Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Muhammad Uzair Javed and Version 2 by Jessie Wu.

The treatment of living organisms is a critical aspect of various environmental and industrial applications, ranging from wastewater treatment to aquaculture. Algal membrane bioreactors (AMBRs) combine membrane separation with biological treatment. The layout of a biological reactor is designed in such a way that it promotes the production of microorganisms that need oxygen and dissolved organic carbon to reproduce. A membrane separates microorganism biomass from wastewater before removing bacteria and suspended particulates.

- algal-based hollow fiber membrane bioreactors

- wastewater treatment

- living organisms

- sustainable

1. Nutrient Removal and Wastewater Treatment

Currently, microalgae are among the most promising renewable raw resources for producing several subproducts [1][2][54,55]. Microalgae are appealing from both an economic and environmental standpoint, as during their cultivation and processing, carbon dioxide (CO2) emissions from burning may be captured, and wastewater may be treated [3][4][5][56,57,58]. Due to their low costs and associated environmental advantages, the high-potential method for tertiary treatment in wastewater treatment facilities is microalgae-based systems (WWTPs) (Table 1) [6][7][8][9][10][11][12][13][14][15][16][17][59,60,61,62,63,64,65,66,67,68,69,70].

Table 1.

Features of several algae-based membrane bioreactor methods.

| Method | Membrane Type | Algae Species | Aim | References |

|---|---|---|---|---|

| Photobioreactor MBR | Flat-sheet membranes | Microlagae (Spirulina Chlorella) |

|

[8][61] |

| Suspended Algae MBR | Submerged membranes | Mixed algal consortium |

|

[9][62] |

| Immobilized Algae MBR | Immobilized algae films | Immobilized microalgae or cyanobacteria |

|

[10][11][63,64] |

| Photobioreactor MBR | High-density polyethylene (HDPE) hollow fiber microfiltration | Chlorella sp. ADE4, Chlorella vulgaris |

|

[12][65] |

| Tubular Algae MBR | Tubular membranes | Diatoms (Navicula) |

|

[13][14][66,67] |

| Photobioreactor MBR | Polyvinylidenefluoride (PVDF) hollow fiber microfilter (MF) membrane | Algae-bacterial consortium (species not specified) |

|

[15][68] |

| Submerged Algae MBR | Hollow fiber membranes | Chlorella and Scenedesmus |

|

[16][69] |

| Polyvinylidenefluoride (PVDF) hollow fiber membranes with nano- TiO2 | Chlorella vulgaris |

|

[17][70] | |

| Polyvinylidenefluoride (PVDF) | Chlorella emersonii |

|

[18][71] | |

| Polyvinylidenefluoride (PVDF) | Chlorella vulgaris |

|

[19][72] |

Wastewater treatment utilizing microalgae consumes 40% less energy to extract nutrients than standard wastewater treatment, which lowers expenses [20][21][22][73,74,75]. It also utilizes less energy overall. On the one hand, nitrogen and inorganic phosphates are utilized by microalgae, which advances the growth of microalgae and also improves oxygen production. On the other hand, coliforms are also eradicated by microalgae since the ambient growth settings for microalgae are unfavorable for these bacteria. The growth of microalgae can be regulated by some limiting factors, mainly phosphorus and nitrogen [23][76]. Scenedesmus sp., Nitzschia spp. Desmodesmus sp., Neochloris sp., Chlorella sp., and Chlamydomonas spp. are some of the genera of microalgae utilized for the treatment of wastewater [7][24][60,77].

Microalgae cultures may be harvested using membrane bioreactors, which is a highly promising technology [25][78]. This is because they use less energy and cost than centrifuges while yet retaining virtually all of the biomass [26][79]. As reported in several papers, the amounts of microalgae in a bioreactor without a membrane are remarkably lower than in an MBR [19][26][72,79]. Moreover, since the solid retention time (SRT) in a membrane bioreactor differs from the hydraulic retention time (HRT), membrane filtration in a membrane bioreactor avoids the washing out of the microalgae culture. Higher yields and biomass concentrations are attained with this approach [26][27][79,80]. Handling household wastewater, which has relatively low nitrogen and phosphorus contents, also influences the concentration of nutrients [28][81]. The decrease in volume that results from the elimination of nutrients found in urban wastewater is another benefit of utilizing algal-based membrane bioreactors (AMBR) [26][79].

However, if the effluent is untreated wastewater, a possible drawback of MBRs is that it may cause the microalgae strains that are being cultured in the effluent to die, in which case a suitable pre-treatment must be designed. In a similar way, it is critical to carefully choose the microalgae species that will be grown because not all of them can adjust to the wastewater’s circumstances [29][82]. The significant danger that the microalgae culture might get contaminated and the time-consuming and expensive labor required for microalgae harvesting are two additional drawbacks of these algal membrane bioreactors (AMBRs) [30][83].

The study by Merriman et al. [31][84] evaluated how mass transfer affected three distinct methods of delivering gas: bubbling through an open tube, a porous diffuser, and a unique hollow fiber membrane (HFM) manifold. The utilization of hollow fiber membranes demonstrated a significantly superior approach to bubbling and a commercial diffuser to be employed in thin-film algae growth systems like the Algal Turf Scrubber technology in terms of how successfully they delivered CO2 gas into the system [31][84]. In another study, nano-TiO2 additives were produced and used in polyvinylidene fluoride (PVDF) hollow fiber membranes for high-density algae (Chlorella vulgaris) production. The membranes with nano-TiO2 inserted displayed increased surface hydrophilicity and a total resistance that was around 50% less than the control. This woresearchk showed that high-density algae cultivation and wastewater cleaning benefitted from the improved antifouling capability of PVDF/TiO2 nanocomposite membranes [19][72]. Conclusively, algal-based hollow fiber membrane bioreactors offer a promising method for the elimination of nutrients and treatment of wastewater, particularly in the field of biological wastewater management, because it is an affordable, environmentally friendly, and high-throughput approach, contributing to the fortification of water bodies from eutrophication and related ecological imbalances.

2. Bioremediation of Contaminated Water Bodies

In the 21st century, people are extremely concerned about the global water problems and resource depletion brought on by exponential population expansion, industrialization, and urbanization. Numerous sectors have grown as a result of the global surge in human population. It is, therefore, essential to have excessive water resources on hand and the creation of excellent effluent by employing suitable treatment methods. Although wastewater has a negative influence on the well-being of ecosystems and the health of individuals, it also contains precious materials that are very useful economically. According to Barros et al. [32][85], it is possible to recycle wastewater and use the rare earth resource elements praseodymium (Pr), terbium (Tb), cerium (Ce), yttrium (Y), lanthanum (La), and europium (Eu) once more in the cycle of production. The market value of these recycled rare earth metals is significant, varying from USD 4.50 per kg to USD 95 per kg. Even though resource recovery from wastewater is a new field, interest in it will increase as the world’s population rises and resources become scarcer.

It is currently regarded as a crucial tactic for bioremediating water bodies while maximizing resource recovery since it has acquired a lot of traction. This cutting-edge strategy seizes the chance to improve resource extraction while also taking on the crucial duty of cleaning up contaminated water sources. Hollow fiber membrane bioreactors (HFMBR) stand out as key contributors to the development of this prospective solution because of their practical and efficient methodology. AHFMBRs stand out even more in this context since they offer a wide range of advantages while creating the fewest challenges.

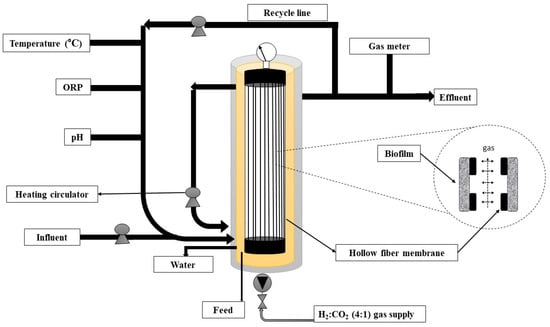

HFMBRs provide various benefits, including high efficiency, ease of operation at normal pressures, and reduced operational costs. Additionally, with HFMBR systems, the membrane separates the feed and stripping solution; as a result, the issue of flooding, diversion, and foaming may be efficiently avoided. The membrane bioreactor’s performance completely depends on its hydrophobicity characteristics, which, with time, may degrade owing to a wetting issue. In order to retain the membrane’s resilience under challenging circumstances during wastewater treatment, much work has been conducted to enhance its qualities. Figure 14 displays a schematic representation of a hollow fiber membrane biofilm reactor system.

Figure 14.

Schematic diagram of hollow fiber membrane biofilm reactor system.

3. Pharmaceuticals and Personal Care Product Removal

Although existing wastewater treatment approaches have a high treatment efficiency for conventional contaminants, they are not capable of stripping off arising contaminants (ECs), such as pharmaceutical items and personal care products (PPCPs). Contaminants from PPCPs are now widely distributed and have been documented in 71 nations, including Antarctic areas [33][34][86,87]. As PPCPs are often persistent in the environment, they must be eliminated using cutting-edge, environmentally friendly treatment methods. Their entry into the aquatic environment is one of the prime concerns. PPCPs and their metabolites have often been found in sediments, biotic elements, surface waters, and the ground at concentrations varying from ng/L to g/L [35][88]. Because of their distinctive physiochemical characteristics and stable nature, they may survive in the environment for a long period of time. The effluent discharge from wastewater treatment facilities (WWTPs) is one of the main ways that PPCPs enter the aquatic system. Additionally, PPCP toxins can leak into groundwater and surface waterways when municipal solid waste dumps also include rejected PPCPs [34][87].

According to Pai et al. [36][89], some present solutions may offer restricted removal, such as 11.9–41.2% from the filtering approach [34][87]. According to the study by Ramirez-Morales et al. [37][90], 47% of the 70 medicines from wastewater treatment plants that were tested were discharged into the effluent, providing a health risk to those who drank recycled water [37][90]. Although PPCPs are found in treated wastewater at much lower concentrations (ng/L) [38][39][91,92], they have significant functional impacts, like the induction of intersexuality and antibiotic resistance genes, a reduction in aquatic sperm counts, and impacts on the endocrine system. AHFMBR has developed as a favorable equipment for the mitigation of PPCPs from wastewater [40][41][42][93,94,95].

Through biotransformation processes, microalgae exhibit the ability to absorb, metabolize, and degrade a range of medicinal and personal care compounds. Increased contact time between the microalgae and the PPCPs because of the inclusion of hollow fiber membranes in AHFMBRs increases the removal efficiency [43][96]. This cutting-edge method not only tackles the rising issue of PPCP pollution in aquatic habitats but also provides a long-term, low-cost method for removing it from wastewater treatment operations [44][97]. Additionally, ongoing research in this field continues to optimize algal-based hollow fiber membrane bioreactor systems for enhanced PPCP removal, making it a promising technology in the pursuit of cleaner water resources.

A study by Schmitt et al. [45][98] evaluated ozonation with a hollow fiber membrane bioreactor for pharmaceutical abatement and bromate reduction and compared its functioning with that of bubble columns in wastewater. The results of this researchtudy demonstrated that HFMBR can create a noticeable concentration of hydroxy radicals while restricting bromate production in real treated wastewater [45][98]. In another study, carbamazepine, sulfadimidine, sulfamethoxazole, atenolol, norfloxacin, and primidone elimination properties of two distinct charged composite hollow fiber nanofiltration (NF) membranes were characterized. The charge, molecular weight, and hydrophilicity of the various medicinal compounds were examined in relation to their saturation adsorption behaviors on each membrane surface. The findings showed that both the PEI-NF and PIP-NF membranes initially exhibited a very high adsorption rate before reaching adsorption equilibrium. Due to the molecular weight, charge, and hydrophilicity of the pharmaceutical molecules, there were no glaring disparities in the saturation adsorption times of the various pharmaceutical molecules on the two membrane surfaces [46][99]. Furthermore, the study by Wei et al. [47][100] showed how effectively positively charged hollow fiber NF membranes (PFI-NF) remove PPCPs and environmental estrogenic hormones (EEHs). By adjusting the operating pressure, temperature, ionic strength, and cation species, the separation properties were assessed. Pharmaceutical compounds’ rejection by the PEI-NF membrane was somewhat impacted by both their molecular makeup and diffusion coefficient. Additionally, water samples from genuine tap water plants showed a strong removal effect for PPCPs and EEHs by the PEI-NF membrane [47][100].

The aforementioned studies highlight the potential of hollow fiber membranes in the treatment of PPCPs. Moreover, it provides a viewpoint that the synergistic approach of algal-based hollow fiber membrane bioreactors will manifest as a double-edged sword in this context. Even though there has not been much research done on this approach, experts believe it has a promising future.

3.4. Other Potential Applications

AHFMBRs find applications in various other fields. For example, the study by Vu and Loh [48][101] developed a hollow fiber membrane photobioreactor (HFMP) for microalgal growth and bacterial wastewater treatment. Chlorella vulgaris culture and Pseudomonas putida cultures were circulated through the two sides of each of the HFMP. An HFMP with more fibers was able to produce improved glucose biodegradation, showing how easily the HFMP may be scaled up for improved wastewater treatment effectiveness [48][101]. Moreover, HFMBRs are also utilized in the cultivation of algal biomass, specifically with the aim of biofuel production. By optimizing the flow rates (5–45 mL/min) of culture medium recirculating across the hollow fiber membranes, Roopashri and Makam [49][43] investigated the utility of the HFMP module to boost the microalgal growth rate by means of efficient mass transfer. The findings of this research indicated that the HFMPBR module is a superior option for growing algae to produce a greater amount of biomass [49][43]. Table 2 demonstrates the benefits, applications, and important parameters of different hollow fiber membrane types in bioreactors [50][51][52][53][54][55][56][57][102,103,104,105,106,107,108,109].

Table 2.

Benefits, applications, and important parameters of different hollow fiber membrane types in bioreactors.

| Hollow Fiber Membrane Type | Benefits | Important Parameters | Applications | References |

|---|---|---|---|---|

| Polymeric hollow fiber | Suitable for various water sources Tolerant to chemical cleaning Cost-effective High mechanical strength |

Solute Concentration Transmembrane Pressure (TMP) Crossflow Velocity Backwashing Feedwater Quality Chemical Compatibility Filtration Time Monitoring Membrane Age Membrane Integrity |

Municipal wastewater treatment Industrial wastewater treatment Drinking water purification |

[50][51][102,103] |

| Composite hollow fiber | Improved selectivity Versatile for various applications Enhanced fouling resistance |

Crossflow velocity Solute concentration Chemical cleaning Membrane integrity Monitoring Transmembrane pressure (TMP) Feedwater quality Shear stress |

Industrial wastewater treatment High-temperature water treatment Biopharmaceutical production |

[52][53][104,105] |

| Hollow fiber MBRs | Compact footprint High-quality treated water Efficient simultaneous treatment and filtration |

Crossflow velocity Solute concentration Membrane module design Air scouring Operating temperature Transmembrane pressure (TMP) Backwashing Pre-treatment Chemical cleaning Filtration time Feedwater quality |

Industrial wastewater treatment Municipal wastewater treatment Reuse applications |

[54][55][106,107] |

| Ceramic hollow fibers | Long lifespan Excellent chemical and thermal resistance Suitable for harsh conditions |

Crossflow velocity Chemical cleaning Feedwater quality Solute concentration Operating temperature Transmembrane pressure (TMP) Feedwater quality Shear stress Monitoring Membrane integrity |

High-temperature water treatment Industrial wastewater treatment Biopharmaceutical production |

[56][57][108,109] |

Microalgae use light to convert CO2 and nutrients into biomass, which may then be employed as a biofuel. However, in closed photo-bioreactors, the availability of light and CO2 frequently limits the number of algae that can be produced and can be challenging to manage with conventional diffuser systems [58][110]. A hollow fiber membrane photo-bioreactor (HFMPB) was examined in the study by Kumar et al. [59][111] to enhance the available contact area of interfaces, thus allowing the transfer of gas, treatment of high nutrient strength (412 mg NO3−-N L−1) wastewater, and creation of algal biomass that may be utilized as a biofuel. The findings indicate that an HFMPB is a potential choice for greenhouse gas mitigation since it combines CO2 sequestration, wastewater treatment, and biofuel generation [59][111]. Moreover, the increased compaction, as well as the reduced cost, allows a hollow fiber membrane module to be selected over a flat-sheet configuration in the anaerobic membrane bioreactor (AnMBR) system. Nitrogen and phosphorus are two nutrients found in the effluent from anaerobic wastewater treatment that may potentially be utilized for nonpotable purposes. Industrial wastewater treated with AnMBR results in up to a 20-fold reduction in sludge production over aerobic treatment. Additionally, it lowers the cost of doing business. AnMBR runs at a high sludge retention time (SRT), which guarantees an enhanced rate of COD elimination. This aids the microorganism’s adaptation to the various components of industrial effluent even further [60][112].