The Amazon rainforest, spanning multiple countries in South America, is the world’s largest equatorial expanse, housing a vast array of relatively unknown plant and animal species. Encompassing the planet’s greatest flora, the Amazon offers a tremendous variety of plants from which natural lignocellulosic fibers (NLFs) can be extracted. In this century, NLFs, which have long been utilized by indigenous populations of the Amazon, have garnered interest as potential reinforcements for composites, whether polymer- or cement-based, in various technical applications such as packaging, construction, automotive products, and ballistic armor. A comparison with synthetic materials like glass, carbon, and aramid fibers, as well as other established NLFs, highlights the cost and specific property advantages of Amazon natural fibers (ANFs).

- natural lignocellulosic fibers

- NLFs

- Amazon rainforest

- composite materials

- engineering applications

- sustainability

1. Natural Lignocellulosic Fibers

2. Amazon Natural Fibers

The Amazon region is globally recognized for its immense natural and cultural diversity. Located in South America, the Amazon spans eight countries: Brazil, Bolivia, Colombia, Ecuador, Guyana, Peru, Venezuela, and Suriname. However, the majority of its expanse is located in Brazil. The Amazon stands out for harboring the greatest fauna and flora on the planet, representing approximately 20% of the world’s biodiversity [164][31]. Figure 2 illustrates a map of South America, highlighting the Brazilian Amazon region.

2.1. Açaí

The açaí palm, scientifically known as Euterpe oleraceae Mart., is a palm tree belonging to the Arecaceae family and is widely cultivated in the Brazilian Amazon region. This plant is prominently featured due to its economic significance in regional fruit cultivation, particularly in the state of Pará, where the production and commercialization of açaí pulp generate a significant market [166][33]. The fruit holds considerable nutritional value and is a fundamental part of the diet in the states of Pará and Amapá. Its composition is characterized by high levels of lipids, proteins, fibers, and anthocyanins [167][34]. The primary cultivation areas for this species are located in the estuary region of the Amazon River, considered its center of origin. In this area, dense and diverse populations inhabit periodically flooded lands due to tides [168][35]. The açaí fruit has a rounded shape, and approximately 70% of the fruit consists of residues, with only 3% of these residues being composed of lignocellulosic fibers. Although these residues can be used in bioenergy production, it is advisable to separate the fibers from the seeds since burning these components together can result in charcoal with varied chemical composition and thermal behavior, potentially altering the physical and mechanical properties of a specific material in which açaí fiber has been used [174][36]. The fibers from the açaí mesocarp are by-products of pulp extraction and adhere to the fruit’s seed [174][36]. These fibers are lignocellulosic in nature and have an elliptical shape with an average thickness of 130 μm and a length of about 18 mm. They have a slightly higher density than water, approximately 1.11 g/cm3. Generally, açaí fibers are underutilized due to their toxic residues, leading to various environmental issues, and the extracted fiber yield is low [175,176,177][37][38][39]. Despite açaí being well-known, primarily for consumption, the properties of its fiber are relatively unexplored. Nevertheless, there are studies in the literature that examine the fiber’s properties and its application in composite materials. Castro et al. [178][40] conducted a study on the production of composites using two distinct polymeric matrices, namely, polypropylene (PP) and high-impact polystyrene (HIPS), both derived from recycling processes. In this study, pressed açaí fibers were employed as reinforcement agents in the composites. The manufacturing of the composites took place through the hot compression method, and their properties were subsequently evaluated through tensile, compression, and impact tests. The tensile test results revealed significantly superior performance for the PP/açaí composite compared to the HIPS/açaí composite. Furthermore, the PP/açaí composite demonstrated higher impact resistance when contrasted with the HIPS/açaí composite. Notably, the HIPS/açaí composite exhibited superior properties only in terms of compression resistance, indicating an overall inferior mechanical behavior. This phenomenon is attributed to the low interfacial adhesion present in the HIPS/açaí composite. Thus, this study emphasizes the importance of the choice of polymeric matrix and the quality of the interface between components in determining the mechanical properties of composites.2.2. Babassu

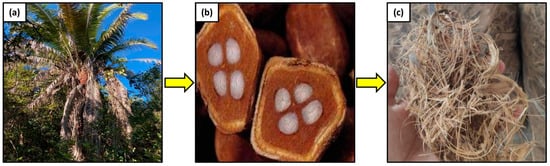

The babassu, belonging to the Arecaceae family and the Attalea genus, has the Brazilian species Attalea speciosa, a palm tree that can reach up to 20 m in height, as illustrated in Figure 3a. Its fruit contains oleaginous and edible seeds, with a high number of coconuts per cluster (between 150 and 250) and an average of four clusters per palm tree [181][41]. The fruits, as shown in Figure 3b, are ellipsoidal, measuring 8 to 15 cm in length and 5 to 7 cm in diameter, weighing between 90 and 280 g [182,183][42][43]. In Brazil, there are numerous babassu groves distributed from the southern Amazon region to the northeast, with occurrences also in Bolivia for the Attalea speciosa species [184][44]. In the states of Maranhão, Piauí, and Tocantins, the largest expanses of babassu forests in Brazil are found, forming homogeneous, dense, and naturally dark clusters due to the proximity of the large babassu palm trees [185][45]. This region is recognized as the world’s largest concentration of oil-producing plants and the primary source of extractive plant production, known as the “Mata dos Cocais” [186][46].

2.3. Buriti

The fiber from the Buriti palm (Mauritia Flexuosa) originates from a plant that is widely found in different regions of Brazil, with the main occurrence in the Amazon. Although buriti is also found in the Brazilian central region, as well as in the states of Bahia, Ceará, Maranhão, Minas Gerais, and Piauí, it is found predominantly in regions with a tropical climate, with an annual average temperature of between 26 °C and 30 °C and a rainfall of between 200 mm and 400 mm [199,200][56][57]. Buriti palm trees (Figure 5a) display some notable characteristics, reaching significant heights of up to 40 m, with a stem diameter between 50 and 60 cm. The leaves, which are over 15 cm long, remain attached to the stem after death, before eventually falling off. These leaves are widely used to make handicrafts and as roofing material in community dwellings. The fruit of the Buriti palm tree has horny scales with a reddish-brown hue, while the inner pulp displays an orange color. This pulp proves to be versatile, serving as human food, bait for hunting, a source of oil, and with potential medicinal applications. This diversity of uses highlights the ecological and socioeconomic significance of this species in local communities [201][58].

2.4. Carnauba

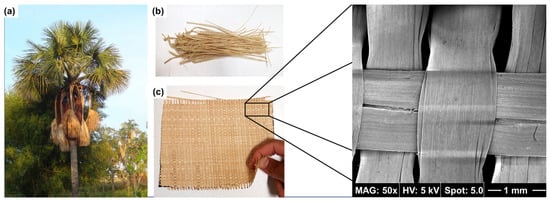

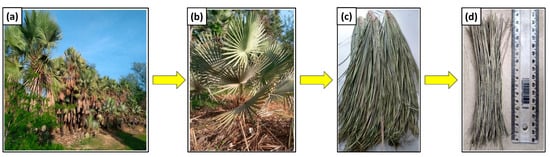

The Carnauba tree, illustated in Figure 6a, is classified as a palm of the Arecaceae family and has xerophytic characteristics. Its scientific name is Copernícia prunífera and it originated in Brazil. The term “carnauba” comes from the indigenous language and means “the tree that scratches”, an allusion to the 44 thorns distributed along the stem. In addition to its primary name, the plant is also known by variations such as carnaúva, carnaba, carandaúba, and carnaíba. The genus Copernicia comprises approximately 28 species, distributed in regions of India and South America. On the South American continent, species such as Copernícia tectorum (found in Venezuela and Colombia), Copernícia alba (found in Bolivia, Argentina, and Paraguay), and Copernícia prunífera are predominant in Brazil [218][71].

2.5. Curaua

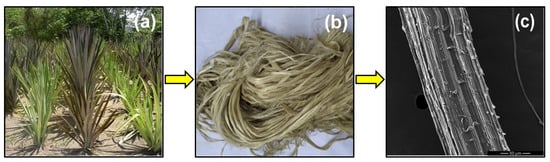

Curauá (Ananas Erectifolius) is a hydrophilic species native to the Amazon region, from which lignocellulosic fibers are extracted, known for their excellent mechanical properties [228][74]. In the Amazon, curauá fibers are widely recognized in the Amazon River basin region, particularly in the western part of the state of Pará, where the first commercial plantations of this plant were pioneeringly established [229,230][75][76]. Distinctive characteristics of curauá include hard, flat, and erect leaves, with an average length of 1–1.5 m, a width of approximately 40 mm, and a thickness of 5 mm. Each curauá plant exhibits a remarkable leaf production, averaging 50–60 per year, weighing about 150 g each [231][77]. This yield results in an annual production of 3–9 tons of dry fibers per hectare, notably relying on natural irrigation from rainfall throughout the year [230,232][76][78]. Beyond its economic significance, curauá fibers play a crucial role in the traditional practices of indigenous peoples. Indigenous communities use these fibers to craft ropes, hammocks, and fishing lines, requiring materials with high strength and deformability [233][79]. This application underscores the versatility of curauá fibers, combining remarkable mechanical properties with a sustainable origin. Figure 7 illustrates the curauá plant and the fiber resulting from the extraction of the plant’s leaves.

2.6. Guaruman

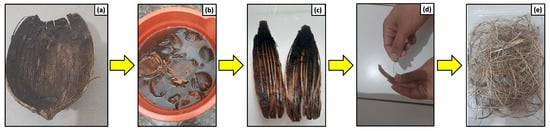

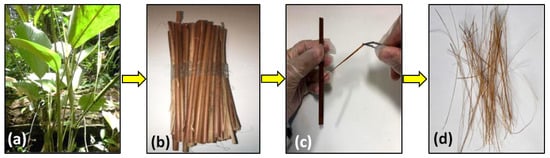

The guaruman plant (Ischnoshiphon Koern) is frequently found along the riverbanks in the Amazon region, especially in the Salgado Paeaense area in the state of Pará. Extracted from this region, these plants play a crucial role as raw material for handicrafts [250][94]. The Amazon is renowned for its vast diversity of native plant species, which play fundamental roles in food, medicine, construction, and fiber production. In the specific context of guaruman, this plant holds significant importance in the culture of riverside caboclos and various indigenous tribes. It is widely used in crafting, particularly in the creation of the famous straw weaving, a highly popular practice in the Para region [250,251][94][95]. Guaruman, also known as arumã, belongs to the Marantaceae family and is typically found in flooded várzea areas along riverbanks [252][96]. Barcarena, in the state of Pará, and more specifically, the Utinga-Açu community, are the main hubs for artisanal production of products made from guaruman fibers. The extraction process involves processing the guaruman stem, resulting in flexible, durable fibers with a distinctive golden hue, as illustrated in Figure 8 [250][94].

2.7. Periquiteira

The Periquiteira (Cochlospermum orinocense), also known as tree cotton, Envira-Branca, or Buxixão, is a plant from the Bixaceae family. This plant is characterized by being a medium-sized tree, ranging from 12 to 28 m in height, with a straight cylindrical trunk that can measure 40 to 75 cm and remain unbranched for up to half of the tree’s height. Its bark is whitish, with vertical fissures and fiber detachment, with 60 cm of cataphylls [255,256][98][99]. The wood has a coarse texture, a straight grain, is tasteless but slightly fragrant when fresh, lightweight, smooth, with low resistance to decay and attack by wood-eating insects, and it grows best in a sunny position. It is a fast-growing tree [256,257][99][100]. The occurrence of the Periquiteira is in Brazil, specifically in the Amazon Rainforest, but it also extends to countries in South America such as Peru, Colombia, Venezuela, and the Guianas. It mainly grows in more open areas of advanced secondary growth, in upland areas not subject to periodic flooding, plain areas, and highlands, usually on dry clay at altitudes of up to 450 m in Peru [256][99]. In Brazil, the Periquiteira is found in the states of Roraima, Rondônia, Amapá, Pará, Amazonas, Acre, Maranhão, and Mato Grosso [257][100].2.8. Piassava

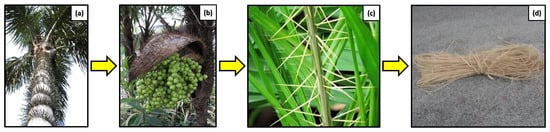

Piaçava is a palm tree native to Brazil, belonging to the Arecaceae family. Its popular name comes from the indigenous Tupi language, meaning “Fibrous Plant”. The different species of Piaçava are found mainly in the states of Acre (Aphandria natalia), Figure 9a and Bahia (Attalea funifera), and Amazonas (Leopoldinia piassaba). This palm is capable of growing in low-fertility soils that are unsuitable for many crops [260][101].

2.9. Tucum

The tucum, scientifically named Astrocaryum vulgare (Figure 10a), is a palm tree typical of the Amazon region. This plant has several scientific names, such as Astrocaryum chambira Burret and Astrocaryum aculeatum G. The fruits of the tucum are called tucumã and are widely used in local cuisine. In addition, the palm has a thorny trunk and can be used as a living fence to protect crops in short-cycle forestry of pioneer species. The purpose of this fence is to protect the seedlings from herbivory by animals [276][112].

2.10. Ubim

Ubim is a palm from the Arecaceae family, also known by its scientific name Geonoma baculífera [289][122]. The word ubim comes from the indigenous language, specifically the Tupi u’bi. The palm is also known by other names, such as Geonoma estevaniana Burret, Gynestum baculiferum Poit., Geonoma acutiflora Mart [290][123]. The Arecaceae family includes the genus geonoma, which is made up of small palms that generally grow in the understory. This genus is one of the largest in the Americas and is home to 15 species that are widely distributed across the continent, especially in tropical regions [291][124]. The species of Geonoma are commonly found in areas with high levels of rainfall, and are one of the most prevalent plant species in these environments. Palms of the genus Geonoma have a preference for riparian forest vegetation that occurs along watercourses, as well as open vegetation [292][125]. Ubim is a small cespitose palm with multiple, smooth stems and elongated, unbranched fibers. Its height varies between 1 and 4 m, with a diameter of 1 to 3 cm. The stem can be erect or partially creeping, and the plant has seven to twelve leaves, sparsely branched inflorescences, and globose or ovoid fruits. This species is typically found in the understory of forests with high rainfall, riparian forests, floodplains and igapós. The ubim is adapted to humid environments, is considered shade-tolerant, and generally grows in places with low incidence of direct light [289][122]. The occurrence of the ubim covers Central and South America, with records in the Guianas, Peru, Bolivia, and Venezuela. In Brazil, this plant can be found in the states of Amazonas, Acre, Amapá, Pará, Maranhão, and Piauí [294,295][126][127]. This species is widely used in the Amazon by extractivist communities who depend on the sustainable exploitation of various native species to meet their needs for construction materials for rural buildings. The leaves of the ubim, when intertwined along a stick, form ubim “cloths”, which are used as a covering in the constructions of these communities. This is a traditional practice, especially among those who live close to the border between Brazil and Bolivia. In Bolivia, ubim is commercially exploited, which indicates that the species may also have commercial potential on the Brazilian side [296][128]. In addition to its use in construction, ubim also has ecological importance for some indigenous and riverside communities. Ubim fibers are used to make baskets, mats, and other handicrafts. In addition, this plant has potential for ornamental purposes in gardens and interiors. Ubim is widely used in the Amazon and Acre regions; however, the plant’s potential application depends on the development of the market, which currently lacks a regular and abundant supply of the product. It also faces the apparent lack of awareness of its existence on the part of consumers in the city of Rio Branco, in the state of Acre, which represents the largest potential market for this product in the region [296][128]. In addition to the potential of ubim daughters, ubim fiber has yet to be widely applied as a reinforcing material in industrialized products and engineering applications. Unlike better-known fibers such as sisal, bamboo, curaua, coconut, jute, and others, there are practically no scientific reports studying the properties of ubim fiber and its application.References

- Akil, H.; Omar, M.; Mazuki, A.M.; Safiee, S.; Ishak, Z.M.; Bakar, A.A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121.

- Sanjay, M.R.; Arpitha, G.; Yogesha, B. Study on mechanical properties of natural-glass fibre reinforced polymer hybrid composites: A review. Mater. Today Proc. 2015, 2, 2959–2967.

- Tonk, R. Natural fibers for sustainable additive manufacturing: A state of the art review. Mater. Today Proc. 2021, 37, 3087–3090.

- Crewther, W. The stress—Strain characteristics of animal fibers after reduction and alkylation. Text. Res. J. 1965, 35, 867–877.

- Liu, X.; Wang, L.; Wang, X. Evaluating the softness of animal fibers. Text. Res. J. 2004, 74, 535–538.

- Ammar, Z.; Ibrahim, H.; Adly, M.; Sarris, I.; Mehanny, S. Influence of natural fiber content on the frictional material of brake pads—A review. J. Compos. Sci. 2023, 7, 72.

- Al-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt fiber reinforced concrete: A compressive review on durability aspects. Materials 2023, 16, 429.

- Tao, W.; Wang, B.; Wang, N.; Guo, Y.; Li, J.; Zhou, Z. Research progress on basalt fiber-based functionalized composites. Rev. Adv. Mater. Sci. 2023, 62, 20220300.

- Dvorkin, L.; Konkol, J.; Marchuk, V.; Huts, A. Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers. Materials 2023, 16, 3969.

- Peng, Z.; Zhang, H.; Feng, Q.; Zheng, Y. Improvement of basalt fiber dispersion and its effect on mechanical characteristics of oil well cement. J. Build. Eng. 2023, 76, 107244.

- Wang, N.; Liu, H.; Huang, F. Effects of Hybrid Rockwool–Wood Fiber on the Performance of Asbestos-Free Brake Friction Composites. Lubricants 2023, 11, 27.

- Yavuz, H. Effect of limestone usage on tribological properties in copper and asbestos-free brake friction materials. Ind. Lubr. Tribol. 2023, 75, 238–245.

- Suphamitmongkol, W.; Khanoonkon, N.; Rungruangkitkrai, N.; Boonyarit, J.; Changniam, C.; Sampoompuang, C.; Chollakup, R. Potential of Pineapple Leaf Fibers as Sound and Thermal Insulation Materials in Thailand. Prog. Appl. Sci. Technol. 2023, 13, 26–32.

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, Mechanical, and Thermal Properties of Natural Fiber-Reinforced Epoxy Composites for Construction and Automotive Applications. Appl. Sci. 2023, 13, 5126.

- Khatri, H.; Naveen, J.; Jawaid, M.; Jayakrishna, K.; Norrrahim, M.; Rashedi, A. Potential of natural fiber based polymeric composites for cleaner automotive component Production-A comprehensive review. J. Mater. Res. Technol. 2023, 25, 1086–1104.

- El Hawary, O.; Boccarusso, L.; Ansell, M.P.; Durante, M.; Pinto, F. An overview of natural fiber composites for marine applications. J. Mar. Sci. Eng. 2023, 11, 1076.

- Haramina, T.; Hadžić, N.; Keran, Z. Epoxy Resin Biocomposites Reinforced with Flax and Hemp Fibers for Marine Applications. J. Mar. Sci. Eng. 2023, 11, 382.

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.; Selvakumar, K.K.; Jyothi, M.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457.

- Özkılıç, Y.O.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M.; Mailyan, L.R.; Meskhi, B.; Chernil’nik, A.; Ananova, O.; Aksoylu, C.; Madenci, E. Lightweight expanded-clay fiber concrete with improved characteristics reinforced with short natural fibers. Case Stud. Constr. Mater. 2023, 19, e02367.

- Mansor, M.; Nurfaizey, A.; Tamaldin, N.; Nordin, M. Natural fiber polymer composites: Utilization in aerospace engineering. In Biomass, Biopolymer-Based Materials, and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 203–224.

- Asim, M.; Saba, N.; Jawaid, M.; Nasir, M. Potential of natural fiber/biomass filler-reinforced polymer composites in aerospace applications. In Sustainable Composites for Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 253–268.

- Dhas, J.E.R.; Arun, M. A review on development of hybrid composites for aerospace applications. Mater. Today Proc. 2022, 64, 267–273.

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162.

- Bismarck, A.; Mishra, S.; Lampke, T. Plant fibers as reinforcement for green composites. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005; pp. 52–128.

- Anandjiwala, R.D.; Blouw, S. Composites from bast fibres-prospects and potential in the changing market environment. J. Nat. Fibers 2007, 4, 91–109.

- Ticoalu, A.; Aravinthan, T.; Cardona, F. A review of current development in natural fiber composites for structural and infrastructure applications. In Proceedings of the Southern Region Engineering Conference (SREC 2010), Toowoomba, Australia, 11–12 November 2010.

- Bhattacharyya, D.; Subasinghe, A.; Kim, N.K. Natural fibers: Their composites and flammability characterizations. Multifunct. Polym. Compos. 2015, 1, 102–143.

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364.

- Jayaraman, K. Manufacturing sisal–polypropylene composites with minimum fibre degradation. Compos. Sci. Technol. 2003, 63, 367–374.

- Tsoumis, G. Science and Technology of Wood: Structure, Properties, Utilization; Van Nostrand Reinhold New York: New York, NY, USA, 1991; Volume 115.

- da Costa Tavares, M.G. A Amazônia brasileira: Formação histórico-territorial e perspectivas para o século XXI. GEOUSP Espaço E Tempo (Online) 2011, 15, 107–121.

- Rorato, A.C.; Dal’Asta, A.P.; Lana, R.M.; Dos Santos, R.B.; Escada, M.I.S.; Vogt, C.M.; Neves, T.C.; Barbosa, M.; Andreazzi, C.S.; Dos Reis, I.C.; et al. Trajetorias: A dataset of environmental, epidemiological, and economic indicators for the Brazilian Amazon. Sci. Data 2023, 10, 65.

- Buchdid Camargo Neves, L.T.; Dos Santos Campos, D.C.; Souza Mendes, J.K.; Urnhani, C.O.; Mattos De Araujo, K.G. Quality of Fruits Manually Processed of Acai (Euterpe oleracea MART.) and BACABA (Oenocarpus bacaba MART.). Rev. Bras. De Frutic. 2015, 37, 729–738.

- Yokomizo, G.K.I.; Mochiutti, S.; de Queiroz, J.A.L.; dos Santos, G.R.; Furtado, R.G.; Brandão, A.P.; Colares, I.B. Parameter estimates for genetic characters of assai palm trees fruits in Amapá State. Ciência Florest. 2016, 26, 985–993.

- Nascimento, R.J.S.d.; Couri, S.; Antoniassi, R.; Freitas, S.P. Composição em ácidos graxos do óleo da polpa de açaí extraído com enzimas e com hexano. Rev. Bras. De Frutic. 2008, 30, 498–502.

- Bufalino, L.; de Sena Neto, A.R.; Tonoli, G.H.D.; de Souza Fonseca, A.; Costa, T.G.; Marconcini, J.M.; Colodette, J.L.; Labory, C.R.G.; Mendes, L.M. How the chemical nature of Brazilian hardwoods affects nanofibrillation of cellulose fibers and film optical quality. Cellulose 2015, 22, 3657–3672.

- Subramoniam, R.; Huisingh, D.; Chinnam, R.B.; Subramoniam, S. Remanufacturing Decision-Making Framework (RDMF): Research validation using the analytical hierarchical process. J. Clean. Prod. 2013, 40, 212–220.

- Al-Oqla, F.M.; Sapuan, M.S.; Ishak, M.R.; Aziz, N.A. Combined multi-criteria evaluation stage technique as an agro waste evaluation indicator for polymeric composites: Date palm fibers as a case study. BioResources 2014, 9, 4608–4621.

- Al-Oqla, F.M.; Sapuan, S. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354.

- Castro, C.D.P.d.C.; Dias, C.G.B.T.; Faria, J.d.A.F. Production and evaluation of recycled polymers from açaí fibers. Mater. Res. 2010, 13, 159–163.

- de Carvalho, C.M.R.G.; Castro, G.C.; dos Santos, G.M.; Campelo, J.E.G.; Sarmento, J.L.R.; Carvalho, M.D.F. Aproveitamento integral do coco babaçu como estratégia de educação e desenvolvimento social sustentável. Extensão Em Foco 2020, 21, 156–164.

- Lorenzine, H.; Sousa, H.; Coelho, L.; Medeiros, J.; Nikolaus, B. Palmeiras No Brasil; Plantarum: Nova Odessa, Brazil, 1996; p. 70.

- Lorenzi, H.; Noblick, L.; Kahn, F.; Ferreira, E. Flora Brasileira-Arecaceae (Palmeiras); Instituto Plantarum: Nova Odessa, Brazil, 2010.

- González-Pérez, S.E.; Coelho-Ferreira, M.; Robert, P.d.; Garcés, C.L.L. Conhecimento e usos do babaçu (Attalea speciosa Mart. e Attalea eichleri (Drude) AJ Hend.) entre os Mebêngôkre-Kayapó da Terra Indígena Las Casas, estado do Pará, Brasil. Acta Bot. Bras. 2012, 26, 295–308.

- Silva, G.; Barroso, M.E.; Silva, D.L.; Conceição, G. A importância do coco babaçu para a comunidade escolar e extrativista no município de São João do Arraial/PI. Agrar. Acad. 2016, 3.

- Santana, S.A.; Vieira, A.P.; da Silva Filho, E.C.; Melo, J.C.; Airoldi, C. Immobilization of ethylenesulfide on babassu coconut epicarp and mesocarp for divalent cation sorption. J. Hazard. Mater. 2010, 174, 714–719.

- Global Biodiversity Information Facility GBIF. Ocorrência Attalea Speciosa Mart. ex Spreng. 2023. Available online: https://www.gbif.org/pt/species/8174773 (accessed on 10 November 2023).

- Carrazza, L.R.; Ávila, J.C.C.; Silva, M.L.D. Manual Tecnológico de Aproveitamento Integral do Fruto e da Folha do Babaçu (Attalea spp.), 2nd ed.; ISPN: Brasília, Brazil, 2012; ISBN 978-85-63288-06-6.

- Soler, M.P.; Vitali, A.d.A.; Muto, E.F. Tecnologia de quebra do coco babaçu (Orbignya speciosa). Food Sci. Technol. 2007, 27, 717–722.

- de Morais, J.P.G.; Campana, M.; Del Valle, T.A.; Moreira, T.G.; da Silva, E.D.R.; do Prado, R.F.; de Oliveira, R.E. Inclusion of babassu bran produced in milk production in Amazonia. Trop. Anim. Health Prod. 2021, 53, 527.

- Costa, R.M.; Leite, M.R.L.; Matos, S.d.S.; Sousa, R.C.M.d.; Silva-Matos, R.R.S.d.; Bezerra, A.A.d.C. Quality of pre-sprouted sugarcane seedlings grown on substrates with decomposed babassu palm stem. Pesqui. Agropecu. Trop. 2021, 51.

- dos Anjos, S.S.N.; do Nascimento Neto, J.O. Avaliação do impacto de política de subvenção econômica na cadeia produtiva de biodiesel de Babaçu. Rev. Em Agronegócio E Meio Ambiente 2021, 14, 1–16.

- Chaves, Y.S.; da Silveira, P.H.P.; Neuba, L.d.M.; Junio, R.F.P.; Ribeiro, M.P.; Monteiro, S.N.; Nascimento, L.F.C. Evaluation of the density, mechanical, thermal and chemical properties of babassu fibers (Attalea speciosa.) for potential composite reinforcement. J. Mater. Res. Technol. 2023, 23, 2089–2100.

- De Lemos, A.L.; Mauss, C.J.; Santana, R.M.C. Characterization of natural fibers: Wood, sugarcane and babassu for use in biocomposites. Cellul. Chem. Technol. 2017, 51, 711–718.

- Chaves, Y.S.; da Silveira, P.H.P.M.; Monteiro, S.N.; Nascimento, L.F.C. Babassu Coconut Fibers: Investigation of Chemical and Surface Properties (Attalea speciosa). Polymers 2023, 15, 3863.

- Endress, B.A.; Horn, C.M.; Gilmore, M.P. Mauritia flexuosa palm swamps: Composition, structure and implications for conservation and management. For. Ecol. Manag. 2013, 302, 346–353.

- Peters, C.M.; Balick, M.J.; Kahn, F.; Anderson, A.B. Oligarchic forests of economic plants in Amazonia: Utilization and conservation of an important tropical resource. Conserv. Biol. 1989, 3, 341–349.

- Lawrence, A.; Phillips, O.L.; Ismodes, A.R.; Lopez, M.; Rose, S.; Wood, D.; Farfan, A.J. Local values for harvested forest plants in Madre de Dios, Peru: Towards a more contextualised interpretation of quantitative ethnobotanical data. Biodivers. Conserv. 2005, 14, 45–79.

- da Cruz Demosthenes, L.C.; Nascimento, L.F.C.; Monteiro, S.N.; Costa, U.O.; da Costa Garcia Filho, F.; da Luz, F.S.; Oliveira, M.S.; Ramos, F.J.H.T.V.; Pereira, A.C.; Braga, F.O. Thermal and structural characterization of buriti fibers and their relevance in fabric reinforced composites. J. Mater. Res. Technol. 2020, 9, 115–123.

- Mesa, L.; Galeano, G. Palms uses in the Colombian Amazon. Caldasia 2013, 35, 351–369.

- Abreu, Y.; Ávila, R.; Gonçalves, T. The buriti agro extractivism: An alternative for the development of the Brazilian Amazon Region. Int. J. Soc. Sci. Entrep. 2014, 1, 189–197.

- Virapongse, A. Social mechanisms and mobility: Buriti palm (Mauritia flexuosa) extractivism in Brazil. Hum. Ecol. 2017, 45, 119–129.

- Sosnowska, J.; Walanus, A.; Balslev, H. Asháninka palm management and domestication in the Peruvian Amazon. Hum. Ecol. 2015, 43, 451–466.

- Draper, F.C.; Roucoux, K.H.; Lawson, I.T.; Mitchard, E.T.; Coronado, E.N.H.; Lähteenoja, O.; Montenegro, L.T.; Sandoval, E.V.; Zaráte, R.; Baker, T.R. The distribution and amount of carbon in the largest peatland complex in Amazonia. Environ. Res. Lett. 2014, 9, 124017.

- Demosthenes, L.C.d.C.; Luz, F.S.d.; Nascimento, L.F.C.; Monteiro, S.N. Buriti Fabric Reinforced Epoxy Composites as a Novel Ballistic Component of a Multilayered Armor System. Sustainability 2022, 14, 10591.

- da Silva Santos, R.; de Souza, A.A.; De Paoli, M.A.; de Souza, C.M.L. Cardanol–formaldehyde thermoset composites reinforced with buriti fibers: Preparation and characterization. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1123–1129.

- Júnior, H.L.O.; Moraes, A.; Poletto, M.; Zattera, A.J.; Amico, S.C. Chemical composition, tensile properties and structural characterization of buriti fiber. Cellul. Chem. Technol. 2016, 50, 15–22.

- Pelegrini, K.; Donazzolo, I.; Brambilla, V.; Coulon Grisa, A.M.; Piazza, D.; Zattera, A.J.; Brandalise, R.N. Degradation of PLA and PLA in composites with triacetin and buriti fiber after 600 days in a simulated marine environment. J. Appl. Polym. Sci. 2016, 133.

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.; Margem, F.M. Thermogravimetric stability of polymer composites reinforced with less common lignocellulosic fibers—An Overview. J. Mater. Res. Technol. 2012, 1, 117–126.

- Neves Monteiro, S.; de Oliveira Braga, F.; Pereira Lima, E.; Henrique Leme Louro, L.; Wieslaw Drelich, J. Promising curaua fiber-reinforced polyester composite for high-impact ballistic multilayered armor. Polym. Eng. Sci. 2017, 57, 947–954.

- Junio, R.F.P.; de Mendonça Neuba, L.; Souza, A.T.; Pereira, A.C.; Nascimento, L.F.C.; Monteiro, S.N. Thermochemical and structural characterization of promising carnauba novel leaf fiber (Copernicia prunifera). J. Mater. Res. Technol. 2022, 18, 4714–4723.

- Junio, R.F.P.; Nascimento, L.F.C.; Neuba, L.d.M.; Souza, A.T.; Moura, J.V.B.; Garcia Filho, F.d.C.; Monteiro, S.N. Copernicia prunifera leaf fiber: A promising new reinforcement for epoxy composites. Polymers 2020, 12, 2090.

- Melo, J.D.D.; Carvalho, L.F.M.; Medeiros, A.M.; Souto, C.R.; Paskocimas, C.A. A biodegradable composite material based on polyhydroxybutyrate (PHB) and carnauba fibers. Compos. Part B Eng. 2012, 43, 2827–2835.

- Castro, D.O.d.; Ruvolo-Filho, A.; Frollini, E. Materials prepared from biopolyethylene and curaua fibers: Composites from biomass. Polym. Test. 2012, 31, 880–888.

- Souza, S.; Ferreira, M.; Sain, M.; Ferreira, M.; Pupo, H.; Cherian, B.; Leão, A. The use of curaua fibers as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 700–720.

- Santos, P.A.; Spinacé, M.A.; Fermoselli, K.K.; De Paoli, M.A. Efeito da forma de processamento e do tratamento da fibra de curauá nas propriedades de compósitos com poliamida-6. Polímeros 2009, 19, 31–39.

- Leão, A.; Sartor, S.M.; Caraschi, J.C. Natural fibers based composites—Technical and social issues. Mol. Cryst. Liq. Cryst. 2006, 448, 161–763.

- de Freitas, A.E.; Padilha, F.d.J.; Barros, S.d.S.; Khan, T.M.; Pereira, B.; Barbosa, W.T.; Barbosa, J.D.; Calderaro, F.L.; da Silva, S.; Quirino, M.G.; et al. Curauá fiber from plants produced by tissue culture: Thermal, mechanical, and morphological characterizations. Cellulose 2023, 30, 2841–2858.

- Garcés, C.L.L.; Pérez, S.E.G.; Silva, J.A.d.; Araújo, M.O.d.; Coelho-Ferreira, M. Objetos indígenas para o mercado: Produção, intercâmbio, comércio e suas transformações. Experiências Ka’apor e Mebêngôkre-Kayapó. Bol. Do Mus. Para. Emilio Goeldi. Cienc. Humanas 2015, 10, 659–680.

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; da Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical properties of composites with graphene oxide functionalization of either epoxy matrix or curaua fiber reinforcement. J. Mater. Res. Technol. 2020, 9, 13390–13401.

- Zah, R.; Hischier, R.; Leão, A.L.; Braun, I. Curauá fibers in the automobile industry—A sustainability assessment. J. Clean. Prod. 2007, 15, 1032–1040.

- Gomes, A.; Matsuo, T.; Goda, K.; Ohgi, J. Development and effect of alkali treatment on tensile properties of curaua fiber green composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1811–1820.

- Gomes, A.; Goda, K.; Ohgi, J. Effects of alkali treatment to reinforcement on tensile properties of curaua fiber green composites. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2004, 47, 541–546.

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561.

- Teixeira, F.P.; de Andrade Silva, F. On the use of natural curauá reinforced cement based composites for structural applications. Cem. Concr. Compos. 2020, 114, 103775.

- Teixeira, R.S.; Santos, S.F.d.; Christoforo, A.L.; Savastano, H., Jr.; Lahr, F.A.R. Extrudability of cement-based composites reinforced with curauá (Ananas erectifolius) or polypropylene fibers. Constr. Build. Mater. 2019, 205, 97–110.

- Meliande, N.M.; Oliveira, M.S.; Silveira, P.H.P.M.d.; Dias, R.R.; Marçal, R.L.S.B.; Monteiro, S.N.; Nascimento, L.F.C. Curaua—Aramid Hybrid Laminated Composites for Impact Applications: Flexural, Charpy Impact and Elastic Properties. Polymers 2022, 14, 3749.

- Meliande, N.M.; Silveira, P.H.P.M.d.; Monteiro, S.N.; Nascimento, L.F.C. Tensile Properties of Curaua—Aramid Hybrid Laminated Composites for Ballistic Helmet. Polymers 2022, 14, 2588.

- Meliande, N.M.; Oliveira, M.S.; Pereira, A.C.; Balbino, F.D.P.; da Silva Figueiredo, A.B.H.; Monteiro, S.N.; Nascimento, L.F.C. Ballistic properties of curaua-aramid laminated hybrid composites for military helmet. J. Mater. Res. Technol. 2023, 25, 3943–3956.

- da Silva, A.O.; de Castro Monsores, K.G.; Oliveira, S.d.S.; Weber, R.P.; Monteiro, S.N. Ballistic behavior of a hybrid composite reinforced with curaua and aramid fabric subjected to ultraviolet radiation. J. Mater. Res. Technol. 2018, 7, 584–591.

- de Campos, A.; Claro, P.C.; Luchesi, B.R.; Miranda, M.; Souza, F.V.; Ferreira, M.D.; Marconcini, J.M. Curaua cellulose sheets dip coated with micro and nano carnauba wax emulsions. Cellulose 2019, 26, 7983–7993.

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Biocomposites based on poly (butylene succinate) and curaua: Mechanical and morphological properties. Polym. Test. 2015, 45, 168–173.

- Borsoi, C.; Scienza, L.C.; Zattera, A.J. Characterization of composites based on recycled expanded polystyrene reinforced with curaua fibers. J. Appl. Polym. Sci. 2013, 128, 653–659.

- Santos, N.S.S.; Carneiro, S.C.P.M.H.d.S. Utilização do trançado de palha como estratégia para o desenvolvimento sustentável do setor moveleiro. Simpósio De Eng. De Produção 2005, 13, 2005.

- Costa , M.O.; Souza, F.S.; Andrade, S.M.C. Ensaios de tração e de absorção de água em compósitos de resina poliester e fibra da tala de Guarumã. In Proceedings of the 21º CBECIMAT - Congresso Brasileiro de Engenharia e Ciência dos Materiais, Cuiabá, Brazil, 9–13 November 2014; Volume 21, pp. 3736–3741.

- Pinheiro, M.A.; Gomes, L.G.; Silva, A.C.R.d.; Candido, V.S.; Reis, R.H.M.; Monteiro, S.N. Guaruman: A natural Amazonian fiber with potential for Polymer composite reinforcement. Mater. Res. 2019, 22, e20190092.

- Reis, R.H.M.; Nunes, L.F.; Oliveira, M.S.; de Veiga Junior, V.F.; Filho, F.D.C.G.; Pinheiro, M.A.; Candido, V.S.; Monteiro, S.N. Guaruman fiber: Another possible reinforcement in composites. J. Mater. Res. Technol. 2020, 9, 622–628.

- Batista, J.S.; de Moraes, M.F.; da Silva, R.S.D.; da Cruz, W.J.A.; Carniello, M.A. Cochlospermum orinocense (bixaceae) ocorrentes na bacia do guaporé, mato grosso, Brasil. In Proceedings of the 64º Congresso Nacional de Botânica, Belo Horizonte, Brazil, 10–15 November 2013; p. 1.

- Figueiredo, P.S.d.; Ribeiro, É.K.M.D.; Lacerda, D.M.A.; Girnos, E.C. Estratégia reprodutiva de Cochlospermum orinocense (Kunth) Steud.: Fenologia, biologia floral e sistema de cruzamento em uma espécie pioneira de florestas na Amazônia. Braz. J. Bot. 2009, 32, 781–792.

- Reflora. Cochlospermum Orinocense (Kunth) Steud. 2023. Available online: https://floradobrasil.jbrj.gov.br/reflora/listaBrasil/ConsultaPublicaUC/BemVindoConsultaPublicaConsultar.do?invalidatePageControlCounter=&idsFilhosAlgas=&idsFilhosFungos=&lingua=&grupo=&familia=null&genero=&especie=&autor=&nomeVernaculo=&nomeCompleto=Cochlospermum+orinocense&formaVida=null&substrato=null&ocorreBrasil=QUALQUER&ocorrencia=OCORRE&endemismo=TODOS&origem=TODOS®iao=QUALQUER&estado=QUALQUER&ilhaOceanica=32767&domFitogeograficos=QUALQUER&bacia=QUALQUER&vegetacao=TODOS&mostrarAte=SUBESP_VAR&opcoesBusca=TODOS_OS_NOMES&loginUsuario=Visitante&senhaUsuario=&contexto=consulta-publica (accessed on 10 November 2023).

- Monteiro, S.N. Properties and structure of Attalea funifera piassava fibers for composite reinforcement—A critical discussion. J. Nat. Fibers 2009, 6, 191–203.

- Ferreira, D.C.d.O.N.; Ferreira, A.d.S.; Monteiro, S.N. Weibull analysis of tensile tested piassava fibers with different diameters. Matéria 2018, 23.

- Elzubair, A.; Bonelli, C.M.C.; Suarez, J.C.M.; Mano, E.B. Morphological, structural, thermal and mechanical characterization of piassava fibers. J. Nat. Fibers 2007, 4, 13–31.

- Pimentel, N.M.; Del Menezzi, C. Rendimento do processamento dos produtos oriundos da fibra vegetal da piaçava (Attalea funifera). Nativa 2020, 8, 137–144.

- Bonelli, C.; Elzubair, A.; Suarez, J.C.M.; Mano, E.B. Comportamento térmico, mecânico e morfológico de compósitos de polietileno de alta densidade reciclado com fibra de piaçava. Polímeros 2005, 15, 256–260.

- Turini, E. Proposta de preços mínimos safra 2013/2014. Produtos da sociobiodiversidade. Propos. De Preços Mínimos 2014, 3, 5–19.

- Fornari, C.I.; Fornari, J.; Celso, C. Avaliação da força de cisalhamento de fibras longas de piaçava em poliéster insaturado. Estud. Tecnol. Em Eng. 2013, 9.

- Guimarães, C.A.L.; Silva, L.A.M. Piaçava da Bahia (Attalea funifera Martius): Do Extrativismo à Cultura Agrícola; Editus: Ilhéus, Brazil, 2012.

- Agrize, P.L.; da Silva, B.D.L.; Carvalho Veiga, B.; Rocha, C.A.A.; Garcia Filho, F.d.C.; Braga, F.d.O. Structure and mechanical behavior of lignosulfonate-treated piassava (Attalea funifera) fibers. Matéria 2023, 28, e20230041.

- dos Santos, F.M.; de Souza, T.F.; Barquete, D.M.; Amado, F.D. Comparative analysis of the sisal and piassava fibers as reinforcements in lightweight cementitious composites with EVA waste. Constr. Build. Mater. 2016, 128, 315–323.

- Miranda, C.S.; Fiuza, R.P.; Carvalho, R.F.; José, N.M. Efeito dos tratamentos superficiais nas propriedades do bagaço da fibra de piaçava Attalea funifera martius. Quím. Nova 2015, 38, 161–165.

- Marinelli, A.L.; Monteiro, M.R.; Ambrósio, J.D.; Branciforti, M.C.; Kobayashi, M.; Nobre, A.D. Desenvolvimento de compósitos poliméricos com fibras vegetais naturais da biodiversidade: Uma contribuição para a sustentabilidade amazônica. Polímeros 2008, 18, 92–99.

- Vasques, J.C. Nanocompósito de Poli(óxido de etileno) Reforçado Com Nanocristais de Celulose Extraídos da Fibra de Tucum. Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2018.

- Ferreira, E.L. Manual das Palmeiras do Acre, Brasil; Instituto Nacional de Pesquisas/Universidade Federal do Acre: Rio Branco, Brazil, 2005.

- Abreu, R.; Nunes, N.L. Tecendo a tradição e valorizando o conhecimento tradicional na Amazônia: O caso da “linha do tucum”. Horiz. Antropol. 2012, 18, 15–43.

- Jensen, O.H.; Balslev, H. Etnobotánica de la palma de fibra Astrocaryum chambira (Arecaceae) en la Amazonía ecuatoriana. Econ. Bot. 1995, 49, 309–319.

- Vormisto, J. Making and marketing chambira hammocks and bags in the village of Brillo Nuevo, northeastern Peru. Econ. Bot. 2002, 56, 27–40.

- Coomes, O.T. Rain forest ‘conservation-through-use’? Chambira palm fibre extraction and handicraft production in a land-constrained community, Peruvian Amazon. Biodivers. Conserv. 2004, 13, 351–360.

- Bernal, R.; Torres, C.; García, N.; Isaza, C.; Navarro, J.; Vallejo, M.I.; Galeano, G.; Balslev, H. Palm management in south america. Bot. Rev. 2011, 77, 607–646.

- Acevedo, L.M.G. El tejido en chambira, una actividad que une más que sogas. Bol. De Antropol. Univ. De Antioq. 2005, 19, 164–185.

- Castaño-Arboleda, N.; Cárdenas, D.; Rodriguez, E.O. Ecología, Aprovechamiento y Manejo Sostenible de Nueve Especies de Plantas del Departamento del Amazonas, Generadoras de Productos Maderables y No Maderables; Instituto Amazónico de Investigaciones Científicas “SINCHI”: Bogotá, Colombia, 2006; ISBN 978-958-8317-21-2.

- Henderson, A.; Galeano, G.; Bernal, R. Field Guide to the Palms of the Americas; Princeton University Press: Princeton, NJ, USA, 2019; Volume 5390.

- Anderson, A.B. Os nomes e usos de palmeiras entre uma tribo de índios Yanomama. Acta Amaz. 1977, 7, 5–13.

- Jardim, M.A.G.; Santos, G.d.; Medeiros, T.D.S.; Francez, D.d.C. Diversidade e estrutura de palmeiras em floresta de várzea do estuário amazônico. Amazôn. Ciênc. Desenvolv. 2007, 2, 67–84.

- Punt, W.; Wessels Boer, J. A palynological study in geonomoid palms. Acta Bot. Neerl. 1966, 15, 266–275.

- de Granville, J.J. La distribución de las palmas en Guyana Francesa. Acta Amaz. 1989, 19, 115–138.

- Rocha, A.E.S.d.; Silva, M.F.F.d. Aspectos fitossociológicos, florísticos e etnobotânicos das palmeiras (Arecaceae) de floresta secundária no município de Bragança, PA, Brasil. Acta Bot. Bras. 2005, 19, 657–667.

- Siviero, A.; Lin, C.M.; Silveira, M.; Daly, D.C.; Wallace, R.H. Etnobotânica e Botânica Econômica do Acre; Edufac: Rio Branco, Brazil, 2016; 410p, ISBN 978-85-8236-027-9.