Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Francisco Jose Alguacil.

Since CO2 is an important component of gas emissions, its removal from gas streams is of the utmost importance to fulfill various environmental requirements. The technologies used to accomplish this removal are based mainly on absorption, as well as adsorption and membrane processing. Among the materials used in the above separation processes, materials in nano forms offer a potential alternative to other commonly used macromaterials.

- CO2

- absorption

- adsorption

- membranes

1. Introduction

One of the main global concerns is related to the increasing concentration of CO2 in the atmosphere, a consequence of the use of fossil fuels, boosting the greenhouse impact. There is no doubt that greenhouse gas emissions produce climate problems, resulting in challenges in reaching sustainable development. Greenhouse gas emissions are mainly a result of energy production (nearly 70% of global emissions). Many countries have considered the importance of reducing CO2 emissions to fulfill environmental policies related to zero-carbon discharge, helping to reduce the presence of carbon in a number of sectors, with special interest in the energy sector. However, the time to achieve the transition from today’s polluting energy production to a future of zero-emissions technology still seems long, and this is because there is a constant flux of information and developments to improve the capture of contaminant gases (CO2, H2S, CH4, etc.) from gas streams in order to clean them and contribute to a better environment.

Among the technologies employed for this capture, and in the case of CO2 specifically, absorption, adsorption, and membrane technologies are the most widely proposed. Several recent reviews on the utilization of these technologies have been published, including the use of membranes [1]; MXene-based membranes [2]; composite membranes [3,4][3][4]; microporous membranes composed of nanopores [5]; nanomaterials [6[6][7][8][9][10][11],7,8,9,10,11], and more specifically, graphene and its 2D nanomaterial derivatives [12]; nanomaterials derived with support from artificial intelligence (AI) [13]; kaolinite-based nanomaterials [14]; MXene nanoderivatives [15]; azobenzene-based supramolecular materials [16]; carbon-bearing nanomaterials [17]; nanobiotechnology using microalgae [18]; nanomaterials for catalyst-assisted solvent regeneration in absorption processes using amine [19]; and finally, some general reviews on technologies for CO2 removal from gas streams [20,21,22,23][20][21][22][23].

2. Nanomaterials and CO2 Absorption

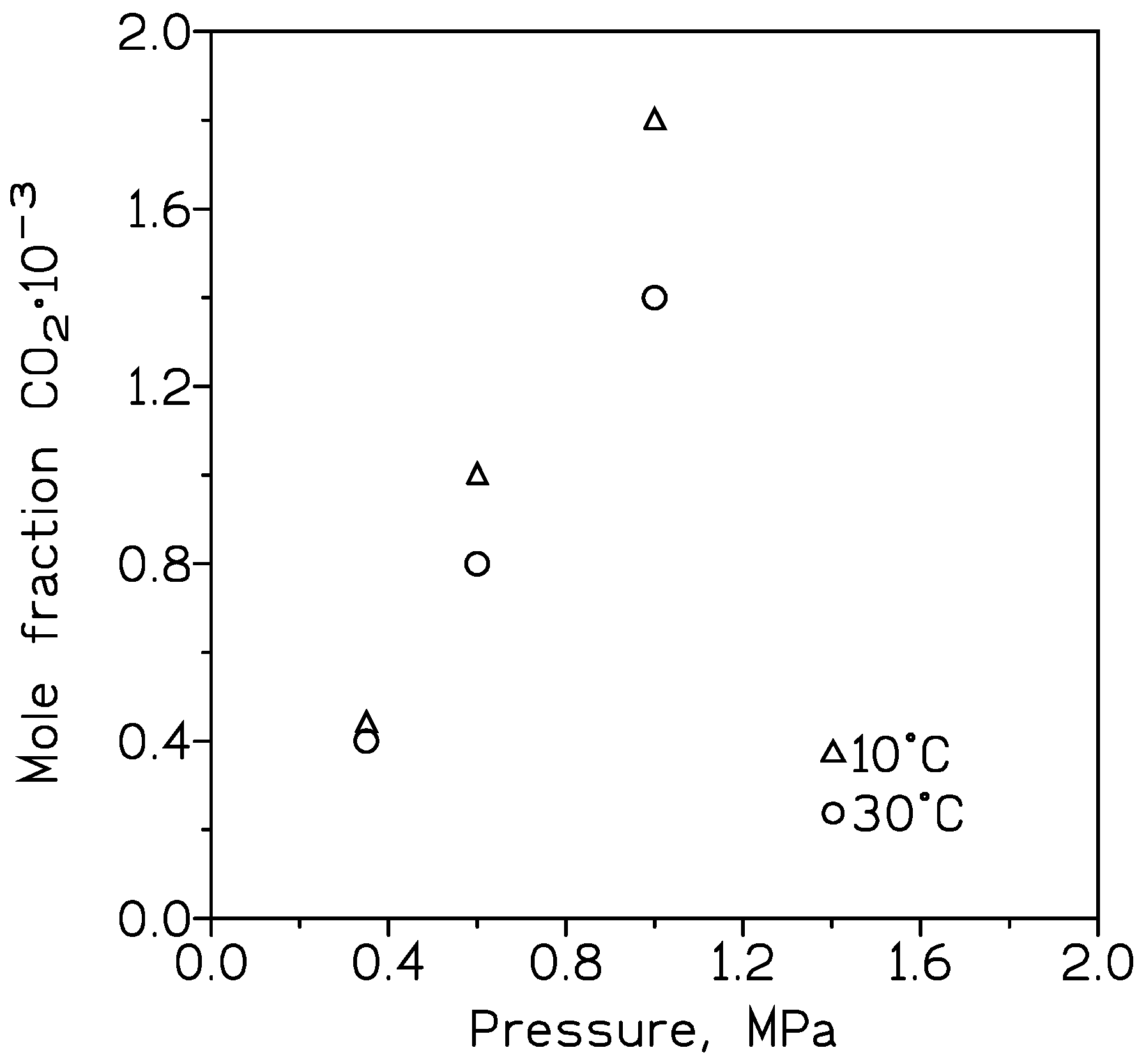

With quick kinetics, absorption techniques produce remarkable CO2 removal (90%) from gases. The most-used absorbents to achieve this removal include amines, ammonia–water solutions, and alkali compounds. Both pre- and post-combustion processes can integrate these technologies into their general procedure. Besides physical absorption, chemical-driven absorption processes have three components: absorber, solvent, and stripper. Different pieces of equipment were used to capture CO2, i.e., spray columns, packed beds, rotating packed beds, bubble columns, and tray tower absorber layouts. The absorption of CO2 on Al2O3/MeOH [24] was investigated, and the addition of a porous nickel metal foam increased CO2 capture compared to pure MeOH; this increase was attributable to the forced bubble-breaking mechanism and the hydrodynamics in relation to the process. Moreover, there was a direct relation with the CO2 absorption and the pressure and temperature used in the CO2 capture process (Figure 1). For a constant pressure, increasing the temperature decreased the gas capture, whereas for a constant temperature, increasing the pressure produced a greater removal of CO2 from the gas stream. Also, an increase (0.01–0.1 wt%) in the Al2O3 content is accompanied by an increase in the capture of CO2 with the alcohol.

Figure 1. Approximate CO2 removal in MeOH at various temperatures and pressures.

3. Nanomaterials and CO2 Adsorption

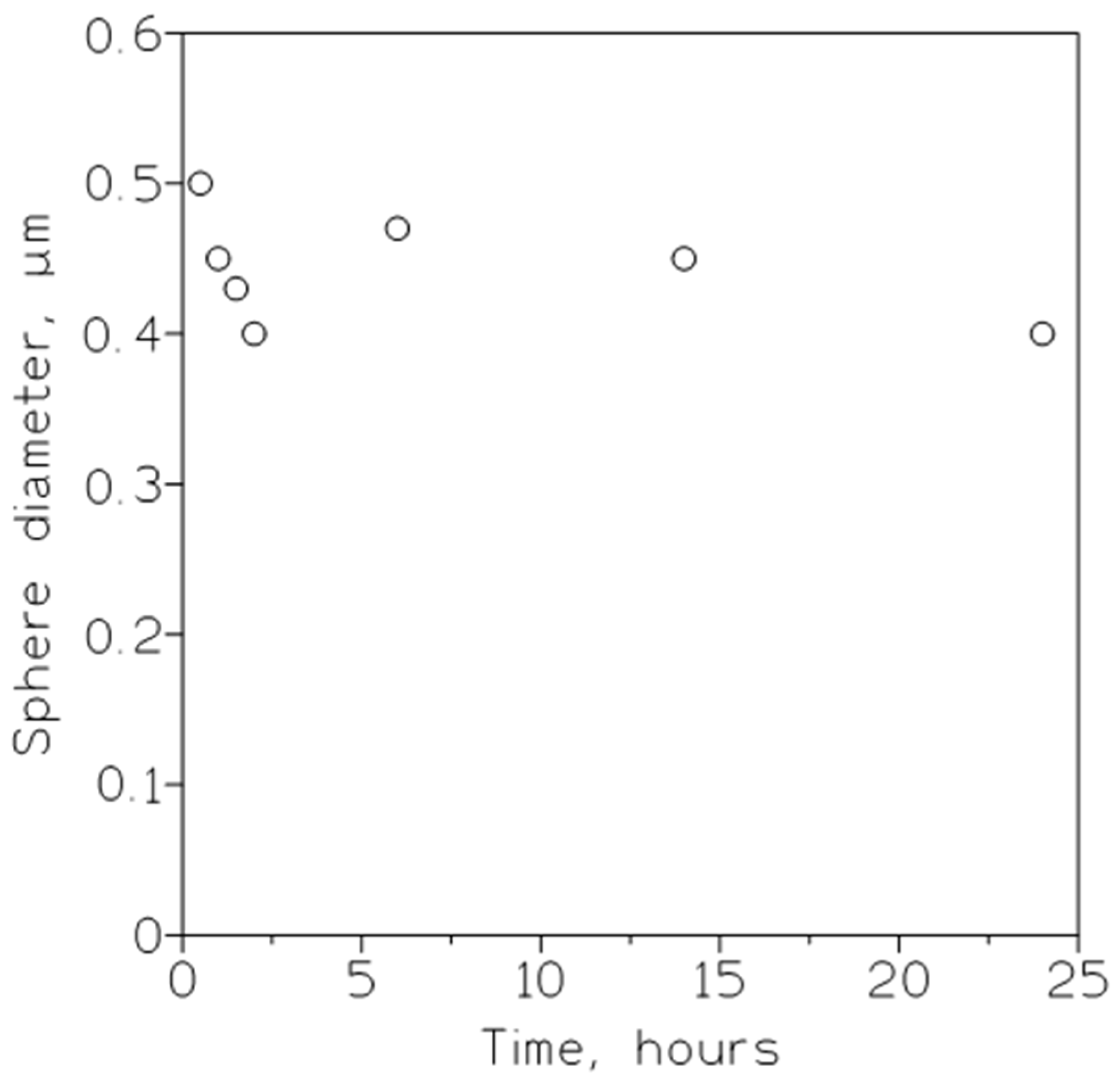

Adsorption processing involves the use of a solid material on which CO2 (and other gases and solutes) is captured by means of physical or chemical processes or a combination of both. Key parameters to yield the best adsorptive properties of the materials are: porosity, pore size, operational stability, presence of reactive groups towards CO2 adsorption, etc., whereas the equipment used is usually described as a packed or fluidized bed. The fabrication of carbon nanofibers (CNFs) via biaxial electrospinning was investigated [41][40]. Polymethylmethacrylate (PMMA) and polyacrylonitrile (PAN) were used as core and shell precursors, respectively. Further, Co3O4 nanoparticles were included in the PAN shell, increasing its roughness and surface area. The uniform distribution of Co3O4 resulted in a better flexibility of the hollow carbon nanofiber material (HCNF-Co), providing more vacant oxygen sites to increase CO2 adsorption loading. HCNF-Co nanofibers exhibited CO2 capture uptake of 3.28 mmol/g at 25 °C. Experimental results indicated that HCNF-Co had remarkable CO2 selectivity (S = 26) over N2. Heterojunctions of Co3O4 with different morphologies and modified carbon nitride (CN) were investigated in order to optimize their properties to degrade CO2 under UV–visible irradiation [42][41]. A solvothermal synthesis was used to fabricate the cobalt oxide from metal–organic framework structures, yielding ultrathin 2D Co3O4 nanosheets (Co3O4-NS). These nanosheets presented improved photocatalytic properties compared to those of the bulk Co3O4/CN composites. CO2 reduction was improved due to (i) the match of the planar surface of CN and the 2D structure of Co3O4-NS, which resulted in a larger interface, and (ii) improvement in charge carrier lifetime. The authors of [43][42] described the utilization of 2D nanomaterial MXenes and activated carbon (AC) to form sandwich-type materials and nanocomposites for CO2 adsorption using a fixed-bed column. These investigations included CO2 breakthrough measurements at a fixed 15% CO2 concentration, with an inlet flow rate at 200 mL/min and temperatures in the 25–55 °C range. The highest CO2 adsorption load (near 9 mg/g) was yielded with AC/MXene sandwich adsorbent at 25 °C, which was nearly a 37% improvement in CO2 adsorption capacity over the use of pristine AC. AC/MXene sandwich-type nanomaterials can be used, with a small loss of their CO2 adsorption uptake, under various cyclic experiments. ZIF-8 hollow nanospheres, for selective CO2 separation and storage, were developed [44][43]. The optimum hollow ZIF-8 nanosphere material, with a uniform size distribution (Figure 2), had a CO2 adsorption uptake of 2.24 mmol/g at 0 °C and 1.75 bar, selective (12.15) CO2/N2 separation, 1.5–1.75 wt% CO2 storage capacity, and a reasonable stability, up to four CO2 adsorption/desorption cycles, at 25 °C.

Figure 2. Influence of synthesis time on the average diameter of soft template hollow ZIF-8 nanospheres. Surfactant/oil ratio: 75 g/L.

References

- Yuan, Z.; Tang, J.; Chen, D.; Li, Y.; Hong, Z.; He, X. Membranes for hydrogen rainbow toward industrial decarbonization: Status, challenges and perspectives from materials to processes. Chem. Eng. J. 2023, 470, 144328.

- Ahmad, I.; Alayande, A.B.; Jee, H.; Wang, Z.; Park, Y.-J.; Im, K.S.; Nam, S.Y. Recent progress of MXene-based membranes for high-performance and efficient gas separation. Diam. Relat. Mater. 2023, 135, 109883.

- Dai, Y.; Niu, Z.; Luo, W.; Wang, Y.; Mu, P.; Li, J. A review on the recent advances in composite membranes for CO2 capture processes. Sep. Purif. Technol. 2023, 307, 122752.

- Luo, W.; Li, F.; Li, H.; Zhang, Z.; Zhang, X.; Liang, Y.; Huang, G. From 0D to 3D nanomaterial-based composite membranes for CO2 capture: Recent advances and perspectives. J. Environ. Chem. Eng. 2023, 11, 110657.

- Dai, Y.; Niu, Z.; Wang, Y.; Zhong, S.; Mu, P.; Li, J. Recent advances and prospect of emerging microporous membranes for high-performance CO2 capture. Sep. Purif. Technol. 2023, 318, 123992.

- Alli, Y.A.; Oladoye, P.O.; Ejeromedoghene, O.; Bankole, O.M.; Alimi, O.A.; Omotola, E.O.; Olanrewaju, C.A.; Philippot, K.; Adeleye, A.S.; Ogunlaja, A.S. Nanomaterials as catalysts for CO2 transformation into value-added products: A review. Sci. Total Environ. 2023, 868, 161547.

- Baena-Moreno, F.M.; Leventaki, E.; Riddell, A.; Wojtasz-Mucha, J.; Bernin, D. Effluents and residues from industrial sites for carbon dioxide capture: A review. Environ. Chem. Lett. 2023, 21, 319–337.

- Hanifa, M.; Agarwal, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. A review on CO2 capture and sequestration in the construction industry: Emerging approaches and commercialised technologies. J. CO2 Util. 2023, 67, 102292.

- Li, H. CO2 capture by various nanoparticles: Recent development and prospective. J. Clean. Prod. 2023, 414, 137679.

- Segneri, V.; Trinca, A.; Libardi, N.; Colelli, L.; Micciancio, M.; Vilardi, G. Nanoparticles used for CO2 capture by adsorption: A review. Chem. Eng. Trans. 2023, 101, 133–138.

- Youns, Y.T.; Manshad, A.K.; Ali, J.A. Sustainable aspects behind the application of nanotechnology in CO2 sequestration. Fuel 2023, 349, 128680.

- Azni Farhana Mazri, N.; Arifutzzaman, A.; Kheireddine Aroua, M.; Ekhlasur Rahman, M.; Ali Mazari, S. Graphene and its tailoring as emerging 2D nanomaterials in efficient CO2 absorption: A state-of-the-art interpretative review. Alex. Eng. J. 2023, 77, 479–502.

- Chen, H.; Zheng, Y.; Li, J.; Li, L.; Wang, X. AI for nanomaterials development in clean energy and carbon capture, utilization and storage (CCUS). ACS Nano 2023, 17, 9763–9792.

- Chen, M.; Yang, T.; Han, J.; Zhang, Y.; Zhao, L.; Zhao, J.; Li, R.; Huang, Y.; Gu, Z.; Wu, J. The application of mineral kaolinite for environment decontamination: A review. Catalysts 2023, 13, 123.

- Cui, Y.; Zhu, J.; Tong, H.; Zou, R. Advanced perspectives on MXene composite nanomaterials: Types synthetic methods, thermal energy utilization and 3D-printed techniques. iScience 2023, 26, 105824.

- Younis, M.; Ahmad, S.; Atiq, A.; Farooq, M.A.; Huang, M.; Abbas, M. Recent progress in azobenzene-based supramolecular materials and applications. Chem. Rec. 2023, 23, e202300126.

- Zhu, W.; Yue, Y.; Wang, H.; Zhang, B.; Hou, R.; Xiao, J.; Huang, X.; Ishag, A.; Sun, Y. Recent advances on energy and environmental application of graphitic carbón nitride (g-C3N4)-based photocatalysts: A review. J. Environ. Chem. Eng. 2023, 12, 110164.

- de Morais, M.G.; Vargas, B.P.; da Silva Vaz, B.; Cardias, B.B.; Costa, J.A.V. Advances in the synthesis and applications of nanomaterials to increase CO2 biofixation in microalgal cultivation. Clean Technol. Environ. Policy 2023, 25, 617–632.

- Waseem, M.; Al-Marzouqi, M.; Ghasem, N. A review of catalytically enhanced CO2-rich amine solutions regeneration. J. Environ. Chem. Eng. 2023, 11, 110188.

- Chowdhury, S.; Kumar, Y.; Shrivastava, S.; Patel, S.K.; Sangwai, J.S. A review on the recent scientific and commercial progress on the direct air capture technology to manage atmospheric CO2 concentrations and future erspectives. Energy Fuels 2023, 37, 10733–10757.

- Jaiswar, G.; Dabas, N.; Chaudhary, S.; Jain, V.P. Progress in absorption of environmental carbon dioxide using nanoparticles and membrane technology. Int. J. Environ. Sci. Technol. 2023, 20, 10385–10404.

- Peu, S.D.; Das, A.; Hossain, M.S.; Akanda, M.A.; Akanda, M.M.; Rahman, M.; Miah, M.N.; Das, B.K.; Islam, A.R.; Salah, M.M. A comprehensive review on recent advancements in absorption-based post combustion carbon capture technologies to obtain a sustainable energy sector with clean environment. Sustainability 2023, 15, 5827.

- Zhang, C.; Zhang, X.; Su, T.; Zhang, Y.; Wang, L.; Zhu, X. Modification schemes of efficient sorbents for trace CO2 capture. Renew. Sustain. Energy Rev. 2023, 18, 113473.

- Boldoo, T.; Ham, J.; Cho, H. Evaluation of CO2 absorption characteristics of low cost Al2O3/MeOH nanoabsorbent using porous nickel foam for high efficiency CO2 absorption system. J. Clean. Prod. 2023, 384, 135624.

- Ge, B.-B.; Yan, J.; Zhong, D.-L.; Lu, Y.-Y.; Li, X.-Y. CO2 capture enhancement by forming tetra-n-butyl ammonium bromide semiclathrate in graphite nanofluids. Can. J. Chem. Eng. 2023, 101, 4128–4137.

- Geng, Z.; Yang, Y.; Wang, Y.; Zhu, T.; Xu, W. Catalytic regeneration of amine-based absorbents for CO2 capture: The effect of acidic sites and accessibility. Sep. Purif. Technol. 2023, 327, 124889.

- Itas, Y.S.; Razali, R.; Tata, S.; Kolo, M.; Lawal, A.; Alrub, S.A.; El Ghoul, J.; Khandaker, M.U. DFT studies on the effects of C vacancy on the CO2 capture mechanism of silicon carbide anotubes photocatalyst (Si12C12-X; X = 1; 2). Silicon 2023, 1–11.

- Jin, G.; Wang, H.; Zhang, K.; Zhang, H.; Fan, J.; Wang, J.; Guo, D.; Wang, Z. ZIF-8 based porous liquids with high hydrothermal stability for carbon capture. Mater. Today Commun. 2023, 36, 106820.

- Li, Y.; Lu, H.; Liu, Y.; Wu, K.; Zhu, Y.; Liang, B. CO2 absorption and desorption enhancement by nano-SiO2 in DBU-glycerol solution with high viscosity. Sep. Purif. Technol. 2023, 309, 122983.

- Mahdavi, H.; Sadiq, M.M.; Smith, S.J.D.; Mulet, X.; Hill, M.R. Underlying potential evaluation of the real-process applications of magnetic porous liquids. J. Mater. Chem. A 2023, 11, 16846–16853.

- Tengku Hassan, T.N.A.; Mohd Shariff, A.; Abd Aziz, N.F.; Mustafa, N.F.A.; Tan, L.S.; Abdul Halim, H.N.; Mohamed, M.; Hermansyah, H. Aqueous potassium salt of L-cysteine as potential CO2 removal solvent: An investigation on physicochemical properties and CO2 loading capacity. Sustainability 2023, 15, 11558.

- Wang, S.-L.; Xiao, Y.-Y.; Zhou, S.-D.; Jiang, K.; Yu, Y.-S.; Rao, Y.-C. Synergistic effect of water-soluble hydroxylated multi-wall carbon nanotubes and graphene nanoribbons coupled with tetra butyl ammonium bromide on kinetics of carbon dioxide hydrate formation. Energies 2023, 16, 5831.

- Wang, X.; Bao, Z.; Akhmedov, N.G.; Hopkinson, D.; Hoffman, J.; Duan, Y.; Egbebi, A.; Resnik, K.; Li, B. Unique biological amino acids turn CO2 emission into novel nanomaterials with three switchable product pathways. Environ. Technol. Innov. 2023, 32, 103279.

- Zabelina, A.; Dedek, J.; Guselnikova, O.; Zabelin, D.; Trelin, A.; Miliutina, E.; Kolska, Z.; Siegel, J.; Svorcik, V.; Vana, J.; et al. Photoinduced CO2 conversion under Arctic conditions─the high potential of plasmon chemistry under low temperature. ACS Catal. 2023, 13, 3830–3840.

- Zare, A.; Darvishi, P.; Lashanizadegan, A.; Zerafat, M. Theoretical and experimental investigation of CO2 solubility in nanofluids containing NaP zeolite nanocrystals and ionic liquid. Can. J. Chem. Eng. 2023, 101, 3925–3936.

- Zarei, F.; Keshavarz, P. Intensification of CO2 absorption and desorption by metal/non-metal oxide nanoparticles in bubble columns. Environ. Sci. Pollut. Res. 2023, 30, 19278–19291.

- Zhao, X.; Ding, Y.; Ma, L.; Zhu, X.; Wang, H.; Cheng, M.; Liao, Q. An amine-functionalized strategy to enhance the CO2 absorption of type III porous liquids. Energy 2023, 279, 127975.

- Khanmohammadian, E.; Mohammadi, M.; Hashemi, R.; Eslami, S.; Reza Ehsani, M. Improvement of gas hydrate-based CO2 capture from CH4/CO2 mixture using silica and modified silica nanoparticles in the presence of potassium hydroxide. Fuel 2023, 334, 126458.

- Lu, T.; Li, Z.; Du, L. Enhanced CO2 geological sequestration using silica aerogel nanofluid: Experimental and molecular dynamics insights. Chem. J. 2023, 474, 145566.

- Ali, N.; Babar, A.A.; Wang, X.; Yu, J.; Ding, B. Hollow, porous, and flexible Co3O4-doped carbon nanofibers for efficient CO2 capture. Adv. Eng. Mater. 2023, 25, 2201335.

- Anagnostopoulou, M.; Zindrou, A.; Cottineau, T.; Kafizas, A.; Marchal, C.; Deligiannakis, Y.; Keller, V.; Christoforidis, K.C. MOF-derived defective Co3O4 nanosheets in carbon nitride nanocomposites for CO2 photoreduction and H2 production. ACS Appl. Mater. Interfaces 2023, 15, 6817–6830.

- Arifutzzaman, A.; Musa, I.N.; Aroua, M.K.; Saidur, R. MXene based activated carbon novel nano-sandwich for efficient CO2 adsorption in fixed-bed column. J. CO2 Util. 2023, 68, 102353.

- Butt, F.S.; Lewis, A.; Rea, R.; Mazlan, N.A.; Chen, T.; Radacsi, N.; Mangano, E.; Fan, X.; Yang, Y.; Yang, S.; et al. Highly-controlled soft-templating synthesis of hollow ZIF-8 nanospheres for selective CO2 separation and storage. ACS Appl. Mater. Interfaces 2023, 15, 31740–317545.

- Chen, P.-B.; Yang, J.-W.; Rao, Z.-X.; Wang, Q.; Tang, H.-T.; Pan, Y.-M.; Liang, Y. Efficient in-situ conversion of low-concentration carbon dioxide in exhaust gas using silver nanoparticles in N-heterocyclic carbene polymer. J. Colloid Interface Sci. 2023, 652, 866–877.

- Chi, S.; Ye, Y.; Zhao, X.; Liu, J.; Jin, J.; Du, L.; Mi, J. Porous molecular sieve polymer composite with high CO2 adsorption efficiency and hydrophobicity. Sep. Purif. Technol. 2023, 307, 122738.

- Giraldo, L.J.; Medina, O.E.; Ortiz-Perez, V.; Franco, C.A.; Cortes, F.B. Enhanced carbon storage process from flue gas streams using rice husk silica nanoparticles: An approach in shallow coal bed methane reservoirs. Energy Fuels 2023, 37, 2945–2959.

- Gu, Y.-M.; Wang, Y.-H.; Zhao, S.-S.; Fan, H.-J.; Liu, X.-W.; Lai, Z.; Wang, S.-D. N-donating and water-resistant Zn-carboxylate frameworks for humid carbon dioxide capture from flue gas. Fuel 2023, 336, 126793.

- He, Y.; Wang, Z.; Cao, A.; Xu, X.; Li, J.; Zhang, B.; Kang, L. Construction of graphene oxide-coated zinc tetraphenyporphyrin nanostructures for photocatalytic CO2 reduction to highly selective CH4 product. J. Colloid Interface Sci. 2023, 638, 123–134.

- Hosseini, S.R.; Omidkhah, M.; Mehri Lihgyan, Z.; Norouzbahari, S.; Ghadimi, A. Synthesis, characterization, and gas adsorption performance of an efficient hierarchical ZIF-11@ZIF-8 core–shell metal–organic framework (MOF). Sep. Purif. Technol. 2023, 307, 122679.

- Iranvandi, M.; Tahmasebpoor, M.; Azimi, B.; Heidari, M.; Pevida, C. The novel SiO2-decorated highly robust waste-derived activated carbon with homogeneous fluidity for the CO2 capture process. Sep. Purif. Technol. 2023, 306, 122625.

- Issa, G.; Kormunda, M.; Tumurbaatar, O.; Szegedi, A.; Kovacheva, D.; Karashanova, D.; Popova, M. Impact of Ce/Zr ratio in the nanostructured ceria and zirconia composites on the selective CO2 adsorption. Nanomaterials 2023, 13, 2428.

- Jin, Z.; Zhang, J.; Qiu, J.; Hu, Y.; Di, T.; Wang, T. Nitrogen vacancy-induced spin polarization of ultrathin zinc porphyrin nanosheets for efficient photocatalytic CO2 reduction. J. Colloid Interface Sci. 2023, 652, 122–131.

- Liu, Z.; Lu, Y.; Wang, C.; Zhang, Y.; Jin, X.; Wu, J.; Wang, Y.; Zeng, J.; Yan, Z.; Sun, H.; et al. MOF-derived nano CaO for highly efficient CO2 fast adsorption. Fuel 2023, 340, 127476.

- Liu, M.; Ma, C.; Cheng, X.; Gao, K.; Zhang, G.; Wang, D.; Liu, F. New insight into multiple hydrogen-bond networks of functional organosilicas system for collaborative transformation of CO2 under mild conditions. Sep. Purif. Technol. 2023, 317, 123937.

- Lopez-Arias, M.; Moro, C.; Francioso, V.; Elgaali, H.H.; Velay-Lizancos, M. Effect of nanomodification of cement pastes on the CO2 uptake rate. Constr. Build. Mater. 2023, 404, 133165.

- Mahdipoor, H.R.; Ebrahimi, R.; Ganji Babakhani, E.; Halladj, R.; Safari, N.; Ganji, H. Investigating the selective adsorption of CO2 by MIL-101(Cr)-NH2 and modeling the equilibrium data using a new three-parameter isotherm. Colloids Surf. A Physicochem. Eng. Asp. 2023, 675, 131971.

More