Aquaponics emerges as a beacon of hope, showcasing how humanity can adapt, innovate, and thrive while preserving the delicate balance of our natural resources. Within aquaponic systems, a symbiotic cycle unfolds: fish waste serves as vital nutrients for plants, while these same plants act as natural filters, purifying the water destined to circulate back to the fish tanks. This harmonious relationship between aquatic life and vegetation fosters a closed-loop ecosystem, significantly curbing water wastage and elevating the system’s overall sustainability. This method not only produces high-quality organic vegetables and fruits but also sustainable protein sources, addressing the challenges of both food security and water conservation.

- aquaponics

- automation

- food sustainability

- food sovereignty

1. Introduction

23. Aquaponics

2.1. Nomenclature in Aquaponics and Legislation

3.1. Nomenclature in Aquaponics and Legislation

Rakocy [15] explains that aquaponics involves the cultivation of aquatic organisms alongside plant growth without soil. However, to avoid confusion, the term “aquaponics” should specifically refer to hydroponic plant cultivation without any substrate. Lennard [16] proposes a revised definition where the waste generated by feeding aquatic organisms must supply at least 50% of the necessary nutrients for optimal plant growth. This specific approach, known as aquaponics sensu stricto (s.s.), solely utilizes hydroponic methods (aqua-farming techniques without soil or substrates like sand or rock or gravel). Fish production combined with algae production in photobioreactors or separate tanks is now a common feature of integrated systems for aquaculture. Aquaponics sensu lato (s.l.) is employed in both indoor and outdoor substrate aquaponics, incorporating horticultural strategies for growing herbs, cultivating or gardening plants, and conventional soil-based agricultural crop production. This approach leverages the buffer, nutrient storage, and mineralization processes of different substrates. Aquaponic systems can be broadly classified into four types: open pond, domestic, demonstration, and commercial, each serving different purposes and functions. In modern commercial aquaponics, the three main designs are: one-loop “coupled aquaponic systems (CAS)”, two-loop “decoupled aquaponic systems (DAS)” [17], and multiloop decoupled aquaponic systems (DAPSs) [18]. CASs are utilized at various scales, including domestic systems for personal use, social projects like school aquaponics [19], and commercial production exceeding 100 m2. Open-pond aquaponics encompasses system variations that combine a hydroponic component with free surface waters like lakes or ponds, either on-pond or on land. Domestic aquaponics encompasses all types of systems used for private purposes, ranging from small-scale systems for personal consumption to hobby/backyard systems for home production. Aquaponic demonstration systems are specifically constructed to showcase the food chain in aquaponic production, and are often used in classrooms or workshops. Commercial aquaponics serves diverse purposes such as urban gardening, roof aquaponics, living towers, vertical aquaponics, and small to semi-commercial systems (>50–100 m2). Larger-scale commercial operations (100–500 m2 and beyond) trend towards industrialized, highly mechanized production. Aquaponics, aligning with the UN Sustainable Development Goals, faces hurdles in organic certification due to EU Regulation’s strict guidelines [19]. Proposed changes, such as incorporating soil in hydroponic areas and enhancing fish welfare, require collaborative efforts from horticulture, aquaculture, and organics. Despite challenges, the industry garners significant interest, hinting at promising market opportunities. Notably, aquaponics lacks specific inclusion in Europe’s agricultural policies [20]. South Africa also lacks dedicated aquaponics policies [21], and in Egypt, aquaponics lacks legal recognition. Certainly, investigating organic certification for aquaponic production is crucial for its acceptance as a healthy and sustainable local food source, even though it may not be a mandatory requirement for the industry to flourish. To enhance organic aquaponics, revising legislation in line with statutory organic certification standards (as seen in the USA and the EU) is crucial. According to the UK’s DEFRA (Department of Food and Rural Affairs), organic farming avoids the use of human-made fertilizers, pesticides, growth regulators, and GMOs (Genetically Modified Organisms), promoting environmentally, socially, and economically sustainable production [22]. Current rules might lack scientific bases and favor existing hierarchies. Embracing innovations like controlled aquaponic greenhouses is environmentally friendly. Certification should adapt to these advances, emphasizing science-based, ethical, and nature-oriented production. To achieve these goals, outlined below are specific policies for organic aquaponics. Proposed policies prioritize environmental, social, and economic sustainability while excluding basic regulations on water quality, organic fish feed, antibiotics, or pesticides. Crops regulations: Plants can be grown in various hydroponic systems, with soil-based substrates allowed. Fertility in coupled aquaponic systems should come from aquaculture water, while fish waste enhances soil fertility in both coupled and decoupled systems. Aquaculture regulations: Fish and aquatic organisms must meet welfare standards, considering habitat, diurnal cycles, and environmental stimulation. Tanks should include species-specific enrichments like structures, shelters, or sandy substrates. Local species fitting water parameters should be chosen to reduce the need for artificial heating or cooling. Regular checks for distress signs are essential. Systems regulations: Organic aquaponic systems must primarily rely on fish water and waste for nutrients. Any additions, like seaweed extracts, must be organic and sustainable. Coupled systems should avoid substances harmful to fish health. The use of alternative energy systems and water harvesting is encouraged, especially in water-deficient areas.2.2. Aquaponic Systems Development

3.2. Aquaponic Systems Development

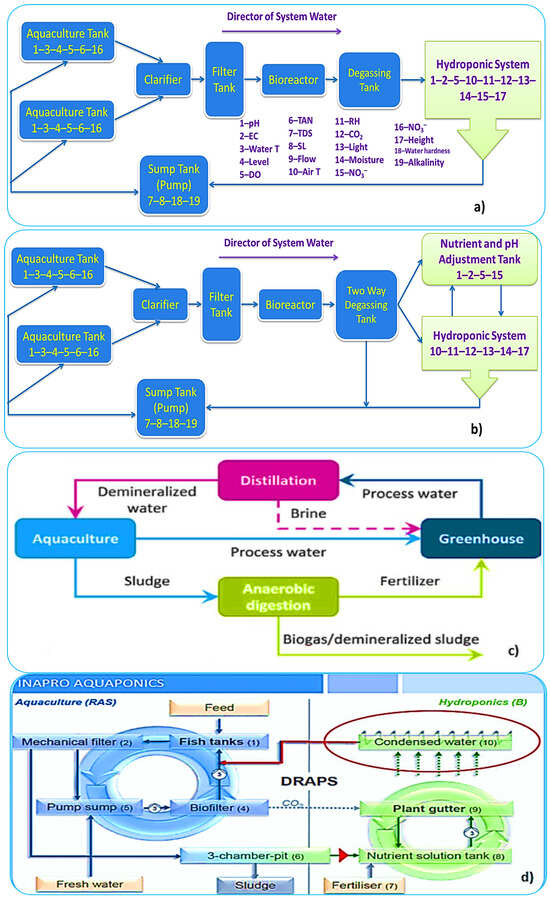

Coupled aquaponic systems (CASs) operate as single continuous loops, with water flowing in a single direction or towards an outlet in each tank [23], shown in Figure 25. In contrast, decoupled aquaponic systems (DASs) have two separate loops between which solutions can flow [24], shown in Figure 25. This allows for greater control over water parameters in the hydroponic portion without affecting the aquaculture portion, resulting in superior filtration and better manipulation of nutrient concentrations and pH level [25][26][25,26]. Nutrient supplementation can enhance plant quality and reduce the risk of nutrient deficiencies [27]. Double recirculation aquaponic systems (DRAPSs) optimize fish production while allowing for dynamic adjustments in nutrient concentrations and pH levels [28], shown in Figure 25.

2.3. Recirculating Aquaculture Systems (RASs)

3.3. Recirculating Aquaculture Systems (RASs)

2.4. Hydroponic Components

3.4. Hydroponic Components

Hydroponics is a soilless agricultural technique utilizing a nutrient-rich solution for crop cultivation. It can be implemented as a closed or open system [34][57]. Among hydroponic methods, the NFT (nutrient film technique) system yields lower lettuce and nitrate elimination compared to clutter DWC (deep water culture) [35][58]. Media beds provide an ample surface area for nitrifying bacteria growth and function as physical filters, eliminating the need for a separate biofilter [36][56]. However, Pattillo [37][60] noted that the maintenance cost of media bed culture is a significant drawback. Sediment accumulation disrupts water flow, resulting in uneven fertilization and the formation of anaerobic zones. Media bed culture is more suitable for smaller-scale aquaponic operations, while low-maintenance hydroponic components like DWC are better suited for larger-scale projects [23].34. Aquaponics Systems Performance

3.1. Fish Species, Feed, and Growth Indicators

4.1. Fish Species, Feed, and Growth Indicators

Aquatic organisms tolerant of high population densities and elevated levels of TN, TP, TSS, and potassium are crucial for productive aquaponic systems [38][34]. Species capable of thriving near densities of 0.06 kg/L are suitable, while fish above this threshold should not be stored [39][65]. Nile tilapia are widely used and considered excellent for aquaponics due to their adaptability, followed by carp and African catfish [40][41][66,67]. Nile tilapia can tolerate high TSS and nitrite levels up to 4.67 mg/L and survive at dissolved oxygen levels of 0.5–1.0 mg/L, allowing for higher stocking densities to meet plant nutrient requirements [42][68]. Fish feed constitutes 70% of aquaculture costs, but only 20–30% of the nitrogen (N) content is consumed by fish, while 70–80% is released into the water as waste or utilized in aquaponics [43][44][72,73]. Fish meal, despite being rich in amino acids and phosphorus, lacks essential micronutrients and potassium for plant growth [45][74]. Polyculture, involving different aquatic species, shows potential for enhancing plant growth in aquaponics but requires further research [33][46][47][46,75,76]. The impacts of excretion from different fish species on nutrient levels in aquaponic solutions and plant yields remain uncertain. Exploring alternative fish feeds that generate wastewater with higher levels of potassium (K) and magnesium (Mg) and maximizing nutrient conversion into plant biomass requires additional investigation.3.2. Plant Species, Nutrients, Growth, and Indexes

4.2. Plant Species, Nutrients, Growth, and Indexes

Leafy vegetables are ideal for aquaponics due to their fast growth, short growth period, low nutrient demands, and nitrogen tolerance [48][77]. Commonly grown crops include basil, herbs, tomatoes, lettuce, salad greens, chard, pepper, kale, and cucumbers, chosen based on fish density and nutrient levels [33][47][49][46,62,76]. Nutrient absorption varies throughout plant growth stages, with an optimal uptake of P, K+, S, Ca2+, and Mg2+ at pHs from 6.0–8.0. Other nutrients like Fe2+, Mn2+, B3+, Cu2+, and Zn2+ are best absorbed at a pH below 6.0 [50][78]. Leafy greens require higher nitrate levels than fruiting vegetables, and larger root areas enhance nitrate absorption. Flowering crops are more valuable but have greater nutrient needs and longer growth cycles, posing challenges in aquaponics [51][79]. Combining a trout farm with a NFT culture for lettuce and basil can yield a 12.5% ROI and lower water remediation costs [52][80]. Leafy greens and herbs are popular due to their year-round availability and restaurant demand [44][53][71,73]. Li et al. [46][75] considered plant number, height, fresh weight, and fish-to-plant ratios to estimate FCR and SGR. Researchers have analyzed plant yields, leaf nutrient content, and plant quality indexes to assess productivity [54][55][56][81,82,83], while others have incorporated microalgae bacteria to increase nitrogen use efficiency and reduce N2O emissions [57][84]. Leaf quality is assessed visually using a 1–4 scale for color, known as the PQI [50][51][57][78,79,84]. Leaf yellowing may result from nutrient deficiencies or inadequate fish feed. Aquaponics productivity is evaluated through plant, water, and fish performance, while increased yields are measured by assessing biomass growth in plants and fish [50][58][59][59,78,85].3.3. Nitrifying Bacteria and Microflora

4.3. Nitrifying Bacteria and Microflora

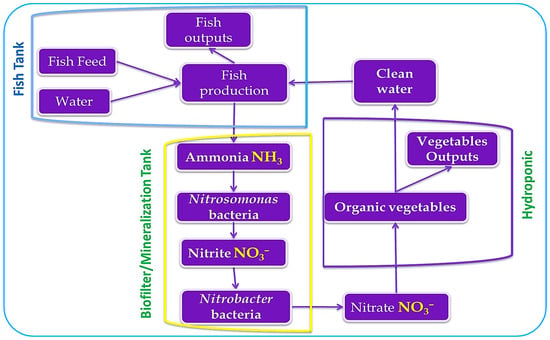

Aquaponics involves nitrification, converting TAN to nitrites and nitrates through two steps [60][86], shown in Figure 36. Ammonia-oxidizing bacteria (AOB) and nitrate-oxidizing bacteria (NOB) facilitate this process. TAN is produced by fish through their waste and gills [31][44]. AOB use TAN as an energy source, while plants prefer NH4+. Nitrosomonas bacteria transform ammonia to nitrite, while Nitrobacter bacteria convert nitrite to nitrate [50][78]. Nitrite, a byproduct of ammonia processed by AOB, poses a threat to aquatic life when it exceeds 0–1 mg/L. Maintaining nitrite levels within this range is crucial for the well-being of fish, plants, and bacteria. Nitrates, generated through NOB’s nitrification process, serve as a nitrogen source for plants and are fish-safe when kept below 90 mg/L. To ensure proper biofilter design, maintaining levels between 50 and 100 ppm is recommended.