Uranium, a cornerstone for nuclear energy, facilitates a clean and efficient energy conversion. In the era of global clean energy initiatives, uranium resources have emerged as a vital component for achieving sustainability and clean power. To fulfill the escalating demand for clean energy, continual advancements in uranium mining technologies are imperative. Currently, established uranium mining methods encompass open-pit mining, underground mining, and in situ leaching (ISL). Notably, in situ leaching stands out due to its environmental friendliness, efficient extraction, and cost-effectiveness. Moreover, it unlocks the potential of extracting uranium from previously challenging low-grade sandstone-hosted deposits, presenting novel opportunities for uranium mining.

- uranium mining

- in situ leaching (ISL)

- permeability modification

- fluid flow

- geochemical reaction

- information system

1. Introduction

2. Permeability Modification Technique for In Situ Leaching

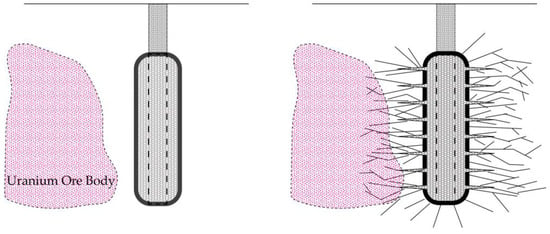

In situ leaching relies on seepage of leaching solution in the porous media of uranium deposits [121][36]. As a result, a key element determining the usability of this mining method and a major barrier to its widespread adoption is the permeability of the uranium deposit [122][37]. In situ leaching techniques are typically considered unsuitable for uranium deposits with low inherent permeability (<0.5 m/d) [123][38]. To address this challenge, many scholars have concentrated their studies on permeability modification techniques for low-permeability uranium deposits, thereby broadening the application of in situ leaching [123,124,125,126][38][39][40][41]. While hydraulic fracturing, a widely used approach for enhancing permeability in oil and gas reservoirs [127[42][43],128], has been proven ineffective for uranium deposits [124][39], blasting-enhanced permeability (BEP) has emerged as a promising and effective technique for this specific context [125][40]. The schematic diagram in Figure 1 illustrates the underlying principle of the BEP technique for enhancing the permeability of uranium deposits. Experimental and simulation methods have substantiated that blasting can initiate well-connected fracture networks. The creation of sustainable and large-scale seepage channels within the networks is a crucial factor in improving the permeability of low-permeability uranium deposits. This enhancement enables subsequent applications of in situ leaching and facilitates the flow of leaching solution [125][40]. This application of BEP in in situ leaching for uranium mining is also referred to as in situ blasting leaching [126][41] or in situ fragmentation leaching [129][44].

3. Prediction Technique for Fluid Flow and Geochemical Reaction for In Situ Leaching

The in situ leaching process of uranium deposits involves intricate fluid flow and geochemical reactions. The fluid flow within the porous media of the ore body, as well as the reactions between the leaching solution and uranium minerals within the ore body, undergo dynamic changes that significantly impact in situ leaching efficiency. To comprehend these dynamic changes more effectively, some scholars have proposed utilizing reactive transport models (RTMs) tailored to the specific characteristics of different uranium deposits to predict these dynamic variations accurately [145,146][61][62]. The reactive transport model plays a crucial role in studying the behavior of solutes in the subsurface environment [147,148,149][63][64][65]. Its wide application extends to predicting fluid behavior in porous media during petroleum and natural gas production [146[62][66],150], as well as in the sequestration of carbon dioxide in saline aquifers [151][67]. In recent years, this technique has progressively been applied to the in situ leaching of uranium deposits. When studying fluid flow and geochemical reactions in uranium deposits using reactive transport models, it is convenient to choose mature commercial and open-source software such as PHREEQC (version 3) [152[68][69],153], MT3DMS (version 5) [154][70], TOUGHREACT (version 4) [155][71], and Geochemist’s Workbench (version 6) [156][72] to directly establish and simulate research models. In cases where customized or advanced simulations are required, it is necessary to utilize programming languages such as Python (version 3), MATLAB (version 2010), and R (version 4) to write code for more flexible control over model implementation and simulation. In laboratory research focused on in situ leaching for uranium mining, column experiments are commonly employed [157,158][73][74]. These experiments utilize tall column-like containers to hole uranium ore samples, simulating the actual in situ leaching process by injecting leaching solutions into the column. Such experiments help researchers assess the flow of leaching solutions and the migration of uranium-bearing pregnant solutions, providing valuable insights into the effectiveness of in situ leaching. In 2019, Laurent et al. proposed a one-dimensional reactive transport model for column experiments [111][75]. This approach thoroughly integrates the hydraulic properties of the leaching solution. Grounded in chemical reaction kinetics, this reactive transport model also considers the influence of grain size, providing nuanced insights into the dynamics of the leaching process. Although limited to 1D laboratory experiments, this methodology offers a deeper understanding of the hydrological and chemical processes occurring during in situ leaching. Afterward, Lagneau et al. exemplified the application of the reactive transport model in practical in situ leaching of uranium deposits [159][76]. By employing a reactive transport model, they precisely fitted historical data for 61 wells in one uranium block and subsequently assessed and predicted results for another block. This demonstration underscores the robustness of the model in real-world production scenarios. In 2022, Collet et al. developed a three-dimensional reactive transport model to comprehensively simulate coupled hydrodynamic and geochemical processes during in situ leaching [35], aiming to predict production outcomes. This 3D reactive transport model is based on the HYTEC program code [160,161][77][78]. It employs actual data from uranium deposits, incorporating deposit hydrodynamic parameters and mineral descriptions as a 3D geological model for hydrological processes. The simulation integrates geochemical processes and relevant mineralogical databases (including kinetic and mineral databases, along with underlying chemical processes) as a geochemical model. Finally, specific parameters of operational conditions (such as well placement, leaching solution composition, injection and extraction rates, etc.) serve as input parameters for coupled simulations of hydrodynamic and geochemical processes. This comprehensive reactive transport model facilitates fitting historical data and predicting future production in actual uranium mining scenarios. It accurately considers the details of practical in situ leaching, including realistic mineral balances, dissolution rates, and recovery rates. It has been successfully applied in large-scale, real-world, in situ uranium mining production, demonstrating precise predictive capabilities. Furthermore, reactive transport models are beneficial in the context of CO2-O2 leaching, which entails more complex mechanisms. They can serve to quantitatively elucidate site-specific geochemical processes during leaching and also aid in comprehending the storage of CO2 as a gas phase due to capillary mechanisms in the permeable pores of uranium deposits [98][79]. This dual function enhances insights into the effectiveness of CO2-O2 leaching and its long-term environmental impact in the context of CO2 utilization and storage. Reactive transport models, in addition to their capability to predict production based on uranium deposit characteristics, are also employed for evaluating downgradient transport at in situ leaching sites. This aids in optimizing management decisions and facilitating groundwater remediation post-in situ leaching [162[80][81],163], contributing to maximizing returns and ensuring the sustainable development of uranium mining through in situ leaching.4. Information Technology for In Situ Leaching

In order to enhance the efficiency and sustainability of the entire in situ leaching process for uranium mining, a data-driven and intelligent information system with comprehensive analytical capabilities has become a notable innovation. The system offers thorough information on geological, technical, and economic elements to optimize the development and operation of mining sites. It is specifically developed to facilitate intelligent management and decision-making during the in situ leaching of uranium deposits. The Seversk Technological Institute of the National Research Nuclear University (MEPhI) developed an informational support software package specifically designed to manage the in situ leaching process for uranium mining [164][82]. Operating on client–server technology, the software facilitates interaction between client programs and data storage through SQL queries, making it applicable at any stage of in situ leaching operations. There are seven interconnected information systems within the software package: (1) the mining–geological information system (MGIS) collects and processes raw geological data, generates 2D/3D mathematical models, calculates uranium reserves, and visually presents the production layer’s information status; (2) the technological information system constructs a model for the geological–technical mining complex, coordinates technical data processing, evaluates relationships, and generates operational reports to ensure data integrity; (3) the geo-technological modeling system simulates in situ leaching and pollutant migration using geological mathematical models of the uranium deposit and numerical models of the mining complex; (4) the geo-information expert analytical system (GEAS) visualizes all information in the entire mining operation process, analyzes hydrodynamic flow in the production layer, optimizes solutions, and reduces reagent usage in the in situ leaching process; (5) the techno-economic system employs economic mathematical models to calculate the economic performance of uranium mining units, including fundamental costs and other economic indicators related to unit development; (6) the computer-aided design system designs and optimizes mining development patterns based on initial data derived from geological and mathematical models of the deposit; and (7) the mining planning system predicts and formulates mining plans for operational units, ensuring planned uranium production levels based on multifactor statistical models of productivity. The software package offers advantages such as a modular architecture, scalability, and expandability. Its optimal database structure ensures both data integrity and consistency, complemented by seamless integration mechanisms with existing enterprise information systems. The collaborative utilization of the seven information systems within the package enhances the intelligence of geotechnical enterprise management through comprehensive analysis of geological and geotechnical data, multifaceted modeling of geotechnical processes, and intelligent decision support. The collaboration between the Seversk Institute of Technology and ARMZ Uranium Holding Company has led to further enhancements of the software package, giving rise to the Smart ISL site digital mining system [24]. This system is currently capable of managing uranium production through informationization, utilizing automated data collection and remote control of wellfields. It comprehensively analyzes geological and operational data, as well as hydrogeological and technical simulations. In practical production scenarios, the system optimizes processes, enhances extraction efficiency, and reduces risks. This progression toward digitalization and intelligence in in situ leaching technology provides a sustainable and efficient intelligent solution for future uranium mining.References

- Storrs, K.; Lyhne, I.; Drustrup, R. A Comprehensive Framework for Feasibility of CCUS Deployment: A Meta-Review of Literature on Factors Impacting CCUS Deployment. Int. J. Greenh. Gas Control 2023, 125, 103878.

- Yao, J.; Han, H.; Yang, Y.; Song, Y.; Li, G. A Review of Recent Progress of Carbon Capture, Utilization, and Storage (CCUS) in China. Appl. Sci. 2023, 13, 1169.

- Han, J.; Li, J.; Tang, X.; Wang, L.; Yang, X.; Ge, Z.; Yuan, F. Coal-Fired Power Plant CCUS Project Comprehensive Benefit Evaluation and Forecasting Model Study. J. Clean. Prod. 2023, 385, 135657.

- Bai, X.; Yan, G.; Kong, S.; Yao, J.; Wen, P.; Li, G.; Li, J.; Zhang, J. Suppression of Anthracite Dust by a Composite of Oppositely-Charged Ionic Surfactants with Ultra-High Surface Activity: Theoretical Calculation and Experiments. Fuel 2023, 344, 128075.

- Su, C.-W.; Pang, L.-D.; Qin, M.; Lobonţ, O.-R.; Umar, M. The Spillover Effects among Fossil Fuel, Renewables and Carbon Markets: Evidence under the Dual Dilemma of Climate Change and Energy Crises. Energy 2023, 274, 127304.

- Bai, X.; Yan, G.; Kong, S.; Yang, T.; Yao, J.; Wen, P.; Li, G. Study on the Mechanism of the Influence of Surfactant Alkyl Chain Length on the Wettability of Anthracite Dust Based on EDLVO Theory and Inverse Gas Chromatography. Fuel 2023, 353, 129187.

- Yao, J.; Li, G.; Wu, J. Application of In-Situ Combustion for Heavy Oil Production in China: A Review. J. Oil Gas Petrochem. Sci. 2018, 1, 69–72.

- Fetisov, V.; Gonopolsky, A.M.; Davardoost, H.; Ghanbari, A.R.; Mohammadi, A.H. Regulation and Impact of VOC and CO2 Emissions on Low-carbon Energy Systems Resilient to Climate Change: A Case Study on an Environmental Issue in the Oil and Gas Industry. Energy Sci. Eng. 2023, 11, 1516–1535.

- Yao, J.; Song, Y. Dynamic Analysis Approach to Evaluate In-Situ Combustion Performance for Heavy Oil Production. J. Oil Gas Petrochem. Sci. 2019, 2, 42–47.

- Vieira, L.C.; Longo, M.; Mura, M. From Carbon Dependence to Renewables: The European Oil Majors’ Strategies to Face Climate Change. Bus. Strategy Environ. 2023, 32, 1248–1259.

- Li, G.; Yao, J.; Song, Y.; Tang, J.; Han, H.; Cui, X. A Review of the Metallogenic Mechanisms of Sandstone-Type Uranium Deposits in Hydrocarbon-Bearing Basins in China. Eng 2023, 4, 1723–1741.

- Rehm, T.E. Advanced Nuclear Energy: The Safest and Most Renewable Clean Energy. Curr. Opin. Chem. Eng. 2023, 39, 100878.

- Wu, Y.; Xie, Y.; Liu, X.; Li, Y.; Wang, J.; Chen, Z.; Yang, H.; Hu, B.; Shen, C.; Tang, Z.; et al. Functional Nanomaterials for Selective Uranium Recovery from Seawater: Material Design, Extraction Properties and Mechanisms. Coord. Chem. Rev. 2023, 483, 215097.

- Degueldre, C. Uranium as a Renewable for Nuclear Energy. Prog. Nucl. Energy 2017, 94, 174–186.

- Costa Peluzo, B.M.T.; Kraka, E. Uranium: The Nuclear Fuel Cycle and Beyond. Int. J. Mol. Sci. 2022, 23, 4655.

- Watkins, J.K.; Gonzales, A.; Wagner, A.R.; Sooby, E.S.; Jaques, B.J. Challenges and Opportunities to Alloyed and Composite Fuel Architectures to Mitigate High Uranium Density Fuel Oxidation: Uranium Mononitride. J. Nucl. Mater. 2021, 553, 153048.

- Muellner, N.; Arnold, N.; Gufler, K.; Kromp, W.; Renneberg, W.; Liebert, W. Nuclear Energy—The Solution to Climate Change? Energy Policy 2021, 155, 112363.

- Wu, R.; Xu, Z.; Gong, W.; Cai, J.; Ning, J. Genesis of Baixingtui Uranium Deposit in Songliao Basin. Uranium Geol. 2012, 3, 142–147.

- Rong, H.; Jiao, Y.; Wu, L.; Ji, D.; Li, H.; Zhu, Q.; Cao, M.; Wang, X.; Li, Q.; Xie, H. Epigenetic Alteration and Its Constraints on Uranium Mineralization from the Qianjiadian Uranium Deposit, Southern Songliao Basin. Earth Sci.-J. China Univ. Geosci. 2016, 41, 2675–2696.

- Cuney, M. The Extreme Diversity of Uranium Deposits. Minim. Depos. 2009, 44, 3–9.

- Jiao, Y.; Wu, L.; Rong, H.; Zhang, F. Review of Basin Uranium Resources in China. Earth Sci.-J. China Univ. Geosci. 2021, 46, 2675.

- Jin, R.; Yu, R.; Miao, P. Basin Uranium Mineralization Law; Springer: Singapore, 2023; pp. 325–356.

- World Nuclear Association. Available online: https://world-nuclear.org/information-library/nuclear-fuel-cycle/mining-of-uranium/world-uranium-mining-production.aspx (accessed on 21 August 2023).

- OECD. Uranium 2022: Resources, Production and Demand. Available online: https://read.oecd-ilibrary.org/nuclear-energy/uranium-2022_2c4e111b-en (accessed on 11 May 2023).

- Espinoza, D.; Goycoolea, M.; Moreno, E.; Newman, A. MineLib: A Library of Open Pit Mining Problems. Ann. Oper. Res. 2013, 206, 93–114.

- Ben-Awuah, E.; Richter, O.; Elkington, T.; Pourrahimian, Y. Strategic Mining Options Optimization: Open Pit Mining, Underground Mining or Both. Int. J. Min. Sci. Technol. 2016, 26, 1065–1071.

- Petersen, J. Heap Leaching as a Key Technology for Recovery of Values from Low-Grade Ores—A Brief Overview. Hydrometallurgy 2016, 165, 206–212.

- Abzalov, M.Z. Sandstone-Hosted Uranium Deposits Amenable for Exploitation by In Situ Leaching Technologies. Appl. Earth Sci. 2012, 121, 55–64.

- Abzalov, M.Z.; Drobov, S.R.; Gorbatenko, O.; Vershkov, A.F.; Bertoli, O.; Renard, D.; Beucher, H. Resource Estimation of In Situ Leach Uranium Projects. Appl. Earth Sci. 2014, 123, 71–85.

- Padilla, G.A.; Cisternas, L.A.; Cueto, J.Y. On the Optimization of Heap Leaching. Miner. Eng. 2008, 21, 673–678.

- Ghorbani, Y.; Becker, M.; Mainza, A.; Franzidis, J.-P.; Petersen, J. Large Particle Effects in Chemical/Biochemical Heap Leach Processes—A Review. Miner. Eng. 2011, 24, 1172–1184.

- Ghorbani, Y.; Franzidis, J.-P.; Petersen, J. Heap Leaching Technology—Current State, Innovations and Future Directions: A Review. Miner. Process. Extr. Metall. Rev. 2016, 37, 73–119.

- Robertson, S.W.; van Staden, P.J.; Cherkaev, A.; Petersen, J. Properties Governing the Flow of Solution through Crushed Ore for Heap Leaching. Hydrometallurgy 2022, 208, 105811.

- Van Lien, T.; Dinh, T.T.; Dung, N.T.K. Study on Leaching Systems and Recovery for PALUA–PARONG Low Grade Uranium Sandstone Ores. Hydrometallurgy 2020, 191, 105164.

- Collet, A.; Regnault, O.; Ozhogin, A.; Imantayeva, A.; Garnier, L. Three-Dimensional Reactive Transport Simulation of Uranium In Situ Recovery: Large-Scale well Field Applications in Shu Saryssu Bassin, Tortkuduk Deposit (Kazakhstan). Hydrometallurgy 2022, 211, 105873.

- Zeng, S.; Song, J.; Sun, B.; Wang, F.; Ye, W.; Shen, Y.; Li, H. Seepage Characteristics of the Leaching Solution during In Situ Leaching of Uranium. Nucl. Eng. Technol. 2023, 55, 566–574.

- Yin, S.; Yang, X.; Chen, W.; Wang, L.; Chen, X. Permeability Characteristics of Sandstone-Type Uranium Deposits under Different Temperature and Confining Pressure. J. Cent. South Univ. 2023, 30, 2302–2312.

- Wang, W.; Liang, X.; Niu, Q.; Wang, Q.; Zhuo, J.; Su, X.; Zhou, G.; Zhao, L.; Yuan, W.; Chang, J.; et al. Reformability Evaluation of Blasting-Enhanced Permeability in In Situ Leaching Mining of Low-Permeability Sandstone-Type Uranium Deposits. Nucl. Eng. Technol. 2023, 55, 2773–2784.

- De Silva, V.R.S.; Ranjith, P.G.; Perera, M.S.A.; Wu, B.; Wanniarachchi, W.A.M. A Low Energy Rock Fragmentation Technique for In-Situ Leaching. J. Clean. Prod. 2018, 204, 586–606.

- Yuan, W.; Wang, W.; Su, X.; Wen, L.; Chang, J. Experimental and Numerical Study on the Effect of Water-Decoupling Charge Structure on the Attenuation of Blasting Stress. Int. J. Rock Mech. Min. Sci. 2019, 124, 104133.

- Liu, Y.; Huang, L.; He, G.; Hu, N.; Zhou, S.; Yu, Q.; Ding, D. Damage and Stability Analysis of Sandstone-Type Uranium Ore Body under Physical and Chemical Action of Leaching Solution. Arch. Min. Sci. 2023, 68, 409–423.

- Yuan, B.; Xu, C.; Wang, K.; Zhang, W.; Moghanloo, R.G.; Sun, X.; Wang, Y.; Zhou, T. Enhance Horizontal Well Performance by Optimising Multistage Hydraulic Fracture and Water Flooding. Int. J. Oil Gas Coal Technol. 2017, 15, 25–46.

- Yuan, B.; Wood, D.A.; Yu, W. Stimulation and Hydraulic Fracturing Technology in Natural Gas Reservoirs: Theory and Case Studies (2012–2015). J. Nat. Gas Sci. Eng. 2015, 26, 1414–1421.

- Yang, J.; Tan, K.; Huang, X. Evaluation and Analysis of Geological Condition of In-Situ Fragmentation Leaching Uranium. China Nucl. Sci. Technol. Rep. 2003, 2, 157–172.

- Himanshu, V.K.; Mishra, A.K.; Roy, M.P.; Singh, P.K. Overview of Underground Metalliferous Mining. In Blasting Technology for Underground Hard Rock Mining; Springer Nature: Singapore, 2023; pp. 9–24.

- Cai, Z.; Li, X.; Lei, B.; Yuan, J.; Hong, C.; Wang, H. Laboratory Experimental Laws for the Radon Exhalation of Similar Uranium Samples with Low-Frequency Vibrations. Sustainability 2018, 10, 2937.

- Debashish, M.; Rajesh, K. Advanced Vibration Management to Improve Productivity and Optimize Cost for Excavation of Iron Ore: A Case Study. In Proceedings of the Conference on Recent Advances in Rock Engineering (RARE 2016), Bengaluru, India, 16–18 November 2016; Atlantis Press: Paris, France, 2016.

- Niu, Q.; Hu, M.; He, J.; Zhang, B.; Su, X.; Zhao, L.; Pan, J.; Wang, Z.; Du, Z.; Wei, Y. The Chemical Damage of Sandstone after Sulfuric Acid-Rock Reactions with Different Duration Times and Its Influence on the Impact Mechanical Behaviour. Heliyon 2023, 9, e22346.

- Liu, Y.; Iglauer, S.; Cai, J.; Amooie, M.A.; Qin, C. Local Instabilities during Capillary-Dominated Immiscible Displacement in Porous Media. Capillarity 2019, 2, 1–7.

- Yun, M.; Yu, B.; Cai, J. Analysis of Seepage Characters in Fractal Porous Media. Int. J. Heat Mass Transf. 2009, 52, 3272–3278.

- Qu, Z.; Yao, J.; Yang, Y.; Wang, B.; He, L. Laboratory Experiments of a Microfluidic Model for Imbibition. J. Petrochem. Univ. 2014, 37, 64–66.

- Yao, J. Microfluidic Studies on Snap-Off during Imbibition Process. Master Thesis, China University of Petroleum (East China), Qingdao, China, 2014.

- Yao, J. A Microfluidic Model for Visualizing Snap-Off During Imbibition. Ph.D. Dissertation, University of Wyoming, Laramie, WY, USA, 2017.

- Yao, J. Microfluidic Studies of Geometrically-Mediated Snap-Off. Master Thesis, University of Wyoming, Laramie, WY, USA, 2014.

- Roy, M.P.; Himanshu, V.K.; Kaushik, A.P.; Singh, P.K. Influence of Ring Blasting Pattern on the Safety of Nearby Underground Structures. Sādhanā 2022, 47, 192.

- Zhang, Z.-X.; Sanchidrián, J.A.; Ouchterlony, F.; Luukkanen, S. Reduction of Fragment Size from Mining to Mineral Processing: A Review. Rock Mech. Rock. Eng. 2023, 56, 747–778.

- Vennes, I.; Mitri, H.; Chinnasane, D.R.; Yao, M. Effect of Stress Anisotropy on the Efficiency of Large-Scale Destress Blasting. Rock Mech. Rock. Eng. 2021, 54, 31–46.

- Kan, J.; Dou, L.; Li, J.; Li, X.; Bai, J.; Wang, M. Characteristics of Microseismic Waveforms Induced by Underground Destress Blasting: Comparison with Those Induced by Ground Blasting and Coal Mining. Front. Earth Sci. 2022, 10, 797358.

- Ye, Z.; Chen, M. Characteristics of Peak Load on a Borehole Wall in Water-Coupling Blasting. J. Eng. Mech. 2023, 149, 04022087.

- Huo, X.; Qiu, X.; Shi, X.; Chen, H.; Gou, Y.; Yu, Z. Experimental and Numerical Investigation on the Peak Value and Loading Rate of Borehole Wall Pressure in Decoupled Charge Blasting. Int. J. Rock Mech. Min. Sci. 2023, 170, 105535.

- Johnson, R.H.; Paradis, C.J.; Kent, R.D.; Tigar, A.D.; Reimus, P.W. Single-Well Push–Pull Tracer Test Analyses to Determine Aquifer Reactive Transport Parameters at a Former Uranium Mill Site (Grand Junction, Colorado). Minerals 2023, 13, 228.

- Cheng, Y.; Arora, B.; Şengör, S.S.; Druhan, J.L.; Wanner, C.; van Breukelen, B.M.; Steefel, C.I. Microbially Mediated Kinetic Sulfur Isotope Fractionation: Reactive Transport Modeling Benchmark. Comput. Geosci. 2021, 25, 1379–1391.

- Deng, H.; Navarre-Sitchler, A.; Heil, E.; Peters, C. Addressing Water and Energy Challenges with Reactive Transport Modeling. Environ. Eng. Sci. 2021, 38, 109–114.

- Schabernack, J.; Fischer, C. Improved Kinetics for Mineral Dissolution Reactions in Pore-Scale Reactive Transport Modeling. Geochim. Cosmochim. Acta 2022, 334, 99–118.

- Chen, J.; Dai, Z.; Yang, Z.; Pan, Y.; Zhang, X.; Wu, J.; Reza Soltanian, M. An Improved Tandem Neural Network Architecture for Inverse Modeling of Multicomponent Reactive Transport in Porous Media. Water Resour. Res. 2021, 57, e2021WR030595.

- Xiong, Y.; Hou, Z.; Tan, X.; Luo, J.; Yue, Y.; Wu, K. Constraining Fluid-Rock Interactions during Eogenetic Karst and Their Impacts on Carbonate Reservoirs: Insights from Reactive Transport Modeling. Appl. Geochem. 2021, 131, 105050.

- Harrison, A.L.; Tutolo, B.M.; DePaolo, D.J. The Role of Reactive Transport Modeling in Geologic Carbon Storage. Elements 2019, 15, 93–98.

- Parkhurst, D.L.; Wissmeier, L. PhreeqcRM: A Reaction Module for Transport Simulators Based on the Geochemical Model PHREEQC. Adv. Water Resour. 2015, 83, 176–189.

- Kempka, T.; Steding, S.; Kühn, M. Verification of TRANSPORT Simulation Environment Coupling with PHREEQC for Reactive Transport Modelling. Adv. Geosci. 2022, 58, 19–29.

- Prommer, H.; Barry, D.A.; Zheng, C. MODFLOW/MT3DMS-Based Reactive Multicomponent Transport Modeling. Groundwater 2003, 41, 247–257.

- Xu, T.; Spycher, N.; Sonnenthal, E.; Zhang, G.; Zheng, L.; Pruess, K. TOUGHREACT Version 2.0: A Simulator for Subsurface Reactive Transport under Non-Isothermal Multiphase Flow Conditions. Comput. Geosci. 2011, 37, 763–774.

- Kim, B.-J.; Ko, M.-S. Two-Dimensional Reactive Transport Model as a New Approach for Identifying the Origins and Contribution of Arsenic in a Soil and Water System. Sci. Total Environ. 2023, 898, 165468.

- Ladeira, A.C.Q.; Morais, C.A. Uranium Recovery from Industrial Effluent by Ion Exchange—Column Experiments. Miner. Eng. 2005, 18, 1337–1340.

- Dangelmayr, M.A.; Reimus, P.W.; Wasserman, N.L.; Punsal, J.J.; Johnson, R.H.; Clay, J.T.; Stone, J.J. Laboratory Column Experiments and Transport Modeling to Evaluate Retardation of Uranium in an Aquifer Downgradient of a Uranium In-Situ Recovery Site. Appl. Geochem. 2017, 80, 1–13.

- Laurent, G.; Izart, C.; Lechenard, B.; Golfier, F.; Marion, P.; Collon, P.; Truche, L.; Royer, J.-J.; Filippov, L. Numerical Modelling of Column Experiments to Investigate In-Situ Bioleaching as an Alternative Mining Technology. Hydrometallurgy 2019, 188, 272–290.

- Lagneau, V.; Regnault, O.; Descostes, M. Industrial Deployment of Reactive Transport Simulation: An Application to Uranium In Situ Recovery. Rev. Miner. Geochem. 2019, 85, 499–528.

- Lagneau, V.; van der Lee, J. HYTEC Results of the MoMas Reactive Transport Benchmark. Comput. Geosci. 2010, 14, 435–449.

- van der Lee, J.; De Windt, L.; Lagneau, V.; Goblet, P. Module-Oriented Modeling of Reactive Transport with HYTEC. Comput. Geosci. 2003, 29, 265–275.

- Yang, Y.; Zuo, J.; Qiu, W.; Wu, J.; Que, W.; Zhou, G.; Liu, Z.; Wu, J. Assessment of the Greenhouse Gas Footprint and Environmental Impact of CO2 and O2 In Situ Uranium Leaching. Acta Geol. Sin.-Engl. Ed. 2023, 97, 986–994.

- Chen, M.; Jiang, Z.; Feng, G.; Chen, M.; Du, Z. Improving the Efficiency of In Situ Uranium Leaching (Remediation) with Periodic Injection and Extraction: Insight from Reactive Transport Modeling and Field Test. J. Hydrol. 2024, 630, 130767.

- Sprocati, R.; Rolle, M. Integrating Process-Based Reactive Transport Modeling and Machine Learning for Electrokinetic Remediation of Contaminated Groundwater. Water Resour. Res. 2021, 57, e2021WR029959.

- Noskov, M.; Istomin, A.; Kesler, A.; Cheglokov, A. Innovative Intellectual Management Technology of Uranium Mining by the ISL Method. In Proceedings of the International Symposium on Uranium Raw Material for the Nuclear Fuel Cycle: Exploration, Mining, Production, Supply and Demand, Economics and Environmental Issues (URAM-2018), Vienna, Austria, 25–29 June 2018; International Atomic Energy Agency: Vienna, Austria, 2018; p. 157.