You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Eulalia Skawińska and Version 2 by Mona Zou.

Increasing energy security is a crucial component of achieving the Sustainable Development Goals (SDGs). Three main factors influence energy security: (1) the efficiency of resource use in energy production, (2) the extent of energy losses, and (3) the use of new energy sources. Novel food products can impact these factors. Assuring sustainable growth and development in the long run calls for technical, social, political, economic, ethical, and research integrity solutions to ensure a reliable supply of clean and affordable energy and nutritious food for everyone, which highly impact well-being and health.

- new foods

- energy saving

- artificial intelligence (AI)

1. AI-Aided Ways to Save Energy in Food Production

Energy intensity across all EU countries, measured in kG of oil equivalent per thousand pounds, showed a decline during the period 2011–2021 in all countries. The countries that made the most progress in this regard were Bulgaria, Estonia, and Malta [1][12]. These achievements were possible in part due to the use of new, more efficient food drying technologies [2][13], overcoming barriers, applying new ideas [3][14], waste management, and modernization of production processes, e.g., [4][15]. Energy savings in the food industry’s cold supply chains also contributed to reducing energy consumption [5][16].

In the European Union, all member states have been required to reduce their industrial energy consumption steadily from 2011 to 2021. As per the regulations, these countries must save an average of 1.5% of their total energy consumption yearly by 2030. The annual energy savings will begin at 1.3% until the end of 2025, and then gradually increase to 1.9% during the final period until the end of 2030 [6][17]. Meeting these recommendations requires broader energy conservation in the food sector and the economy in general. The food industry encompasses all steps from the farm to the consumer, including agriculture, purchasing, wholesaler processing, commercial units, and the final customer. This process takes a considerable amount of time and involves multiple stages: raw materials are produced, stored, processed, and transported between different units as the product becomes more mature or finished. These activities are influenced by environmental conditions such as temperature, humidity, and light, which can affect the quality of the material or product. Depending on the type of food product, the appropriate physical conditions, especially temperature and humidity, need to be maintained and monitored during transportation of raw materials, semi-finished, or finished food products [7][18]. Published research shows that 33% of the world’s food is wasted along the food chain [8][9][10][19,20,21], and with it the energy and other resources used for its production and marketing, making food waste and loss a serious challenge. It is estimated that around 14% of the food produced is lost between the time of harvest and delivery to the market. Furthermore, approximately 18% of global food production is wasted, with 11% of this waste happening in households, 5% in restaurants and bars, and 2% in trade [11][22].

The social and economic significance of the aforementioned issues prompts their management through information technology (IT) such as artificial intelligence (AI) and machine learning (ML). Since the late 1950s, there has been an ongoing a shift from mechanical electronic technology to digital electronics. This transformation has accelerated in the past 50 years, driven by the invention of the Internet and advancements in computer hardware and mobile technology, leading to what is known as the digital revolution [12][23]. The rapid development of information and communication technology has transformed various aspects of social life, economies, businesses, and management, leading to the emergence of digital economy [13][24]. In Europe, this process has been particularly intensive in the past decade. Since 2015, digital adoption has increased notably throughout the EU, with the digital economy and society index (DESI), an index tracking indicators on Europe’s digital performance, rising from below 40 in 2015 to above 60 in 2020 [14][25].

AI and computer science can improve agricultural production for consumer needs, according to various authors, e.g., [15][26], including food processing in terms of its sensory advantages and distribution channels. The literature on the subject covers various scenarios and use cases of machine learning, machine vision, and sustainable global learning for future food production [16][27]. As the food production chain encompasses various stages, it is essential to involve energy-efficient technologies throughout the whole chain including farming, appropriate packaging, and maintaining proper temperature during transport and storage. The following section explores the potential and the application of these new technologies to save energy along the food chain in more detail.

1.1. Artificial Intelligence and Machine Learning

The definition of artificial intelligence is complex, but for the purpose of clarity, it is limited to artificially intelligent systems, simulating human intelligence processes, especially computer systems. Specific applications of AI include expert systems, natural language processing, speech recognition, and machine vision [17][28]. There are various definitions available, but most of them fall into one of the following four categories: systems that can think like humans, act like humans, think rationally, and act rationally. Additionally, an AI computer should have the ability to gather knowledge, apply it, and learn. Machine learning is a branch of artificial intelligence (AI) and computer science focusing on the use of data and algorithms to imitate the way humans learn, gradually improving its accuracy [18][29]. Artificial intelligence models require large amounts of labeled data, which can be expensive and biased. Self-supervised learning provides a solution by allowing models to learn from unlabeled data without overt labeling. This approach enables the model to learn from large datasets without the need for human labeling [19][30]. With the help of computer technologies and artificial intelligence, it is now possible to use large sets of experimental data from actual production processes to create new equipment and algorithms for real-time intelligent machines. These machines can build models that characterize individual manufacturing processes, which can facilitate production operations and product quality controls. These models are commonly known as artificial intelligence-based computer vision [20][31]. Investment activity in this area is dominated by start-ups and rising [21][32], with the global market growth from EUR 0.5 trillion to EUR 4.1 trillion between 2012 and 2015.

1.2. Artificial Intelligence in Agriculture

World agriculture is on the cusp of significant improvements as AI technologies rapidly advance and become more widely used in this area. AI has the potential to revolutionize crop management and agricultural productivity by enabling rapid diagnosis of plant diseases, efficient application of agrochemicals, and providing expert agronomic advice to growers. However, the systemic risks of using ML and AI models as expert systems in agriculture are often under-appreciated and poorly understood. Some of the key risk factors include the interoperability, reliability, and relevance of data [22][36]. The suggested risk-mitigation measures are applying frameworks for responsible and human-centered innovation, setting data cooperatives for improved data transparency and ownership rights, and initial deployment of agricultural AI in digital sandboxes [22][36].

By analyzing large data sets, AI algorithms can extract valuable information that supports decision-making and management in areas such as crop farming, animal production, automatic control processes, and robotics. These models and the information they provide are essential tools for improving the efficiency and productivity of agri-food systems. The collection of data in various agri-food sectors such as cultivation, field crop production, horticulture, animal production, water management, irrigation, machinery, barriers, and challenges can lead to better management decisions but also create new challenges. The use of AI technology in this domain brings up various risks, ethical issues, and societal implications. Questions must be raised about how to govern the usage of these technologies, and how to incorporate socio-ethical value considerations into the policy and legal frameworks under development [23][37] as current agricultural practices transition to smart farming, robotic farming, and the use of automated drones [24][38].

1.3. Artificial Intelligence in Food Processing and Distribution

Numerous papers and books have presented and evaluated AI- and ML-based approaches for various food processing operations, including drying, frying, baking, canning, extrusion, encapsulation, and fermentation, to predict the kinetics of these processes [25][39]. The development of ML-based models and their practical implementation can be achieved through a step-by-step procedure, as outlined in [26][40]. Another area of the food production chain in which the integration of artificial intelligence (AI) applications is becoming increasingly popular is transportation. Here, ICT technologies can help optimize transportation routes and reduce losses [27][41] and costs [28][29][42,43]. By applying machine learning (ML) and robotics, it is possible to control transportation routes and ensure the safe transportation of fresh or sensitive food [30][44]. The goal of these methods is to integrate various elements of the food transport chain to maintain better quality, sustainability, and efficiency.

According to STATISTA, the demand for food robotics equipment is expected to increase by about 5 million units in the next 5 to 7 years, among others due to the implementation of AI and ML in the food industry [31][45]. The use of these technologies can bring numerous benefits, such as reducing packaging costs, speeding up service, increasing consumer satisfaction, and minimizing human errors [24][38]. This, in turn, leads to lower losses, increased positive feedback, and increased consumer trust [32][46]. AI applications also reduce the time taken for placing orders by voice, making the process more personal and advantageous, especially in large processing plants. This brings profits, particularly in the long term. The elimination of irregularities contributes to reducing losses and costs within the company. For instance, errors in quality levels, numerous complaints due to incorrect grammage, poor labeling or marking, and exceeding permitted temperatures or humidity during storage and transportation can be avoided [7][18].

Artificial intelligence enabled agents, Internet of Things (IoT), sensors, and blockchain technology can be combined to maximize the supply network and increase the revenue of all parties involved along the agri-food value chain [33][47]. Blockchain is a technology that can record multiple transactions from multiple parties across a complex network. Changing the records inside the blockchain requires the consensus of all parties involved, thus giving a high level of confidence in the data [34][48]. This way, blockchain technology can support the traceability and transparency of the food supply chain, possibly increasing the trust of consumers, and in combination with AI, intelligent precision farming can be achieved.

The list of scientific papers exploring different applications of new technologies in a variety of food processing operations is long, while more systematic and comprehensive works are few. Among the latter, the following books are especially helpful [35][36][37][38][49,50,51,52].

1.4. Artificial Intelligence in Preservation and Storage of Food

A significant issue in the food chain is the storage and preservation of food. Every year, a large amount of food becomes spoiled during transportation and storage due to the inability to maintain freshness for an extended period of time. However, the new phase change technology for cold energy storage has revolutionized cold chain logistics. This technology offers several advantages, including stable temperatures and high energy storage density [39][53]. Effective temperature control is crucial for maintaining freshness and preventing spoilage throughout the food supply chain [7][40][18,54]. Having materials that can reduce temperature fluctuations and keep perishable produce fresh for a longer time is crucial. According to Chen et al., phase change materials (PCMs) can absorb or release large amounts of latent heat during phase transition, with minimal temperature fluctuations [41][42][55,56].

The literature review shows that only a few studies address the use of PCMs to preserve food freshness. Refrigeration systems using cold storage PCMs have been found to maintain the ideal temperature state in refrigerated trucks. Additionally, the cost of this method is half that of traditional refrigeration transportation [43][57]. Adding a phase change cold storage layer to the reefer enclosure reduced total energy consumption by 4.7% compared to conventional cold storage [44][58]. There have been several recent reports on insulation PCM boxes that are suitable for refrigerated transportation of fruits and vegetables. These boxes come in various forms, such as trays, multilayer films, foams, and others. Additionally, a new study has provided a novel idea for the design of temperature control materials that can be used in cold chain transportation of food, vegetables, and fruits [39][53].

1.5. Artificial Intelligence and Energy Issues

Application of AI also offers a vast potential for energy saving. The management of electrical grids is becoming increasingly complex as the world shifts towards renewable energy sources such as solar and wind power. This is where AI can play a crucial role. By predicting fluctuations in demand and adjusting the supply accordingly, AI can help balance the grid, prevent blackouts, and increase energetic efficiency. Additionally, AI can optimize the placement and operation of renewable energy infrastructure, such as wind turbines and solar panels, to maximize their energy output. It can also help reduce energy consumption in frozen food transportation by optimizing routes and traffic, reducing fuel consumption, and CO2 emissions [45][59]. In manufacturing, AI can optimize processes, identify inefficiencies, and improve energy efficiency to reduce costs. Harnessing the power of AI can work towards a world where energy is used efficiently, waste is minimized, and the reliance on fossil fuels is reduced [46][60].

There are three technological gaps that hinder the application of AI in energy saving: (a) difficulty in selecting or combining technologies, (b) various energy-saving effects, and (c) AI effects on control characteristics. AI can optimize manufacturing processes and reduce energy consumption by identifying inefficiencies in production lines and suggesting adjustments. It can help you optimize energy sources and automate energy-saving actions. AI algorithms can also predict energy demand and supply, allowing us to reduce greenhouse gas emissions and mitigate the effects of climate change. A universal workflow combining various AI technologies can achieve consistent energy-saving effects by providing qualitative and quantitative recommendations tailored to different application fields by Squeo [47][61].

2. Design of Novel Food

Various organizations and individuals, directly or indirectly involved in food production, distribution, quality control, sales, and market operations, are constantly seeking new ideas to overcome technical challenges and introduce innovative food products. The interpretation of the concept of a new food product varies across the literature. However, in most countries, the legal definition of a new food product is well-defined. For example, in the United States, the Federal Trade Commission recommends that the term “new” should only be attributed to products that have been available on the market through the usual distribution network for a maximum of six months. Despite the passage of time, Ph. Kotler, in his well-known book [48][63], suggests that new products can be categorized based on their degree of novelty and innovation. These categories include products that create a completely new market and those that enable companies to enter an existing market for the first time, which can be achieved either through horizontal development (by substitution) or vertical development (by quality). Additional products complementing the existing offer, improved and repositioned products for new markets or market segments, are also considered new product lines [49][50][64,65].

In the European Union, novel food is defined as food that has not been consumed to a significant degree by humans in the EU before 15 May 1997, when the first regulation on novel food came into force. Novel food includes newly developed and innovative products, as well as those produced using new technologies, traditional foods from outside the EU, and products not consumed before May 1997 [51][66]. Novel foods must be safe for consumers and properly labeled to avoid misleading consumers. If a novel food is intended to replace another food, it must not be nutritionally advantageous for the consumer. Pre-market authorization of novel foods is necessary based on an evaluation that adheres to the principles mentioned above. In the European Union, the complexities and risk assessments of novel foods are overseen by the European Food Safety Authority (EFSA). When preparing a novel food application, all available knowledge on the novel food should be considered [52][67].

New foods can be categorized based on their nature or source. Botanical, animal-based, and microorganism-based foods are significant areas of interest, with consumers, policymakers, and the industry increasingly exploring alternative and sustainable dietary choices [53][68].

2.1. Development of New Food Products

Developing ideas for new food products or secondary versions of existing ones requires a thorough development process to create a mature design. The journey from the initial idea to the final product can be lengthy due to the need to fulfill several requirements at once. The process of introducing an innovation follows a series of steps outlined below.

New products can be created through original designs, modifications, and improvements to existing products. These changes can be in functional, social, or symbolic dimensions and can be accompanied by new services. In the food market, the number of truly innovative products is limited. There are twelve categories of novel food products, including convenient, light, organic, ethnic, healthy, premium, deluxe, delicatessen, nostalgic, purposeful, variant, and truly new [54][55][56][70,71,72].

According to recent classifications, there are seven conditions that food producers must consider when creating novel products [53][68]. These include meeting consumer demands and sensory attributes, considering the seasonality of ingredients, sourcing and distributing local ingredients, ensuring the safety and traceability of ingredients and final products, manufacturing the food products on a large scale, and minimizing the environmental impact.

Another six-point model of product innovation was presented by Hittmar et al. [57][73]. Its components include the following steps: (1) ensuring the information base; (2) realization of organizational changes; (3) the move to lateral changes; (4) the identification of the innovation process and its management; (5) creating a map of the process; and (6) process optimization. Meanwhile, Bigliardi et al. [58][74] classify three models of innovation implemented in the food industry: technology push, demand-pull, and stage gate. Another interesting model supported by open innovation has been proposed in the early 2000s by Aiking and de Boer [59][75]. In this model, food design involves applying design thinking to every step of the food value chain. The aim is to promote innovation centered on humans throughout the whole food value chain, from production to disposal.

The development of new food products requires the use of innovative methods and engineering processes that ensure the product properties are unique and environmentally safe. Proper control of nutrient availability, satiety, and overall well-being can influence consumer health. Sensory profiles can also be adjusted, which is important when introducing new raw materials and technologies that can shape food choices and habits. Poor sensory experiences or consumer biases can affect these decisions [60][76].

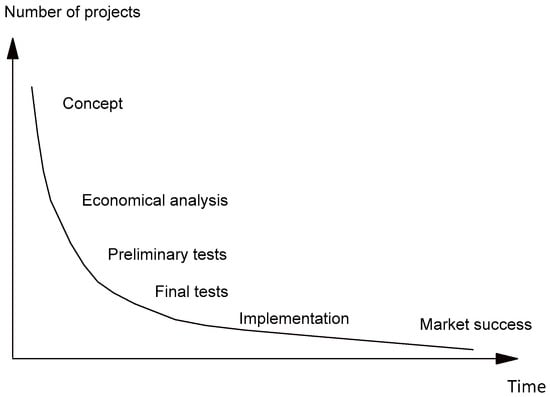

As part of the product development process, the screening and evaluation of numerous product ideas is an essential activity. The objective is to identify and shortlist the most promising product ideas with the greatest potential for success. This process is iterative and involves multiple rounds of evaluation, during which the number of product ideas is reduced (Figure 1). As the product design process continues, the expenditure associated with product development increases.

Establishing connections between the level of achievement in launching new food products and the various factors impacting this level is crucial. To evaluate the success of these launches, one must consider aspects such as market share, sales targets, future profits, technical aspects, company impact and reputation, competitiveness, research and development activities, quality management, implementation speed, and how well the products meet consumer expectations. Steward-Knox and Mitchell argue that “consumer knowledge and retailer involvement are key success factors in food product development” [62][78]. Costa et al. suggest that both technical knowledge and market information are essential for effective product development [63][79]. Novel food technologies are important for food security, safety, and sustainability. However, consumers are often hesitant to accept them, as discussed by Siegrist and colleagues [32][64][46,80]. It is crucial for food-producing companies to anticipate the inevitable expenses of developing new products, regardless of whether they succeed or fail. The company’s top management should play an active role in the product development process by establishing the vision, aligning resources, and rallying support from team members. The most significant methods for finding an idea for a new food product include:

-

developing a list of the product’s current attributes and looking for possible improvements;

-

analyzing relationships between attributes in similar products;

-

identifying structural elements of the product (morphological method);

-

brainstorming in combination with the Ishikawa method.

New ideas can originate from various sources within and without the organization, such as R&D, distributors, consulting firms, universities, and industry institutes. These ideas help shape the new product and ensure that it is competitive and meets the approval of potential buyers. A combination of intellectual and practical efforts is required to define the characteristics of the new product and ensure it is successful in the market. Thus, the role of R&D representatives has been growing in recent years due to two reasons. Firstly, they are experts in product and technological requirements for its creation, and secondly, they are needed to create a prototype or a model of a new product, select appropriate technologies, raw materials, and compositions to ensure its economic implementation, and make sure the product is attractive and stable for the consumer during distribution and use, and resistant to the variability of conditions [65][81].

Many companies rely on analyzing their competitors’ products to generate new ideas. This can involve purchasing their products and studying their quality features or gathering information from published sources [66][82]. Such activities are often part of the company’s imitation strategy, especially when targeting sales to segments with low. In large companies, the process of developing new food product concepts is typically formalized and includes the following: idea generation, evaluation and screening, market research, product specification, feasibility study, production process development, and prototype development and testing [67][83]. This is performed to better organize activities, improve management efficiency, and comply with quality management systems such as ISO 9001 and ISO 26000 [68][84]. Despite the diversity of approaches and positions, the following elements can be distinguished: (1) identifying opportunities and needs, (2) creating an idea to meet these needs, (3) creating a product that materializes the idea, (4) involvement in a variety of activities prior to the start of production, making up the whole.

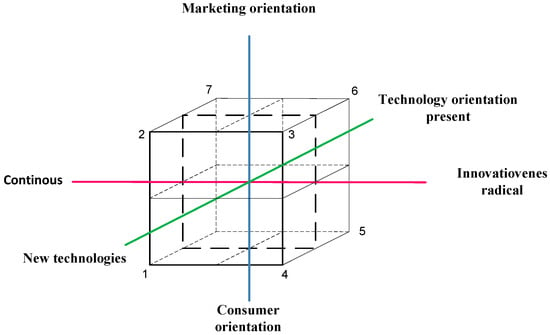

Several strategies informing the creation process of new food can be adopted by the team responsible. The type of new product strategy chosen is determined by three continuous variables: (1) the degree of innovation in the product (continuous or radical innovation); (2) the type of marketing orientation (demand, customer); and (3) the type of technological orientation (current, completely new, etc.) [61][77]. The following figure places the variables and the strategies graphically in a 3D space of innovation, marketing, and technology, with final states as corners of a cube (Figure 2).

Strategies 1 to 4 focus on the use of new technology and research for development, while strategies 5 to 8 are more conservative in terms of technology. However, for specific products, these strategies may not be used in their pure form. For example, strategy 4 is consumer-focused and open to radical innovation and new technology. Strategy 6 involves concentric product diversification, which aims to meet the needs of a new group of consumers through radical innovations while utilizing current technology. On the other hand, strategy 8 is about segmental product differentiation. It aims to expand the scope of satisfying the needs of current and new consumers through continuous and dynamic innovations to master new market segments, without the need to change technology.

2.2. Artificial Intelligence in Development of Novel Food

The role of information technology is becoming increasingly crucial in the design processes of new foods. Initially, ICT was used primarily for information and education purposes such as weather reports, crop prices, and monitoring. It also played an important role in improving the food supply chain [69][70][88,89]. Over the past decade, AI has brought about significant changes in the food industry. It has helped in devising effective marketing strategies, boosting food sales, and analyzing eating habits and preferences. AI has also played a crucial role in food design, new product development, and predicting health problems associated with food consumption [71][90]. Furthermore, AI has emerged as a major solution to food waste problems by estimating food demand quantity, predicting waste volumes, and supporting effective cleaning methods through smart waste management [72][73][91,92].

However, when it comes to food, naturalness is often viewed positively, while technological applications are seen negatively [64][80]. In fact, according to multiple sources, approximately 80% of new products developed by large food and beverage companies end up failing [74][96]. Improving consumer satisfaction is crucial for the success of novel food products, and the challenges and ways to achieve this will be discussed in the following section.