Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Kuok Ho Daniel Tang and Version 2 by Rita Xu.

Textile waste constitutes a significant fraction of municipal solid waste sent to landfill or incinerated. Its innovative management is important to enhance sustainability and circularity.

- municipal solid waste

- sorting

- recycling

- textile waste

1. Introduction

The textile industry produces a substantial amount of waste every year, and currently, most of the waste becomes part of municipal solid waste (MSW) [1][2]. Annually, the world produces approximately 92 million tons of textile waste. The textile industry is also a major contributor of plastic waste, ranking second after the packaging sector with 42 million tons of plastic waste generated per year [3]. In the US, textile waste occupies about 5% of landfill space. China and the US produce the largest quantities of textile waste, at 20 million tons and 17 million tons, respectively [4].

Textile waste can generally be defined as any undesirable or discarded piece of fabric or clothing that is unfit for its original purpose [5]. It can be divided into three large groups depending on the sources, namely, pre-consumer waste, post-consumer waste, and post-industrial waste. Pre-consumer textile waste is generated during the production, manufacturing or processing of textiles and typically comprises fabric scraps, yarns or rejected defective products. Post-consumer textile waste is produced when textile products have been used and are discarded before or at their end of life. Instances of this waste are clothing, bedding or curtains thrown away by households or institutions [5]. Post-industrial textile waste is generated by other industries that use textiles as inputs or outputs, which include discarded medical textiles, automotive textiles or packaging textiles [6].

Textile waste has given rise to negative environmental, economic and social problems. It is a contributor of greenhouse gases, water pollution and soil contamination [7]. The fashion industry alone was reported to produce 10% of the total greenhouse gas emissions and 20% of global wastewater, in addition to consuming large amounts of water, energy and chemicals for the manufacturing of clothes [4][8]. Textile waste is commonly landfilled or incinerated, thus taking up landfill space or adding to the release of toxic substances or microplastics into air, water and soil upon incineration [9]. Economically, textile waste results in revenue loss of the textile industry. An estimated USD 500 billion is lost annually due to underutilization of clothing and lack of recycling. Additionally, the disposal of textile waste incurs expenses [10]. Socially, the disposal of textile waste further widens social inequalities. Used clothing is sent from developed countries to low- and middle-income countries for sorting, categorizing and re-baling prior to being sold in second-hand markets, and these procedures are often performed by low-wage workers [10]. Clothing which fails to make it to the markets is treated as solid waste, thus burdening the MSW systems of low- and middle-income countries while bringing more environmental health hazards [11].

Therefore, the effective management of textile waste could yield positive environmental, economic and social impacts. However, the management of textile waste is faced with multiple challenges. The collection of textile waste is often inadequate, inefficient and unorganized, particularly in developing countries, leading to disrupted and unreliable streams of textile waste for the recycling industry [7]. The heterogeneity and complexity of textile waste due to the diverse blends, dyes, finishes and accessories on textiles render the sorting and separation of waste difficult [12]. The recycling of textile waste faces multiple technical, economic and environmental constraints; for instance, the recycling technologies for natural fibers are not established, whereas the recycling processes for synthetic fibers are usually energy-intensive and polluting [13]. Limitations in the sorting and recycling of textile waste make its disposal the only feasible option in many countries, which is unsustainable, since it occupies valuable landfill space and releases greenhouse gases and leachates [10]. The mismanagement of textile waste, particularly synthetic textiles, aggravates the already alarming plastic pollution, since synthetic textiles constitute a major source of microfibers [14][15].

2. Policies on Textile Waste Management

Policies from governments are essential to driving efforts and innovations in textile waste management. They are indications of global and national commitments which motivate operationalization of and technological development for textile waste management. The UK government, for instance, launched an all-encompassing Waste Prevention Program in March 2021, aiming to reduce environmental and social impacts of textile, as well as other sectors [16]. The program has a list of measures to promote the sustainability of the fashion industry, including encouraging reuse and repair, upscaling circular business models and improving consumer information and education [16]. An Extended Producer Responsibility scheme for textiles is also in the pipeline to hold the UK fashion industry responsible for the costs of the recycling and disposing of their products [17]. The European Union (EU) rolled out a new Circular Economy Action Plan in March 2020 which covers a comprehensive strategy to enhance the sustainability and circularity of the EU textile sector [18]. The strategy promulgates that the design of textile should consider better durability, reusability and recyclability and that textile production should aim to minimize the associated environmental and social impacts. The strategy also probes the possibility of introducing new rules on textile labelling and traceability to provide consumers with clear and reliable information on the sustainability of textile products [9]. In 2019, the United Nations Environment Program already introduced a Textile Flagship Initiative to bring about systemic change towards sustainability and circularity in the textile sector according to three priorities, namely, changing consumption patterns, improving practices and investing in infrastructure [19]. The initiative complements the operationalization of the UN Alliance for Sustainable Fashion introduced in 2018 to coordinate the efforts of various UN agencies and partners to promote sustainable fashion [20]. In the US, in view that textile waste constituted 5.3% of the total MSW generated in 2018, of which 68.5% was landfilled and only 15.2% was recycled, a white paper was jointly released in April 2022 by the Secondary Materials and Recycled Textiles Association and the Council for Textile Recycling to propose strategies for enhancing textile recovery in the US [4][21]. The two institutions assume important roles in the sale, collection, sorting and processing of textile materials, in addition to educating the public on the environmental and economic benefits of textile reuse and recycling [21]. Increasing emphasis on the sustainability and circularity of the textile sector regionally and globally has spurred research and development of new strategies to collect, sort, recycle and reuse textile waste. Currently, these policies focus on six major areas, namely, promoting recycling, sustainability, value addition, regulation compliance, innovation encouragement and entrepreneurship [22]. These areas are interrelated. Promoting recycling emphasizes the recycling of textile waste into new textiles with similar or different functions, as well as other products, ideally with value added to enhance the sustainability of fashion industry. Sustainability underscores the reducing, reusing and recycling of textile waste to improve the economic, social and environmental performances of the textile industry [23]. Value addition focuses on textile waste valorization, as well as value-added products in the textile and apparel industries, for long-term benefits [24]. Regulation compliance ensures that harmful waste is properly disposed of, whereas innovative encouragement drives new technologies and methods for dealing with textile waste. Entrepreneurship aims to create new business opportunities in textile waste recycling. These have driven technological innovations and new businesses in the collection, sorting and recycling of textile waste [22]. The most notable innovations have been in the area of sorting with the commercialization of new machines for the more efficient sorting of textile waste, as well as the mechanical and chemical recycling of waste textiles into new textiles with similar or different functions [23].3. Collection of Textile Waste

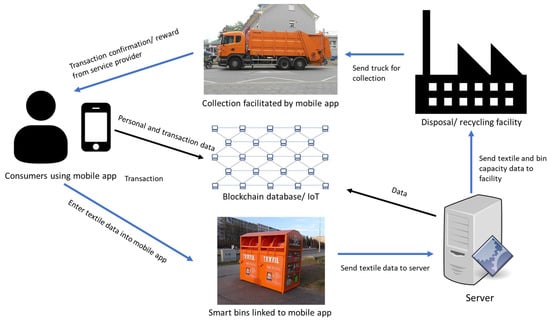

The Internet of Things (IoT) and big data have been proposed to enable the efficient identification and collection of textile waste. For example, smart tags or sensors can be attached to textile products to track their location, usage and condition. This can help to optimize the collection routes, reduce transportation costs and increase the recovery rate of textile waste [25]. IoT sensors enable the real-time monitoring of space availability of textile waste containers for optimization of collection routes (Figure 1). Additionally, they contribute to waste collection optimization through the tracking of radio frequency identification as well as the use of sensors and cameras to obtain input on the amount, type and location of textile waste [26]. This helps lower transportation costs, fuel consumption and greenhouse gas emissions associated with waste collection [26]. Big data can also be used to analyze the supply and demand of textile waste and to match waste collectors with recyclers (Figure 1) [27]. Specifically, waste collection efficiency and effectiveness are improved by feeding real-time data on waste generation, collection and disposal to predictive analytics and decision support tools to plan and optimize collection routes, schedules and methods [27].

Figure 1. Integration of blockchain, the IoT and mobile applications in textile data collection.

4. The Sorting of Textile Waste

The sorting of textile waste is important for successful textile recycling, as it determines the quality and quantity of the recycled fibers and products. It is challenging due to the presence of different types of fabrics, colors, patterns and contaminants in the textile waste streams. Technologies have been developed to facilitate the sorting of textile waste. One of the technologies involves the use of hyperspectral imaging and artificial intelligence. It uses a camera that can capture images of textile waste in different wavelengths and light. The images are then fed to an algorithm for analysis and fabric classification based on fiber composition and the contaminants present. This technology provides high accuracy and speed in sorting textile waste [32]. Another technology combines near-infrared (NIR) spectroscopy and optical sorting, with the former emitting infrared radiation and measuring the radiation reflected by textile waste [33]. The spectral signatures enable different types of fabrics, such as cotton, polyester, wool and silk, to be distinguished, and the presence of dyes, coatings and finishes to be detected. A machine is employed to sort the fabrics based on their spectral signatures [33]. In fact, a device called PICVISA (DFactory Barcelona, Barcelona, Spain), which combines near-infrared spectroscopy and an RGB (red, blue, green) camara, has been developed and commercialized to sort fabrics based on their composition and color [34]. This technology facilitates the efficient sorting of large quantities of textile waste and product textile fractions suitable for different recycling processes [34]. Another example is WASTEX (Wastex, Barcelona, Spain), which uses NIR, RGB, together with artificial intelligence, for the highly efficient sorting of textiles to produce high-quality recycled yarn feedstock [35]. However, these technologies can be costly. The integration of artificial intelligence algorithms to analyze voluminous spectral data requires fast computers, sensitive detectors and large data storage capacity. Hyperspectral and NIR imaging may encounter noise and interference due to brightness non-uniformity and pixel abnormality, among others, which could negatively affect the performance of artificial intelligence algorithms, leading to errors or misclassification [36]. Nonetheless, with successful commercialization of advanced sorting machines integrating these technologies, textile waste sorting is expected to be increasingly efficient and cost-effective.References

- Tang, K.H.D.; Darwish, N.M.; Alkahtani, A.M.; AbdelGawwad, M.R.; Karácsony, P. Biological Removal of Dyes from Wastewater: A Review of Its Efficiency and Advances. Trop. Aquat. Soil Pollut. 2022, 2, 59–75.

- Salman, M.; Demir, M.; Tang, K.H.D.; Cao, L.T.T.; Bunrith, S.; Chen, T.-W.; Darwish, N.M.; AlMunqedhi, B.M.; Hadibarata, T. Removal of cresol red by adsorption using wastepaper. Ind. Domest. Waste Manag. 2022, 2, 1–8.

- Kasavan, S.; Yusoff, S.; Guan, N.C.; Zaman, N.S.K.; Fakri, M.F.R. Global trends of textile waste research from 2005 to 2020 using bibliometric analysis. Environ. Sci. Pollut. Res. 2021, 28, 44780–44794.

- Huun, K. Textile Waste. Available online: https://www.colorado.edu/ecenter/2021/10/05/textile-waste (accessed on 5 November 2023).

- Stanescu, M.D. State of the art of post-consumer textile waste upcycling to reach the zero waste milestone. Environ. Sci. Pollut. Res. 2021, 28, 14253–14270.

- Tomovska, E.; Jordeva, S.; Trajković, D.; Zafirova, K. Attitudes towards managing post-industrial apparel cuttings waste. J. Text. Inst. 2017, 108, 172–177.

- Pensupa, N.; Leu, S.-Y.; Hu, Y.; Du, C.; Liu, H.; Jing, H.; Wang, H.; Lin, C.S.K. Recent Trends in Sustainable Textile Waste Recycling Methods: Current Situation and Future Prospects. Top. Curr. Chem. 2017, 375, 76.

- Lee, K.K.; Tang, K.H.D. Agaricales (Gilled Mushrooms) as Biosorbents of Synthetic Dye. Malays. J. Med. Health Sci. 2020, 16 (Suppl. S11), 10–17.

- European Parliament. The Impact of Textile Production and Waste on the Environment (Infographics). Available online: https://www.europarl.europa.eu/pdfs/news/expert/2020/12/story/20201208STO93327/20201208STO93327_en.pdf (accessed on 5 November 2023).

- Yalcin-Enis, I.; Kucukali-Ozturk, M.; Sezgin, H. Risks and Management of Textile Waste. In Nanoscience and Biotechnology for Environmental Applications; Gothandam, K.M., Ranjan, S., Dasgupta, N., Lichtfouse, E., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 29–53.

- Bick, R.; Halsey, E.; Ekenga, C.C. The global environmental injustice of fast fashion. Environ. Health 2018, 17, 92.

- Dissanayake, D.G.K.; Weerasinghe, D.U. Fabric Waste Recycling: A Systematic Review of Methods, Applications, and Challenges. Mater. Circ. Econ. 2021, 3, 24.

- Kamble, Z.; Behera, B.K. Upcycling textile wastes: Challenges and innovations. Text. Prog. 2021, 53, 65–122.

- Tang, K.H.D. Microplastics in agricultural soils in China: Sources, impacts and solutions. Environ. Pollut. 2023, 322, 121235.

- Tang, K.H.D. Enhanced plastic economy: A perspective and a call for international action. Environ. Sci. Adv. 2023, 2, 1011–1018.

- DEFRA. Government Unveils Plans for Wide-Ranging Waste Prevention Programme. Available online: https://www.gov.uk/government/news/government-unveils-plans-for-wide-ranging-waste-prevention-programme (accessed on 6 November 2023).

- Dawson, L. ‘Our Waste, our Resources; A Strategy for England’–Switching to a circular economy through the use of extended producer responsibility. Environ. Law Rev. 2019, 21, 210–218.

- Farmer, A. Developing the Circular Economy in the European Union. In Circular Economy: Global Perspective; Ghosh, S.K., Ed.; Springer: Singapore, 2020; pp. 389–412.

- Petrie, L. Sustainability and Circularity in the Textile Value Chain: A Global Roadmap; UNEP: Paris, France, 2023; Available online: https://www.unep.org/resources/publication/sustainability-and-circularity-textile-value-chain-global-roadmap (accessed on 6 November 2023).

- United Nations. What Is the UN Alliance for Sustainable Fashion? Available online: https://unfashionalliance.org/ (accessed on 6 November 2023).

- RRS. White Paper: Textile Recovery in the U.S. Available online: https://recycle.com/white-paper-textile-recovery-in-the-us/ (accessed on 6 November 2023).

- Chand, S.; Chand, S.; Raula, B. Textile and apparel industries waste and its sustainable management approaches. J. Mater. Cycles Waste Manag. 2023, 25, 3132–3143.

- Shamsuzzaman, M.; Hossain, I.; Saha, T.; Roy, A.; Das, D.; Ahmed, M.T.; Podder, S.K. Waste Management in Textile Industry BT—Advanced Technology in Textiles: Fibre to Apparel; Rahman, M.M., Mashud, M., Rahman, M.M., Eds.; Springer Nature: Singapore, 2023; pp. 279–299.

- Tang, K.H.D. Valorization of Plastic Waste through Incorporation into Construction Materials. Civ. Sustain. Urban Eng. 2022, 2, 96–109.

- Manglani, H.; Hodge, G.L.; Oxenham, W. Application of the Internet of Things in the textile industry. Text. Prog. 2019, 51, 225–297.

- Padilla II, D.D. The Internet of Things (IoT): Making Waste Collection Part of a Smarter Future. Waste Advantage. Florida September 2021. Available online: https://wasteadvantagemag.com/the-internet-of-things-iot-making-waste-collection-part-of-a-smarter-future/ (accessed on 5 November 2023).

- Hack-Polay, D.; Rahman, M.; Billah, M.M.; Al-Sabbahy, H.Z. Big data analytics and sustainable textile manufacturing. Manag. Decis. 2020, 58, 1699–1714.

- Dursun, E.; Ulker, Y.; Gunalay, Y. Blockchain’s potential for waste management in textile industry. Manag. Environ. Qual. Int. J. 2023, 34, 1174–1197.

- Gökbunar, H.B.; Soylu, B. Blockchain Enabled Lateral Transshipment System for the Redistribution of Unsold Textile Products in a Circular Economy BT—Advances in Intelligent Manufacturing and Service System Informatics; Şen, Z., Uygun, Ö., Erden, C., Eds.; Springer Nature: Singapore, 2024; pp. 630–640.

- Samsukha, A. Role of Technologies and Mobile Apps in Waste Management. Forbes. September 2022. Available online: https://www.forbes.com/sites/forbestechcouncil/2022/09/09/role-of-technologies-and-mobile-apps-in-waste-management/?sh=39e124417d26 (accessed on 5 November 2023).

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.-S. Possibility Routes for Textile Recycling Technology. Polymers 2021, 13, 3834.

- Du, W.; Zheng, J.; Li, W.; Liu, Z.; Wang, H.; Han, X. Efficient Recognition and Automatic Sorting Technology of Waste Textiles Based on Online Near infrared Spectroscopy and Convolutional Neural Network. Resour. Conserv. Recycl. 2022, 180, 106157.

- Cura, K.; Rintala, N.; Kamppuri, T.; Saarimäki, E.; Heikkilä, P. Textile Recognition and Sorting for Recycling at an Automated Line Using Near Infrared Spectroscopy. Recycling 2021, 6, 11.

- Recyclinginside. Recycling Post-industrial Waste in the Textile Industry: A Circular Future. Available online: https://recyclinginside.com/separation-and-sorting-technology/recycling-post-industrial-waste-in-the-textile-industry-a-circular-future/ (accessed on 7 November 2023).

- Wastex. Textile Sorting Technologies. Available online: https://www.wastexrecycling.com/ (accessed on 7 November 2023).

- Wu, Y.; Xu, Z.; Yang, W.; Ning, Z.; Dong, H. Review on the Application of Hyperspectral Imaging Technology of the Exposed Cortex in Cerebral Surgery. Front. Bioeng. Biotechnol. 2022, 10, 906728. Available online: https://www.frontiersin.org/articles/10.3389/fbioe.2022.906728 (accessed on 7 November 2023).

More