The search for sustainability in the Supply Chain (SC) is one of the tasks that most concerns business leaders in all manufacturing sectors because of the importance that the Supply Chain has as a transversal tool and due to the leading role that it has been playing lately.

- sustainability

- supply chain management

- manufacturing system

- automotive

- aerospace

- shipbuilding

- transports

Note: The following contents are extract from your paper. The entry will be online only after author check and submit it.

1. Introduction

It can be said that a Supply Chain is composed of all the interested parties: customers, suppliers, manufacturers, transporters, warehousemen, etc. Each organization includes all the functions involved in it starting from the development of the new product, marketing, manufacturing, finance, to customer service and whose purpose is to satisfy the needs of the customer while generating profits in the process for itself [1].

Each Supply Chain will be divided into different stages, and within each stage, several actors can coexist, so it should really be called a Supply Network. All stages are connected through the flow of products, information, and funds—in both directions—aimed at maximizing the total value generated by the Supply Chain. The success of a Supply Chain should not be measured at each stage but in its total profitability. Therefore, the success of a Supply Chain lies in the efficiency of its management [2].

In addition, Supply Chain must adapt both to changes in technology and to customer requirements in order to remain competitive. The manufacturing Supply Chain is of the pull type as the processes are carried out in response to the request of the customer, which is also known as a reactive process [3].

Each connection between the stages of the Supply Chain (supplier–manufacturer–distributor–retailer–customer) has the processes required for each process cycle (sales order cycle, replenishment cycle, manufacturing cycle, procurement cycle), and these connection processes are divided into sub-processes at the same time [4]. The cycle view is useful when establishing information systems to support Supply Chain operations when considering operational decisions because it establishes the roles and responsibilities of each member and the expected outcome of each process.

Therefore, Supply Chain activities are framed within three macro processes: CRM, Customer Relationship Management; ISCM, Internal SCM; and SRM, Supplier Relationship Management. Figure 1 details these three framework processes [1].

Figure 1. Macro Supply Chain processes adapted from [1].

Information is disrupted as it moves up the chain because the information shared in the stages is incomplete. The lack of coordination can be called “the whip effect”. This lack of coordination damages relations between the different stages where there is a tendency to blame other stages thinking that theirs is doing well, which causes a loss of trust between the different stages and makes coordination efforts difficult [5].

In the present case, transport companies tend to report on greenhouse gas emissions, fuel consumption, and transport efficiency. From an environmental perspective, they report on four categories: energy consumption, water consumption, greenhouse gas emissions, and waste generation.

The role of sustainability in the Supply Chain today has become crucially important in both its design and the operations that concern it while improving its performance [6]. The framework presented by the United Nations World Summit in 2005 identifies three pillars on which sustainable economic, environmental, and social development rests.

In order to build a more sustainable Supply Chain, companies must clearly define the reasons for developing more sustainable approaches to fuel interest from customers who are reluctant to pay more for sustainable products [7].

2. Results and Discussion

2.1. Aerospace

Starting with the aerospace sector and considering the above-mentioned search arguments, a total of 18 articles are established that deal with this industry, of which 13 include sustainability in their content. Only two articles have been excluded because the criteria established were not met.

After evaluating the adaptation that this type of industry whose production engineer-to-order is characterized by the activities that must be added in order to comply with the established lead time, whether in terms of commercial management, procurement, production, or logistics and distribution in the case of the Supply Chain, the difficulty that smaller companies face in adapting to Industry 4.0 becomes clear. While large companies are more aware of the changes they must make in this adaptation, the Supply Chain is made up of these and other smaller and less developed companies in terms of both resources and organizational capacity for the integration of Industry 4.0, one of their concerns being the susceptibility to external breakdown [10][8][9][10].

Engineers, to order environments, develop Lean methodologies to accelerate delivery time among other techniques. Lean practices such as Just In Time (JIT) and Visual Management show how certain areas improve the potential impacts of business performance as well as the overall Supply Chain [11]. In addition to Lean, Green is another paradigm that focuses on the requirements that I4.0 makes, from product and process design, production planning and control, and communication with suppliers. Furthermore, the flexibility in the development of shared communication with suppliers is a fundamental requirement for the competitiveness of the Supply Chain [12]. To achieve this required competitiveness, in addition to enhancing management and sustainability in the Supply Chain, aerospace companies demonstrate the impact of product life management (PLM) systems by managing the entire product life cycle, from the first marketing idea to the after-sales service [13].

With regard to the digitalization of the framework processes of the Supply Chain, technologies such as the Internet of Things become important for companies in the sector interested in the transformation of Industry 4.0. Management principles that improve performance throughout the company focused on the involvement of employees in decision making, and two applications are the most suitable for the implementation of this technology: TQM (total quality management), which is a CRM (Customer Relationship Management) application that allows centralizing in a single database all interactions between a company and customers and the management of relationships with suppliers, and SRM (Supplier Relationship Management), with the intention of establishing positive relationships with the company. In addition, these are also used in the reduction of carbon emissions and the adoption of Green concepts [14].

It could be said that the Internet of Things collaborates closely on energy management in smart factories, smart logistics and transport, and creating smart business models. This is done in four main areas: (1) designing incentive mechanisms to promote green consumer behavior; (2) improving visibility throughout the product life cycle; (3) increasing system efficiency while reducing development and operational costs; and (4) encouraging sustainability monitoring and reporting performance in Supply Chain networks [15].

Moreover, the Internet of Things becomes more important in terms of the need to be able to visualize information in real time [16], as well as the existing improvement in after-sales services achieved through the sensors placed in its products, together with the Big Data technology, which reports on their performance, defects, and usage patterns in the hands of the customer. This fact has changed the business model, and the manufacturer has become the solution to the problem [17].

In this way, the importance of Big Data is confirmed due to the critical challenge that these factories have to process so much information. These intelligent systems are capable of monitoring and controlling the processes of the Supply Chain as well as providing information on breakdowns for the entire system of planning and control of production and finally providing useful solutions to employees [16].

With respect to Additive Manufacturing, it plays an important role in the viability of a complex product. Together with the freedom of product design, the ability to customize and the variety of products are determining factors in the competitiveness of the Supply Chain [18]. The environmental impact, health, and safety seems to be contemplated in this technology that marks a trend in terms of resource consumption [16,18][16][18]. The impact of the technology on production strategy, technical requirements and distribution is still to be resolved [18].

Within the study that allows the development of a conceptual model of the Supply Chain using Blockchain technology, it becomes evident that, as in companies in the aerospace sector, the top management is responsible for making strategic decisions and therefore for designing and implementing sustainability in the organization [15,19][19].

2.2. Shipbuilding

In the case of shipbuilding, there are only five articles that meet the search criteria from which only one had to be removed, which will be analyzed below. In the same way as in the previous section covering the aerospace sector, this section also considers the Engineer-to-order type of production. Thus, this sector faces the same problem of susceptibility to external breakdowns due to the difficulty of small enterprises to adapt to Industry 4.0 [10]. In the same way, the Lean methodology provides benefits in the Engineer-to-order environment, together with the relationship between digital and information technology of the I4.0, which is considered as an established term in the Lean Supply Chain [20].

In addition to the Lean paradigm, there are other Supply Chain Paradigms studied for the shipbuilding sector such as Green, Agile, and Resilient, which in combination with the enabling technologies stand out from the others in Big Data Analysis focused on the reduction of emissions. Data processing enables the reliability and security of data to quantify CO2 emissions from ships and provide information on energy efficiency parameters [21]. Other techniques include optimizing the energy efficiency of the ship by analyzing the energy transfer between the hull, propeller, and main engine; analyzing the optimal engine speeds [22]. After analyzing the data collected, including sea currents, waves, and winds, along with engine logging data, location, and speed, it is possible to predict ship performance, reduce fuel consumption, and thus reduce emissions [23], even by analyzing historical data as a basis for estimating future accidents [24].

Other technologies focused on Supply Chain sustainability are Cloud Computing, Cybersecurity, and Blockchain [25]. Cloud Computing studies the optimization of virtual machine placement. This is a great challenge in terms of the number of physical machines with the aim of reducing energy costs and waste of resources, in addition to minimizing operating expenses dedicated to the target platform [26], in collaboration with other technologies allowing a rapid diagnosis of system efficiency, in particular engine breakdown [27], in addition to collaborating in the sustainable development of the marine economy [28].

Cybersecurity has an important role to ensure the safe operation of ships, in addition to improving the environmental safety of the oceans. With the intention of complying with international regulations, the available resources are studied by analyzing the methods and policies of maritime cybersecurity that guarantee these aspects [29]. At the same time, there are publications that aim to inform staff to help protect cyberspace from adversaries through an introductory view of systems that help manage cyberspace security that simplifies the complexity of cyberspace and the variety of possible attacks.

As for the energy efficiency of cryptocurrencies, Blockchain technology tries to implement and change to more efficient algorithms such as the Proof of Stake (PoS), leaving behind the use of the Proof by Work (PoW) algorithm used to achieve energy sustainability [30].

In the aeronautical sector, these technologies have also taken on a leading role with regard to the sustainability of the Supply Chain, but there is no evidence of this from Cybersecurity. This does not mean that the sector has not focused on the study of this technology; there is evidence related to the characterization of digital manufacturing systems, identification of threats and vulnerability, control, and determination of risks [31].

There are studies that show the benefits of Blockchain, Internet of Things, and Fog Computing technologies in the application to a system that allows the identification and tracking of the pipes of a ship during its construction [32]. Likewise, no publications on Fog Computing technology have been published in the aeronautical sector as a technology that drives the Supply Chain and its sustainability, although in the same way as Cybersecurity, it does in other areas [33].

The Internet of Things has also been applied in other sector companies revealing a great impact on the performance of the Supply Chain and highlighting the potential for improvement not only in the economic but also in the environmental and social sustainability aspects. Its use allows a sustainable development in collaboration with the strategic and organizational management of the companies. In addition, it offers solutions attending to criteria such as the management of services or operations from the perspective of business based on intelligent operations [34].

2.3. Automotive

In the case of the automotive industry, there are a total of 54 publications, of which two have been eliminated and three have been evaluated in the sectors studied. In this case, and to consider the difference of the previous sectors, the type of production corresponds to the mass production; however, the Lean methodology is also present in this type of production.

One of the improvements in the operation and control of the plant is done through the relationships of the key performance indicators (KPIs). This performance measurement system of a Lean production system provides answers at the strategic, tactical, and operational levels in the implementation of I4.0 projects [35]. In addition to the contribution of Lean guaranteeing an efficient use of resources, in combination with Agile, they act as drivers for the general improvement of performance. As a decision support tool for decision making by identifying potential I4.0 technologies, the Lean–Agile combination adopts strategies that help achieve the overall objectives of the organization [36].

Another possible combination with Lean that is used as a lever to strengthen relationships is with Green practices. The result in this case would be Green Supply Chain Management, where Lean facilitates the collaboration with suppliers and environmental programs. At the same time, following a process innovation strategy based on I4.0 technologies, in addition to improving the Lean effect, leads to better economic results. However, companies will have to choose to obtain better performance by charging suppliers in environmental programs or by investing in I4.0 technologies, but not in both [37]. This is because innovation in technologies does not have the same impact on the Green Supply Chain; if the intention is to improve performance by targeting technologies, then Green is not being improved and vice-versa.

In the same way, it has been demonstrated that I4.0 technologies do not improve the performance of the Lean Supply Chain, and it can be negative to think that better results will be achieved by acquiring a technology than through management practices [38]. However, there are other studies that indicate that the Green and Lean approach can improve the content of I4.0 by adapting product and process design, manufacturing planning and control, cooperation with suppliers, shared information and customer energy and value through flexibility and process re-engineering, with communication between Supply Chain players being essential. All this makes the Supply Chain more flexible and visible and can be made possible through I.40 enabling technologies [12].

Supported by these information and communication technologies and Lean Manufacturing management methods, a new generation of manufacturing systems is born, which is called a Small Scale Intelligent Manufacturing System that is capable of generating value and meeting customer demands. In addition, in order to carry out Green Manufacturing, a Closed-loop Supply Chain model was developed [39]. This concept of Closed-Loop is not new; it was introduced by Solvang in 2007, defining it as a Supply Chain without waste [40], and it is related to a more current concept such as the circular economy.

This circular economy is favored by the interconnectivity promoted by Industry 4.0 allowing for real-time data collection, communication, and data analysis [41], although the transition between Industry 3.0 and 4.0 presents barriers between the Circular Supply Chain and Industry 4.0 [42]. Among the barriers to implementation of I4.0 are the workforce capable of understanding Industry 4.0, ineffective legislation and control, and short-term corporate objectives. These barriers, combined with the lack of funding for I4.0 initiatives, are causing organizations to develop an integrated strategic approach that is capable of utilizing the improved knowledge of I4.0 and the circular economy in order to take advantage of the increased profits from products and process designs that promote energy efficiency [43].

To achieve the effectiveness of Industry 4.0 in the sustainability of the Supply Chain, initiatives are identified from the organizational, legal, and ethical perspective and technological strategies. Within these technological strategies are the need for integration of technological platforms, data-sharing protocols, and a lack of internet-based network infrastructure [44]. Data-based technology and operations provide opportunities for new methods and operations to become an adopter of Industry 4.0 [45].

In order to know the facilitators of the sustainable Supply Chain, Figure 2 shows the most significant ones looking for the highest demand for digital, horizontal, and vertical integration and End-to-End.

The framework of Supply Chain processes in which the Internet of Things becomes highly important had already been appreciated earlier in the aerospace sector [14]. And the impact it has on the performance of the Supply Chain by improving economic, environmental and social sustainability aspects in shipbuilding [14]. It could therefore be said that the Internet of Things and environmentally friendly practices are the most influential factors in becoming a sustainable and industry-compliant organization 4.0 [46].

This is not the case with Additive Manufacturing, despite the fact that its adoption has many effects from the viability of a complex product, the freedom of design or the ability to mass customize, there are still contradictions with regard to the complexity and flexibility of the Supply Chain in addition to not being profitable in the automotive industry [18]. Just the opposite of the other two sectors

Furthermore, there are studies that show how simulation boosts the flexibility and efficiency of the automotive Supply Chain by using simulation based on multi-objective optimization and developing a decision support model [47]. This flexible simulation-based approach allows risks to be assessed prior to implementation with a positive impact on Supply Chain risk management, saving many real resources, which makes the Supply Chain more sustainable [48,49][48][49].

Another way to achieve sustainability in production is through the use of Just in Time material in the assembly lines; this is achieved by implementing decentralized logistics areas known as supermarkets. At the same time, it was observed how the cost of shipping material across the assembly line is the most influential factor in reducing the total cost of the supermarket. It was through simulation that the optimum location of these supermarkets on the assembly lines was optimized [50]. Hence, the simulation allows us to optimize from a particular point of view any necessary movement by making iterations until the optimal solution is reached. This same concept is used in previous sectors, but there are no simulation-related applications for it.

The simulation also served as a semantic validator of Big Data, due to the fact that the Big Data technology showed indetermination when analyzing the data that could be solved through simulation. This shows that Big Data technology requires improvement [51]. However, it is the analysis of Big Data that drives artificial intelligence to achieve sustainable manufacturing and circular economy capabilities [52].

Figure 2. Sustainable Supply Chain facilitators.

The expected connection in the automotive factories make the amount of shared data very large through the activities of the Supply Chain and in the interaction of product and service in the cloud. This shows the need to implement Cybersecurity through the integration of Supply Chain management—marketing integration [53]. In addition to marketing integration, the other areas addressed within the Supply Chain also benefit from Cybersecurity.

An adaptation of cloud computing with the use of robots, cloud robotics, are key to the virtual creation and integration of computational and physical processes resulting in the Cyber–Physical–Systems key to the transition to the sustainable digital world [54]. These systems make it necessary to analyze Cybersecurity risks in a globalized Supply Chain. Some occur due to cyber-attacks that cause an operational disruption in the SC; others cause an operational disruption affecting the entire Supply Chain, and others are produced by an inappropriate interaction between man and machine [55]. In addition to Cybersecurity, security in the traceability of operations is also necessary, for which a reference architecture of the applicability of Blockchain technology is necessary as well [56].

However, it seems that most companies prefer the implementation of only one technology to the adoption and integration of several. Most of them invest in the Internet of Things, Cloud Computing, or Radio Frequency Identification due to the optimization of resources, ease of access from anywhere, or for decision-making based on visibility. Others choose Big Data Analytics because of the speed in detecting failures with a better customer service and reduction of preventive maintenance. Furthermore, some companies rely on Blockchain to improve the traceability and transparency, which increases trust with stakeholders [57]. Several of these technologies such as Robotics, Automated Guided Vehicles, or Additive Manufacturing help reduce wasted resources and emissions by setting up a collaborative program. Thereby, when innovation costs are shared, the motivation to invest more is greater, and this translates into better Supply Chain performance [58]. It can be said that either the actors in the Supply Chain work collaboratively and support each other, or there will be no success in the performance of the Supply Chain [38]. It seems fundamental for the growth of Industry 4.0 and the coordination between the entities of the Supply Chain to establish models in daily environments, competition, and cost-sharing contracts [59].

In spite of seeking solutions such as collaboration, there is a lot of resistance that companies encounter when it comes to putting into practice the management changes that a sustainable Supply Chain carries out. As mentioned above, the size of companies has an influence, making it easier for larger companies to implement changes than for smaller ones. Another barrier is found at the level of employees and middle management in the face of increased control and performance measurement in real time, fearing changes in management [60,61] [60][61] in addition to the lack of knowledge on the part of the managers of knowing if they will return the investment and will obtain benefit nor in time [62]. It could be said that one of the biggest problems the automotive industry faces is in management and organization [63]. There are also barriers due to lack of knowledge of I4.0 by suppliers [61]. The lack of technological infrastructure also makes implementation more difficult considering that there is no management support for the implementation of I4.0 [61,62][61][62].

On the other hand, there are findings that show that neither customer loyalty nor satisfaction is relevant to the success of Supply Chain management. The customer experience will be a differentiator in the future, and it will work to maintain the support of the rest of the factors [64].

However, there are still areas to be exploited that can be beneficial in the automotive industry [65]. In order to help the leaders of the companies make their plants intelligent, it is clear that there is a need for integration, collaboration, and transparency of all the members of the chain [66]. Leaders are encouraged to establish sustainable policies, training programs focused on I4.0 and to consider I4.0 as a strategic decision to improve costs, reduce resources and energy consumption, and contribute to the development of healthy societies [44]. However, this integration, behavior, and trust will be reflected when it is manifested by including the concept in the vision and mission of their organizations [13].

One of the proposals still to be developed is the servicing of Supply Chain management with respect to I4.0 applications [67]. Another is the implementation of I4.0 concepts at multiple levels of the Supply Chain. Within this multi-stage implementation proposal, they discourage talkers that go from a cultural, multifunctional approach and continuous improvement. It proposes to start from the focus organization for later integration of the partner organizations until arriving at the intelligent factory where the Supply Chains are connected among themselves and with their systems and the machines are linked to a common network system [68]. Finally, the proposal relating to installations and the application to the recovery of the value of the product at the end of its life cycle could be mentioned [69].

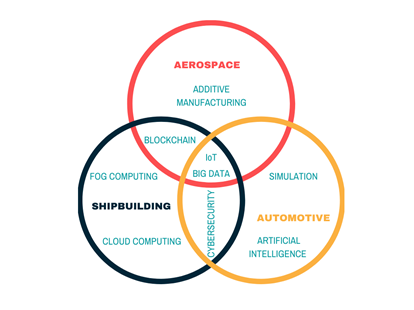

Figure 3 shows, as a summary, the technologies that each of the sectors studied considers applicable to boost sustainability in the Supply Chain. It shows how only Big Data and the Internet of Things are common to all three sectors. Similarly, Figure 4 shows the methodologies and practices that each of the sectors studied apply to the sustainable Supply Chain.

Figure 3. Focus technologies in Supply Chain Management (SCM) digitalization.

Figure 4. Sustainable Supply Chain-driving methodologies.

References

- Chopra, S.; Meindl, P. Administración de la Cadena de Suministro; Cruz Castillo, L.M., Gutierrez Hernández, B., Eds.; 5th.; Pearson Educación, S.A.: México, México, 2013; ISBN 978-607-32-2133-7.

- Heizer, J.; Render, B. How China Sees America; Cañizal, A., Bazaco, E., Eds.; 8th.; Pearson Educación, S.A.: Madrid, Spain, 2012; Volume 91; ISBN 9788578110796.

- Ballou, R.H. The evolution and future of logistics and supply chain management. Eur. Bus. Rev. 2007, 19, 332–348, doi:10.1108/09555340710760152.

- Sanchez Loppacher, J. Compitiendo a Través de la Cadena del Negocio. Supply Chain Management; Scarfi, J., Ed.; 1st.; Temas Grupo Editorial: Buenos Aires, Argentina, 2013; ISBN 9789871826568.

- Biswal, J.N.; Muduli, K.; Satapathy, S. Critical analysis of drivers and barriers of sustainable supply chain management in Indian thermal sector. Int. J. Procure. Manag. 2017, 10, 411–430, doi:10.1504/IJPM.2017.085033.

- Pirvulescu, P.; Enevoldsen, P. Supply Chain management in the age of digitalization. Int. J. Supply Chain Manag. 2019, 8, 414–428.

- Felsberger, A.; Reiner, G. Sustainable Industry 4.0 in Production and Operations Management: A Systematic Literature Review. Sustainability 2020, 12, 7982, doi:10.3390/su12197982.

- Vera Carrasco, O. Cómo escribir artículos de revisión. Rev. Med. La Paz 2009, 15, 63–69.

- Briner, R.B.; Denyer, D.; Rousseau, D. Systematic Review and Evidence Synthesis as a Practice and Scholarship Tool. In The Oxford Handbook of Evedence-Based Management; Press, O.U., Ed.; Oxford University Press: New York, NY, USA, 2012; pp. 112–129.

- Müller, J.M.; Voigt, K.I. The Impact of Industry 4.0 on Supply Chains in Engineer-to-Order Industries - An Exploratory Case Study. IFAC PapersOnLine 2018, 51, 122–127, doi:10.1016/j.ifacol.2018.08.245.

- Haddud, A.; Khare, A. Digitalizing supply chains potential benefits and impact on lean operations. Int. J. Lean Six Sigma 2020, 11, 731–765, doi:10.1108/IJLSS-03-2019-0026.

- Duarte, S.; Cruz-Machado, V. An investigation of lean and green supply chain in the Industry 4.0. Proc. Int. Conf. Ind. Eng. Oper. Manag. 2017, 2017, 255–265.

- Masudin, I.; Wastono, T.; Zulfikarijah, F. The effect of managerial intention and initiative on green supply chain management adoption in Indonesian manufacturing performance. Cogent Bus. Manag. 2018, 5, 1–19, doi:10.1080/23311975.2018.1485212.

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953, doi:10.1016/j.cie.2018.11.030.

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064, doi:10.1016/j.resconrec.2020.105064.

- Kiel, D. What do we know about “Industry 4. 0” so far ? [rewarded with IAMOT Best Student Paper Award]. Int. Assoc. Manag. Technol. 2017, 2, 9–22.

- Omar, Y.M.; Minoufekr, M.; Plapper, P. Business analytics in manufacturing: Current trends, challenges and pathway to market leadership. Oper. Res. Perspect. 2019, 6, 100127, doi:10.1016/j.orp.2019.100127.

- Franco, D.; Miller Devós Ganga, G.; de Santa-Eulalia, L.A.; Godinho Filho, M. Consolidated and inconclusive effects of additive manufacturing adoption: A systematic literature review. Comput. Ind. Eng. 2020, 148, 106713, doi:10.1016/j.cie.2020.106713.

- Nayak, G.; Dhaigude, A.S. A conceptual model of sustainable supply chain management in small and medium enterprises using blockchain technology. Cogent Econ. Financ. 2019, 7, doi:10.1080/23322039.2019.1667184.

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Martínez-Jurado, P.J. Information and digital technologies of Industry 4.0 and Lean supply chain management: A systematic literature review. Int. J. Prod. Res. 2020, 58, 5034–5061, doi:10.1080/00207543.2020.1743896.

- Zaman, I.; Pazouki, K.; Norman, R.; Younessi, S.; Coleman, S. Challenges and opportunities of big data analytics for upcoming regulations and future transformation of the shipping industry. Procedia Eng. 2017, 194, 537–544, doi:10.1016/j.proeng.2017.08.182.

- Yan, X.; Wang, K.; Yuan, Y.; Jiang, X.; Negenborn, R.R. Energy-efficient shipping: An application of big data analysis for optimizing engine speed of inland ships considering multiple environmental factors. Ocean Eng. 2018, 169, 457–468, doi:10.1016/j.oceaneng.2018.08.050.

- Anan, T.; Higuchi, H.; Hamada, N. New artificial intelligence technology improving fuel efficiency and reducing CO2 emissions of ships through use of operational big data. Fujitsu Sci. Tech. J. 2017, 53, 23–28.

- Hamedifar, H.; Spitzenberger, C.; Stahl, C.; Brown, A.; Nilberg, B.; Demay, V.; Aspholm, O. Terminal and transportation risk assessment for LNG export in North America. In Proceedings of the Petroleum Abstracts, Houston, TX, USA, 04–07 May 2015; Volume 55, pp. 112–113.

- Ramirez-Peña, M.; Fraga, F.J.A.; Salguero, J.; Batista, M. Assessing sustainability in the shipbuilding supply chain 4.0: A systematic review. Sustainability 2020, 12, doi:10.3390/SU12166373.

- Riahi, M.; Krichen, S. A multi-objective decision support framework for virtual machine placement in cloud data centers: a real case study. J. Supercomput. 2018, 74, 2984–3015, doi:10.1007/s11227-018-2348-z.

- Carbone, R.; Montella, R.; Narducci, F.; Petrosino, A. DeepNautilus: A Deep Learning Based System for Nautical Engines’ Live Vibration Processing. In Proceedings of the Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2019; Volume 11679 LNCS, pp. 120–131.

- Ju, D.; Shen, B. Sustainable development of marine economy guided by knowledge cloud services. In Proceedings of the 2nd International Conference on Networking and Distributed Computing, ICNDC 2011, Beijing, China, 21–24 September 2011; pp. 235–239.

- McGillivary, P. Why maritime cybersecurity is an ocean policy priority and how it can be addressed. Mar. Technol. Soc. J. 2018, 52, 44–57, doi:10.4031/MTSJ.52.5.11.

- Koštál, K.; Krupa, T.; Gembec, M.; Vereš, I.; Ries, M.; Kotuliak, I. On transition between PoW and PoS. In Proceedings of the International Symposium Electronics in Marine, Zadar, Croatia, 16–19 September 2018; Volume 2018-Septe, pp. 207–210.

- Wu, D.; Ren, A.; Zhang, W.; Fan, F.; Liu, P.; Fu, X.; Terpenny, J. Cybersecurity for digital manufacturing. J. Manuf. Syst. 2018, 48, 3–12, doi:10.1016/j.jmsy.2018.03.006.

- Fernández-Caramés, T.M.; Fraga-Lamas, P.; Suárez-Albela, M.; Díaz-Bouza, M.A. A fog computing based cyber-physical system for the automation of pipe-related tasks in the industry 4.0 shipyard. Sensors (Switzerland) 2018, 18, doi:10.3390/s18061961.

- Malik, S.; Azur, K.M.; Rouf, R.; Kontsos, A. The industry internet of things (IIoT) as a methodology for autonomous diagnostics, prognostics in aerospace structural health monitoring. Struct. Health Monit. 2019, 1, 1007–1015, doi:10.12783/shm2019/32214.

- Mastos, T.D.; Nizamis, A.; Vafeiadis, T.; Alexopoulos, N.; Ntinas, C.; Gkortzis, D.; Papadopoulos, A.; Ioannidis, D.; Tzovaras, D. Industry 4.0 sustainable supply chains: An application of an IoT enabled scrap metal management solution. J. Clean. Prod. 2020, 269, 122377, doi:10.1016/j.jclepro.2020.122377.

- Ante, G.; Facchini, F.; Mossa, G.; Digiesi, S. Developing a key performance indicators tree for lean and smart production systems. IFAC PapersOnLine 2018, 51, 13–18, doi:10.1016/j.ifacol.2018.08.227.

- Raji, I.O.; Rossi, T. Exploring industry 4. 0 technologies as drivers of lean and agile supply chain strategies. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Toronto, Canada, 23-25 Octuber 2019; pp. 292–303.

- De Giovanni, P.; Cariola, A. Process innovation through industry 4.0 technologies, lean practices and green supply chains. Res. Transp. Econ. 2020, 100869, doi:10.1016/j.retrec.2020.100869.

- Tortorella, G.; Miorando, R.; Mac Cawley, A.F. The moderating effect of Industry 4.0 on the relationship between lean supply chain management and performance improvement. Supply Chain Manag. 2019, 24, 301–314, doi:10.1108/SCM-01-2018-0041.

- Yu, H.; Solvang, W.D. Enhancing the competitiveness of manufacturers through Small-scale Intelligent Manufacturing System (SIMS): A supply chain perspective. 2017 6th Int. Conf. Ind. Technol. Manag. ICITM 2017 2017, 101–107, doi:10.1109/ICITM.2017.7917904.

- Wei, D.; Solvang, Ziqiong Deng, B.S. A Closed-loop Supply Chain Model for Managing Overall Optimization of Eco-efficiency. In Proceedings of the POMS 18th Annual Conference, Dallas, TX, USA; 2007; pp. 007-0582(14).

- Takhar, S.S.; Liyanage, K. The impact of Industry 4.0 on sustainability and the circular economy reporting requirements. Int. J. Integr. Supply Manag. 2020, 13, 107–139, doi:10.1504/IJISM.2020.107845.

- Ozkan-Ozen, Y.D.; Kazancoglu, Y.; Kumar Mangla, S. Synchronized Barriers for Circular Supply Chains in Industry 3.5/Industry 4.0 Transition for Sustainable Resource Management. Resour. Conserv. Recycl. 2020, 161, 104986, doi:10.1016/j.resconrec.2020.104986.

- Kumar, P.; Singh, R.K.; Kumar, V. Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resour. Conserv. Recycl. 2021, 164, 105215, doi:10.1016/j.resconrec.2020.105215.

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179, doi:10.1016/j.psep.2018.04.018.

- Avilés-Sacoto, S.V.; Avilés-González, J.F.; García-Reyes, H.; Bermeo-Samaniego, M.C.; Cañizares-Jaramillo, A.K.; Izquierdo-Flores, S.N. A glance of industry 4.0 at supply chain and inventory management. Int. J. Ind. Eng. Theory Appl. Pract. 2019, 26, 486–506.

- Bhagawati, M.T.; Manavalan, E.; Jayakrishna, K.; Venkumar, P. Identifying Key Success Factors of Sustainability in Supply Chain Management for Industry 4.0 Using Dematel Method; Proceedings of International Conference on Intelligent Manufacturing and Automation. Lecture Notes in Mechanical Engineering, Tokyo, Japan, 27-30th September 2019; Springer: Singapore, 2019; https://doi.org/10.1007/978-981-13-2490-1_54.

- Ivanov, D.; Das, A.; Choi, T.M. New flexibility drivers for manufacturing, supply chain and service operations. Int. J. Prod. Res. 2018, 56, 3359–3368, doi:10.1080/00207543.2018.1457813.

- Schluter, F.; Hetterscheid, E. A Simulation Based Evaluation Approach for Supply Chain Risk Management Digitalization Scenarios. 2017 Int. Conf. Ind. Eng. Manag. Sci. Appl. ICIMSA 2017, 1–5, doi:10.1109/ICIMSA.2017.7985579.

- Hoffa-Dabrowska, P.; Grzybowska, K. Simulation modeling of the sustainable supply chain. Sustainability 2020, 12, doi:10.3390/su12156007.

- Fathi, M.; Nourmohammadi, A.; Ghobakhloo, M.; Yousefi, M. Production sustainability via supermarket location optimization in assembly lines. Sustainability 2020, 12, doi:10.3390/su12114728.

- Vieira, A.A.; Dias, L.M.; Santos, M.Y.; Pereira, G.A.; Oliveira, J.A. On the use of simulation as a Big Data semantic validator for supply chain management. Simul. Model. Pract. Theory 2020, 98, 101985, doi:10.1016/j.simpat.2019.101985.

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. Int. J. Organ. Anal. 2020, doi:10.1108/IJOA-04-2020-2120.

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346, doi:10.1108/BPMJ-04-2017-0088.

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital supply chain model in Industry 4.0. J. Manuf. Technol. Manag. 2019, doi:10.1108/JMTM-08-2018-0280.

- Pandey, S.; Singh, R.K.; Gunasekaran, A.; Kaushik, A. Cyber security risks in globalized supply chains: conceptual framework. J. Glob. Oper. Strateg. Sourc. 2020, 13, 103–128, doi:10.1108/JGOSS-05-2019-0042.

- Bodkhe, U.; Tanwar, S.; Parekh, K.; Khanpara, P.; Tyagi, S.; Kumar, N.; Alazab, M. Blockchain for Industry 4.0: A comprehensive review. IEEE Access 2020, 8, 79764–79800, doi:10.1109/ACCESS.2020.2988579.

- Raut, R.D.; Gotmare, A.; Narkhede, B.E.; Govindarajan, U.H.; Bokade, S.U. Enabling Technologies for Industry 4.0 Manufacturing and Supply Chain: Concepts, Current Status, and Adoption Challenges. IEEE Eng. Manag. Rev. 2020, 48, 83–102, doi:10.1109/EMR.2020.2987884.

- Liu, B.; De Giovanni, P. Green process innovation through Industry 4.0 technologies and supply chain coordination. Ann. Oper. Res. 2019, doi:10.1007/s10479-019-03498-3.

- Ghosh, D.; Sant, T.G.; Kuiti, M.R.; Swami, S.; Shankar, R. Strategic decisions, competition and cost-sharing contract under industry 4.0 and environmental considerations. Resour. Conserv. Recycl. 2020, 162, 105057, doi:10.1016/j.resconrec.2020.105057.

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Change 2019, 146, 119–132, doi:10.1016/j.techfore.2019.05.021.

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and supply chain sustainability: framework and future research directions. Benchmarking 2018, doi:10.1108/BIJ-03-2018-0056.

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. EMJ Eng. Manag. J. 2020, 00, 1–15, doi:10.1080/10429247.2020.1783935.

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112, doi:10.1016/j.jclepro.2020.120112.

- Princes, E. Facing disruptive challenges in supply chain 4.0. Int. J. Supply Chain Manag. 2020, 9, 52–57.

- Schniederjans, D.G.; Curado, C.; Khalajhedayati, M. Supply chain digitisation trends: An integration of knowledge management. Int. J. Prod. Econ. 2020, 220, 107439, doi:10.1016/j.ijpe.2019.07.012.

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on supply chain performance. Prod. Plan. Control 2020, 0, 1–19, doi:10.1080/09537287.2020.1712487.

- Tabaklar, T.; Yildirim, C. The development of servitization concept in the era of industry 4.0 through SCM perspective. Handb. Res. Strateg. Fit Des. Bus. Ecosyst. 2019, 593–615, doi:10.4018/978-1-7998-1125-1.ch026.

- Shao, X.F.; Liu, W.; Li, Y.; Chaudhry, H.R.; Yue, X.G. Multistage implementation framework for smart supply chain management under industry 4.0. Technol. Forecast. Soc. Change 2021, 162, doi:10.1016/j.techfore.2020.120354.

- Ivascu, L. Measuring the implications of sustainable manufacturing in the context of industry 4.0. Processes 2020, 8, 1–20, doi:10.3390/PR8050585.