Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Anna Kowalewska and Version 2 by Jessie Wu.

Organosilicon polymers (silicones) are of enduring interest both as an established branch of polymer chemistry and as a segment of commercial products. Their unique properties were exploited in a wide range of everyday applications. The research attention polysiloxanes attracted as the materials of choice for various emerging technologies was tremendous. A rapid improvement in bulk modification strategies can be observed as well as the design of a new generation of PDMS-based smart materials, including flexible wearable electronics, sensors, coatings or e-skin.

- silicone elastomers

- PDMS

- self-healing

- synergistic enhancement

- smart materials

1. Polysiloxanes for Self-Healable Electronic Skin Applications

On-skin electronics should maintain the electrical function and simultaneously mimic the mechanical properties of biological systems. Materials designed for wearable artificial electronic skin applications (soft robotics and interface materials for on-skin electronics or human–machine interfaces) should thus display high mechanical flexibility, high breathability and a rapid mechanism of intrinsic autonomous self-healing that would provide efficient regeneration in unfavorable environments or after damage [1][86]. Preferably, such materials should be also capable of intelligently sensing environmental stimuli [2][87].

Siloxane polymers are suitable for electronic skin applications because of their biocompatibility, good air permeability, appropriate mechanical properties (modulus and stretchability) and chemical stability [3][2]. Several examples of hybrid S-H polysiloxanes designed or potentially suitable for the use as electronic skin have been already cited [4][5][6][7][61,65,67,77]. Another illustration can be PDMS combined with polyborosiloxanes (PBS) in interpenetrating “solid–liquid” elastomers (SLEs) that can mimic the velocity-sensitive ability of the human skin [8][88]. The dynamic network is formed by boroxine bonds whereas the polysiloxane chains form a permanent covalent scaffold. This system was elastic as well as structurally stable, stretchable and self-healing. The mechanical properties were dependent on strain rates. Superstretchability of up to 2100% and recovery of the initial shape upon unloading was noted. The dissociation and association of the dynamic network was found to be time-dependent and therefore the modulus of SLEs varied with strain rates. The introduction of carbon nanotubes (CNT, 5 wt.%) provided electric conductivity that was also responsive to strain rates. This system was used to fabricate strain–rate-responsive sensors (mechanoreceptors) with the ability to distinguish different contact velocities and mimicking the touching-rate sensibility of skin [8][88]. PDMS-dithiothreitol block polymers were shown to self-heal rapidly due to their high mobility and efficient formation of hydroxyl and boronate ester dynamic crosslinks [9][89]. The polymer not only presented a satisfactory mechanical strength (up to 0.43 MPa) and high stretchability (up to 1500%) but also recovered completely its original mechanical features at room temperature with an ultrafast rate in ambient environments (only ≤30 s after damage for 100% recovery). It also showed reconfigurability to any surface and had excellent self-adhesiveness (~102 N m−1) to various surfaces both in air and under water. Moreover, the material was used for the fabrication of on-skin electrophysiological (EP) electrodes that displayed stable signal collection in air and under water, even during motion. Only 2 s were required to recover 100% conductivity without any external stimuli.

2. Flexible Strain Sensors

Self-healing, flexible pressure and strain sensors are also greatly promising for intelligent wearable electronic devices. High sensitivity, long-term durability and stretchability are required for such applications. Their self-healing effectiveness depends on the structure of a conductive network, mechanical properties of the matrix and effectiveness of the self-healing mechanism [10][90]. In addition to earlier cited examples [11][12][13][14][15][16][35,59,66,68,71,83], a stretchable hyperbranched polysiloxane elastomer with self-healing features based on D-A chemistry should be mentioned [17][91]. It demonstrated good tensile properties and robust mechanical strength (0.87 MPa) as well as high sensitivity to human motions. The self-healing efficiency achieved 85% in a relatively short time (thermal treatment at 130 °C for 10 min and 80 °C for 48 h) and admixing carbon black (CB) as the conductive filler by the solution blending–casting method enabled application of the composite in wearable flexible sensors. The content of CB affected the mechanical strength of the composite but also adversely the self-healing effectiveness. However, thermal healing may not be the best option for a wearable intelligent systems.

More efficient seem to be the sensors formed with the use of silicones crosslinked by dynamic bonds reversibly active at room temperature, especially multicomponent systems. A conductive bilayer strain sensor made of polysiloxane self-healing by acid–amine interactions and containing a thin film of carboxyl-functionalized carbon nanotubes was shown to be highly sensitive and self-adhesive [18][92]. The ultrasoft and self-adhesive polysiloxane substrate can provide a sufficient comfort in contact with the human skin. The sensor exhibited linearity (regulated by the thickness of the CNT layer), low hysteresis and long-term durability with a gauge factor of 33.99 at 55% strain. Human motions of various strength, including bending/unbending of fingers or knees but also coughing and swallowing, were detected with satisfactory sensing performance.

A dynamic microphase separation due to the combined action of hydrogen bonding, disulphide bonds and π–π interactions was exploited to furnish S-H polysiloxane elastomers with a tuneable tensile strength of 1.89–3.33 MPa, stretchability of 347–1722%, and an extreme fracture toughness 28.6 MJ/m3 [19][58]. A “sandwich-structure” flexible sensor device for detecting human motions was prepared with this material. Another example can be a strain sensor of high sensitivity, short response time and long-term durability and good mechanical integrity (672% elongation at break, 1.41 MPa tensile strength and Young’s modulus of 0.39 MPa) that was prepared using self-repairable crosslinked elastomer substrate and conductive layer of CNT [20][93]. The self-healing effect in this case was based on the dynamic disulfide, imine and hydrogen bonds (91% healing efficiency) whereas the mechanical parameters resembled those of human skin. The sensor demonstrated an effective electrical conductivity and sensitivity to various human body motions (gauge factor (GF) = 24.1), short response time (120 ms) and long-term durability (4000 cycles).

3. Coatings

The term “smart coatings” refer to a class of materials used for the preparation of tailored functional coatings that can respond to certain intrinsic or extrinsic stimuli [21][94]. Smart and self-healing polymeric materials are of high interest for adjustable protection against the corrosion of metallic and non-metallic surfaces [22][95]. Smart ice-phobic coatings with responsive behaviors to external stimuli, such as changes of temperature, electrical and magnetic fields or pH are also of high interest [23][96]. The most recent trends in surface protection technologies include the formation of hydrophobic and superhydrophobic coatings or introduction of anti-fouling agents. Self-healing processes are required for the repair of coated areas damaged by ageing or action of aggressive events either by mending the defects or by inhibition of the corrosion process. In Researchers hthe earlier parts of this review, we have discussed the suitability of various S-H polysiloxane materials as smart protective coatings [24][25][26][27][28][29][46,62,63,74,75,78].

4. Self-Healing of Multifunctional Silicone Elastomers with Antimicrobial Properties

New trends in the design of antimicrobial silicone elastomers aim to develop new multifunctional materials with a range of useful properties including their recyclability and self-repair [30][7]. High-performance antimicrobial and antifouling materials with an in-built ability to recover mechanical strength can be used as fouling-release and corrosion-resistant polymer coatings. For example, flame retardant, self-healing and recyclable hybrid materials with >90% antimicrobial efficiency were obtained with PDMS, 2,2-bis(hydroxymethyl)propionic acid as the intermediate chain extender and crosslinked by interactions with tannic acid that is a natural antimicrobial substance [31][97]. The products exhibited good mechanical and tensile properties, with σmax up to 7.5 MPa and εmax up to 1540%. The mechanical properties and S-H mechanism was related to the dual action of H-bonding interactions and multiple dynamic phenol carbamate bonds with tannic acid macromolecules. The carbamates dissociated reversibly at 120 °C and a complete recovery was achieved on cooling (>85% after 18 h at 85 °C).

Another approach that can influence S-H ability, mechanical strength and antimicrobial properties is based on the application of nanoparticles of metal ions and oxides, especially zinc derivatives [32][98]. Although it can adversely affect chain diffusion and self-repair efficiency, dynamic thermally reversible ionic bonds can provide such polymers with recyclability and shape memory. For example, the tensile strength of PDMS-polythiourethane (PTU) composites was increased by ~20% while elongation at break was enhanced of ~30% on addition of 1 wt.% zinc oxide micro/nanoparticles. At this amount of t-ZnO, the phase structure containing microdomains was most homogeneous. Antimicrobial hydrophobic coatings of improved adhesion were also obtained with PDMS end grafted with 2-(2-benzimidazolyl)ethanethiol and zinc ions [33][99]. The synergistic SH effect was achieved by combination of dynamic Zn2+-imidazole coordination complexes and hydrogen bonding.

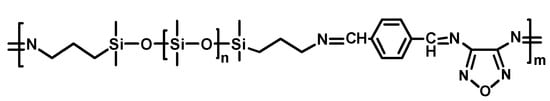

The antimicrobial and antifouling properties of S-H silicones are likewise very important for smart wearable electronics and robotics. ZnO nanoparticles grafted on the surface of MWCNTs were applied as microwave absorbers in a silicone-based composite self-healable via Diels–Alder chemistry [34][100]. The combined action of dynamic imine and hydrogen bonds with the coordination of zinc ions was reported for a silicone elastomer prepared with α,ω-aminopropyl terminated polydimethylsiloxane (PDMS, Mn = 3000), terephthalaldehyd and 3,4-diaminofurazan (DAF) (Scheme 1) [35][101].

Scheme 1.

Chemical structure of PDMS-TA-DAF.

The properties of this elastomer were further enhanced by the coordination of Zn2+ with nitrogen and oxygen atoms of 3,4-diaminofurazan of 1,2,5-oxadiazole structure. The elastomer was effectively repaired at 100 °C with the first ηs of 89.5% due to the synergistic action of imine bonds and zinc ion coordination bonds. The antibacterial efficiency of the material against E. coli and S. aureus was 99.9993% and 99.9997%, respectively. This significant effect is related both to the presence of biologically active 1,2,5-oxadiazole in the 3,4-diaminofurazan structure and the effect of zinc ions that helped to achieve the antibacterial ability.