Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Mona Zou and Version 1 by Artur Mielcarek.

Under-cover soilless cultivation is an important technique of crop production. Due to the lack of contact with soil and precipitation, the root system of crops grown must be provided with water and all necessary nutrients in the form of a solution (nutrient medium). This nutrient medium needs to be fed in excess to ensure proper plant development and the expected qualitative and quantitative parameters of the crop yield, which means that in the case of, e.g., tomato cultivation, 20–80% of the supplied medium must be removed from the root system and managed. Uncontrolled discharge of this drainage water poses a significant threat to the environment, causing contamination of surface waters and groundwaters.

- drainage water

- circular economy

- soilless plant cultivation

- water recovery

- phosphorus recovery

1. Water and Nutrients Management

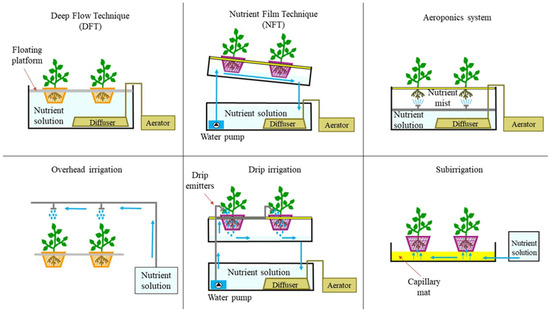

Due to the type of substrate, soilless cultivation systems may be divided into those where plant roots grow into porous mineral substrates (e.g., sand, mineral wool, gravel), organic substrates (e.g., peat, bark, rice husks) or a mixture thereof; and into hydroponic and aeroponic ones in which plant roots are immersed in a medium or in the air without permanent filling (Figure 1) [7][1].

Figure 1. Fertigation methods.

Soilless tomato cultivation most often entails the use of substrates which, owing to their porosity, retain the nutrient medium, protect the roots from temperature fluctuations, and promote the flow of air and water [19][2]. These can be PE (polyethylene) or PVC (polyvinyl chloride) containers, plastic-lined planters, or plastic bags filled with mineral wool or coconut fiber that are placed in channels to collect a nutrient medium solution that is supplied by drip trays [1][3]. The width and length of the growing modules vary depending on the substrate used, the size of the containers, and the space available [20][4]. For example, modules with dimensions 1000 × 200/195 × 75 mm, 1200 × 200/195 × 75 mm and 1330 × 200/195 × 75 mm are frequently used in the greenhouse cultivation of tomatoes. Modules with these dimensions make it possible to provide an adequate volume of substrate for 4–6 plants. In the EU Member States, fruit vegetables are grown in the soilless system mainly on coconut fiber, pumice, perlite, and mineral wool, and are irrigated by means of a drip system. In turn, leafy vegetables and herbs are grown deploying a deep flow technique (DFT), nutrient film technique (NFT), and floating systems (Figure 1) [21][5].

In the deep flow technique, plants float on a floating platform and their roots are constantly immersed in a nutrient solution and aerated with diffusers [3][6]. This technique works well in the cultivation of plants that have a developed root system [19][2].

In the nutrient film technique (NFT), plants are grown in baskets suspended on a pipe or a PCV gutter at an angle of about 1–2%. The nutrient medium is delivered through channels and flows in accordance with the pipe’s fall (gravity) into a tank from which it is recirculated back and supplied continuously to the plants, keeping the root system at constant humidity [3,19][2][6]. The appropriate spacing of plants in the planter is determined depending on the crop type [19][2]. Plants producing little biomass, like lettuce, strawberries, and herbs, work best in this system. The medium composition changes slightly as it passes through the system, which enables its multiple recirculation before its composition changes so much that it will need to be exchanged [3][6].

There are also aeroponic systems, in which plants are supported, for example, in polystyrene panels, while their roots are suspended in the air. By this means, the roots are well aerated, which promotes faster growth of plants. The roots are periodically sprayed with a so-called nutrient mist to provide necessary nutrients and maintain adequate humidity. The frequency of nutrient medium spraying (usually every 2–3 min for 30–60 s) depends on the crop type, plant growth stage, the growing season, and sun exposure. Aeroponics is used for growing lettuce or spinach, and the yield produced can be up to 10 times higher than in the case of conventional soil cultivation [2,19,22][2][7][8].

Modern systems deployed in soilless crop cultivation provide fertilizers and water in an integrated way, and, therefore, the macroelements and microelements necessary for the proper growth of plants are delivered in the form of water-soluble fertilizer salts [6][9], whereas irrigation and fertilization are applied in a low-dose and frequent manner. Savvas et al. [1][3] distinguished the following irrigation systems: overhead, drip-irrigation, and subirrigation (Figure 1).

In overhead systems (above the plant), water or nutrients are delivered by irrigation pipes fixed over the plants on a platform that sprays the crops by sliding over them. These systems are commonly applied in the production of potted plants [1][3].

In drip-irrigation systems, water is delivered to the substrate or rhizosphere usually once an hour for a few minutes using drip emitters. Due to its precision and very efficient water use (this system ensures up to 95% performance [23][10]), it is the most commonly used solution, in particular for the cultivation of cucumbers, tomatoes, onions, or bell peppers, i.e., plants characterized by large biomass growth and requiring large volumes of water and nutrients [1,2][3][7]. In recirculated systems, excess medium is returned back to the tank and supplied at the appropriate frequency, while in the open system, it is supplied by slow dripping [19][2].

In turn, sub-irrigation is mainly applied to produce potted plants. The planters should be lined with a substrate having good capillary properties because the nutrient solution is applied below the rhizosphere and moves upwards due to capillary forces [1][3]. This also results in the concentration of salt in the upper layers, thus limiting the salinity of the nutrient solution, which runs slower than in the drop-irrigation system. In addition, the spread of pathogens that are not able to move in the opposite direction and do not reach the circulating solution is also reduced [21][5].

Regardless of the soilless cultivation method used, the nutrient medium flowing through the system undergoes a “concentration effect”. This is a negative outcome of the increase in nutrient concentration in the medium outflowing from the system, which results from the advantage of transpiration over the uptake of nutrients by plants. In order to maintain the appropriate values of the physicochemical indicators of the nutrient medium, an additional volume is used, which is referred to as overflow or drainage water (DW) [24,25][11][12].

Usually, such an overflow accounts for 20–30% of the nutrient medium delivered [15][13]. In the case of tomato cultivation, the standard volume of the overflow that can prevent nutrient medium salinization accounts for 25–50% [21][5]. However, when the electrolytic conductivity (EC) reaches 3–5 mS/cm or when evapotranspiration is diminished, the volume of DW can be from 20 to as much as 80% of the dosed nutrient medium [22][8]. Dyśko (2004) investigated the changes in nutrient content, pH and EC in the nutrient solution used for growing tomatoes on mineral wool and determined the increase in the change in concentration of the individual components. An increase in concentration occurred in N (62%), P (24%), K (48%), Ca (100%), Mg (91%), Na (112%), Cl (13%), S (75%), Fe (35%), Cu (100%), Zn (67%) and B (69%). There was also an increase in EC (54%) and pH (11%). In the studies cited, only Mn showed a decrease in concentration, which amounted to 15%. These values were calculated on the basis of average values from two years (2002–2003), which included 17 determinations per year made at weekly intervals. The cultivation was carried out in central Poland [24][11].

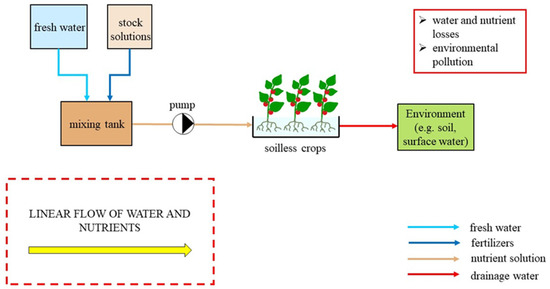

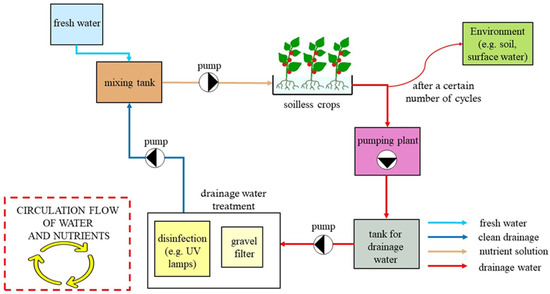

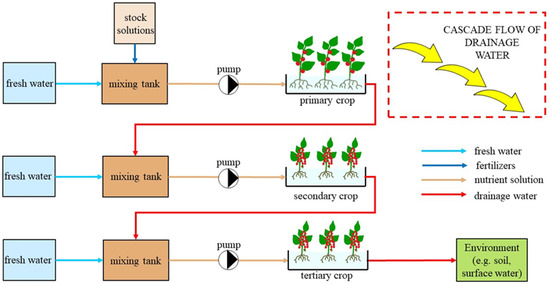

Open-circuit, closed-circuit, or cascade systems may also be distinguished considering the methods applied for the management of excess medium (Figure 2, Figure 3 and Figure 4) [7][1].

Figure 2. Open-circuit systems.

Figure 3. Closed-circuit systems—recirculation.

Figure 4. Closed-circuit systems—cascade systems.

1.1. Open-Circuit Systems

In these systems, the excess DW is discharged untreated directly into the natural environment (Figure 2) [16][14]. This is commonly practiced in many places around the world, including Poland [21,26,27,28][5][15][16][17]. Open fertilization systems are widely found in almost all Mediterranean countries (e.g., Spain, Italy, Turkey, Morocco) [29,30][18][19] and in Portugal [31][20]. The procedure of frequent exchange of the nutrient medium in open-circuit systems facilitates its quality control and thereby enables achieving a crop yield of a desired quality and quantity. It also allows for easier protection of plants from infections [2][7]. Apart from being the most commonly used solution, this cultivation system also poses the greatest threat to the natural environment and is not viable economically considering the costs associated with water and nutrients consumption. At the same time, there is still a lack of technically and economically feasible large-scale solutions that could be implemented instead of open-circuit systems, which disrupt the environmental and economic sustainability of soilless crops. The scale of the problem is illustrated by the example of Spain, where only 12% of the 3000 hectares of soilless crops in Almeria are grown in a closed system. In South Korea, crops cultivated in a system with nutrient medium recirculation account for 5% of the 3355 arable hectares [32][21]. According to Dyśko et al. [33][22], the open-circuit system is still the main method for growing tomatoes in Poland, while recirculation is deployed only in a few facilities growing vegetables, including mainly those producing low biomass and requiring low variability of the nutrient medium composition [33][22].

DW outflowing from the soilless cultivation system has high concentrations of nitrogen and phosphorus, with the total nitrogen concentration ranging from 150 to 600 mg N/L, and that of total phosphorus from 30 to 400 mg P/L [34,35][23][24]. Mielcarek et al. [28][17] analyzed DW from a facility located in the north-eastern Poland, intended for tomato cultivation on mineral wool. The year-round qualitative analysis of DW demonstrated a concentration of nitrogen in the range of 270–615 mg N/L and that of phosphorus in the range of 35–104 P/L. In turn, in the study conducted by Kwon et al. [27][16], these values oscillated between 48–494 mg N/L and 12.7–106 mg P/L. Apart from nitrogen and phosphorus compounds, other macronutrients and micronutrients contained in the nutrient medium, such as calcium, magnesium, or potassium, are discharged with the drainage water [27,36][16][25].

DW from open-circuit systems can theoretically be collected and re-used in recirculation systems or for fertilization of less demanding crops or field crops in a cascade system [20][4]. Massa et al. [41][26] determined differences in water losses in the soilless cultivation of tomatoes between open-circuit and closed-circuit systems. In a closed-circuit system, water losses reached 2680, 1960, and 1420 m3/ha over 167 days of cultivation with nutrient medium exchanged 14, 10, and 7 times, respectively, depending on the irrigation strategy. In contrast, 7168 m3/ha of drainage water was discharged during cultivation in the open-circuit system at the 50% overflow.

1.2. Closed-Circuit Systems

Closed-circuit systems are the future of soilless crop cultivation in greenhouses. In some countries, they are already legally mandatory, especially in nature-protected areas. They allow reducing water and nutrient losses caused by the use of the overflow. Unfortunately, their application faces serious challenges, like changes in the composition of the nutrient medium that has passed through the system, as well as the presence of pathogens and root secretions, including phytohormones, that inhibit plant development [6][9]. There are two main ways of managing the overflow in closed circuits: recirculation—using DW in the cultivation of the same crop (Figure 3), and the so-called cascade systems—using DW in the cultivation of another, less demanding crop (Figure 4) [42][27].

In some solutions (e.g., liquid-culture soilless) and crops with low biomass growth (e.g., herbs, bell peppers, strawberries, or seedlings), the recirculation of the nutrient medium does not require a significant development of the system. This is due to relatively small changes in the nutrient medium composition during the flow through the installation. In this case, the pH and EC measurements are usually sufficient to determine the fresh water dose needed to dilute DW in the next recirculation cycle, without the need to replenish the medium with nutrients. During cultivation of bell peppers on mineral wool in a recirculated system, the nutrient medium can be exchanged at a frequency of 4 to 8 weeks, whereas the EC and pH should be adjusted every 3 days. In strawberry cultivation, the nutrient substrate should be exchanged every 8 weeks, and in basil cultivation, every 2 weeks [43][28]. At the same time, these examples indicate that, despite the possibility of recirculation, DW should be discharged out of the system from time to time. However, the re-use of DW for a certain period of time may enable a 40–50% reduction in fertilizer consumption [44][29]. In the Netherlands and Belgium, soilless tomato cultivation with DW recirculation produces yields of between 80 and 90 kg/m2 and ensures 1 m3 water consumption per 70–160 kg of fruit. For comparison, in open-field conventional soil cultivation systems, the yield of tomatoes is 8–15 kg/m2 and 1 m3 of water is consumed per 6–15 kg of fruit [45][30]. However, in the case of growing tomatoes, which are characterized by high biomass growth, a high transpiration rate, and, above all, a growing period of one crop for up to 10–11 months within a year, DW recirculation requires much more advanced solutions. They are primarily aimed at protecting the crop from the spread of pathogens and the adverse effects of phytohormones and other root secretions. In this case, the recirculation system requires constructing stations for, i.e., disinfection or desalination of the nutrient medium or water used for dilution. Otherwise, DW recirculation can diminish the quantity and quality of crop yields that greenhouse owners cannot afford [42][27].

The electrolytic conductivity (EC) and pH are some of the most important parameters of the nutrient medium, as they affect the absorption of nutrients by plants, and their recommended values vary depending on the crop being grown [46][31]. The pH and EC measurements are fast, simple, and relatively cheap. The optimal pH for tomatoes is 5.5–6.0, and the EC should not exceed 1.9 mS/cm [47][32]. For comparison, the DW in soilless tomato cultivation is usually characterized by pH > 6.0 and EC > 3.0 mS/cm [28][17]. The pH value of the nutrient medium largely determines the uptake of individual elements. At pH > 7.0, the uptake of micronutrients (except for molybdenum) and phosphorus decreases, while macroelements, in particular sulfur, calcium, and potassium, are absorbed in excess. In turn, macroelements are not absorbed at pH < 5.0. The pH can be regulated in fertilizer tanks using nitric acid or phosphoric acid [46][31]. According to Tong et al. (2023), an increase in the electrolytic potential of 1 mS/cm beyond the optimum value may result in 10% losses of tomato yields [48][33]. Too low EC causes insufficient supply of certain nutrients to plants, whereas too high EC exposes them to soil salinity and physiological drought [6][9]. Achieving the desired nutrient medium composition requires knowing the DW composition and the right DW-to-water ratio. However, the concentrations of ions absorbed by crops depend on their species, the stage of crop development, and weather conditions. This means that determining the right doses is not an easy task. There are several methods of DW recirculation. The most commonly used solution involves mixing DW with fresh water and then, based on the EC of the final solution, supplementing nutrients mainly based on literature data and the experience of the technologist, rather than on current determinations of solution composition [21][5]. Another problem is posed by the accumulation of Na+ and Cl− in recirculated DW. They negatively affect the quantity and quality of the crop yield. For this reason, long-term recirculation of the same DW solution is impossible and the nutrient medium must be exchanged periodically [1][3]. Thus, even the most advanced closed-circuit systems generate greenhouse wastewater, which should be managed [20,21][4][5].

A fairly new, not yet fully proven, disinfection method involves the use of ultrasounds, which cause cavitation-based destruction of microorganisms. Very high frequency sounds result in the formation of ever larger and unstable gas bubbles between water particles, which at some point implode, destroying pathogens [50][34].

DW desalination and disinfection can also be performed via reversed osmosis, but this process entails high operating costs [34][23]. In this method, sedimentary and carbon filters are used in front of the ion-exchange membrane to remove suspended solids and organic molecules [53][35]. Martin-Gorriz et al. [54][36] applied reversed osmosis and ultrafiltration to treat DW in a hydroponic system. The re-use of DW allowed reducing the pressure of hydroponic cultivation on the surface waters of the receiver by 72%, but this resulted in a 37% increase in pressure on global warming and air acidification as a result of building additional infrastructure and equipment compared to the open-system cultivation.

Zamora-Izquierdo et al. [55][37] developed a highly automated crop management system that was tested in a greenhouse in tomato cultivation with recirculation. It consisted of four units: a nutrient medium preparation unit, an irrigation unit, a DW disinfection unit, and a tap water purification unit. In the nutrient medium preparation unit, nutrients, disinfected drainage water, tap water, and water from the reverse osmosis system were mixed, and the composition of the nutrient solution was automatically controlled based on EC, pH, and temperature using the fertilization control module. The irrigation control unit was installed in the irrigation unit, and the untreated DW was pre-filtered to remove contaminants. Disinfection was based on electrolysis, and the tap water purification unit was equipped with devices for reversed osmosis enabling reduction of the EC of the tap water used to dilute the DW. This system enabled over 30% savings in water consumption and over 80% savings in fertilizer consumption compared to an open-circuit system. Rufí-Salís et al. [56][38] tested an open and a closed system in the hydroponic cultivation of green beans on the roof. The DW was filtered using a sand filter, then disinfected with UV lamps. The study demonstrated 40% daily savings of water used for irrigation and 35–54% savings of nutrients in the case of the closed-circuit system (with recirculation). Fresh water may be sourced for recirculation from rainwater, but this requires constructing tanks for its retention. The annual amount of precipitation is also difficult to predict, especially in a changing climate [21][5]. In the Netherlands and Belgium, the vast majority of greenhouses are equipped with recirculation systems [57][39]. However, studies carried out in Dutch facilities for soilless crop cultivation have shown that, despite technical possibilities of recirculation, DW is discharged to the natural environment even at the slightest doubt as to the quality of water in terms of both its composition and the presence of pathogens or growth inhibitors [58][40].

There are also closed-circuit systems without recirculation, in which DW is accumulated in tanks and then used for the cultivation of other crops (cascade systems) [59][41].

1.3. Cascade Cropping Systems

Cascade systems involve the discharge of the nutrient medium from the primary crop, having high requirements regarding the medium composition to the secondary crop and exhibiting greater tolerance to changes in the nutrient medium composition (Figure 4) [60][42]. This cropping system is the least widespread [21][5]. The cascade management of the nutrient medium allows for savings in the consumption of water and minerals [29,60][18][42]. An example of the cascade management of DW was presented by Karatsivou et al. (2023) who used tomato as a primary crop, and then lettuce, spinach, and parsley as secondary crops [60][42]. The efficiency of nitrogen and phosphorus consumption increased by more than 50%, spinach yield increased by 14% compared to standard nutrient-medium-fed crops, whereas the efficiency of water consumption per lettuce, spinach, and parsley biomass growth was 50%, 30%, and 14% higher, respectively, compared to the standard nutrient medium. These results were due to the use of DW from the cultivation of a more-demanding crop with a nutrient medium having a much better composition compared to the standard medium that would be used in secondary crop cultivation. In turn, the results achieved by García-Caparrós et al. (2018) support the conclusion that crops intended for cascade cultivation should be appropriately selected [58][40]. The aforementioned authors irrigated rosemary crops with DW from the soilless cultivation of melon. In this case, the system enabled saving water and removing nitrates, but caused a decrease in rosemary yield compared to the cultivation variant with a standard nutrient medium. A key parameter for planning the number and type of plants that can be used in secondary cultivation is the variability of nutrient contents in the outflow from the primary cultivation [42][27]. A safe solution for cascade systems is to use DW from the soilless cultivation of field crops. Given the buffer properties of the soil, as well as a much larger area of open-field crops compared to under-cover crops, DW can account for a small percentage of the total fertilization used in this cropping system. However, the question of classifying DW as a fertilizing solution and placing it on the market remains unresolved.

1.4. Fertilizers

Proper and precise fertilization has a significant impact on the growth, development, and yield of plants. The composition of the nutrient medium is precisely calculated based on an analysis of water consumed for fertigation and adapted to the current stage of plant growth and atmospheric conditions, including primarily the temperature and the intensity of sunlight [61][43]. The fertilizing media are prepared from chemical compounds containing one or more nutrients. They also often contain non-nutritive compounds. Sixteen elements need to be provided to ensure the proper growth and development of plants, i.e., carbon (C), hydrogen (H), oxygen (O), phosphorus (P), potassium (K), nitrogen (N), sulfur (S), calcium (Ca), magnesium (Mg), iron (Fe), boron (B), manganese (Mn), copper (Cu), zinc (Zn), molybdenum (Mo), and chlorine (Cl). An additional, but not necessary, element is silicon (Si). Phosphorus (which usually curbs the primary production in ecosystems) and nitrogen are of key significance considering natural environment protection, including mainly surface waters. The nutrient media should be prepared with high concentrations of components that are completely soluble in water. The basic fertilizers used for their preparation include: calcium nitrate, Ca(NO3)2; potassium nitrate, KNO3; magnesium nitrate, Mg(NO3)2; ammonium nitrate, NH4NO3; potassium sulphate, K2SO4; magnesium sulphate monohydrate, MgSO4∙H2O; magnesium sulphate heptahydrate, MgSO4∙7H2O; potassium monophosphate, KH2PO4; monoammonium phosphate, NH4H2PO4; calcium chloride, CaCl2∙6H2O; and potassium chloride, KCl. In addition, pH correction is achieved with nitric acid (V), HNO3, phosphoric acid (V), H3PO4, and hydrochloric acid, HCl, which serve as additional sources of nutrients. Iron, manganese, copper, zinc, boron, and molybdenum are introduced in the form of micronutrient fertilizers containing one, two, or more components. Apart from boron and molybdenum, these compounds are usually introduced in the form of chelates, ensuring good assimilation by plants. Fertilizer delivery devices include volumetric (quantitative) and proportional dispensers. The volumetric dispensers seem to be simpler to operate and are less expensive; however, they are dependent on changes in water pressure and do not adjust the fertilizer concentration to the fluctuations in pH or electrical conductivity (EC), unlike the proportional dispensers, which respond to these changes with the appropriate fertilizer dose [1][3].

2. The Impact of Soilless Cultivation on the Natural Environment

The environmental impact can be estimated based on the quantity and quality of the discharged DW described earlier. It is noteworthy that there are few studies showing the results of the determination of environmental quality within greenhouses. The use of closed-circuit systems in soilless crop cultivation is more environmentally friendly, but unfortunately is not as widespread as the use of open-circuit systems [19][2]. However, both systems generate DW which needs to be discharged into the natural environment. Uncontrolled discharge of untreated DW causes all the nutrients present in the medium (in particular nitrogen, potassium, calcium, and magnesium) to pervade the environment [25][12]. These pollutants have the ability to migrate in the ground, which causes contamination of groundwater, wells, and rivers located even at a considerable distance from the contamination source, i.e., the greenhouse [64][44]. In the case of surface waters, an additional dose of biogenic compounds, especially phosphorus, significantly accelerates their eutrophication [45,56][30][38]. This is an undesirable and dangerous phenomenon having multiple consequences, including the mass blooming of algae, a deficit of dissolved oxygen, and the release of toxins [53][35]. Investigations conducted by Komosa and Roszyk [65][45] and Kowalczyk et al. [66][46] indicate that the concentration of certain minerals in well waters increased in the vicinity of greenhouses with crops grown in the soilless system with open water and sewage management systems. Similar observations were made by Komosa [67][47], who investigated the mineral composition of water from wells located in the vicinity of Kalisz city (Poland). His research demonstrated an increase in the pollution of well waters with plant nutrients and ballast ions. Dyśko and Kaniszewski [68][48] studied samples of groundwater collected from under the greenhouse and from the area located 25 m and 300 m away from the greenhouse. The nitrate nitrogen content (N–NO3) was 117 mg/L and decreased proportionally to the distance from the greenhouse. Furthermore, Kowalczyk et al. (2013) [69][49] analyzed water from deep-water wells located in areas with a high proportion of soilless crops between 2011 and 2013. It turned out that not only groundwater, but also deeper water layers were affected by greenhouse-derived contaminants as they contained both nutrients and ballast components and had slightly alkaline pH (pH = 7.00–7.07) and EC > 0.7 mS/cm. In the case of water with such a high EC, it is difficult to determine the correct proportions of components of the nutrient medium, which often prevents its use in soilless crops, especially in the case of such species as greenhouse cucumber. Vegetable production also entails the use of plant protection agents that can penetrate the natural environment [45][30]. Pesticides are intentionally used to protect crops from fungi, insects, or weeds, but when they pervade the natural environment they pose a threat to various aquatic organisms, fish, soil microorganisms, birds, and even humans [70][50]. Vermeulen et al. [71][51] conducted a study which demonstrated that up to 3.3% of the plant protection agents used in greenhouse cultivation were emitted into the environment. The scale of these point sources of contamination means that the greenhouse may be considered a real threat to the natural environment.

The use of different substrates can also have an adverse impact on the natural environment. Drainage water from tomato cultivation on organic substrates has been found to contain less nutrients than that from cultivation on mineral wool, and, therefore, the organic medium has been found to be more beneficial for the environment [68][48]. On the other hand, the extraction of peat (organic substrate) from peat bogs, which constitute wildlife habitats and are very important for the hydrological cycle and water quality, can upset the environmental balance. Hence, substitutes are being sought for this type of substrate; sand and bark seem competitive in this case as they have a small carbon footprint and are relatively cheap. Life-cycle assessment is a useful method for determining the various environmental impacts associated with a product throughout its life span [23][10]; therefore, attention is paid to problems posed by the disposal of substrates and high energy consumption during production, as in the case of using mineral wool [7][1].

Various strategies for managing the overflow can be implemented, including closed-circuit or cascade systems, to mitigate the effects of wastewater discharge from the greenhouse [64][44]. The re-use of the nutrient medium can minimize, for example, the effects of eutrophication of water receivers; however, it should be borne in mind that a closed-circuit system requires additional infrastructure needing electricity supply, thus contributing to global warming and the scarcity of fossil resources to a greater extent than an open (linear) system does [54,56][36][38].

References

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153.

- Ampim, P.A.Y.; Obeng, E.; Olvera-Gonzalez, E. Indoor Vegetable Production: An Alternative Approach to Increasing Cultivation. Plants 2022, 11, 2843.

- Savvas, D.; Gianquinto, G.; Tuzel, Y.; Gruda, N. Soilless Culture. In Good Agricultural Practices Principles for Greenhouse Vegetable Production in the Mediterranean Region; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; pp. 303–354. ISBN 978-92-5107649-1.

- Pignata, G.; Casale, M.; Nicola, S. Water and Nutrient Supply in Horticultural Crops Grown in Soilless Culture: Resource Efficiency in Dynamic and Intensive Systems. In Advances in Research on Fertilization Management of Vegetable Crops; Springer: Cham, Switzerland, 2017; pp. 183–219. ISBN 978-3-319-53624-8.

- Massa, D.; Magán, J.J.; Montesano, F.F.; Tzortzakis, N. Minimizing Water and Nutrient Losses from Soilless Cropping in Southern Europe. Agric. Water Manag. 2020, 241, 106395.

- EI-Kazzaz, A. Soilless Agriculture a New and Advanced Method for Agriculture Development: An Introduction. Agric. Res. Technol. Open Access J. 2017, 3, 555610.

- Tüzel, Y.; Gül, A.; Tüzel, I.H.; Öztekin, G.B. Different Soilless Culture Systems and Their Management. J. Agric. Food Environ. Sci. 2019, 73, 7–12.

- Rani, R.S.; Kumar, H.V.H.; Mani, A.; Reddy, B.S.; Rao, C.S. Soilless Cultivation Technique, Hydroponics—A Review. Curr. J. Appl. Sci. Technol. 2022, 41, 22–30.

- Putra, P.A.; Yuliando, H. Soilless Culture System to Support Water Use Efficiency and Product Quality: A Review. Agric. Agric. Sci. Procedia 2015, 3, 283–288.

- Parada, F.; Gabarrell, X.; Rufí-Salís, M.; Arcas-Pilz, V.; Muñoz, P.; Villalba, G. Optimizing Irrigation in Urban Agriculture for Tomato Crops in Rooftop Greenhouses. Sci. Total Environ. 2021, 794, 148689.

- Dyśko, J. Recyrkulacja Pożywki w Bezglebowej Uprawie Pomidora. Owoce Warzywa Kwiaty 2004, 7, 8–9.

- Dyśko, J.; Kaniszewski, S.; Kowalczyk, W. The Influence of Drainage Water from Greenhouse Soilless Culture on Pollution of Shallow Groundwater. Infrastrukt. I Ekol. Teren. Wiej. 2013, 2/I/2013, 127–135.

- Kleiber, T. Pollution of the Natural Environment in Intensive Cultures under Greenhouses. Arch. Environ. Prot. 2012, 38, 45–53.

- Breś, W. Estimation of Nutrient Losses from Open Fertigation Systems to Soil during Horticultural Plant Cultivation. Pol. J. Environ. Stud. 2009, 18, 341–345.

- Muñoz, P.; Flores, J.S.; Antón, A.; Montero, J.I. Combination of Greenhouse and Open-Field Crop Fertigation Can Increase Sustainability of Horticultural Crops in the Mediterranean Region. Acta Hortic. 2017, 1170, 627–633.

- Kwon, M.J.; Hwang, Y.; Lee, J.; Ham, B.; Rahman, A.; Azam, H.; Yang, J.S. Waste Nutrient Solutions from Full-Scale Open Hydroponic Cultivation: Dynamics of Effluent Quality and Removal of Nitrogen and Phosphorus Using a Pilot-Scale Sequencing Batch Reactor. J. Environ. Manag. 2021, 281, 111893.

- Mielcarek, A.; Rodziewicz, J.; Janczukowicz, W.; Dobrowolski, A. Analysis of Wastewater Generated in Greenhouse Soilless Tomato Cultivation in Central Europe. Water 2019, 11, 2538.

- García-Caparrós, P.; Llanderal, A.; Maksimovic, I.; Lao, M.T. Cascade Cropping System with Horticultural and Ornamental Plants under Greenhouse Conditions. Water 2018, 10, 125.

- Thompson, R.B.; Gallardo, M.; Rodríguez, J.S.; Sánchez, J.A.; Magán, J.J. Effect of N Uptake Concentration on Nitrate Leaching from Tomato Grown in Free-Draining Soilless Culture under Mediterranean Conditions. Sci. Hortic. 2013, 150, 387–398.

- Santos, M.G.; Moreira, G.S.; Pereira, R.; Carvalho, S.M.P. Assessing the Potential Use of Drainage from Open Soilless Production Systems: A Case Study from an Agronomic and Ecotoxicological Perspective. Agric. Water Manag. 2022, 273, 107906.

- Ahn, T.I.; Yang, J.S.; Park, S.H.; Im, Y.H.; Lee, J.Y. Nutrient Recirculating Soilless Culture System as a Predictable and Stable Way of Microbial Risk Management. J. Clean. Prod. 2021, 298, 126747.

- Dyśko, J.; Szczech, M.; Kaniszewski, S.; Kowalczyk, W. Parameters of Drainage Waters Collected during Soilless Tomato Cultivation in Mineral and Organic Substrates. Agronomy 2020, 10, 2009.

- Richa, A.; Touil, S.; Fizir, M.; Martinez, V. Recent Advances and Perspectives in the Treatment of Hydroponic Wastewater: A Review. Rev. Environ. Sci. Biotechnol. 2020, 19, 945–966.

- Saxena, P.; Bassi, A. Removal of Nutrients from Hydroponic Greenhouse Effluent by Alkali Precipitation and Algae Cultivation Method. J. Chem. Technol. Biotechnol. 2013, 88, 858–863.

- Bryszewski, K.Ł.; Rodziewicz, J.; Janczukowicz, W. Effect of Bio-Electrochemical Treatment of Hydroponic Effluent on the Nutrient Content. Appl. Sci. 2022, 12, 9540.

- Massa, D.; Incrocci, L.; Maggini, R.; Carmassi, G.; Campiotti, C.A.; Pardossi, A. Strategies to Decrease Water Drainage and Nitrate Emission from Soilless Cultures of Greenhouse Tomato. Agric. Water Manag. 2010, 97, 971–980.

- Rufí-Salís, M.; Parada, F.; Arcas-Pilz, V.; Petit-Boix, A.; Villalba, G.; Gabarrell, X. Closed-Loop Crop Cascade to Optimize Nutrient Flows and Grow Low-Impact Vegetables in Cities. Front. Plant Sci. 2020, 11, 596550.

- Richa, A.; Fizir, M.; Touil, S. Advanced Monitoring of Hydroponic Solutions Using Ion-Selective Electrodes and the Internet of Things: A Review. Environ. Chem. Lett. 2021, 19, 3445–3463.

- Savvas, D.; Gruda, N. Application of Soilless Culture Technologies in the Modern Greenhouse Industry—A Review. Eur. J. Hortic. Sci. 2018, 83, 280–293.

- Thompson, R.B.; Incrocci, L.; van Ruijven, J.; Massa, D. Reducing Contamination of Water Bodies from European Vegetable Production Systems. Agric. Water Manag. 2020, 240, 106258.

- Pomiar i Regulacja PH i EC w Ogrodnictwie. Available online: https://royalbrinkman.pl/bank-wiedzy/pielegnacja/nawozy/regulacja-ph-i-ec-wskazowki (accessed on 28 August 2023).

- Wójcik, P.; Dyśko, J.; Kaniszewski, S.; Kowalczyk, W.; Nowak, J.S. Zrównoważone Nawożenie Roślin Ogrodniczych: Opracowanie Zbiorowe; Instytut Ogrodnictwa: Skierniewice, Poland, 2014; ISBN 9788389800572.

- Tola, E.K.; Al-Gaadi, K.A.; Madugundu, R.; Patil, V.C.; Sygrimis, N. Impact of Water Salinity Levels on the Spectral Behavior and Yield of Tomatoes in Hydroponics. J. King Saud Univ. Sci. 2023, 35, 102515.

- Czarnecka, A. Metody Dezynfekcji Pożywki Do Fertygacji, Cz.2. Available online: https://www.podoslonami.pl/technika/metody-dezynfekcji-pozywki-do-fertygacji-cz-2/ (accessed on 31 August 2023).

- Kumar, R.R.; Cho, J.Y. Reuse of Hydroponic Waste Solution. Environ. Sci. Pollut. Res. 2014, 21, 9569–9577.

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Gallego-Elvira, B.; Marín-Membrive, P.; Terrero, P.; Martínez-Alvarez, V. Recycling Drainage Effluents Using Reverse Osmosis Powered by Photovoltaic Solar Energy in Hydroponic Tomato Production: Environmental Footprint Analysis. J. Environ. Manag. 2021, 297, 113326.

- Zamora-Izquierdo, M.A.; Santa, J.; Martínez, J.A.; Martínez, V.; Skarmeta, A.F. Smart Farming IoT Platform Based on Edge and Cloud Computing. Biosyst. Eng. 2019, 177, 4–17.

- Rufí-Salís, M.; Petit-Boix, A.; Villalba, G.; Sanjuan-Delmás, D.; Parada, F.; Ercilla-Montserrat, M.; Arcas-Pilz, V.; Muñoz-Liesa, J.; Rieradevall, J.; Gabarrell, X. Recirculating Water and Nutrients in Urban Agriculture: An Opportunity towards Environmental Sustainability and Water Use Efficiency? J. Clean. Prod. 2020, 261, 121213.

- Incrocci, L.; Thompson, R.B.; Fernandez-Fernandez, M.D.; De Pascale, S.; Pardossi, A.; Stanghellini, C.; Rouphael, Y.; Gallardo, M. Irrigation Management of European Greenhouse Vegetable Crops. Agric. Water Manag. 2020, 242, 106393.

- Beerling, E.A.M.; Blok, C.; Van Der Maas, A.A.; Van Os, E.A. Closing the Water and Nutrient Cycles in Soilless Cultivation Systems. Acta Hortic. 2014, 1034, 49–55.

- Breś, W.; Trelka, T. Effect of Fertigation on Soil Pollution during Greenhouse Plant Cultivation. Arch. Environ. Prot. 2015, 41, 75–81.

- Karatsivou, E.; Elvanidi, A.; Faliagka, S.; Naounoulis, I.; Katsoulas, N. Performance Evaluation of a Cascade Cropping System. Horticulturae 2023, 9, 802.

- Hussain, A.; Iqbal, K.; Aziem, S.; Mahato, P.; Negi, A. A Review on the Science of Growing Crops without Soil (Soilless Culture)-a Novel Alternative for Growing Crops. Int. J. Agric. Sci. 2014, 7, 833.

- Elvanidi, A.; Reascos, C.M.B.; Gourzoulidou, E.; Kunze, A.; Max, J.F.J.; Katsoulas, N. Implementation of the Circular Economy Concept in Greenhouse Hydroponics for Ultimate Use of Water and Nutrients. Horticulturae 2020, 6, 83.

- Komosa, A.; Roszyk, J. Przydatność Wody Do Fertygacji–Wapń. In Proceedings of the Ogólnopolska Konferencja Naukowa–Efektywność Stosowania Nawozów w Uprawach Ogrodniczych, AR Lublin, Lublin, Poland, 8–9 June 1998; pp. 9–10.

- Kowalczyk, W.; Dyśko, J.; Felczyńska, A. Ocena Stopnia Zanieczyszczenia Składnikami Nawozowymi Wody z Ujęć Głębinowych Na Terenach o Skoncentrowanej Produkcji Szklarniowej. Nowości Warzywnicze 2010, 51, 29–34.

- Komosa, A. Podłoża Inertne-Postęp Czy Inercja? Zesz. Probl. Postępów Nauk Rol. 2002, 485, 147–167.

- Dyśko, J.; Kaniszewski, S. Contamination of Shallow Groundwater by the Soilless Tomato Culture. J. Agric. Sci. Technol. 2018, 20, 121–128.

- Kowalczyk, W.; Dyśko, J.; Felczynska, A. Tendencje Zmian Zawartości Wybranych Składników Mineralnych w Wodach Stosowanych Do Fertygacji Warzyw Uprawianych Pod Osłonami. Infrastrukt. I Ekol. Teren. Wiej. 2013, 2/I/2013, 167–175.

- Pogăcean, M.O.; Gavrilescu, M. Plant Protection Products and Their Sustainable and Environmentally Friendly Use. Environ. Eng. Manag. J. 2009, 8, 608–627.

- Vermeulen, T.; van Os, E.; Linden, A.M.A.; Wipfler, E.L. Need for Clean Water and Recirculation to Reduce Emissions of Plant Protection Products from Soilless Cultivation. Acta Hortic. 2017, 1176, 87–94.

More