Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Adriana Saraceni and Version 2 by Rita Xu.

Cost per vehicle kilometre is derived using the total cost of ownership method adjusted with the inclusion of labour costs and the impact of solar panel application on fuel efficiency while travel time-related and capacity occupations and reliability benefits serve as a basis for the total possible number of parcels delivered.

- autonomous ground vehicles

- last-mile delivery

- electric cars

1. Introduction

The collocation “last mile” indicates the final leg of technology that connects an end-user to the rest of the internet network in telecommunications [1]. In the logistics sector, the term refers to direct end-customer interaction [2], while last mile logistics (LML) is experiencing enhanced attention from the scientific community [3]. This interest is related to trends in purchasing behaviour and demographics, as well as increasing challenges that practitioners face while trying to keep up with the basic LML principle: minimizing the freight movement required to satisfy demand while minimizing costs and negative impact [4].

LML is affected by the growth of e-commerce, given that massive internet penetration has allowed retail companies to discover new business models and engage with the buyer as directly as possible, regardless of his geographical location. The COVID-19 pandemic induced an additional shift towards online sales [5], estimating e-retail sales to reach 21.8% of all retail sales in 2024, namely 6.5 trillion US dollars in the absolute state [6]. For logistics service providers (LSPs), an increase in direct-to-consumer deliveries means an increase in freight movements, resulting in higher costs and the danger of customer dissatisfaction associated with insolvency to meet growing delivery standards [7][8][7,8]. Nowadays, 55% of the population is living in the cities [9], and the ratio is expected to rise to 65–70% by 2050 [10][11][10,11]. Rising density in urban regions entails logistical challenges associated with the delivery volume increase, the location of consolidation centres, and vehicle routing in congested areas [12]. On top of that, the ageing workforce in industrialized countries contributes to an increasing labour shortage, especially in physically demanding and low-payment environments like parcel delivery [13]. The increase in global parcel traffic, especially in cities with congestion, air and noise pollution, creates additional burdens considering climate change and sustainability, as transport is the most problematic emitting sector in Europe [14]. Responsive governmental legislation aims to improve “health and the global climate” [15] along with slowly increasing customers’ sustainable awareness [16], forcing LSPs to consider new delivery solutions, taking into account their impact on the planet and people while maintaining economic expediency and competition. One of the possible new solutions in the logistics industry became the emergence of advanced autonomous systems supported by recent developments in the field of electrification, artificial intelligence and technology. While three categories of autonomous last-mile delivery robots have been described in the literature most regularly, Wheeled Sidewalk Pods (Droids), Drones, and Autonomous Ground Vehicles (AGVs) with lockers [17][18][17,18], the last provide a multitude of advantages for large-scale urban parcel delivery capable of simultaneously addressing customer satisfaction, sustainability, and cost-efficiency challenges [19].

2. Efficiency in Last-Mile Logistics

Mounting research focuses on LMD efficiency, either in terms of direct [20][27] or indirect costs and externalities [21][22][23,28]. Such growing interest is partly related to the spread of home delivery, which hinders the exploitation of economies of scale or marginal benefit models. LMD is considered one of the least efficient and most expensive sections of the entire supply chain [23][29], accounting for up to 75% of total logistics costs [24][30]. Nonetheless, companies typically charge less than the order’s cost to fulfil it, while customers wish to pay even less than the current cost [23][29]. Challenges are ample, like the “customer not at home” issue, poor predictability of delivery time, inability to choose a delivery window opposite to excess mileage due to limited availability, low customer density, returns and sustainability concerns [25][26][27][28][31,32,33,34]. Most of the literature on LMD efficiency thus examines its transport component and can be conditionally divided into two categories: optimization of traditional delivery modes and innovative solutions. Efficiency is predominant in this study, especially costs and supplement cost-related benefits. The profitability of any chosen solution or significant savings should be compared to a baseline situation. Among the papers reviewed, the vehicle routing problem (VRP) is central due to its longstanding existence and broad application scope. Researchers have examined cost minimization of route re-planning [29][35], path optimization related to time windows [30][36], or departure time [31][37], and customer density [32][33][38,39]. Others explore optimization possibilities via order consolidation [19][34][19,40], or the most efficient parcel location inside a truck [35][41]. Such approaches are widely used by LSPs like FedEx, UPS, and DHL for higher-level decision-making and planning support for everyday tours and vehicle loading.3. Traditional Delivery Mode Optimization and Innovations

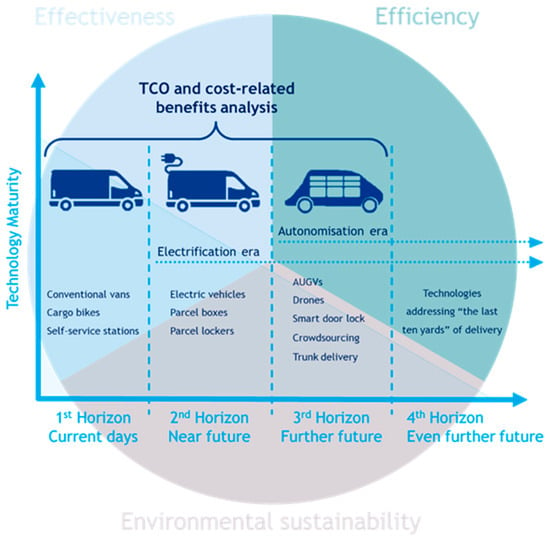

Innovative solutions aim to overcome traditional effectiveness hurdles in a way that may improve customer satisfaction, reduce costs or even discover new business models. The VRP is highly used when analysing options like drone delivery [36][42] or cost minimization capabilities depending on customer-to-locker assignment [37][43]. Some papers examine new options [38][39][44,45] or new against regular delivery modes [40][41][46,47]. Nonetheless, many stumbling blocks remain, for instance, consumer and government reluctance to implement innovations, lack of the necessary technological background, and the issue of the uncertain paybacks from the optimization obtained by innovation [42][43][44][48,49,50]. Boysen et al. (2020) [45][51] define conventional vans, cargo bikes and self-service stations as status-quo contemporary methods, while drones, autonomous delivery robots (bots or droids), crowdsourcing and reception boxes as near-future concepts. For the further future, ideas on flying warehouses, mobile parcel lockers and autonomous vehicles are presented. Schröder et al. (2018) [46][52] offer the technology maturity overview with four time horizons, the first representing the current LMD transformation, driven by vehicle electrification and unattended delivery. The second horizon brings semiautonomous delivery vehicles, which in approximately ten years will be supplemented by fully autonomous vehicles and drones during the third horizon. The fourth horizon goes beyond 2030 and only provides optimistic hopes for technologies addressing “the last ten yards” of delivery. Figure 1 illustrates the variety of innovative delivery solutions in accordance with the four time horizons.

Figure 1. Conceptual framework.