd.: London, UK, 1994; ISBN 0727720139. [Google Scholar]

- Ebrahimi, A.; Tinjum, J.M.; Edil, T.B. Protocol for testing fouled railway ballast in large-scale cyclic triaxial equipment. Geotech. Test. J. 2012, 35. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Xie, W.; Roberts, R. Scattering analysis of ground-penetrating radar data to quantify railroad ballast contamination. NDT E Int. 2008, 41, 441–447. [Google Scholar] [CrossRef]

- Paiva, C.; Ferreira, M.; Ferreira, A. Ballast drainage in Brazilian railway infrastructures. Constr. Build. Mater. 2015, 92, 58–63. [Google Scholar] [CrossRef]

- Al-qadi, I.L.; Asce, F.; Xie, W.; Roberts, R.; Leng, Z. Data Analysis Techniques for GPR Used for Assessing Railroad Ballast in High Radio-Frequency Environment. J. Transp. Eng. 2010, 136, 392–399. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Tinjum, J.M.; Edil, T.B. Maintenance model for railway substructure. Geotech. Eng. J. SEAGS AGSSEA 2014, 45, 48–55. [Google Scholar]

- Makarov, A.I.; Ermakov, V.A.; Ekimov, D.A. Application of Textural Features in the Analysis of Breakstone Grading. J. Min. Sci. 2019, 55, 40–44. [Google Scholar] [CrossRef]

- Wnek, M.; Tutumluer, E.; Moaveni, M.; Gehringer, E. Investigation of aggregate properties influencing railroad ballast performance. Transp. Res. Rec. 2013, 2374, 180–189. [Google Scholar] [CrossRef]

- Qian, Y.; Boler, H.; Moaveni, M.; Tutumluer, E.; Hashash, Y.M.A.; Ghaboussi, J. Characterizing Ballast Degradation through Los Angeles Abrasion Test and Image Analysis. Transp. Res. Rec. J. Transp. Res. Board 2014, 2448, 142–151. [Google Scholar] [CrossRef]

- Okonta, F.N. Relationships between abrasion index and shape properties of progressively abraded dolerite railway ballasts. Rock Mech. Rock Eng. 2014, 47, 1335–1344. [Google Scholar] [CrossRef]

- Sun, Q.D.; Indraratna, B.; Nimbalkar, S. Deformation and Degradation Mechanisms of Railway Ballast under High Frequency Cyclic Loading. J. Geotech. Geoenvironmental Eng. 2016, 142, 04015056. [Google Scholar] [CrossRef]

- Indraratna, B.; Sun, Y.; Nimbalkar, S. Laboratory Assessment of the Role of Particle Size Distribution on the Deformation and Degradation of Ballast under Cyclic Loading. J. Geotech. Geoenvironmental Eng. 2016, 142, 04016016. [Google Scholar] [CrossRef]

- Koohmishi, M.; Palassi, M. Effect of particle size distribution and subgrade condition on degradation of railway ballast under impact loads. Granul. Matter 2017, 19, 63. [Google Scholar] [CrossRef]

- Sañudo, R.; Miranda, M.; Markine, V.; Delĺolio, L. The Influence of Train Running Direction and Track Supports Position on the Behaviour of Transition Zones. Transp. Res. Procedia 2016, 18, 281–288. [Google Scholar] [CrossRef]

- Nimbalkar, S.; Indraratna, B.; Dash, S.K.; Christie, D. Improved Performance of Railway Ballast under Impact Loads Using Shock Mats. J. Geotech. Geoenvironmental Eng. 2012, 138, 281–294. [Google Scholar] [CrossRef]

- Aikawa, A. Dynamic characterisation of a ballast layer subject to traffic impact loads using three-dimensional sensing stones and a special sensing sleeper. Constr. Build. Mater. 2015, 92, 23–30. [Google Scholar] [CrossRef]

- Nimbalkar, S.; Indraratna, B. Improved Performance of Ballasted Rail Track Using Geosynthetics and Rubber Shockmat. J. Geotech. Geoenvironmental Eng. 2016, 142, 04016031. [Google Scholar] [CrossRef]

- Lojda, V.; Zikmund, T.; Sojka, K.; Kaiser, J.; Prošek, Z.; Lidmila, M. Microstructural analysis of fly ash-based stabilizer for track bed. Key Eng. Mater. 2017, 731, 66–73. [Google Scholar] [CrossRef]

- Busari, A.; Dahunsi, B.; Akinmusuru, J. Sustainable concrete for rigid pavement construction using de-hydroxylated Kaolinitic clay: Mechanical and microstructural properties. Constr. Build. Mater. 2019, 211, 408–415. [Google Scholar] [CrossRef]

- Awoyera, P.; Akinmusuru, J.; Ede, A.; Jolayemi, J. Novel concrete mixture using silica rich aggregates: Workability, strength and microstructural properties. In Proceedings of the International Structural Engineering and Construction, Chicago, IL, USA, 20–25 May 2019; ISEC Press: Fargo, ND, USA, 2019; Volume 6. [Google Scholar]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9781493966745. [Google Scholar]

- Chen, R.P.; Qi, S.; Wang, H.L.; Cui, Y.J. Microstructure and Hydraulic Properties of Coarse-Grained Subgrade Soil Used in High-Speed Railway at Various Compaction Degrees. J. Mater. Civ. Eng. 2019, 31, 04019301. [Google Scholar] [CrossRef]