Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Lauma Balode and Version 2 by Catherine Yang.

Peatlands can become valuable resources and greenhouse gas sinks through the use of different management practices. Peatlands provide carbon sequestration; however, they are also among the greatest greenhouse gas emissions sources. Peat is undervalued as a resource in the bioeconomy and innovation—a way that could save costs in peatland management.

- climate change

- emissions

- peatland management

- restoration

1. Introduction

Peat plays a vital role in peatland ecosystems for vegetation growth and habitats, ensuring biological diversity [1][2][3][1,2,3]. Peatlands are critical in climate regulation as carbon sinks [1][4][5][6][7][8][9][1,4,5,6,7,8,9]. Peatlands are the most significant natural terrestrial carbon sink, which can continuously attract carbon from the atmosphere over long periods [8][10][11][8,10,11]. While peatlands cover only 3% [12][13][14][12,13,14] of the area, they store 30% of the world’s carbon [8][9][8,9]. The resource’s quality has decreased [15][16][17][18][15,16,17,18], and peat is currently viewed more as an emission source [5][15][19][20][5,15,19,20]. Peatlands have to be managed sustainably, interrupting extensive peatland drainage and extraction [21]. It is estimated that more than half of the peatlands in Europe are lost [22]. The increase in population density and intensity of agricultural practices has driven the increased drainage of large European peatlands [23]. In Europe, 25% of peatlands are estimated to be degraded [23]. In Europe, peatlands can be found in wide areas in Eastern Europe, Central Europe, and Northern Europe. These regions include Ireland, the United Kingdom, Germany, Austria, The Netherlands, Poland, the Nordic countries, and all the Baltic states [24][25][26][24,25,26]. In Finland, more than 30% of the territory is covered with peatlands [12][17][12,17], but in Sweden, it is approximately 15% of the territory’s land surface [4]. In Iceland, peatlands cover ~9% of the total area [27], while in Norway, peatlands cover ~6% of the land territory [12]. About 12% of the peatland area has been drained and used for forestry and agriculture [28]. The water table is low at the drained peatland level; therefore, carbon dioxide (CO2) emissions increase. In peatlands where drainage has been carried out, CO2 is the main GHG emission [29]. It has been determined that drained peatland causes ~2% to 5% of the emissions of greenhouse gas (GHG) emissions and ~10% of CO2 emissions in total [30]. Degraded peatlands produce large GHG emissions and greatly affect peatlands’ water-holding resistance [31]. Peat continues to be one of the main energy sources in Europe, for example, in Sweden and Finland [32]. The extensive drainage of peatlands for agricultural use, extraction as an energy source, and removal of all but a thin peat layer explain the decrease in peat quality [20][33][20,33]. It is predicted that in northern peatlands, GHG emissions from peatlands might increase in the following years because of global warming [34]. The European Union (EU) is rated as the third greatest carbon dioxide (CO2) emitter of degraded peatlands after Russia and Indonesia [31], with annual GHG emissions of roughly 220 million megatons of CO2 equivalents/year [35][36][35,36]. Some of the greatest CO2 emissions in the EU from degraded peatlands are in Poland, Germany, and Finland [31].2. Technologies and Technological Processes in Peat Processing

Peat can serve as a replacement for fossil-based resources. The potential applications of peat biomass include using it as a raw material for building materials, in the food industry, and even as pharmaceutical products. Only a limited perspective can be found in the scientific literature on how peat can be processed for use in innovative products and materials as the key component or additive [37][38][39][57,117,149]. Peat can be used for energy production through gasification, direct combustion to produce electricity, or methane production [40][150]. Direct combustion for power production is a simple method for converting biomass energy into electrical energy. The process involves converting chemical energy into steam and then using this steam to rotate the turbine and generate power [40][150].

Gaseous and liquid substances are transformed at high and elevated temperatures in the gasification process. The thermochemical processes include drying, pyrolysis, combustion, cracking, and reduction. Biomass is converted into gaseous biofuels. It is a more complicated method than direct combustion [40][150].

Peat methane utilisation is a processing method for use with methane fuels, converting biogenic gas into electricity. The actual collection of CH4 from peatlands is meant here [40][150].

Processing techniques for energy peat are summarised in Figure 13.

In Finland, 3–5% is used as a fuel resource [40][150]. However, peat is also used as a raw material in agriculture and livestock farming [40][150]. In northern Europe, peatlands are often transformed into grasslands, which can be used for dairy and livestock farming. In recent years, the bioeconomy has become a possible solution for the more sustainable use of peatlands [36][41][42][36,46,126]. The use of peat for energy purposes is evaluated with the lowest added value [33]. Developing technologies that can convert biomass into liquid biofuels, such as hydrothermal liquefaction, pyrolysis, and gasification, is an active area of research. Volatile organic compounds and carbon found in peat biomass can be converted into liquid biofuel [43][44][102,151].

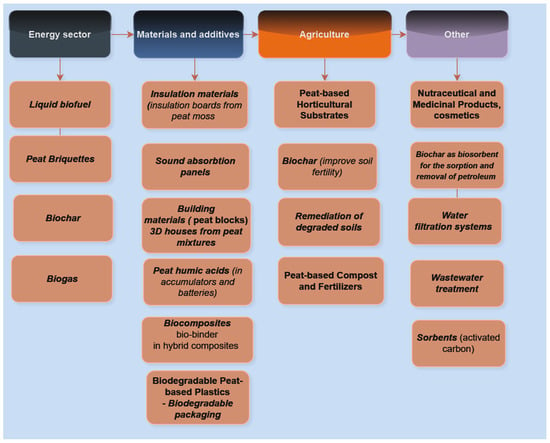

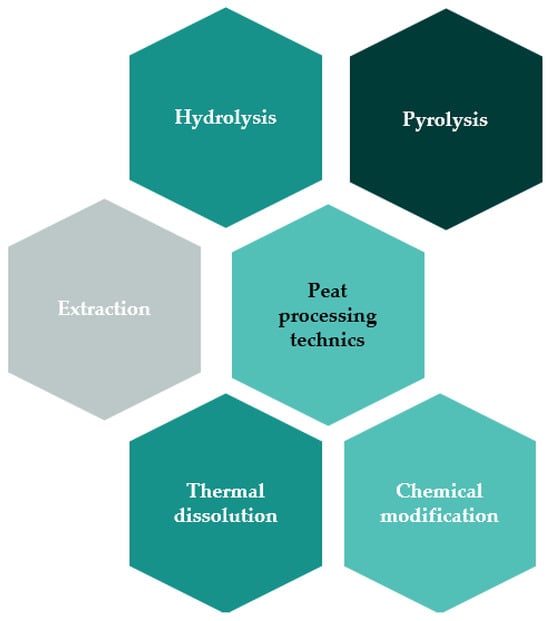

Using different methods, peat can produce thermal insulation and raw materials in various construction materials substrates, and pharmaceutical products [45][46][47][48][49][152,153,154,155,156]. Also, an agro-industrial resource, peat, has a high but not fully used potential [37][50][57,58]. The following section discusses technologies and processing processes for producing non-energy peat materials and products. Before peat can be used as a raw material in products or materials, peat must undergo chemical and thermal treatment processes [43][51][52][55,98,102]. Various methods can be applied to process non-energy peat, such as extraction, pyrolysis, hydrolysis, thermal dissolution, and chemical modification [40][53][95,150]. Peat hydrolysis allows for the extraction of biologically active compounds from organic matter. Peat wax with valuable properties can be obtained for industry and medicinal applications. Pyrolysis produces liquid fuel, coke, and fuel gas [40][53][95,150]. The processing methods of non-energy peat are shown in Figure 24.

3. The Potential of High Added Value of Peat Products and Materials

After the literature review regarding peat processing methods, a further investigation of opportunities for peat’s industrial use in high-added-value products is required. Biomass from paludiculture can be used for innovative product production that might positively affect GHG emission reduction, partly replacing existing products that generate higher emissions [5].

-

Building materials

Peat’s possibilities have been proven in the building sector, where peat soil composite materials can be used as raw materials or additives. Peat soil can be a promising additive in construction materials, strengthening the durability of masonry blocks to meet necessary building standards. It is possible to improve building materials’ characteristics, including insulation properties, using peat as an additive or producing the products themselves [45][46][47][48][49][54][99,152,153,154,155,156]. In building materials, cement has often been used with high-lying peat, moistening peat with water first. Then, after the peat is wholly saturated with water, calcium oxide, which can be obtained by calcining limestone, is added to the peat [47][154]. The search for alternative and innovative thermal insulation solutions in renovation has been more common recently, including using peat as a raw material or additive in thermal insulation panels [37][48][49][55][57,93,155,156].

In Finland, research has been conducted on peat moss use as an effective insulation solution in buildings. It is also possible to use lowland peat as a raw material to produce thermal insulation materials. Thermal insulation materials using peat consist of peat binders, additives, and components for creating a framework [49][56][94,156]. It has been found that thermally treated fen peat, also known as black peat, can be mixed with gypsum and tar, which can then be used to produce thermal insulation materials [33][57][33,157].

There are examples of successful models in which the raw materials for creating heat insulation panels are wood in combination with peat, and the peat serves as a binder. Using peat as a binder makes it possible to produce sound-absorbing panels, whereas several models use natural fibres. These panels, made from natural resources, compete with synthetic materials [45][54][99,152].

If the thermal conductivity of a thermal insulation material is to be assessed, thermal insulation materials where peat is used can be compared to mineral wool on the market. It is estimated that the coefficient of thermal conductivity of peat moss material is 0.35 mW/mK [58][100], which is significantly lower than other insulation materials. In the panel production process, resin strengthens the thermal insulation panels [54][58][99,100].

Peat moss has potential use in the thermal insulation boards used in construction, with lower thermal conductivity in comparison to other materials [58][100]. Mats and moss slabs with a 100 kg/m3 density are estimated to have a thermal conductivity of 0.04 W/mK [58][100]. Peat moss is estimated to absorb ~30 times its weight in water before it becomes saturated [58][100]. Insulation panels made from peat moss possess better mechanical properties than wood panels. Peat moss panels are denser in comparison to other materials. Peat moss boards that contain tannin are comparable to cotton, and wet-processed peat moss boards have a higher water absorption than dry-processed [58][100].

3D-printed houses.

Peat mixture as an innovative solution in the building sector has emerged in recent years in Europe. Peat use in construction materials is more common in Norway, where peat is used in building new houses or renovating. Peat’s use in producing 3D-printing technologies as a construction material has been investigated in Estonia [49][57][59][156,157,158]. Geokar peat blocks are made using peat processed into a paste combined with straw or sawdust, which can be used to construct thermal insulation panels. Peat blocks can even be used for up to 75 years. It is estimated that using peat blocks in the building sector can reduce energy consumption. Architects have increasingly used biopositive materials in renovation and eco-building. Another possibility for peat use in construction is fibreboard made from agricultural residues and peat moss. Fibreboard using peat moss was evaluated as an effective and practical solution among the other insulation materials [49][59][156,158].

Peat has been successfully used as an effective thermal insulation material with high thermal properties. Peat’s thermal conductivity as an insulation material is from 0.037 to 0.08 W/m/K) [59][158]. Peat also has attractive antibacterial properties for use in construction materials [59][158].

A new type of peat composite building material was developed, allowing for the three-dimensional printing of entire house structures (walls, floors, ceilings, etc.). Peat can be used as a filler to improve materials’ thermal properties. The test samples were 3D-printed using a novel printing apparatus. The print head was a nozzle that conveyed a moist peat–ash mixture with compressed air [59][158]. In existing 3D printing technologies, concrete fibre clay has been used, but in test samples, a mixture of peat, silica, ash, and water was used for printing. The samples were kept at room temperature and 100% relative humidity [59][158]. Currently, the vast majority of production is focused on either planting substrates or using the product as fuel for heating purposes. It is possible to utilise peat as a building material, including for the 3D printing of whole buildings and for creating panels that provide thermal and acoustic insulation. Peat composite materials and their use as construction materials have been evaluated for their potential to reduce CO2 emissions from peat [59][158].

-

Biocomposites from peat

Peat composite materials in blocks or pellets are estimated to have potential in design and construction. The possibility of using peat is presented in the production of biological adhesives, where peat is a binder. For peat to be used as a biological binder, it must first be treated using hydro cavitation [60][159]. Biodegradable polymers should also be added to composite materials. Composite materials can be used both in construction and as a material for furniture production [61][160].

-

Packaging

Research shows that it is possible to use peat as an ingredient in biodegradable packaging, also promoting carbon sequestration. These packaging materials are an alternative solution to traditional plastics from fossil materials, reducing GHG emissions. Studies have shown a promising efficiency for peat as a raw material in packaging production. It has been investigated that it is possible to use peat as a raw material in producing biodegradable containers and films, thus offering the opportunity to use biological materials instead of traditional fossil materials. Such materials are rated as highly resistant to moisture and rotting risks [30][53][56][30,94,95].

-

Sorbents

It is possible to produce biosorbents from peat. Sorbents can be made from unprocessed peat. Biochar, where peat is used as a raw material, can serve as an alternative solution to chemical sorbents. Using biochar produced from peat positively affects carbon sequestration and water retention and improves soil fertility. Peat has been assessed as having a high potential for environmental remediation [62][161]. Using peat and producing activated carbon to purify liquid or gaseous media from pollution is also possible. The processing methods used are heat treatment and chemical modification. During the pyrolysis of peat, volatile organic compounds and moisture are separated, forming a denser carbon content. After removing organic compounds, the structure is porous, and biochar can provide better sorption. Decomposed peat can produce solid sorbents used to purify water from heavy metals, wastewater, and radioactive compounds [63][64][65][146,147,162]. The use of peat moss in biochar production has proven the possibility of removing higher concentrations of heavy metals from polluted water—with peat biochar, it was possible to remove more than 80% of lead and almost 40% of cadmium compounds from polluted water. Due to its porous structure and hydrophobicity, peat can be used as a sorbent to separate crude oil from water. Peat biosorbents are both a cost-effective solution, and biologically produced sorbents have been used more in recent years to remove crude oil in marine compared to chemical sorbents [63][64][65][146,147,162].

Activated carbon can also be used in the food industry, as well as in the pharmaceutical field. The possibilities of using activated carbon are also highly appreciated in the chemical industry, as it can be used to produce synthetic fibres. Compared to synthetic fibres, peat fibres are rated at lower costs. A low ash content characterises peat, and it is, therefore, evaluated as promising to produce activated carbon as a sorbent [65][162].

-

Filtration systems

The possibility of peat has been assessed for use in water filtration systems and municipal wastewater treatment. Peat is suitable for water treatment because of its porosity and filtering properties, essential for removing pollution from water. Peat is used as activated carbon or as a peat filter. With a peat filter or activated carbon, it is possible to purify water from heavy metals and organic compounds [66][163]. Peat moss can be used as a raw material to produce activated carbon. Activated carbon can be widely used in soil and water purification from organic and inorganic pollution sources [6].

-

Medicine and cosmetics

The possibilities of using peat are still being studied in pharmaceuticals and medicine. The use of peat in physiotherapy has been estimated as a potential application due to its heat capacity because of its decomposition state. Other uses include natural steroid formulations that use peat or anti-wrinkle products with peat ingredients. The selection of proper preparations requires research and the selection of raw materials, as the preparations must have a certain chemical composition and organic and mineral compounds [6][65][6,162].

-

Use of Humic acids

It is possible to dye paper with peat humic acids, reducing the release of hazardous compounds into wastewater that the dyed paper would otherwise cause. Studies have indicated that peat humic acids can be used as additives to influence the structure and properties of lubricants. Peat can be converted into humic acids and used to mix and process rubber. Humic acids have a wide range of uses: possible additives, antioxidants, pigment dispersants, and colourants [33].

-

Remediation of degraded soils

The potential for using peat has been assessed directly for the economically beneficial restoration of degraded soils. Peat material is used as a solution in rehabilitation processes. The use of peat to restore degraded soils is also called bioremediation. During this, peat separates oil and other polluting substances from soils, for example. In bioremediation, the absorbed oils are transformed into water and CO2 using peat [14][33][14,33].

The applications of peat based on the literature mentioned above are shown in Figure 35.