1. Supercritical Fluid Extraction (SFE)

SFE is notable for being an eco-friendly method that is used to extract NPs

[1][43]. This technique utilizes supercritical fluids, which are substances that operate at temperatures and pressures above their critical points, to selectively extract desired compounds of interest from the initial material. Notably, carbon dioxide (CO

2) takes the forefront as the most widely used supercritical fluid in SFE

[2][44]. SFE offers distinct advantages compared to traditional extraction methods, because it uses non-flammable and non-toxic solvents, guaranteeing both safety and environmental friendliness. Since SFE is very selective, it can preserve the purity of NPs during extraction by allowing for lower temperatures

[3][45]. Additionally, SFE minimizes residue production during extraction, a notable improvement over the conventional method. The recyclability of supercritical fluids further reduces residue, contributing to a reduced environmental footprint in the NP industry

[4][20].

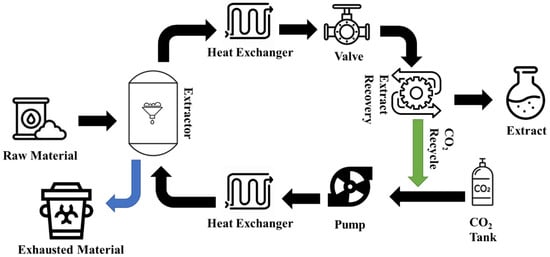

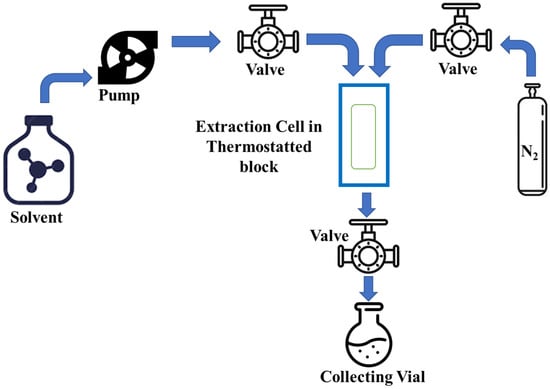

As illustrated in

Figure 1, the SFE system is made up of an extraction vessel, heat exchangers, pressure release valve, pump, and extract recovery, among other necessary parts

[5][46]. In the initial stage of the extraction process, waste material is introduced into the extraction vessel. A pressure release valve and temperature controllers are attached to the extraction vessel to ensure that the conditions are always optimal. Usually, the main vessel is filled with CO

2 that is pumped under specific conditions (Pc = 5.7 MPa and Tc < 5 °C). Heat exchangers cool the CO

2 at both the inlet and exit of the extraction vessel. Following this, a combination of pressure and temperature is applied, decreasing the solvation properties of the used SFE fluid. The desired bioactive NPs dissolve in the fluid, and separation occurs in the extract separator, facilitated by an outlet valve

[6][47]. This SFE process persists until the highest recovery rates of the desired bioactive NPs are achieved from the waste material sample.

Figure 1. The schematic flow of the supercritical fluid extraction system.

The efficacy of supercritical CO

2 (scCO

2) in extraction is particularly pronounced for nonpolar phytochemicals due to its robust solvation capabilities. Polarized phytochemicals, on the other hand, are problematic because of their poor solubility in scCO

2. The addition of small quantities of co-solvents, such as “ethyl alcohol, water, methanol, ethyl acetate, acetone, or acetonitrile”, is effective in passing this limitation. This adjustment enhances the solubility of polar phytochemicals, leading to an increased yield of phytochemicals in the extract. An impressive 30% increase in the extraction yield of primary cannabinoids from industrial hemp by-products was observed when ethanol was added to scCO

2 as a co-solvent

[7][48]. Furthermore, the phenolic and flavonoid yields were significantly increased, and the antioxidant capacity was significantly enhanced with ethanol as a co-solvent

[8][49]. Studies have also highlighted the positive correlation between ethanol-modified scCO

2 and the recovery yield of extracts, along with their antioxidant activity

[9][50]. To further improve scCO

2 extraction, a co-solvent consisting of ethanol and water was also used

[10][51].

In contrast to traditional extraction methods, SFE boasts several distinct advantages. Firstly, it consistently yields higher quantities of extracts while maintaining their biological activities, outperforming conventional techniques like Soxhlet

[11][55]. For example, SFE not only extracts more oils from apple seeds compared with Soxhlet but also produces extracts with superior oxidative stability. Additionally, SFE is characterized by its simplicity, rapid operation, and exceptional efficiency, resulting in impressive yields. Secondly, the dissolution characteristics of the supercritical fluid can be easily enhanced by adjusting the pressure to a particular temperature. Thirdly, SFE stands out as a non-flammable and non-explosive green extraction technique, ensuring minimal environmental impact. Lastly, adding trace quantities of entrainers to SFE can enhance the polar phytochemicals’ solubility, altering the polarity of the extraction medium. In addition, the cost-effective recyclability of the extraction medium further underscores the economic and environmental benefits of SFE

[12][3].

2. Subcritical Water Extraction (SWE)

The term “subcritical water” describes heated water that is subjected to a pressure high enough to keep it in a liquid state at a critical pressure, between the boiling point of 100 °C and the critical point of 374 °C

[13][65]. Its diffusivity properties improve with increasing temperature and its “surface tension, viscosity, and dielectric constant” all decrease. It is interesting to note that at 250 °C and 2.5 MPa, the dielectric constant of water drops to 25, which is similar to organic solvents such as methanol (ε = 33) and ethanol (ε = 24) at 25 °C. In this state, water dissolves a wide range of compounds with medium to low polarity, similar to organic solvents

[14][15][16][66,67,68].

SWE, also known as “Pressurized Hot Water Extraction (PHWE)”, is a novel method for extracting bioactive NPs from matrices that include food, agricultural products, and by-products. The utilization of heated water as the solvent for extraction is the defining characteristic of this technique

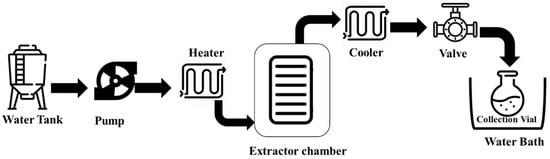

[17][18][69,70]. The SWE procedure is carried out in an extractor chamber that is pre-loaded with the sample matrices and a certain quantity of inert material, most often sand, to avoid sample aggregation. The four sequential steps of the extraction mechanism are depicted in the schematic flow diagram of SWE (

Figure 2). The first step is to pressurize and heat the sample matrix to a high temperature in order to desorb the solute at different active sites. Extracts are diffused into the matrix in the second step. Step three relies on the sample matrix; in this stage, solutes may separate from the matrix and dissolve in the extraction solvent. Filling the extraction cell with the sample solution and eluting it is the last step

[19][71].

Figure 2. The schematic flow of the subcritical water extraction system.

SWE stands out as a versatile method due to water’s unique ability to act as a universal solvent, accommodating both polar and nonpolar phytochemicals. Leveraging its capability to dissolve both types of phytochemicals, SWE was applied to extract steviol glycosides and antioxidants (both polar and nonpolar) from

Bertoni leaves. Higher yields were obtained from this extraction when carried out at a higher temperature of 160 °C as opposed to the lower temperature of 100 °C

[20][72]. Moreover, SWE makes it easier to selectively extract phytochemicals with particular biological activities. For example, its ability to selectively extract phenolic compounds from

kānuka leaves with a high antioxidant capacity is particularly noteworthy, as it outperforms conventional ethanol extraction

[21][73].

Water, when used in SWE, has demonstrated superiority in recovering phytochemicals compared with other solvents. A number of studies have compared SWE to other extraction methods, such as maceration, Soxhlet, reflux extraction, and others, to determine its extraction efficiency and activities. These works, as referenced in

[22][23][24][25][88,89,90,91], consistently demonstrate that SWE is superior to other extraction techniques or, at the very least, comparable to them, when only one solvent is used. Water was determined to be the most effective solvent for subsequent extractions after a study compared its efficiency to that of “acetone, n-hexane, 96% ethanol, ethyl acetate, and methylene chloride”. The SWE that used water had the highest levels of polyphenolics, flavonoids, and antioxidant activity

[24][90].

On the other hand, polyphenols, which are also referred to as polyhydroxyphenols, constitute a structural class predominantly found in nature, characterized by the presence of multiple phenolic units and the absence of nitrogen-based functions. These compounds have the remarkable ability to resist oxidation, and are commonly found in a wide variety of foods, including herbs, nuts, tea, algae, leaves, fruits, and vegetables

[26][92]. The majority of experiments have consistently demonstrated the superiority of SWE over maceration, Soxhlet, and others

[27][28][93,94]. On the other hand, a recent study offered an opposing viewpoint, arguing that pomegranate peel is better valued at SWE’s lower temperatures. According to the study’s findings, MAE is more effective than SWE in this situation for phenolic extraction from pomegranate peel, especially when trying to produce an extract devoid of 5-hydroxymethylfurfural

[28][94].

Furthermore, organic acids (e.g., fatty acids) in NPs are ubiquitous in plant tissues, including stems, roots, and fruits. All these acids are water- or ethanol-soluble and manifest acidic properties, yet they pose challenges in dissolving in other organic solvents. The use of SWE was investigated for the extraction of organic acids from diverse matrices, such as ferulic acid, gallic acid, and chlorogenic acid. Nevertheless, it unavoidably coextracted additional active ingredients, such as “proteins and phenolics

[29][95], flavonoids

[30][96], lipids, peptides, amino acids”, and other organic compounds. Recent research on sweet and sour cherry stems used SWE to extract sugars, organic acids, alcohols, and other organic compounds. Remarkably, the two samples’ chemical compositions were discovered to be similar

[31][97].

In general, SWE offers several advantages over steam distillation, providing superior products in less time and with lower energy consumption. Water’s unique properties, such as its eco-friendliness, universal solvent capabilities, suitability for recovering thermally labile phytocompounds, and widespread availability, make it the preferred extractant in SWE.

3. Ultrasound-Assisted Extraction (UAE)

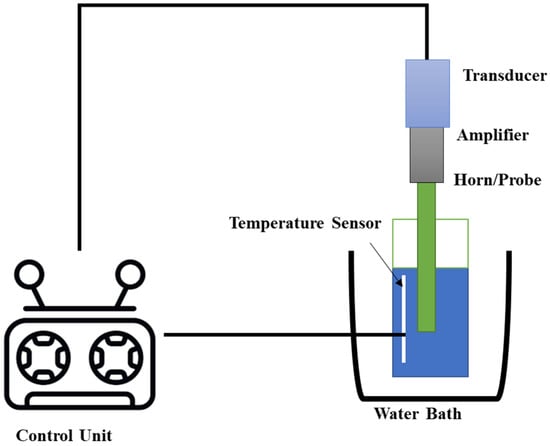

UAE is commonly performed with an ultrasonic probe or bath, both of which, as illustrated in

Figure 3, depend on a piezoelectric transducer to provide ultrasonic power. The solid matrix is suspended in a solvent in an ultrasonic bath apparatus, which consists of a stainless steel tank linked to the transducer. The ultrasonic probe, in contrast, is a horn or probe attached to a transducer that, when submerged in the extraction vessel, transmits ultrasound waves into the medium with little energy loss. Because of the greater ultrasonic intensity at the probe tip, probe-based systems are often considered to be a more effective tool for bioactive NP extraction than bath systems

[32][33][98,99].

Figure 3. The ultrasound-assisted extraction (UAE) technique setup or system.

UAE uses solvent extraction and ultrasonic waves to extract desired chemicals from a wide range of materials. “Acidified water, alcohols, ethanol, acetone, and water” are some of the solvents that have been used to extract various compounds during UAE

[34][100]. Ultrasound, with frequencies higher than what humans can hear (>20 kHz), consists of cycles of expansions and contractions of molecules, effectively extracting them from a source material

[35][101]. Increased solvent-to-waste sample contact area and cell wall permeability are both mechanical effects of ultrasonic cavitation

[12][3].

The number of bioactive NPs produced with UAE is greatly affected by the pretreatment of food scraps. Blanching, drying, and milling are some of the pretreatment processes, that raw materials go through when trying to extract pectin and polysaccharides from fruit and vegetable by-products. Blanching is a process that eliminates enzymes by quickly cooling the by-products in an ice bath after being immersed in hot water for 3 to 5 min at temperatures between 80 °C and 100 °C

[36][102]. The drying process involves placing the sample in a hot air oven set at a temperature range of 45 °C to 60 °C for 24 to 72 h until a constant weight is achieved. Then, the dried peels are ground into particles smaller than 0.25 mm in diameter using an electric grinder

[37][38][103,104].

UAE has emerged as a versatile and efficient method for extracting bioactive NPs from various sources. This technique has been widely investigated for the extraction of compounds such as pectin

[39][105], polyphenols

[40][106], oils

[41][107], and many others from fruits, vegetables, and agriculture residues.

UAE stands out as a pivotal technique for extracting bioactive compounds, showcasing its broad applicability. Noteworthy achievements include the successful extraction of phenolic compounds from strawberries

[42][117], yielding favorable results. Additionally, this technique has been used to extract phenolic derivatives and anthocyanines from grape peels, as documented in another study

[43][118]. In contrast to the 120 min needed for the maceration method, which produced lower quantities, a comparative study showed that UAE significantly reduced extraction time to 30 min, highlighting its efficiency. In addition, UAE is great at increasing the rate of extraction while using a smaller amount of solvent

[44][45][119,120]. Consequently, UAE emerges as a preferred and efficient extraction method.

However, recent studies have noted that the frequency used in UAE can actively modify and positively impact the extraction of chemicals from a material

[46][121]. Intriguingly, a study found that phenolic yields were higher at 40 kHz compared with 120 kHz

[47][122]. This observation emphasizes the need for a thorough exploration of ultrasonic parameters, encouraging researchers to simultaneously evaluate and optimize these factors to enhance extraction efficiency. The dynamic interplay between frequency and extraction outcomes underscores the importance of meticulous parameter adjustment for effective and tailored UAE processes.

4. Microwave-Assisted Extraction (MAE)

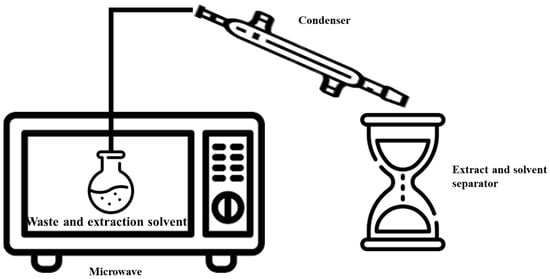

MAE is a modern technique for NPs extraction that combines the use of microwaves with solvents. It is extremely useful for enhancing extraction kinetics by heating the solvent and material at frequencies between 300 MHz and 300 GHz. This heating process is achieved with the direct impact of microwaves on polar molecules, leading to energy conversion through dipolar rotations. MAE is a new extraction method that uses microwave energy to quickly and efficiently remove bioactive NPs from a variety of sources (see

Figure 4 for a schematic diagram). The heating in MAE is directly correlated with the dielectric constant of the solvents

[48][123].

Figure 4. Microwave-assisted extraction system.

The MAE process unfolds through a series of systematic steps to ensure the efficient extraction of phytochemicals from diverse sources. Commencing with the generation of electromagnetic (EM) waves, this process effectively segregates targeted compounds from the waste matrix (e.g., peel) by creating heightened pressure and temperature conditions. Afterward, bioactive cellular components in the waste matrix (sample) interact with the waves, which transport photon energy and cause the bound moisture in the waste to be heated. The resultant cellular-level pressure buildup causes rapid cellular swelling and rupture, which allows the chosen solvent to diffuse into the waste matrix. In the end, targeted phytochemical solutes are leached from the waste matrix using this orchestrated sequence

[49][39].

The extraction process in MAE encompasses the diffusion of solvents into the sample, followed by the separation of the solute from the functional site and, ultimately, the release of solutes into the solvents. This technique excels in preserving the biological activities of the extracts. An illustrative instance is the improvement in microwave-assisted extraction (MAE) for extracting green tea, demonstrating its ability to boost the antioxidant activity of phytochemicals. Additionally, this optimization has shown gains in the extracts’ intended color quality and total phenolic content. The efficacy of MAE extends beyond extraction, contributing to an enhancement in the key properties in the obtained extracts

[50][124].

The MAE technique has proven to be versatile in obtaining a range of phytochemicals, including saponins, polyphenols, sterols, and flavonoids, from a variety of plant sources

[51][52][53][137,138,139]. The direct impact of microwaves on these compounds contributes to the effectiveness of the extraction process. This highlights the adaptability of MAE in acquiring diverse phytochemicals across different plant sources

[54][140].

Furthermore, operating parameters such as microwave power, extraction time, and temperature play crucial roles in influencing the extraction efficiency in MAE. An example that demonstrates this point is the successful carotenoids extracted from carrot waste. The results showed that the extraction time and microwave power played a significant role in this process. The optimization of these parameters becomes imperative for achieving desired outcomes in MAE

[55][141]. It has also been observed that the high dielectric constant of polar solvents, such as water or ethanol, can increase the heating of the solvent–sample mixture in MAE. Therefore, it is recommended to utilize solvents with lower dielectric constants when extracting thermolabile compounds that require relatively lower temperatures. One way to keep thermolabile phytochemicals intact during extraction is to immerse plant material in a solvent that is transparent to microwaves, like n-hexane

[56][142]. This strategic solvent selection contributes to the efficient and targeted extraction of bioactive compounds.

Compared to conventional solvent extraction methods, MAE offers numerous advantages over traditional solvent extraction techniques, such as being rapid and cost-effective, requiring less solvent, and exhibiting a higher extraction rate. However, certain limitations exist, primarily related to its suitability for relatively smaller phenolic molecules such as quercetins and isoflavones, which demonstrate stability within the microwave temperature range. It is noteworthy that MAE is most beneficial for capturing phytochemicals that are substantially lost using conventional methods. For instance, in food processing, conventional methods result in significant flavonoid loss; hence, MAE proves invaluable for extracting flavonoids intended as food additives for supplementation

[57][143].

5. Pressurized Liquid Extraction (PLE)

PLE is a fast extraction method that achieves targeted compound extraction by directly interacting liquid solvent with waste matrix particles (e.g., plants) under subcritical temperature and high pressure. The effectiveness of this extraction process is intricately tied to three key aspects: “the nature of the matrix, mass transfer, and solubility”. Important factors in the extraction efficiency are the matrix’s properties, the compound that needs to be extracted, and the distribution of the compound within the matrix

[58][144]. High temperatures are essential for improving the mass transfer and solubility characteristics between the extraction solvent and the plant matrix. This improvement in temperature leads to more efficient extraction kinetics, ultimately contributing to enhanced extraction processes

[59][145].

The solvent is circulated through the extraction cell or column in the PLE process, usually with the help of an HPLC (high-performance liquid chromatography) pump (see in Figure 5) to efficiently remove the bioactive NPs of interest from the waste matrix. This process maintains constant pressure and temperature initially to initiate static extraction, stabilizing the system and facilitating solvent diffusion through the plant matrix. Subsequently, dynamic extraction begins with the maintenance of the required pressure and solvent flow rate.

Figure 5. The pressurized liquid extraction system.

Recent years have seen a number of studies that have used PLE to extract bioactive NPs from various agricultural by-products or agricultural products derived from a wide variety of food matrices, such as cereals, microalgae, fruits, herbs, spices, and vegetables.

PLE is a new, environmentally friendly way to extract valuable compounds from raw materials. Because it makes use of high pressure and temperature, PLE has a high extraction efficiency and is therefore widely used for a variety of NPs, including medicinal plants and fruits. Notably, PLE’s versatility extends to conducting extractions at lower temperatures, protecting target compounds’ bioactivity and stability. This technique is not only highly efficient but also environmentally friendly, generating less waste compared with conventional extraction methods, thereby positioning itself as a sustainable and preferable alternative.

The primary bioactive components of

Centella asiatica, triterpenoids, have been successfully extracted using PLE. These triterpenoids have anti-inflammatory and neuroprotective characteristics, which means they could be used to treat inflammatory and neurological disorders

[4][20]. Additionally,

Melastoma malabathricum, a medicinal plant known for its traditional use in treating inflammatory and diabetic conditions, has had its bioactive compounds extracted using PLE

[60][154]. This showcases the versatility of PLE in accessing bioactive constituents with therapeutic potential from diverse botanical sources.

Nevertheless, despite its advantages, PLE does encounter some constraints. The substantial cost of equipment, especially for small-scale producers

[61][155], and high energy consumption

[62][156] stand out as a notable limitation. Furthermore, the elevated pressure and temperature integral to the PLE process may impact the stability and quality of specific compounds, leading to degradation and potential loss of bioactivity

[63][157]. These challenges highlight the need for a balanced consideration of factors when opting for PLE in various extraction scenarios.

6. Enzyme-Assisted Extraction (EAE)

In certain plant matrices, the extraction of phytochemicals is challenged by the intricate network of polysaccharides and lignin, secured through hydrogen bonding and hydrophobic interactions like van der Waals forces. These phytochemicals, enmeshed in the cell cytoplasm, pose accessibility issues with conventional solvent extraction methods. However, a breakthrough is achieved by pretreating the plant material with specific enzymes

[64][158], releasing bound phytochemicals at high yields. These enzymes, including cellulase, pectinase, and amylase, are introduced during extraction and break down cellular walls and hydrolyze carbohydrates like cellulose and lipid bodies. Two types of extraction methods that make use of enzymes are known as “enzyme-assisted aqueous extraction (EAAE) and enzyme-assisted cold pressing (EACP)”. The former is primarily applied for extracting oils from diverse seeds, while the latter effectively hydrolyzes the cellular wall of plant seeds

[65][159].

EAE is used in tandem with other extraction methods to render non-extractable phytochemicals accessible to solvents, thereby enhancing their susceptibility to extraction. An example highlighting the effectiveness involves the integration of enzymes into microwave processing. This synergistic approach substantially improved the phenolic compound extraction yield, surpassing the limited recovery yields achieved using conventional solvent extraction with water due to the application of higher extraction temperatures and a rapid heating strategy

[66][164]. Furthermore, when compared with alternative extraction methods that did not incorporate enzymes, the pectin yields from different wastes sequentially with enzymes and then administering ultrasound were significantly higher

[67][165]. However, the selection of enzymes poses a challenge and depends on various parameters such as the plant matrix, target compounds, and desired extraction conditions