Improvement of the hot stamping process is important for reducing processing costs and improving the productivity and tensile properties of final components. One major approach to this has been to conduct all or part of the process at lower temperatures.

- low-temperature hot stamping

- hot stamping

Note:All the information in this draft can be edited by authors. And the entry will be online only after authors edit and submit it.

1. Introduction

Owing to the depletion of non-renewable energy resources and the environmental impact of burning fossil fuels, there has been a strong push to improve the fuel efficiency of automobiles in recent years. One of the most feasible approaches is by light-weighting; a 10% weight reduction can lead to an almost 2.5% increase in fuel efficiency [1]. The automotive industry is thus working on reducing vehicle weights with simultaneous improvements in safety and crashworthiness. This can often be achieved either by using lighter materials, such as aluminium alloys, or by using stronger materials such as advanced high strength steels (AHSS) in the body in white (BiW) of vehicles. Hot stamping technology has been developed as a specialised production technique for the manufacture of components from AHSS; this addresses the shortcomings encountered in conventional cold forming technologies, such as poor formability, high impact on the tools and an elevated tendency to springback [2]. The most commonly used AHSS materials are boron (Mn-B) steels, such as 20MnB5, 22MnB5 and 27MnCrB5, which show a yield strength (YS) of above 770 MPa and an ultimate tensile strength (UTS) of above 1300 MPa with a total elongation (TE) of around 6–8% in hot-stamped parts [3]. The most notable example to date of the application of hot-stamped AHSS in the automotive sector is the 2014 Volvo XC90, where hot-stamped sheet steel was applied for around 38% of the BiW, including the front- and rear-side longitudinal members, A-, B- and C-pillar reinforcements, roof rail reinforcements and floor cross members [4]. The 2014 Acura MDX was another notable example, in which hot-stamped steel was adopted for the A- and B-pillars, roof rail and sill reinforcements [5].

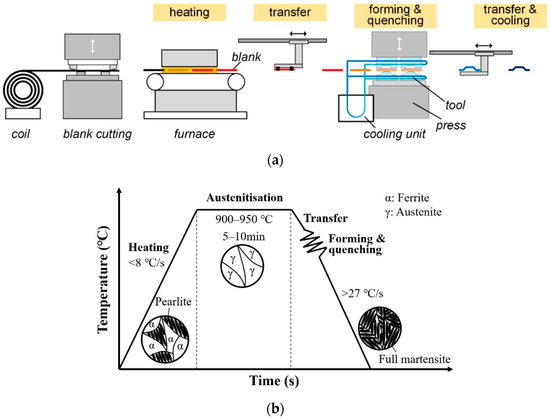

Hot stamping technology for Mn-B steels is now mature and has been commercialised internationally, especially for sheet in the 1500 MPa UTS class. The process chain is illustrated in Figure 1a [6] and a schematic representation of the thermomechanical cycle and the microstructural evolution during the hot stamping process is shown in Figure 1b [7]. During the process, the steel coil is first cut into blanks, heated up to 900–950 °C in a furnace and held isothermally for around 5–10 min until the initial ferrite-pearlite microstructure is completely transformed to austenite [7]. The blanks are subsequently transferred from the furnace to a press, where they are formed at around 700 °C or higher, then quenched to room temperature with a cooling rate of at least 27 °C s−1, this being the critical rate necessary to obtain a fully martensitic transformation in the material, assuring ultimate tensile strength of up to 1700 MPa [8]. Finally, the hot-stamped part is post-treated, applying processes such as tempering, trimming and punching, to satisfy the requirements of commercial customers [1]. Much research into hot stamping technology has already been published. For instance, Karbasian [3] has summarised the hot stamping procedure including the thermal, mechanical, microstructural, and technological aspects and has shown the potential for further investigations. Merklein and Lechler [9] have reported that hot-stamped 22MnB5 steel parts could be produced with an ultimate tensile strength of 1500 MPa. Naderi et al. [10] have investigated and analysed the microstructural evolution and corresponding mechanical properties in B-pillars with different designs during the hot stamping process.

Figure 1. Illustration of conventional hot stamping process for Mn-B steel: (a) Basic hot stamping process chain [6] [6] (Reproduced with permission of Pentera, 2020). (b) Thermomechanical cycle and microstructural evolution during hot stamping.

However, the current hot stamping technology has the following inadequacies [11,12][11][12]: (1) The productivity is low due to a long cycle time including both heating and cooling. (2) The cost of protection against oxidation and decarburisation, such as coating or fabrication in an oxygen-free environment, is high. (3) Due to a low ductility, the product is unsuitable for use in energy-absorbing structures. (4) The process requires a large investment in production equipment (including a cooling system with complex design, large furnace and laser trimming).

Due to the globally increasing demand for application of the hot stamping technology within automobile manufacture, there has been great interest in solving these issues. In recent years, several technologies have been developed to improve the production efficiency and enhance the final performance of hot-stamped components. Section 2 of this paper briefly introduces these recent developments in hot stamping. However, the improvements achieved are still not sufficient and these technologies have not been widely implemented in industrial production. Another approach that has recently attracted a great deal of research attention is that of conducting the process at lower temperatures than are typical in the current conventional hot stamping process. This can significantly reduce the process cycle time and save energy and cost. These desired objectives can be achieved through reducing the heating temperature and/or forming temperature and using advanced materials with lower austenitic transformation temperatures (A1 and A3), e.g., medium-Mn steel (MMn) steels [13–15][13][14][15].

2. Recent Developments in Hot Stamping

Many novel techniques have been proposed and developed to improve the hot stamping process from the points of view of cost savings, productivity and final performance of hot-stamped components. These technologies include advanced approaches to heating, stamping, die-quenching and post-form treatment, as well as the use of tailored heating and quenching and partitioning (Q&P) techniques [16–19][16][17][18][19].

2.1. Advanced Approaches to Heating

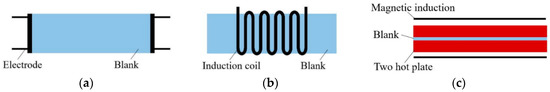

Alternative heating technologies, such as electrical resistance heating, induction heating, and direct contact heating (illustrated schematically in Figure 2), as well as infrared heating, have been used to improve the productivity and energy efficiency by shortening the heating time with respect to that achievable using the conventional roller hearth furnace [17,18][17][18]. These alternative techniques can also reduce the size of the equipment required. Mori et al. [20] proposed the use of rapid electrical resistance heating in hot stamping (Figure 2a). They suggested that the blanks could be heated up to 800–900 °C in only 2 s by connecting two pairs of electrodes; this approach almost eliminates the formation of oxide scale that occurs during longer heating times. Zhang et al. [21] have demonstrated experimentally the feasibility and merits of resistance heating in B1500HS boron steel. However, resistance heating cannot create a uniform distribution of temperature in the blank during the hot stamping process, and this results in poor formability and final mechanical properties. Kollek et al. [22] proposed an advanced rapid heating method using induction heating (Figure 2b), which was implemented through an induction coil carrying high-frequency alternating current (AC). A related method, which used elliptical induction coils to uniformly and rapidly heat 1.2-mm-thick boron steel, was successfully invented, investigated and shown to give good final quality by Kim et al. [23]. Vibrans et al. [24] integrated an induction heating device into a conventional heating line to heat up the sheet rapidly to around 950 °C, after which it was transferred for soaking to a roller hearth furnace. This novel design gave a time saving of about 50% with respect to the conventional process, while avoiding the problem of non-uniform heating. Recently, Ploshikhin et al. [25,26][25][26] have proposed the application of a direct contact heating method (Figure 2c) in which the sheets are press-heated by two hot plates. A heating cycle time of only around 30 s is required to fully austenitise a typical Al-Si-coated boron steel and a good uniform temperature distribution is achieved. This technique requires less production space and has a higher energy efficiency than heating using a roller hearth furnace. In addition, infrared radiation has also been considered as a novel heating method, but this has a relatively low heating rate compared to the methods introduced above. It can be classified into far and near types [20]. Far-infrared heating is good for temperature control and has been gradually developed to be employed in the hot stamping industry [27,28][27][28]. Near-infrared heating has a higher conversion efficiency but with poor temperature control capabilities. Hence, investigations have so far focused on partial heating or local heating. Lee et al. [29,30][29][30] used near-infrared heating devices to locally heat non-quenchable AHSS to reduce the springback induced by cold forming. However, most of the processes described above are still limited to laboratory scale and further work is required to determine their viability for industrial applications.

Figure 2. Advanced heating systems for hot stamping: (a) Resistance heating; (b) Induction heating; (c) Direct contact heating.

2.2. Advanced Stamping and Die Quenching Technologies

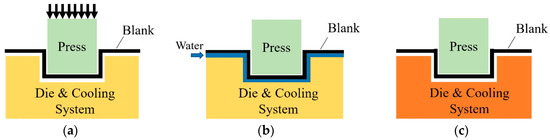

Optimisation of stamping and die quenching systems is another important way of improving the productivity and the final performance of the hot-stamped parts. As shown in Figure 3, three aspects have been considered and investigated: (1) increasing the contact pressure, (2) increasing the heat transfer area and (3) improving the die and cooling system. Schuler [31] has proposed and developed a new type of hot stamping press tool (Figure 3a), named pressure-controlled hardening (PCH), which uses a hydraulic bed cushion to increase the pressure and thus the contact surface between blank and die. The heat transfer coefficient is increased, resulting in a shorter stamping time and leading to higher productivity. Vollmer et al. [32] and Palm et al. [33] experimentally studied the effectiveness of the PCH cushion, demonstrating an increase in productivity from 2–3 strokes per min (spm) with conventional hot stamping equipment to almost 7–8 spm with the cushion. Figure 3b illustrates an attempt to increase the contact area of heat transfer for blanks by direct injection of water into the inevitable gap between the blank and the die during stamping to avoid poor heat transfer. Maeno et al. [34] conducted a series of tests using this water and die quenching technique. Their results showed not only an improvement of productivity to 10 spm, but also an enhanced formability thanks to the more uniform heat transfer. Although these two methods have begun to be applied in commercial production, they require an increased investment in equipment and the return-on-investment for these techniques has not yet been evaluated.

Figure 3. Advanced forming and quenching methods in hot stamping: (a) Increase contact pressure; (b) Improve quenching quality; (c) Improve die and cooling system.

Figure 3c represents other advanced methods adopted in the die and quenching system to improve the heat transfer and the heat and abrasion resistance [35]. Many researchers [36–39][36][37][38][39] have already made great efforts to develop the cooling channel design by analysing the phase transformations in the blank, the design of die structures and the influence of flow velocity. They have also worked to optimise cooling system parameters, such as the gap between the channels and the depth from the channels to the die surface, in order to improve the cooling performance and minimise the quenching time. Despite these achievements, the range of applications of such cooling systems is inevitably restricted by their complex design and the high costs of manufacturing and maintenance. In a different approach, Li et al. [40] recently experimentally and numerically investigated the influence of thermal conductivity of dies on the cooling behaviour and final product performance, using five dies with different thermal conductivities. Their results showed that the cooling performance and formability were significantly improved by increasing the thermal conductivity of the die, showing the feasibility of this approach. However, the investment involved in introducing these dies may be too high for commercial application.

2.3. Tailored Microstructures and the Quenching and Partitioning Process

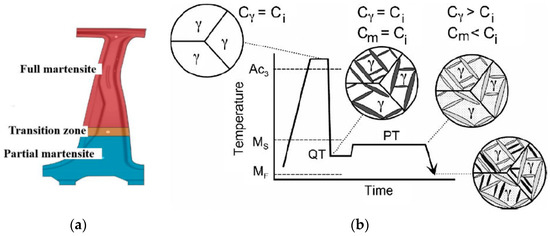

Additionally, in order to improve the final performance of hot-stamped components and widen their application, two novel techniques have been developed, one in which hot stamping is combined with a tailored microstructure [11] and the other in which it is combined with a quenching and partitioning (Q&P) process [41–44][41][42][43][44]. A typical example of a B-pillar with a tailored microstructure after hot stamping is shown in Figure 4a. Here, the upper region has a higher tensile strength with a fully martensitic microstructure to support the vehicle structure. The lower region has a higher ductility with only a partially martensitic microstructure, the remainder consisting of ferrite and pearlite, to absorb more energy during a possible car crash [11]. Several methods are available to obtain tailored microstructures, such as partial heating, differential cooling, tailor-welded and rolled blanks and partial annealing after hot stamping. [45–52][45][46][47][48][49][50][51][52]. For example, Oldenburg [45] used a material combination approach to develop dies comprising materials of different thermal conductivities to achieve different cooling rates as a function of location during the forming stage. This enabled the boron steel microstructure after hot stamping to be tailored. Yun et al. [50] further developed the material combination approach, using lithium nitrate undergoing a phase transformation as the part with low thermal conductivity. This effectively avoided the problem of heat conduction between different materials, and high-quality tailored blanks could be obtained. However, the processes involved in all these approaches are rather complicated and involve extra cost, and the feasibility has so far only been demonstrated on a laboratory scale.

Figure 4. Advanced forming and quenching methods in hot stamping: two novel hot stamping processes for improving the final performance of hot-stamped parts: (a) Tailored microstructure (Adapted with permission from Elsevier [11]); (b) Quenching and partitioning process (reproduced with permission from Elsevier [42]) (Ci, Cγ, Cm represent the carbon contents of the initial alloy, austenite and martensite, respectively).

The Q&P heat treatment process was first proposed by Speer et al. [41–44][41][42][43][44]. As shown in Figure 4b [42], the treatment starts with a full or partial austenitisation followed by rapid cooling to a quenching temperature (QT) between the martensite start temperature (Ms) and martensite finish temperature (Mf) to obtain a predesignated fraction of martensite. In the subsequent partitioning treatment, the material is held at a partitioning temperature (PT), which can be equal to QT (one-step treatment) or somewhat higher than QT (two-step treatment) [53,54][53][54]. The aim of this novel process is to partition carbon into the austenite and increase the stability of this phase at room temperature, thereby improving the final ductility and toughness through the transformation induced plasticity (TRIP) effect in the retained austenite. Based on this, Liu et al. [55,56][55][56] integrated a Q&P treatment into a hot stamping process and examined its efficacy in improving the final performance of conventional hot-stamping boron steel. The ductility was increased from 6.6% to 14.8% after a Q&P treatment at 320 °C for 30 s. Zhu et al. [57] further developed a new hot air system for partitioning; this replaced the conventional furnace to easily and rapidly control the temperature of the blank after quenching with a uniform temperature distribution. However, it is still difficult to achieve isothermal partitioning process in an industrial environment. For the industrial application of Q&P in hot stamping, it is necessary to further investigate the possibility of non-isothermal partitioning and the effect of the Q&P treatment on the impact properties and resistance to hydrogen embrittlement of the steel rather than its ductility only.

2.4. Post-Form Treatments

Finally, post-form treatment processes have also been investigated. Owing to the high strength and hardness of hot-stamped boron steels, wear, chipping and failure in the tools used for post-form machining can cause serious damage, which in turn can lead to high costs and poor productivity [58]. Laser cutting technology is an alternative to mechanical shearing, but it requires high energy input and has a low productivity. Researchers have tried to find different ways to address these shortcomings. For example, Choi et al. [16] have proposed a new hot stamping process for softening local areas and reducing the trimming load, which can improve tool wear. Mori et al. [59] suggested a punching process for AHSS to relax the flow stress in areas with high deformation. So et al. [60] have developed warm blanking as an alternative blanking strategy; here, the temperature of the hot-stamped parts remains above the martensitic transformation temperatures (Ms or Mf) to increase the tool life by reducing the shearing load. In all these methods, it is necessary to improve the structure of the tooling, which could lead to significant additional expense in tool design and manufacturing.

Although, as has been seen, many new developments have been investigated in hot stamping technology in recent years, most of these remain at the level of the laboratory and cannot be applied to benefit industrial production. Recently, however, approaches in which the processing temperature is reduced have attracted much attention owing to their potential as a replacement for conventional hot stamping processes, allowing cost savings, improvements in productivity and better final mechanical properties of stamped parts.

References

- Kiani, ; Gandikota, I.; Rais-Rohani, M.; Motoyama, K. Design of lightweight magnesium car body structure under crash and vibration constraints. J. Magnes. Alloys 2014, 2, 99–108.

- Berglund, The history of hardening of boron steel in northern Sweden. In Proceedings of the 1st International Conference on Hot Sheet Metal. Forming of High.-Performance Steel, Kassel, Germany, 22–24 October 2008; pp. 175–177.

- Karbasian, ; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118.

- Advanced High Strength Steel Technologies in the 2016 Volvo XC90. 2017. Available online: https://www.sasft.org/-/media/files/autosteel/great-designs-in-steel/gdis-2016/track-2---volvo-xc90.ashx (accessed on 20 September 2020).

- Lightweight Door Ring Concepts Using Hot Stamped Laser Welded 2014. Available online: https://www.sasft.org/-/media/files/autosteel/great-designs-in-steel/gdis-2014/gagan-tandon---amtb.ashx (accessed on 20 September 2020).

- Pentera, ; Pierschel, N. Thermo-mechanical interactions in hot stamping. In Preecedings of the CIRP sponsored Conference on Thermal Issues in Machine Tools, Dresden, Germany, 21–23 March 2018.

- Fujisawa, ; Hamada, S.; Koga, N.; Sasaki, D.; Tsuchiyama, T.; Nakada, N.; Takashima, K.; Ueda, M.; Noguchi, H. Proposal for an engineering definition of a fatigue crack initiation unit for evaluating the fatigue limit on the basis of crystallographic analysis of pearlitic steel. Int J. Fract. 2013, 185, 17–29.

- Chang, ; Li, G.; Wang, C.; Li, X.; Dong, H. Effect of quenching and partitioning with hot stamping on martensite transformation and mechanical properties of AHSS. J. Mater. Eng. Perform. 2015, 24, 3194–3200.

- Merklein, ; Lechler, J. Investigation of the thermo-mechanical properties of hot stamping steels. J. Mater. Process. Technol. 2006, 177, 452–455.

- Naderi, ; Ketabchi, M.; Abbasi, M.; Bleck, W. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping. J. Mater. Process. Technol. 2011, 211, 1117–1125.

- Merklein, ; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24.

- Taylor, ; Clough, A. Critical review of automotive hot-stamped sheet steel from an industrial perspective. Mater. Sci Technol. 2018, 34, 809–861.

- Ganapathy, ; Li, N.; Lin, J.; Bhattacharjee, D. Investigation of a new hot stamping process with improved formability and productivity. Procedia Eng. 2017, 207, 771–776.

- Hu, ; Luo, H.W.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464.

- Naderi, ; Ketabchi, M.; Abbasi, M.; Bleak, W. Semi-hot stamping as an improved process of hot stamping. J. Mater. Sci. Technol. 2011, 27, 369–376.

- Choi, ; Lim, W.; Seo, P.; Kang, C.; Kim, B. Softening method for reducing trimming load and improving tool wear resistance in cutting of a hot stamped component. Proceedings of the international conference on technology of plasticity, Technology of plasticity, Aachen, Germany, 25-30 September 2011;. pp. 419–422.

- Kim, ; Chun, M.; Yi, J.; Moon, Y. Pass schedule algorithms for hot open die forging. J. Mater. Process. Technol. 2002, 130, 516–523.

- Lehmann, Developments in the field of Schwartz heat treatment furnaces for press hardening industry. In Proceedings of the 3rd International Conference on Hot Sheet Metal Forming of High-Performance Steel, Kassel, Germany, 13–17 June 2010; pp. 171–180.

- Mori, Smart hot stamping of ultra-high strength steel parts. Trans. Nonferrous Met. Soc. China. 2012, 22, 496–503.

- Mori, ; Bariani, P.F.; Behrens, B.A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Annals Manuf. Technol. 2017, 66, 755–777.

- Zhang, ; Jia, X.; Li, X.; Zhao, Y. Hot stamping of boron alloy steels using resistance heating. In Proceedings of the 2nd International Conference on Civil., Materials and Environmental Sciences, London, UK, 13–14 March 2015; pp. 362–365.

- Kolleck, ; Veit, R.; Merklein, M.; Lechler, J.; Geiger, M. Investigation on induction heating for hot stamping of boron alloyed steels. CIRP Annals Manuf. Technol. 2009, 58, 275–278.

- Kim, K.; Woo, Y.Y.; Park, K.S.; Sim, W.J.; Moon, Y.H. Advanced induction heating system for hot stamping. Int. J. Adv. Manuf. Technol. 2018, 99, 583–593.

- Vibrans, ; Malek, R.; Kotzian, M.; Vogt, C.; Langejurgen, M. Development of an induction heating heating device for heating shaped blanks. Heat Process. 2016, 3, 37–42.

- Ploshikhin, ; Prihodovsky, A.; Kaiser, J.; Brisping, R.; Linder, H.; Lengsdorf, C. New heating technology for furnace-free press hardening process. In Proceedings of the Tools and Technologies for Processing Ultra-High Strength Materials, Graz, Austria, 19–21 September 2011.

- Ploshikhin, ; Prihodovsky, A.; Kaiser, J.; Skutella, L. Contact heating–New heating technology for heat treatment and hot forming. In Proceedings of the Tools and Technologies for Processing Ultra High Strength Materials, Graz, Austria, 19–20 September 2013.

- Aikawa, Far-Infrared Radiation Heating Furnace for Steel Sheet for Hot Stamping. U.S. Patent 20170175218A1, 6 December 2017.

- Kuwayama, Far-Infrared Radiation Multi-Stage Type Heating Furnace for Steel Sheets for Hot Stamping. U.S. Patent 20170159141A1, 8 June 2017.

- Lee, H.; Hwang, J.S.; Lee, C.W.; Yang, D.Y.; Yang, W.H. A local heating method by near-infrared rays for forming of non-quenchable advanced high-strength steels. J. Mater. Process. Technol. 2014, 214, 784–793.

- Lee, H.; Yoon, J.W.; Yang, D.Y. Study on springback from thermal-mechanical boundary condition imposed to V-bending and L-bending processes coupled with infrared rays local heating. Int. J. Mater. Form. 2018, 11, 417–433.

- Hot Stamping Presses with PCH Flex 2015. Available online: https://www.schulergroup.com/major/us/technologien/produkte/formhaerteanlagen/index.html (accessed on 20 September 2020).

- Vollmer, ; Palm, C. Improving the quality of hot stamping parts with innovative press technology and inline process control. J. Phys. Conf. Ser. 2017, 896, 012050.

- Palm, ; Vikkner, R.; Aspacher, J.; Gharbi, M. Increasing performance of hot stamping systems. Procedia Eng. 2017, 207, 765–770.

- Maeno, ; Mori, K.I.; Fujimoto, M. Improvements in productivity and formability by water and die quenching in hot stamping of ultra-high strength steel parts. CIRP Ann. 2015, 64, 281–284.

- Shan, ; Zhang, M.; Jiang, C.; Xu, Y.; Rong, W. Basic study on die cooling system of hot stamping process. Proceedings of the International Conference on Advanced Technology of Design and Manufacture, IET, Beijing, China, 23–25 November 2010; pp. 65–68.

- Valls, ; Casas, B.; Rodriguez, N.; Paar, U. Benefits from using high thermal conductivity tool steels in the hot forming of steels. In Proceedings of the International Conference Hot Forming of Steels and Products Properties, Grado, Italy, 13–16 September 2009.

- Lim, ; Choi, H.; Ahn, S.; Kim, B. Cooling channel design of hot stamping tools for uniform high-strength components in hot stamping process. Int. J. Adv. Manuf. Technol. 2014, 70, 1189–1203.

- Xu, ; Shan, Z.D. Design parameter investigation of cooling systems for UHSS hot stamping dies. Int. J. Adv. Manuf. Technol. 2014, 70, 257–262.

- Lei, ; Cui, J.; Xing, Z.; Fu, H.; Zhao, H. Investigation of cooling effect of hot-stamping dies by numerical simulation. Phys. Procedia 2012, 25, 118–124.

- Li, ; Zhou, L.H.; Wu, X.C.; Zhang, Y.; Li, J.W. The influence of thermal conductivity of die material on the efficiency of hot-stamping process. J. Mater. Eng. Perform. 2016, 25, 4848–4867.

- Clarke, J.; Speer, J.G.; Matlock, D.K.; Rizzo, F.C.; Edmonds, D.V.; Santofimia, M.J. Influence of carbon partitioning kinetics on final austenite fraction during quenching and partitioning. Scr. Mater. 2009, 61, 149–152.

- Edmonds, V.; He, K.; Rizzo, F.C.; De Cooman, B.C.; Matlock, D.K.; Speer, J.G. Quenching and partitioning martensite—A novel steel heat treatment. Mater. Sci. Eng. A 2006, 438, 25–34.

- Speer, ; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622.

- Speer, G.; Edmonds, D.V.; Rizzo, F.C.; Matlock, D.K. Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation. Curr. Opin. Solid St. M. 2004, 8, 219–237.

- Oldenburg, Warm forming of steels for tailored microstructure. In Encyclopedia of Thermal Stresses; Hetnarski, R.B., Ed.; Springer: Dordrecht, The Netherlands, 2014; pp. 6469–6479.

- Laumann, ; Pfestorf, M.; Beil, A.; Geiger, M.; Merklein, M. Crash behaviour of various modern steels exposed to high deformation rates. Key Eng. Mater. 2007, 344, 151–158.

- Mori, ; Maeno, T.; Mongkolkaji, K. Tailored die quenching of steel parts having strength distribution using bypass resistance heating in hot stamping. J. Mater. Process. Technol. 2013, 213, 508–514.

- George, ; Bardelcik, A.; Worswick, M.J. Hot forming of boron steels using heated and cooled tooling for tailored properties. J. Mater. Process. Technol. 2012, 212, 2386–2399.

- Yogo, ; Kurato, N.; Iwata, N. Investigation of hardness change for spot welded tailored blank in hot stamping using CCT and deformation-CCT diagrams. Metall Mater. Trans. A 2018, 49a, 2293–2301.

- Yun, ; Lee, S.H.; Song, K.S.; Cho, W.; Kim, Y. Performance improvement of tailored die quenching using material combinations with phase change material in hot stamping. Int. J. Heat Mass Transfer. 2020, 161, 120286.

- Kim, ; Kang, M.J.; Park, Y.D. Laser welding of Al-Si coated hot stamping steel. Procedia. Eng. 2011, 10, 2226-2231.

- Tajul, ; Maeno, T.; Kinoshita, T.; Mori, K.I. Successive forging of tailored blank having thickness distribution for hot stamping. Int. J. Adv. Manuf. Technol. 2017, 89, 3731–3739.

- Han, H.; Zhong, Y.Y.; Yang, K.; Cui, Z.S.; Chen, J. Application of hot stamping process by integrating quenching and partitioning heat treatment to improve mechanical properties. Procedia Engineer. 2014, 81, 1737–1743.

- Zinsaz-Borujerdi, ; Zarei-Hanzaki, A.; Abedi, H.R.; Karam-Abian, M.; Ding, H.; Han, D.; Kheradmand, N. Room temperature mechanical properties and microstructure of a low alloyed TRIP-assisted steel subjected to one-step and two-step quenching and partitioning process. Mater. Sci. Eng. A 2018, 725, 341–349.

- Liu, P.; Jin, X.J.; Dong, H.; Shi, J. Martensitic microstructural transformations from the hot stamping, quenching and partitioning process. Mater. Charact. 2011, 62, 223–227.

- Liu, P.; Lu, X.W.; Jin, X.J.; Dong, H.; Shi, J. Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process. Scr. Mater. 2011, 64, 749–752.

- Zhu, ; Zhu, J.; Wang, Y.A.; Rolfe, B.; Wang, Z.J.; Zhang, Y.S. Combined hot stamping and Q&P processing with a hot air partitioning device. J. Mater. Process. Technol. 2018, 262, 392–402.

- Yilmaz, ; Kaftanoglu, B.; Hacaloglu, T.; Kilickan, M. Integration of press hardening with codling trimming. In Proceedings of the 5th International Conference on Accuracy in Forming Technology, Chemnitz, Germany, 10–11 November 2015; pp. 105–117.

- Mori, ; Maeno, T.; Fuzisaka, S. Punching of ultra-high strength steel sheets using local resistance heating of shearing zone. J. Mater. Process. Technol. 2012, 212, 534–540.

- So, ; Fassmann, D.; Hoffmann, H.; Golle, R.; Schaper, M. An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process. J. Mater. Process. Technol. 2012, 212, 437–449.

References

- Kiani, ; Gandikota, I.; Rais-Rohani, M.; Motoyama, K. Design of lightweight magnesium car body structure under crash and vibration constraints. J. Magnes. Alloys 2014, 2, 99–108.

- Berglund, The history of hardening of boron steel in northern Sweden. In Proceedings of the 1st International Conference on Hot Sheet Metal. Forming of High.-Performance Steel, Kassel, Germany, 22–24 October 2008; pp. 175–177.

- Karbasian, ; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118.

- Advanced High Strength Steel Technologies in the 2016 Volvo XC90. 2017. Available online: https://www.sasft.org/-/media/files/autosteel/great-designs-in-steel/gdis-2016/track-2---volvo-xc90.ashx (accessed on 20 September 2020).

- Lightweight Door Ring Concepts Using Hot Stamped Laser Welded 2014. Available online: https://www.sasft.org/-/media/files/autosteel/great-designs-in-steel/gdis-2014/gagan-tandon---amtb.ashx (accessed on 20 September 2020).

- Pentera, ; Pierschel, N. Thermo-mechanical interactions in hot stamping. In Preecedings of the CIRP sponsored Conference on Thermal Issues in Machine Tools, Dresden, Germany, 21–23 March 2018.

- Fujisawa, ; Hamada, S.; Koga, N.; Sasaki, D.; Tsuchiyama, T.; Nakada, N.; Takashima, K.; Ueda, M.; Noguchi, H. Proposal for an engineering definition of a fatigue crack initiation unit for evaluating the fatigue limit on the basis of crystallographic analysis of pearlitic steel. Int J. Fract. 2013, 185, 17–29.

- Chang, ; Li, G.; Wang, C.; Li, X.; Dong, H. Effect of quenching and partitioning with hot stamping on martensite transformation and mechanical properties of AHSS. J. Mater. Eng. Perform. 2015, 24, 3194–3200.

- Merklein, ; Lechler, J. Investigation of the thermo-mechanical properties of hot stamping steels. J. Mater. Process. Technol. 2006, 177, 452–455.

- Naderi, ; Ketabchi, M.; Abbasi, M.; Bleck, W. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping. J. Mater. Process. Technol. 2011, 211, 1117–1125.

- Merklein, ; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24.

- Taylor, ; Clough, A. Critical review of automotive hot-stamped sheet steel from an industrial perspective. Mater. Sci Technol. 2018, 34, 809–861.

- Ganapathy, ; Li, N.; Lin, J.; Bhattacharjee, D. Investigation of a new hot stamping process with improved formability and productivity. Procedia Eng. 2017, 207, 771–776.

- Hu, ; Luo, H.W.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464.

- Naderi, ; Ketabchi, M.; Abbasi, M.; Bleak, W. Semi-hot stamping as an improved process of hot stamping. J. Mater. Sci. Technol. 2011, 27, 369–376.

- Choi, ; Lim, W.; Seo, P.; Kang, C.; Kim, B. Softening method for reducing trimming load and improving tool wear resistance in cutting of a hot stamped component. Proceedings of the international conference on technology of plasticity, Technology of plasticity, Aachen, Germany, 25-30 September 2011;. pp. 419–422.

- Kim, ; Chun, M.; Yi, J.; Moon, Y. Pass schedule algorithms for hot open die forging. J. Mater. Process. Technol. 2002, 130, 516–523.

- Lehmann, Developments in the field of Schwartz heat treatment furnaces for press hardening industry. In Proceedings of the 3rd International Conference on Hot Sheet Metal Forming of High-Performance Steel, Kassel, Germany, 13–17 June 2010; pp. 171–180.

- Mori, Smart hot stamping of ultra-high strength steel parts. Trans. Nonferrous Met. Soc. China. 2012, 22, 496–503.

- Mori, ; Bariani, P.F.; Behrens, B.A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Annals Manuf. Technol. 2017, 66, 755–777.

- Zhang, ; Jia, X.; Li, X.; Zhao, Y. Hot stamping of boron alloy steels using resistance heating. In Proceedings of the 2nd International Conference on Civil., Materials and Environmental Sciences, London, UK, 13–14 March 2015; pp. 362–365.

- Kolleck, ; Veit, R.; Merklein, M.; Lechler, J.; Geiger, M. Investigation on induction heating for hot stamping of boron alloyed steels. CIRP Annals Manuf. Technol. 2009, 58, 275–278.

- Kim, K.; Woo, Y.Y.; Park, K.S.; Sim, W.J.; Moon, Y.H. Advanced induction heating system for hot stamping. Int. J. Adv. Manuf. Technol. 2018, 99, 583–593.

- Vibrans, ; Malek, R.; Kotzian, M.; Vogt, C.; Langejurgen, M. Development of an induction heating heating device for heating shaped blanks. Heat Process. 2016, 3, 37–42.

- Ploshikhin, ; Prihodovsky, A.; Kaiser, J.; Brisping, R.; Linder, H.; Lengsdorf, C. New heating technology for furnace-free press hardening process. In Proceedings of the Tools and Technologies for Processing Ultra-High Strength Materials, Graz, Austria, 19–21 September 2011.

- Ploshikhin, ; Prihodovsky, A.; Kaiser, J.; Skutella, L. Contact heating–New heating technology for heat treatment and hot forming. In Proceedings of the Tools and Technologies for Processing Ultra High Strength Materials, Graz, Austria, 19–20 September 2013.

- Aikawa, Far-Infrared Radiation Heating Furnace for Steel Sheet for Hot Stamping. U.S. Patent 20170175218A1, 6 December 2017.

- Kuwayama, Far-Infrared Radiation Multi-Stage Type Heating Furnace for Steel Sheets for Hot Stamping. U.S. Patent 20170159141A1, 8 June 2017.

- Lee, H.; Hwang, J.S.; Lee, C.W.; Yang, D.Y.; Yang, W.H. A local heating method by near-infrared rays for forming of non-quenchable advanced high-strength steels. J. Mater. Process. Technol. 2014, 214, 784–793.

- Lee, H.; Yoon, J.W.; Yang, D.Y. Study on springback from thermal-mechanical boundary condition imposed to V-bending and L-bending processes coupled with infrared rays local heating. Int. J. Mater. Form. 2018, 11, 417–433.

- Hot Stamping Presses with PCH Flex 2015. Available online: https://www.schulergroup.com/major/us/technologien/produkte/formhaerteanlagen/index.html (accessed on 20 September 2020).

- Vollmer, ; Palm, C. Improving the quality of hot stamping parts with innovative press technology and inline process control. J. Phys. Conf. Ser. 2017, 896, 012050.

- Palm, ; Vikkner, R.; Aspacher, J.; Gharbi, M. Increasing performance of hot stamping systems. Procedia Eng. 2017, 207, 765–770.

- Maeno, ; Mori, K.I.; Fujimoto, M. Improvements in productivity and formability by water and die quenching in hot stamping of ultra-high strength steel parts. CIRP Ann. 2015, 64, 281–284.

- Shan, ; Zhang, M.; Jiang, C.; Xu, Y.; Rong, W. Basic study on die cooling system of hot stamping process. Proceedings of the International Conference on Advanced Technology of Design and Manufacture, IET, Beijing, China, 23–25 November 2010; pp. 65–68.

- Valls, ; Casas, B.; Rodriguez, N.; Paar, U. Benefits from using high thermal conductivity tool steels in the hot forming of steels. In Proceedings of the International Conference Hot Forming of Steels and Products Properties, Grado, Italy, 13–16 September 2009.

- Lim, ; Choi, H.; Ahn, S.; Kim, B. Cooling channel design of hot stamping tools for uniform high-strength components in hot stamping process. Int. J. Adv. Manuf. Technol. 2014, 70, 1189–1203.

- Xu, ; Shan, Z.D. Design parameter investigation of cooling systems for UHSS hot stamping dies. Int. J. Adv. Manuf. Technol. 2014, 70, 257–262.

- Lei, ; Cui, J.; Xing, Z.; Fu, H.; Zhao, H. Investigation of cooling effect of hot-stamping dies by numerical simulation. Phys. Procedia 2012, 25, 118–124.

- Li, ; Zhou, L.H.; Wu, X.C.; Zhang, Y.; Li, J.W. The influence of thermal conductivity of die material on the efficiency of hot-stamping process. J. Mater. Eng. Perform. 2016, 25, 4848–4867.

- Clarke, J.; Speer, J.G.; Matlock, D.K.; Rizzo, F.C.; Edmonds, D.V.; Santofimia, M.J. Influence of carbon partitioning kinetics on final austenite fraction during quenching and partitioning. Scr. Mater. 2009, 61, 149–152.

- Edmonds, V.; He, K.; Rizzo, F.C.; De Cooman, B.C.; Matlock, D.K.; Speer, J.G. Quenching and partitioning martensite—A novel steel heat treatment. Mater. Sci. Eng. A 2006, 438, 25–34.

- Speer, ; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622.

- Speer, G.; Edmonds, D.V.; Rizzo, F.C.; Matlock, D.K. Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation. Curr. Opin. Solid St. M. 2004, 8, 219–237.

- Oldenburg, Warm forming of steels for tailored microstructure. In Encyclopedia of Thermal Stresses; Hetnarski, R.B., Ed.; Springer: Dordrecht, The Netherlands, 2014; pp. 6469–6479.

- Laumann, ; Pfestorf, M.; Beil, A.; Geiger, M.; Merklein, M. Crash behaviour of various modern steels exposed to high deformation rates. Key Eng. Mater. 2007, 344, 151–158.

- Mori, ; Maeno, T.; Mongkolkaji, K. Tailored die quenching of steel parts having strength distribution using bypass resistance heating in hot stamping. J. Mater. Process. Technol. 2013, 213, 508–514.

- George, ; Bardelcik, A.; Worswick, M.J. Hot forming of boron steels using heated and cooled tooling for tailored properties. J. Mater. Process. Technol. 2012, 212, 2386–2399.

- Yogo, ; Kurato, N.; Iwata, N. Investigation of hardness change for spot welded tailored blank in hot stamping using CCT and deformation-CCT diagrams. Metall Mater. Trans. A 2018, 49a, 2293–2301.

- Yun, ; Lee, S.H.; Song, K.S.; Cho, W.; Kim, Y. Performance improvement of tailored die quenching using material combinations with phase change material in hot stamping. Int. J. Heat Mass Transfer. 2020, 161, 120286.

- Kim, ; Kang, M.J.; Park, Y.D. Laser welding of Al-Si coated hot stamping steel. Procedia. Eng. 2011, 10, 2226-2231.

- Tajul, ; Maeno, T.; Kinoshita, T.; Mori, K.I. Successive forging of tailored blank having thickness distribution for hot stamping. Int. J. Adv. Manuf. Technol. 2017, 89, 3731–3739.

- Han, H.; Zhong, Y.Y.; Yang, K.; Cui, Z.S.; Chen, J. Application of hot stamping process by integrating quenching and partitioning heat treatment to improve mechanical properties. Procedia Engineer. 2014, 81, 1737–1743.

- Zinsaz-Borujerdi, ; Zarei-Hanzaki, A.; Abedi, H.R.; Karam-Abian, M.; Ding, H.; Han, D.; Kheradmand, N. Room temperature mechanical properties and microstructure of a low alloyed TRIP-assisted steel subjected to one-step and two-step quenching and partitioning process. Mater. Sci. Eng. A 2018, 725, 341–349.

- Liu, P.; Jin, X.J.; Dong, H.; Shi, J. Martensitic microstructural transformations from the hot stamping, quenching and partitioning process. Mater. Charact. 2011, 62, 223–227.

- Liu, P.; Lu, X.W.; Jin, X.J.; Dong, H.; Shi, J. Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process. Scr. Mater. 2011, 64, 749–752.

- Zhu, ; Zhu, J.; Wang, Y.A.; Rolfe, B.; Wang, Z.J.; Zhang, Y.S. Combined hot stamping and Q&P processing with a hot air partitioning device. J. Mater. Process. Technol. 2018, 262, 392–402.

- Yilmaz, ; Kaftanoglu, B.; Hacaloglu, T.; Kilickan, M. Integration of press hardening with codling trimming. In Proceedings of the 5th International Conference on Accuracy in Forming Technology, Chemnitz, Germany, 10–11 November 2015; pp. 105–117.

- Mori, ; Maeno, T.; Fuzisaka, S. Punching of ultra-high strength steel sheets using local resistance heating of shearing zone. J. Mater. Process. Technol. 2012, 212, 534–540.

- So, ; Fassmann, D.; Hoffmann, H.; Golle, R.; Schaper, M. An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process. J. Mater. Process. Technol. 2012, 212, 437–449.