Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Mona Zou and Version 1 by Junaid Nawaz Chauhdary.

The non-judicious use of water at the farm level in traditional irrigation application methods is a present-day concern across the world that can be resolved by enhancing application efficiency through the adoption of advanced irrigation techniques. Sprinkler irrigation is a method that has high application efficiency, which can be further increased when coupled with automation toward precision irrigation. The objectives of this review are to summarize the main aspects of sprinkler and precision irrigation and their development, scope, and future prospects specifically in Asian countries.

- application efficiency

- sprinkler types

- sprinkler nozzles

- irrigation automation

- variable rate irrigation

1. Sprinkler Irrigation

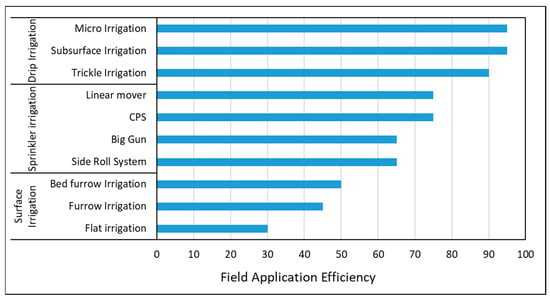

Sprinkler irrigation is a type of pressurized irrigation that irrigates crops by spraying water in the form of small droplets like natural rainfall. It has numerous advantages over surface irrigation or even over other pressurized irrigation technologies like drip irrigation as it can not only apply water to a crop but also flush its leaves and regulate canopy temperature to improve the efficiency of the photosynthesis process. Many research studies have been conducted on sprinkler irrigation that proved its viability and adoptability for economically higher crop production [34,35,36,37][1][2][3][4]. These systems have some limitations and disadvantages over other pressurized irrigation systems. These disadvantages include higher capital and operational costs, damage to soft fruit plants, low application efficiency in windy areas, and unsuitability for fields with fine textured soil [38][5]. Under humid conditions, moisture-related diseases may emerge within the crop canopy due to the presence of excessive moisture after the application of overhead sprinklers [39][6]. Romero et al. [40][7] reported the outbreak of fungal-related diseases within crop plants grown under humid and warm conditions. Belo et al. [41][8] reported management techniques including irrigation time and frequencies to reduce the risks of spreading bacterial-related diseases due to heavy moisture and dirt being splashed into the plant canopy of onion plants. But on the other hand, foliar water application by using an overhead sprinkler is beneficial for plants and good for protecting plants against frost when the temperature is at or below zero °C [42][9]. Despite these minimal limitations, sprinkler irrigation has marvelous advantages with high water application efficiency in the field [43][10]. The field application efficiency of different irrigation systems in comparison with different sprinkler types is illustrated in Figure 61.

Figure 61. Application efficiencies of different types of sprinkler systems.

1.1. Types of Sprinkler Systems

In the early usage of sprinkler systems, single-point sprinklers were used with moveable positions, and the water was supplied to sprinklers through iron pipes [7][11]. The iron pipes were susceptible to erosion and heavy when moving sprinklers from one place to another. Iron pipes were replaced with aluminum pipes in the first phase and then with plastic/PVC pipes along with plentiful progress in the design of irrigation systems in the late 1990s [44][12]. By increasing the understanding of sprinkler systems, moveable machines were developed with sprinkler nozzles that can be transported throughout the field to irrigate entire areas with the same sprinkler setup. This kind of sprinkler system has high application efficiencies and more irrigation coverage with less labor requirements. This form of sprinkler system has many types and is adopted as per field conditions due to specific limitations associated with each type. The features and distribution uniformities (DUs) of different sprinkler systems were obtained from the literature [43,45][10][13] and are shown in Table 1. Generally, Equation (1) is used to calculate the DU of a sprinkler irrigation system. The DU depends on the crop type, field condition, and environmental exposure of a sprinkler system. The maximum DU value belongs to lab experiments and the minimum value belongs to field conditions.

The center pivot system has many advantages over other types; therefore, this type of system has been installed in more than 13% of the area under sprinkler irrigation in China [46][14]. Researchers are working on a center pivot system to increase its efficiencies via a nozzle configuration corresponding to the particular movement speed [47,48][15][16]. Ma et al. studied the uniformity and the application efficacies of a two-span center pivot system and reported a 66.1–68.4% uniformity coefficient [49][17]. Several other researchers worked on other types of moveable sprinklers and conducted performance tests to determine their suitability and to improve the characteristics of existing systems [50,51,52,53][18][19][20][21]. Hand-mover gravity sprinklers are mostly used in hilly areas where sufficient gravitational head is available to operate sprinklers without irrigation pumps [54][22].

1.2. Sprinkler Nozzle

Sprinkler nozzles are key components in the whole sprinkler system and their uniform operation determines the efficiency of the system. The study of sprinkler nozzles was limited before the 1970s; however, the topics gradually received attention due to the increasing demand for sprinkler systems. In the late 1970s, work on designing impact sprinklers was started by an industrial group, and a series of sprinkler nozzles were designed with varying diameters (20 mm to 80 mm inner diameter). The Chinese government put a special effort into the development of new sprinkler nozzles by reverse engineering imported sophisticated nozzles and promoting research and development in the same area [50,55][18][23]. Currently, researchers and enterprises have been working on the development of new products and refining the hydraulic performance of existing sprinklers with structural improvements. Low-pressure sprinklers are an example of the improvement in the design of existing sprinklers.

1.3. Low-Pressure Sprinklers

The increase in energy demand and its high cost are forcing researchers to introduce new developments in the existing irrigation technologies so that these systems could still be used as a viable source in the new era. Normal sprinkler irrigation is operated at a high pressure of around (≥300 KPa), causing more energy consumption [56][24]. The low-pressure sprinkler is a new addition to the existing technology, enabling users to operate sprinklers at <200 KPa and subsequently lowering operating costs with different management strategies [56,57,58][24][25][26]. The key principle of designing a low-pressure sprinkler is to change the internal nozzle structure to reduce the operating pressure without compromising the dispersion uniformity of water droplets.

Li et al. designed a low-pressure rotary sprinkler with different dimensions of scatters and evaluated its performance; the authors reported satisfactory results regarding all selected performance parameters [47][15]. Other researchers improved the jet dispersion in low-pressure sprinklers by introducing a pair of aerated pipes inside the sprinkler nozzle [70][27]. The optimal groove numbers were identified during a series of experiments using D3000 range sprinklers after changing their plate structure [71][28]. Wang et al. [72][29] derived empirical equations for low-pressure sprinklers for operation under varying operating conditions and design parameters [73][30]. Ouazaa et al. derived a calculation model for cunnings of water distribution using low-pressure sprinklers [74][31]. Besides the changes in sprinkler design, researchers improved the field performance of sprinkler irrigation systems by optimizing the pipeline structure to reduce energy loss in order to promote the use of low-pressure sprinklers [75][32]. Tsaboula et al. studied the effects of different wind speeds on water spray through low-pressure sprinklers [76][33].

1.4. Sprinkler Irrigation Use for Crop Production

The use of sprinkler irrigation is not only for water saving but also to improve crop yield and reduce crop production costs by limiting crop inputs. Sprinkler irrigation has many advantages over other pressurized irrigation methods (drip irrigation) including rain characteristics and delivery of higher amounts of water during irrigation in time units. Sprinkler irrigation systems can be effective in large areas with less costly installation costs. The regular operation, maintenance, and operational troubleshooting of sprinkler irrigation systems are easier than drip irrigation. The benefits of sprinkler systems over other irrigation systems have been reported by many researchers [77,78,79,80,81,82][34][35][36][37][38][39]. Sprinkler irrigation can be applied to a variety of crops, soils, and field conditions compared with other systems. These are efficient for keeping crops well flourished and maximizing yield; therefore, about 6% of irrigated area in China has been covered with sprinkler irrigation [7][11].

To obtain better crop response under a sprinkler system, the fertilizer must be applied with water for the highest crop productivity. The overall fertilizer use efficiency has been reported at only 30% [89][40], which can be improved by its application using sprinkler irrigation systems. The injection of fertilizer via sprinkler irrigation is only possible with the use of injection devices. Different injection devices and application methods have been reported according to specific operating or field conditions [41,90,91,92][8][41][42][43].

Irrigation water and fertilizer could be further saved using variable rate technology (VRT), which means specific water application on a particular portion of the field [93][44]. The first VRT system was introduced in Asia in 2014 [94][45] followed by continuous research work on modifications of VRT systems. One researcher attuned the variable spray of the sprinkler nozzle by changing the operating pressure, flow rate, and internal structure [95][46], while another researcher invented the variable spray mechanism of CPS using infrared thermography [96][47]. A GPS-based operating system was developed by a group of scientists, which can apply fertilizer at variable rates by changing the duty cycle and pivoting the operating speed [54][22]. In present times, VRT machines are capable of applying water and fertilizers as per the soil conditions and plant needs [97][48].

2. Precision Irrigation Using Sprinklers

Sprinkler irrigation systems can apply water and fertilizer precisely but manually operated sprinkler systems involve labor for their operation; moreover, it is difficult to apply irrigation as per the real-time crop water requirement, whereas precision irrigation is the latest water-saving technique for maximizing yield and providing water at a desired location based on actual crop water demand [15,131,132,133,134,135,136,137][49][50][51][52][53][54][55][56]. The potential of water saving with precision irrigation through sprinkler systems has been reported as 30% compared with conventional sprinkler systems [138][57]. The concept of precision irrigation is based on the temporal and spatial variation in the application rate of irrigation systems based on real-time crop water requirements [25,26][58][59]. The entire field or application area is tackled as small parts or zones having the same water requirement at a particular time. Then, irrigation is applied in every zone in the desired quantity using a smart application mechanism attached to an irrigation system. Precision irrigation keeps every part of the field at optimum moisture level for proper plant growth in a uniform way [139][60], which improves its productivity, yield quality, and water use efficiency [140][61]. Researchers studied water application via sprinklers using the principles of precision irrigation and reported marvelous results regarding efficient water applications [2,132,141,142,143,144,145,146][51][62][63][64][65][66][67][68]. Precision irrigation involves (1) variable applications of irrigation water in space and time, regulated by the real-time monitoring of irrigation-related parameters in the field using sensors or other tools, (2) analyzing the data to develop irrigation schedules, and (3) feedback and operating mechanisms to control the irrigation machine using GPS to fulfill actual crop water requirements in every section of the field separately. To implement a precision irrigation system, advanced sensing, analyzing (simulating), and control technologies are adopted to achieve its best performance. This understanding of precision irrigation is also expressed as variable rate irrigation.

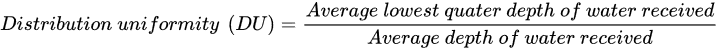

Typical precision irrigation has been drawn by getting inspiration from the literature [147][69] and is shown in Figure 72. A precision system includes a mechanism for field data collection, data transformation to the control center/device, data analysis, and calibrated operation of IoT-based automatic solenoid valves to operate the irrigation system. Under precision applications, irrigation is applied frequently for short durations just to maintain the field water balance of a cropping system at every part of the field. Prior to the application of precision irrigation, the actual water requirement is calculated, and the operating time or intensities are designed for the onward operation of sprinkler vehicles. These calculations are referred to as irrigation scheduling.

Figure 72. Overview of typical precision irrigation mechanism: (a) sensors for data collection from the field; (b) data transformation mechanism and transmitters; (c) data receiver and data analyzer for data calibration and to generate a command for the irrigation system; (d) remotely operated solenoid valves to operate the irrigation system as per commands generated by the data analyzer; and (e) the sprinkler irrigation system.

2.1. Field Parameters Used for Irrigation Scheduling for Precision Irrigation

The monitoring of field conditions is crucial for implementing precision irrigation for food production with minimum water usage. Monitoring of field conditions refers to the data collection regarding irrigation-related parameters that are capable of stating the real-time water balance of the crop system so that the desired water can be applied. Some basic parameters that are related to irrigation scheduling are categorized [17,148][70][71] into three classes or groups. Any of these parameters or the sum of some parameters could be adopted to determine irrigation scheduling under precision irrigation. The first group is associated with soil parameters including soil moisture, soil salinity, soil water absorption capacity, soil pH, etc. The second group is associated with plant parameters including leaf area index (LAI), normalized difference vegetation index (NDVI), stomatal conductance, evapotranspiration, leaf turgor pressure, crop water stress index, etc. Plant-related parameters for irrigation scheduling are relatively difficult to monitor but these parameters exhibit the most realistic picture of plant water balance and present the plant growth expected to be affected by droughts and nutrient deficiencies [149][72]. The third group contained climatic parameters including ambient temperature, humidity, wind speed, solar radiation, precipitation, atmospheric pressure, etc. These climatic parameters are put in the world-renowned “Penman–Monteith evapotranspiration model” for calculating actual evapotranspiration using crop coefficients for the development of irrigation schedules [150][73].

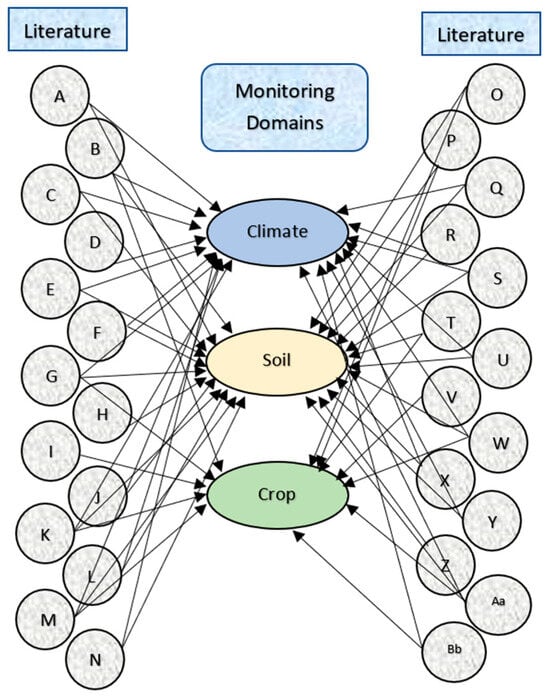

A summary of the literature review regarding the use of different parameters for precision irrigation has been taken from the literature [32][74] and illustrated in Figure 83 after modifications and improvements. The parameters are shown as per previously defined groups (crop parameters, soil parameters, and climatic parameters).

Figure 83. Illustration of the literature showing the domains of monitoring parameters for precision irrigation. A: [151][75]; B: [152][76]; C: [153][77]; D: [154][78]; E: [155][79]; F: [156][80]; G: [150][73]; H: [157][81]; I: [149][72]; J: [158][82]; K: [159][83]; L: [160][84]; M: [161][85]; N: [162][86]; O: [163][87]; P: [164][88]; Q: [165][89]; R: [166][90]; S: [167][91]; T: [168][92]; U: [169][93]; V: [170][94]; W: [143][65]; X: [171][95]; Y: [172][96]; Z: [173][97]; Aa: [174][98]; and Bb: [141][63].

2.2. Data Collection Regarding Irrigation Scheduling for Precision Irrigation

Precision irrigation requires the accurate measurement of field data related to the above-described parameters to implement its full scope in order to obtain maximum advantages. There are several ways to collect field data including the following:

-

Manual monitoring using smart tools;

-

Use of sensors (sensors for soil, plant, and climate parameters);

-

Use of satellite data;

-

Use of UAV for data collection.

2.2.1. Manual Monitoring Using Smart Tools

The accuracy of monitoring field parameters is crucial to implementing precision irrigation in a true sense. The continuous and uninterrupted monitoring of irrigation-related parameters at different points at desired intervals can be conducted manually using smart sensing tools or devices. The biases in data collection by humans have been reported but the data regarding some specific plant or soil-related parameters could still be collected manually by following standard protocols [175][99]. This method of data collection is convenient and easy to follow but it is very low in efficiency.

2.2.2. Use of Sensors

Plant growth is highly dependent on the moisture level in the rhizosphere and frequent monitoring of moisture levels needs to be carried out for accurate irrigation scheduling. Accurate data collection regarding soil moisture on high temporal grounds is the only option for irrigation scheduling in a precise way [169,172,176][93][96][100]. Different kinds of sensors are available in the market and are being used for such purposes. One type is capacitance-based sensors, which are relatively low cost and can measure the moisture level with adequate reliability after efficacious calibration of the sensor with measured field data [177][101]. A more sophisticated device to monitor soil moisture is TDR (time domain reflectometry), which contains two electrodes. These electrodes are inserted in the soil column up to the desired depth and, afterward, an electric signal is generated from one electrode to another to assess the soil moisture by estimating travel time and soil conductance characteristics. The accuracy of TDR is high, but it is expensive to install in large numbers in open fields for monitoring soil moisture at different field spots. Bitella introduced the methodology to measure soil moisture at different depths at the same time using low-cost dielectric probes [131][50] while other researchers used IoT-based field monitoring devices for moisture measurements [162][86]. Huuskonen and Oksanen used drone cameras for remote measurement of soil moisture in upper soil layers [160][84]. Besides soil parameters, the use of climate parameters for irrigation scheduling has the highest ranking due to their extensive use among all contenders [143,149,162,166,178,179,180][65][72][86][90][102][103][104]. Permanent weather stations or weather monitoring devices can be installed in the field to collect real-time climate data. The sensors to monitor plant or soil-related parameters can be installed on the moveable platform of an irrigation system like CPS for real-time monitoring during the irrigation cycle [181][105]. In addition to the moisture, soil and plant nutrients could also be monitored using soil nutrient detectors connected parallel to moisture sensors [182][106]. Joly developed a silicon chip for site-specific monitoring of soil nutrients [183][107].

2.2.3. Application of Remote Sensing for Data Collection

Satellite remote sensing is an excellent and reliable option to collect data on soil and plant-related parameters for irrigation under various environmental conditions throughout the world. The satellites can read ground data using different spectral bands and are capable of differentiating water-stressed crop areas and analyzing crop water needs at high spatial and temporal frequencies [184][108]. Many commercial satellites like MODIS, Landsat, SPOT, etc., offer crop and soil moisture status at high temporal frequency [185][109]. Several researchers used open-source satellite data related to crop evapotranspiration, soil moisture, plant water stress, NDVI, etc., for the implementation of precision irrigation using sprinkler irrigation systems [186,187][110][111]. Reyes [188][112] used a satellite-based vegetation index to estimate actual crop water requirements for the design of irrigation scheduling for precise water applications in the field. Ramirez [189][113] used a GIS-based toolbox to explore satellite data for the assessment of soil moisture to determine crop water requirements. The 10–20% more water saving achieved by using integrated precision cum pressurized irrigation systems has been reported by many researchers who used satellite data for irrigation scheduling of various crops grown under varying field conditions [190,191][114][115].

2.2.4. Use of UAV for Data Collection

UAVs (unmanned aerial vehicles) or “drones” are aircraft with no human pilots. The size of a UAV varies from small to large, depending upon the function that it can perform. UAVs are quick, affordable, and reliable alternatives to satellite data if the application area is small (local scale). Depending on the sensors carried by a UAV, various crop- and soil-based parameters for irrigation scheduling could be collected and monitored in real time at high spatial frequency. Various researchers used UAVs for the determination of crop water requirements [192][116], soil moisture [193][117], and plant water stress [194][118] for the implementation of precision irrigation, and satisfactory results were reported.

2.3. Techniques for Data Analysis and Management of Sprinkler Systems for Precision Irrigation

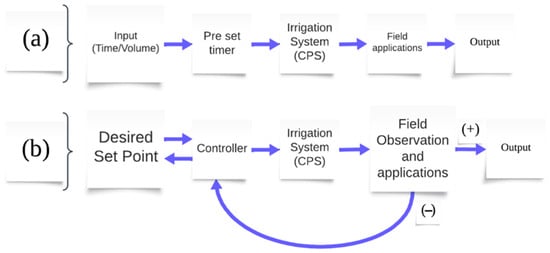

The collected data were analyzed using several sophisticated techniques including modeling tools and multidimensional simulating software (DSSAT(v4.6), MATLAB(R2011b), APSIM (7.1), R(2.4.1.2) etc.) to predict spatially and temporally varied crop water requirements for developing irrigation maps for onward applications of precision irrigation. Mechanized techniques are essential in precision irrigation to manage sprinkler systems for efficient water applications using developed irrigation maps with less energy input and higher crop yield. The mechanized techniques belong to two big categories called open loop technique (OLT) and closed loop technique (CLT). In OLT, irrigation is controlled by a pre-set program designed for a particular field using input data regarding irrigation parameters [195][119]. The OLT is easier to follow and cheaper in cost; therefore, farmers prefer to adopt these techniques for implementing precision irrigation [196][120]. Farmers can set operating conditions (pre-timers, speed, and application rate) for any sprinkler system, which can be monitored during the entire operation of the irrigation machine. Many researchers reported the use of OLT by farmers for precision irrigation in their fields [197,198,199][121][122][123].

The CLT is relatively difficult to implement but is more accurately related to the true spirit of precision irrigation using sprinkler irrigation systems with 20–30% more efficiency [200,201,202][124][125][126]. Progressive farmers use such techniques at their farms. Many studies have been conducted on the applications, adoptability, and benefits of CLT techniques, and significantly positive responses to these techniques for crop production were reported [203,204][127][128]. The controlling mechanism of CLT includes a feedback input mechanism that continuously feeds the field conditions—retrieved from the sensors—to the input controller; then, the operation of irrigation machines is conducted in accordance with this information. The information may relate to climate, soil, or crop parameters [205,206][129][130]. Initially, a bigger irrigation program of variable nature is formulated that is implemented accordingly after retrieving information from the sensors at small time intervals [207,208][131][132]. However, continuous dynamics in field conditions make the control of irrigation extremely cumbersome under CLT. Also, due to the installation of sensors on irrigation machines and in soil profiles, the capital cost exceeds even unaffordable limits. Also, the use of sensors could mislead operators if they are not calibrated properly, which results in immense implementation struggles for farmers. The simplest illustration of precision irrigation using a center pivot sprinkler system under both controlling mechanisms (OLT and CLT) is shown in Figure 94.

Figure 94. Block diagram of (a) open loop technique (OLT) and (b) closed loop technique (CLT) under precision irrigation.

2.4. Use of Controlling Devices for Precision Applications of Sprinkler Irrigation

To perform water application using a sprinkler system according to real-time irrigation scheduling, mechanized systems are used to continuously control the operation of the irrigation system to adopt the true spirit of precision irrigation. The operation of the irrigation system is controlled to maintain the desired irrigation level by controlling the application rate or irrigation time [175][99]. To achieve this, electronic devices called “controllers” have been developed and are available in markets. The selection of controllers is made keeping in view their function, reliability, availability, price, etc. One type of controller is the PID (proportional-integrated derivative) controller. These controllers are widely used due to their simple structure, ease of troubleshooting, and minimum errors but these cannot handle external disturbance and can thus create errors [209][133]. The second type of controller is an AI (intelligent control for precision irrigation) controller. These controllers use the application of artificial intelligence, which makes these devices capable of providing solutions in a smarter way [210][134]. These devices with briskly developed algorithms can emulate the process of human decision making; therefore, these devices have been implemented specifically in sprinkler irrigation machines for precise water applications [211,212][135][136] in different forms like fuzzy logic, etc. [213][137]. On the other hand, these kinds of controllers have complex structures, are higher in price, and are difficult to troubleshoot. The third type of controller is the MPC (model predictive-based irrigation) controller, which is widely used in agriculture and other industries [214,215,216,217,218][138][139][140][141][142]. By installing MPC controllers instead of classical controllers on sprinkler irrigation machines, many benefits including good efficiency, excellent performance, and optimality can be achieved toward the true spirit of precision [219][143]. Future research on the development of smart MPC controllers can improve the efficiency of precision irrigation using sprinkler systems in a convenient way with 20–30% more efficiency.

References

- Xue, J.; Ren, L. Evaluation of Crop Water Productivity under Sprinkler Irrigation Regime Using a Distributed Agro-Hydrological Model in an Irrigation District of China. Agric. Water Manag. 2016, 178, 350–365.

- Liu, H.; Yu, L.; Luo, Y.; Wang, X.; Huang, G. Responses of Winter Wheat (Triticum aestivum L.) Evapotranspiration and Yield to Sprinkler Irrigation Regimes. Agric. Water Manag. 2011, 98, 483–492.

- Sezen, S.M.; Yazar, A.; Kapur, B.; Tekin, S. Comparison of Drip and Sprinkler Irrigation Strategies on Sunflower Seed and Oil Yield and Quality under Mediterranean Climatic Conditions. Agric. Water Manag. 2011, 98, 1153–1161.

- Kiani, A.R. Comparison of Rice Direct Seeding and Transplanting Methods under Different Irrigation Methods. Water Soil 2022, 35, 779–790.

- Ravikumar, V. Sprinkler Irrigation Types and Components. In Sprinkler and Drip Irrigation: Theory and Practice; Ravikumar, V., Ed.; Springer: Singapore, 2023; pp. 3–23. ISBN 978-981-19-2775-1.

- Lomas, J. Sprinkler Irrigation and Plant Disease under Semi-arid Climatic Conditions. EPPO Bull. 2008, 21, 365–370.

- Romero, F.; Cazzato, S.; Walder, F.; Vogelgsang, S.; Bender, S.; Van der Heijden, M. Humidity and High Temperature Are Important for Predicting Fungal Disease Outbreaks Worldwide. New Phytol. 2021, 234, 1553–1556.

- Belo, T.R.; du Toit, L.J.; Waters, T.D.; Derie, M.L.; Schacht, B.; LaHue, G.T. Reducing the Risk of Onion Bacterial Diseases through Managing Irrigation Frequency and Final Irrigation Timing. Agric. Water Manag. 2023, 288, 108476.

- Pan, Q.; Lu, Y.; Hu, H.; Hu, Y. Review and Research Prospects on Sprinkler Irrigation Frost Protection for Horticultural Crops. Sci. Hortic. 2024, 326, 112775.

- Howell, T. Irrigation Efficiency. Encyclopedia of Water Science; CRC: Boca Raton, FL, USA, 2003.

- Yan, H.; Hui, X.; Li, M.; Xu, Y. Development in Sprinkler Irrigation Technology in China. Irrig. Drain. 2020, 69, 75–87.

- Liu, J.; Zang, C.; Tian, S.; Liu, J.; Yang, H.; Jia, S.; You, L.; Liu, B.; Zhang, M. Water Conservancy Projects in China: Achievements, Challenges and Way Forward. Glob. Environ. Chang. 2013, 23, 633–643.

- Patel, N.H.; Prajapati, C.R. Agricultural Sprinkler for Irrigation System. Int. J. Eng. Res. Tech. Res. 2020, 9, 162–166.

- Yan, H.; Ma, J.; Wang, Z. Design and Field Experiment on Fertilizer Injection Device in Center Pivot Irrigation System. Trans. Chin. Soc. Agric. Mach. 2015, 46, 100–106.

- Li, Y.; Bai, G.; Yan, H. Development and Validation of a Modified Model to Simulate the Sprinkler Water Distribution. Comput. Electron. Agric. 2015, 111, 38–47.

- Yan, H.; Yao, P.; Zhu, Y.; Yu, P. Nozzle Configuration and Software for Center Pivot Irrigation System. Trans. Chin. Soc. Agric. Mach. 2011, 42, 84–88.

- Ma, J.; Yan, H.; Wang, C. Effect of End Gun on/off on Variable Rate Fertigation Uniformity and Its Improvement for Center Pivot Irrigation System. J. Hydraul. Eng. 2016, 47, 1577–1584.

- Li, Y.; Chen, W.; Yan, H.; Zhang, Z. Optimization of Structure Parameters for Impulse Water Turbine of Hose Reel Irrigator. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 138–144.

- Cheng, J.; Tang, Y.; Tang, L. Energy Consumption Analysis of Hydraulic Turbine of JP75 Hose Reel Irrigator. J. Drain. Irrig. Mach. Eng. 2016, 34, 1008–1012.

- Maosheng, G.; Wu, P.; Zhu, D.; Zhang, L.; Xiao, X.; Xu, H. Construction and Application of Mobile Spraying Uniformity Model of Hard Hose Traveler. Trans. Chin. Soc. Agric. Eng. 2016, 32, 130–137.

- Li, Y.; Zhang, Z.; Yan, H.; Gu, T. Hydraulic Performance Analysis and Optimization for Water Turbine of JP75 Hose Reel Irrigation Machine. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 100–107.

- Zhang, L.; Hui, X.; Chen, J. Effect of Terrain Slope on Water Distribution and Application Uniformity for Sprinkler Irrigation. Int. J. Agric. Biol. Eng. 2018, 11, 120–125.

- Yuan, S.; Zhu, X.; Li, H.; Ren, Z. Effects of Complete Fluidic Sprinkler on Hydraulic Characteristics Based on Some Important Geometrical Parameters. Trans. Chin. Soc. Agric. Eng. 2006, 22, 113–116.

- Jiang, Y.; Li, H.; Hua, L.; Zhang, D. Three-Dimensional Flow Breakup Characteristics of a Circular Jet with Different Nozzle Geometries. Biosyst. Eng. 2020, 193, 216–231.

- Jiménez-Bello, M.A.; Royuela, A.; Manzano, J.; Prats, A.G.; Martínez-Alzamora, F. Methodology to Improve Water and Energy Use by Proper Irrigation Scheduling in Pressurised Networks. Agric. Water Manag. 2015, 149, 91–101.

- Tarjuelo, J.M.; Rodriguez-Diaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient Water and Energy Use in Irrigation Modernization: Lessons from Spanish Case Studies. Agric. Water Manag. 2015, 162, 67–77.

- Xiang, Q.; Xu, Z.; Chen, C.; Li, H. Experiment on Aeration Water Jet Applied to Low Pressure Impact Sprinkler Irrigation. Trans. Chin. Soc. Agric. Eng. 2016, 32, 54–58.

- Zhang, Y.; Zhang, L.; Zhu, D.; Hui, X. Simulation of Water Distribution and Calculation on Water Application Uniformity for Sprinkler Irrigation on Sloping Land Based on Ballistic Theory. Trans. Chin. Soc. Agric. Eng. 2016, 32, 59–66.

- Wang, X.; Liu, J.; Zhang, Q. Water–Pesticide Integrated Micro-Sprinkler Design and Influence of Key Structural Parameters on Performance. Agriculture 2022, 12, 1532.

- Negeed, E.-S.R.; Hidaka, S.; Kohno, M.; Takata, Y. Experimental and Analytical Investigation of Liquid Sheet Breakup Characteristics. Int. J. Heat Fluid Flow 2011, 32, 95–106.

- Ouazaa, S.; Burguete, J.; Paniagua, M.P.; Salvador, R.; Zapata, N. Simulating Water Distribution Patterns for Fixed Spray Plate Sprinkler Using the Ballistic Theory. Span. J. Agric. Res. 2014, 12, 850.

- Tu, Q.; Li, H.; Wang, X.; Cai, B.; Zhuang, J.; Wang, L. Optimization of Small-Scale Sprinkler Irrigation Systems for Different Indicators. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2013, 29, 83–89.

- Tsaboula, A.; Papadakis, E.-N.; Vryzas, Z.; Kotopoulou, A.; Kintzikoglou, K.; Papadopoulou-Mourkidou, E. Environmental and Human Risk Hierarchy of Pesticides: A Prioritization Method, Based on Monitoring, Hazard Assessment and Environmental Fate. Environ. Int. 2016, 91, 78–93.

- Hedley, C.B.; Bradbury, S.; Watson, E.; Dalrymple, H.; Wright, J. Farm-Scale Trials of Variable Rate Irrigation to Assess the Benefits of Modifying Existing Sprinkler Systems for Precision Application. Int. J. Agric. Manag. 2011, 1, 51–55.

- Brennan, D. Factors Affecting the Economic Benefits of Sprinkler Uniformity and Their Implications for Irrigation Water Use. Irrig. Sci. 2008, 26, 109–119.

- Fan, Y.; Wang, Q.; Zhou, Q.; Duan, F.; Wang, Z.; Chen, Z. Main Problems in Technological Development of Sprinkler Irrigation in China and Corresponding Countermeasures. J. Drain. Irrig. Mach. Eng. 2015, 33, 450–455.

- Wijetunga, S.; Imthiyas, A.W.M.; Karunaratne, W.K.P.; Sirisena, A.H.H.T. Comparison of Water Use by Mango Nursery Plants under Sprinkler and Manual Irrigation—A Case Study at Seed and Planting Material Production Farm in Polonnaruwa. In Proceedings of the International Symposium on Agriculture and Environment 2020, Surakarta, Indonesia, 25–27 August 2020.

- Kumar, R.; Naresh, R.K.; Bhatt, R.; Chandra, M.S.; Kumar, D.; Alamri, S.; Siddiqui, M.H.; Alfagham, A.T.; Kalaji, H.M. Tillage Crop Establishment and Irrigation Methods Improve the Productivity of Wheat (Triticum Aestivum): Water Use Studies, and the Biological Properties and Fertility Status of Soil. Agronomy 2023, 13, 1839.

- Wenzel, J.L.; Conrad, C.; Piernicke, T.; Spengler, D.; Pöhlitz, J. Assessing the Impact of Different Irrigation Levels on Starch Potato Production. Agronomy 2022, 12, 2685.

- Tang, H.; Wang, J.; Xu, C.; Zhou, W.; Wang, J.; Wang, X. Research Progress Analysis on Key Technology of Chemical Fertilizer Reduction and Efficiency Increase. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–19.

- Zhang, M.; Zhao, W.; Li, J.; Li, Y. Fertigation Uniformity and Evaporation Drift Losses of Center Pivot Irrigation System. Paiguan Jixie Gongcheng Xuebao/J. Drain. Irrig. Mach. Eng. 2018, 36, 1125–1130.

- Cai, D.; Zhou, L.; Gu, T.; Yan, H. Yield and Nitrogen Utilization of Winter Wheat under Different Nitrogen Application Frequencies with Sprinkler Irrigation System. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 278–286.

- Li, J. Increasing Crop Productivity in an Eco-Friendly Manner by Improving Sprinkler and Micro-Irrigation Design and Management: A Review of 20 Years’ research at the IWHR, China. Irrig. Drain. 2017, 67, 97–112.

- Evans, R.; King, B. Site-Specific Sprinkler Irrigation in a Water Limited Future. In Proceedings of the 5th National Decennial Irrigation Conference Proceedings, Phoenix, AZ, USA, 5–8 December 2010; Volume 55.

- Zhao, W.; Li, J.; Yang, R.; Li, Y. Field Evaluation of Water Distribution Characteristics of Variable Rate Center Pivot Irrigation System. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2014, 30, 53–62.

- Hu, Z.F. Research and Experiment of Self-Propelled Variable Irrigation System Based on Infrared Thermography; China Agricultural University: Beijing, China, 2014.

- Han, W.; Yao, X.; Zhu, B.; Zhang, C.; Zhou, X.; Wu, P. Test and Evaluation on Variable-Rate Irrigation Sprinkler. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2013, 44, 112+121–126.

- Li, J. Crop Yield and Water Productivity Responses in Management Zones for Variable-Rate Irrigation Based on Available Soil Water Holding Capacity. Trans. ASABE (Am. Soc. Agric. Biol. Eng.) 2017, 60, 1659–1667.

- Semananda, N.P.K.; Ward, J.D.; Myers, B.R. A Semi-Systematic Review of Capillary Irrigation: The Benefits, Limitations, and Opportunities. Horticulturae 2018, 4, 23.

- Bitella, G.; Rossi, R.; Bochicchio, R.; Perniola, M.; Amato, M. A Novel Low-Cost Open-Hardware Platform for Monitoring Soil Water Content and Multiple Soil-Air-Vegetation Parameters. Sensors 2014, 14, 19639–19659.

- Capraro, F.; Tosetti, S.; Rossomando, F.; Mut, V.; Vita Serman, F. Web-Based System for the Remote Monitoring and Management of Precision Irrigation: A Case Study in an Arid Region of Argentina. Sensors 2018, 18, 3847.

- Elijah, O.; Abd Rahman, T.; Orikumhi, I.; Leow, C.Y.; Hindia, M. An Overview of Internet of Things (IoT) and Data Analytics in Agriculture: Benefits and Challenges. IEEE Internet Things J. 2018, 5, 3758–3773.

- Kamilaris, A.; Kartakoullis, A.; Prenafeta-Boldú, F.X. A Review on the Practice of Big Data Analysis in Agriculture. Comput. Electron. Agric. 2017, 143, 23–37.

- Talavera, J.M.; Tobón, L.E.; Gómez, J.A.; Culman, M.A.; Aranda, J.M.; Parra, D.T.; Quiroz, L.A.; Hoyos, A.; Garreta, L.E. Review of IoT Applications in Agro-Industrial and Environmental Fields. Comput. Electron. Agric. 2017, 142, 283–297.

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.-J. Big Data in Smart Farming—A Review. Agric Syst 2017, 153, 69–80.

- Elshaikh, A.E.; Jiao, X.; Yang, S. Performance Evaluation of Irrigation Projects: Theories, Methods, and Techniques. Agric. Water Manag. 2018, 203, 87–96.

- Hedley, C.B.; Yule, I.J. A Method for Spatial Prediction of Daily Soil Water Status for Precise Irrigation Scheduling. Agric. Water Manag. 2009, 96, 1737–1745.

- Cambra, C.; Sendra, S.; Lloret, J.; Lacuesta, R. Smart System for Bicarbonate Control in Irrigation for Hydroponic Precision Farming. Sensors 2018, 18, 1333.

- El Chami, D.; Knox, J.W.; Daccache, A.; Weatherhead, E.K. Assessing the Financial and Environmental Impacts of Precision Irrigation in a Humid Climate. Hortic. Sci. 2019, 46, 43–52.

- Daccache, A.; Knox, J.W.; Weatherhead, E.K.; Daneshkhah, A.; Hess, T.M. Implementing Precision Irrigation in a Humid Climate—Recent Experiences and on-Going Challenges. Agric. Water Manag. 2015, 147, 135–143.

- Smith, R.J.; Baillie, J.; McCarthy, A.C.; Raine, S.R.; Baillie, C.P. Review of Precision Irrigation Technologies and Their Application; University of Southern Queensland: Toowoomba, Australia, 2010.

- CSP. China Rural Statistical Yearbook; China Statistics Press: Beijing, China, 2019.

- Castañeda-Miranda, A.; Castaño-Meneses, V.M. Internet of Things for Smart Farming and Frost Intelligent Control in Greenhouses. Comput. Electron. Agric. 2020, 176, 105614.

- Chen, Y.-A.; Hsieh, W.-H.; Ko, Y.-S.; Huang, N.-F. An Ensemble Learning Model for Agricultural Irrigation Prediction. In Proceedings of the 2021 International Conference on Information Networking (ICOIN), Jeju, Republic of Korea, 13–16 January 2021; pp. 311–316.

- Keswani, B.; Mohapatra, A.G.; Mohanty, A.; Khanna, A.; Rodrigues, J.J.P.C.; Gupta, D.; de Albuquerque, V.H.C. Adapting Weather Conditions Based IoT Enabled Smart Irrigation Technique in Precision Agriculture Mechanisms. Neural Comput. Appl. 2019, 31, 277–292.

- Torres, A.B.B.; da Rocha, A.R.; Coelho da Silva, T.L.; de Souza, J.N.; Gondim, R.S. Multilevel Data Fusion for the Internet of Things in Smart Agriculture. Comput. Electron. Agric. 2020, 171, 105309.

- Kashyap, P.K.; Kumar, S.; Jaiswal, A.; Prasad, M.; Gandomi, A.H. Towards Precision Agriculture: IoT-Enabled Intelligent Irrigation Systems Using Deep Learning Neural Network. IEEE Sens. J. 2021, 21, 17479–17491.

- Chang, C.-L.; Lin, K.-M. Smart Agricultural Machine with a Computer Vision-Based Weeding and Variable-Rate Irrigation Scheme. Robotics 2018, 7, 38.

- Ćulibrk, D.; Vukobratovic, D.; Minic, V.; Alonso Fernandez, M.; Alvarez Osuna, J.; Crnojevic, V. Sensing Technologies for Precision Irrigation; Springer: New York, NY, USA, 2014; ISBN 978-1-4614-8328-1.

- Lakhiar, I.A.; Jianmin, G.; Syed, T.N.; Chandio, F.A.; Buttar, N.A.; Qureshi, W.A. Monitoring and Control Systems in Agriculture Using Intelligent Sensor Techniques: A Review of the Aeroponic System. J. Sens. 2018, 2018, 8672769.

- Fernández, J. Plant-Based Methods for Irrigation Scheduling of Woody Crops. Horticulturae 2017, 3, 35.

- Bauer, J.; Aschenbruck, N. Design and Implementation of an Agricultural Monitoring System for Smart Farming. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture, Tuscany, Italy, 8–9 May 2018; pp. 1–6.

- Abd Rahman, M.K.I.; Zainal Abidin, M.S.; Mahmud, M.S.A.; Buyamin, S.; Ishak, M.H.I.; Emmanuel, A.A. Advancement of a Smart Fibrous Capillary Irrigation Management System with an Internet of Things Integration. Bull. Electr. Eng. Inform. 2019, 8, 1402–1410.

- Abioye, E.A.; Abidin, M.S.Z.; Mahmud, M.S.A.; Buyamin, S.; Ishak, M.H.I.; Rahman, M.K.I.A.; Otuoze, A.O.; Onotu, P.; Ramli, M.S.A. A Review on Monitoring and Advanced Control Strategies for Precision Irrigation. Comput. Electron. Agric. 2020, 173, 105441.

- Saha, H.N.; Chakraborty, S.; Roy, R. Integration of RFID and Sensors in Agriculture Using IOT. In AI, Edge and IoT-Based Smart Agriculture; Elsevier: Amsterdam, The Netherlands, 2022; pp. 361–372.

- Shahzadi, R.; Ferzund, J.; Tausif, M.; Asif, M. Internet of Things Based Expert System for Smart Agriculture. Int. J. Adv. Comput. Sci. Appl. 2016, 7, 341–350.

- Villarrubia, G.; Paz, J.F.D.; Iglesia, D.H.D.L.; Bajo, J. Combining Multi-Agent Systems and Wireless Sensor Networks for Monitoring Crop Irrigation. Sensors 2017, 17, 1775.

- Goap, A.; Sharma, D.; Shukla, A.K.; Rama Krishna, C. An IoT Based Smart Irrigation Management System Using Machine Learning and Open Source Technologies. Comput. Electron. Agric. 2018, 155, 41–49.

- Newlin Rajkumar, M.; Abinaya, S.; Kumar, V. Intelligent Irrigation System—An IOT Based Approach. In Proceedings of the International Conference on Innovations in Green Energy and Healthcare Technologies (IGEHT), Coimbatore, India, 16–18 March 2017.

- Liao, R.; Zhang, S.; Zhang, X.; Wang, M.; Wu, H.; Zhangzhong, L. Development of Smart Irrigation Systems Based on Real-Time Soil Moisture Data in a Greenhouse: Proof of Concept. Agric. Water Manag. 2021, 245, 106632.

- Jia, X.; Huang, Y.; Wang, Y.; Sun, D. Research on Water and Fertilizer Irrigation System of Tea Plantation. Int. J. Distrib. Sens. Netw. 2019, 15, 155014771984018.

- Huuskonen, J.; Oksanen, T. Soil Sampling with Drones and Augmented Reality in Precision Agriculture. Comput. Electron. Agric. 2018, 154, 25–35.

- Abioye, E.A.; Abidin, M.S.Z.; Aman, M.N.; Mahmud, M.S.A.; Buyamin, S. A Model Predictive Controller for Precision Irrigation Using Discrete Lagurre Networks. Comput. Electron Agric. 2021, 181, 105953.

- Nalliah, V.; Ranjan, R. Evaluation of a Capillary-Irrigation System for Better Yield and Quality of Hot Pepper (Capsicum annuum). Appl. Eng. Agric. 2010, 26, 807–816.

- Harun, A.N.; Mohamed, N.; Ahmad, R.; Abdul Rahim, A.; Ani, N. Improved Internet of Things (IoT) Monitoring System for Growth Optimization of Brassica chinensis. Comput. Electron. Agric. 2019, 164, 104836.

- Mohanraj, I.; Ashokumar, K.; Naren, J. Field Monitoring and Automation Using IOT in Agriculture Domain. Procedia Comput. Sci. 2016, 93, 931–939.

- Aleotti, J.; Amoretti, M.; Nicoli, A.; Caselli, S. A Smart Precision-Agriculture Platform for Linear Irrigation Systems. In Proceedings of the 26th International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split, Croatia, 13–15 September 2018.

- Uddin, M.A.; Mansour, A.; Le Jeune, D.; Aggoune, E.H.M. Agriculture Internet of Things: AG-IoT. In Proceedings of the 2017 27th International Telecommunication Networks and Applications Conference (ITNAC), Melbourne, Australia, 22–24 November 2017; pp. 1–6.

- Harun, A.N.; Kassim, M.; Mat, I.; Ramli, S. Precision Irrigation Using Wireless Sensor Network. In Proceedings of the International Conference on Smart Sensors and Application (ICSSA), Kuala Lumpur, Malaysia, 26–28 July 2015.

- Viani, F.; Bertolli, M.; Salucci, M.; Polo, A. Low-Cost Wireless Monitoring and Decision Support for Water Saving in Agriculture. IEEE Sens. J. 2017, 17, 4299–4309.

- Agale, R.R.; Gaikwad, D.P. Automated Irrigation and Crop Security System in Agriculture Using Internet of Things. In Proceedings of the 2017 International Conference on Computing, Communication, Control and Automation (ICCUBEA), Pune, India, 17–18 August 2017; pp. 1–5.

- Wheeler, W.D.; Chappell, M.; van Iersel, M.; Thomas, P. Implementation of Soil Moisture Sensor Based Automated Irrigation in Woody Ornamental Production. J. Environ. Hortic. 2020, 38, 1–7.

- Kothawade, S.N.; Furkhan, S.M.; Raoof, A.; Mhaske, K.S. Efficient Water Management for Greenland Using Soil Moisture Sensor. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), New Delhi, India, 4–6 July 2016; pp. 1–4.

- Lozoya, C.; Mendoza, C.; Aguilar, A.; Román, A.; Castelló, R. Sensor-Based Model Driven Control Strategy for Precision Irrigation. J. Sens. 2016, 2016, 9784071.

- Lozoya, C.; Eyzaguirre, E.; Espinoza, J.; Montes-Fonseca, S.L.; Rosas-Perez, G. Spectral Vegetation Index Sensor Evaluation for Greenhouse Precision Agriculture. In Proceedings of the 2019 IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4.

- Kumar, A.; Surendra, A.; Mohan, H.; Valliappan, K.M.; Kirthika, N. Internet of Things Based Smart Irrigation Using Regression Algorithm. In Proceedings of the 2017 International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Kannur, India, 6–7 July 2017; pp. 1652–1657.

- Chieochan, O.; Saokaew, A.; Boonchieng, E. Internet of Things (IOT) for Smart Solar Energy: A Case Study of the Smart Farm at Maejo University. In Proceedings of the 2017 International Conference on Control, Automation and Information Sciences (ICCAIS), Chiang Mai, Thailand, 31 October–1 November 2017; pp. 262–267.

- Prasad, A.N.; Mamun, K.A.; Islam, F.R.; Haqva, H. Smart Water Quality Monitoring System. In Proceedings of the 2015 2nd Asia-Pacific World Congress on Computer Science and Engineering (APWC on CSE), Nadi, Fiji, 2–4 December 2015; pp. 1–6.

- Anjum, M.N.; Cheema, M.J.M.; Hussain, F.; Wu, R.-S. Precision Irrigation. In Precision Agriculture; Elsevier: Amsterdam, The Netherlands, 2023; pp. 85–101.

- Divya, Y. Smart Water Monitoring System Using Cloud Service. Int. J. Trend Sci. Res. Dev. 2019, 3, 406–408.

- Shigeta, R.; Kawahara, Y.; Goud, G.D.; Naik, B.B. Capacitive-Touch-Based Soil Monitoring Device with Exchangeable Sensor Probe. In Proceedings of the 2018 IEEE Sensors, New Delhi, India, 28–31 October 2018; pp. 1–4.

- Difallah, W.; Benahmed, K.; Bounaama, F.; Belkacem, D.; Saidi, A. Intelligent Irrigation Management System. Int. J. Adv. Comput. Sci. Appl. 2018, 9, 429–433.

- Hamouda, Y.E.M. Smart Irrigation Decision Support Based on Fuzzy Logic Using Wireless Sensor Network. In Proceedings of the 2017 International Conference on Promising Electronic Technologies (ICPET), Deir El-Balah, Palestine, 16–17 October 2017; pp. 109–113.

- Islam, M.; Al-Momin, M.; Tauhid, A.; Hossain, M.; Sarker, S. IoT Based Smart Irrigation Monitoring & Controlling System in Agriculture. Int. J. Recent Technol. Eng. (IJRTE) 2020, 8, 2436–2440.

- Bogue, R. Sensors Key to Advances in Precision Agriculture. Sens. Rev. 2017, 37, 1–6.

- Zhang, X.; Zhang, J.; Li, L.; Zhang, Y.; Yang, G. Monitoring Citrus Soil Moisture and Nutrients Using an IoT Based System. Sensors 2017, 17, 447.

- Joly, M.; Mazenq, L.; Marlet, M.; Temple-Boyer, P.; Durieu, C.; Launay, J. Multimodal Probe Based on ISFET Electrochemical Microsensors for In-Situ Monitoring of Soil Nutrients in Agriculture. Proc. West Mark Ed. Assoc. Conf. 2017, 1, 420.

- Karthikeyan, L.; Chawla, I.; Mishra, A.K. A Review of Remote Sensing Applications in Agriculture for Food Security: Crop Growth and Yield, Irrigation, and Crop Losses. J. Hydrol. 2020, 586, 124905.

- Bwambale, E.; Naangmenyele, Z.; Iradukunda, P.; Agboka, K.M.; Houessou-Dossou, E.A.Y.; Akansake, D.A.; Bisa, M.E.; Hamadou, A.-A.H.; Hakizayezu, J.; Onofua, O.E.; et al. Towards Precision Irrigation Management: A Review of GIS, Remote Sensing and Emerging Technologies. Cogent Eng. 2022, 9, 2100573.

- Elnashar, A.; Abbas, M.; Sobhy, H.; Shahba, M. Crop Water Requirements and Suitability Assessment in Arid Environments: A New Approach. Agronomy 2021, 11, 260.

- Tessema Roba, N.; Kebede Kassa, A.; Yadeta Geleta, D. Modeling Climate Change Impacts on Crop Water Demand, Middle Awash River Basin, Case Study of Berehet Woreda. Water Pract. Technol. 2021, 16, 864–885.

- Reyes-González, A.; Kjaersgaard, J.; Trooien, T.; Hay, C.; Ahiablame, L. Estimation of Crop Evapotranspiration Using Satellite Remote Sensing-Based Vegetation Index. Adv. Meteorol. 2018, 2018, 4525021.

- Ramírez-Cuesta, J.; Mirás-Avalos, J.; Rubio-Asensio, J.; Intrigliolo, D. A Novel ArcGIS Toolbox for Estimating Crop Water Demands by Integrating the Dual Crop Coefficient Approach with Multi-Satellite Imagery. Water 2018, 11, 38.

- Fares, A.; Awal, R.; Fares, S.; Johnson, A.B.; Valenzuela, H. Irrigation Water Requirements for Seed Corn and Coffee under Potential Climate Change Scenarios. J. Water Clim. Chang. 2016, 7, 39–51.

- Garrido-Rubio, J.; Calera Belmonte, A.; Fraile Enguita, L.; Arellano Alcázar, I.; Belmonte Mancebo, M.; Campos Rodríguez, I.; Bravo Rubio, R. Remote Sensing-Based Soil Water Balance for Irrigation Water Accounting at the Spanish Iberian Peninsula. Proc. Int. Assoc. Hydrol. Sci. 2018, 380, 29–35.

- Mokhtari, A.; Ahmadi, A.; Daccache, A.; Drechsler, K. Actual Evapotranspiration from UAV Images: A Multi-Sensor Data Fusion Approach. Remote Sens. 2021, 13, 2315.

- Zeyliger, A.M.; Muzalevskiy, K.V.; Zinchenko, E.V.; Ermolaeva, O.S. Field Test of the Surface Soil Moisture Mapping Using Sentinel-1 Radar Data. Sci. Total Environ. 2022, 807, 151121.

- Ortega-Farias, S.; Esteban-Condori, W.; Riveros-Burgos, C.; Fuentes-Peñailillo, F.; Bardeen, M. Evaluation of a Two-Source Patch Model to Estimate Vineyard Energy Balance Using High-Resolution Thermal Images Acquired by an Unmanned Aerial Vehicle (UAV). Agric. For. Meteorol. 2021, 304, 108433.

- Bwambale, E.; Abagale, F.K.; Anornu, G.K. Smart Irrigation Monitoring and Control Strategies for Improving Water Use Efficiency in Precision Agriculture: A Review. Agric. Water Manag. 2022, 260, 107324.

- Crous, C.J.; Samways, M.J.; Pryke, J.S. Grasshopper Assemblage Response to Surface Rockiness in Afro-Montane Grasslands. Insect Conserv. Divers. 2014, 7, 185–194.

- Montesano, F.F.; van Iersel, M.W.; Parente, A. Timer versus Moisture Sensor-Based Irrigation Control of Soilless Lettuce: Effects on Yield, Quality and Water Use Efficiency. Hortic. Sci. 2016, 43, 67–75.

- Sudarmaji, A.; Sahirman, S.; Saparso; Ramadhani, Y. Time Based Automatic System of Drip and Sprinkler Irrigation for Horticulture Cultivation on Coastal Area. IOP Conf. Ser. Earth Environ. Sci. 2019, 250, 012074.

- Krishnan, R.S.; Julie, E.G.; Robinson, Y.H.; Raja, S.; Kumar, R.; Thong, P.H.; Son, L.H. Fuzzy Logic Based Smart Irrigation System Using Internet of Things. J. Clean. Prod. 2020, 252, 119902.

- O’Shaughnessy, S.; Urrego Pereira, Y.; Evett, S.; Colaizzi, P.; Howell, T. Assessing Application Uniformity of a Variable Rate Irrigation System in a Windy Location. Appl. Eng. Agric. 2013, 29, 497–510.

- Takács, S.; Bíró, T.; Helyes, L.; Pék, Z. Variable Rate Precision Irrigation Technology for Deficit Irrigation of Processing Tomato. Irrig. Drain. 2018, 68, 234–244.

- Yari, A.; Madramootoo, C.; Woods, S.; Adamchuk, V. Performance Evaluation of Constant Versus Variable Rate Irrigation: Variable Rate Irrigation. Irrig. Drain. 2017, 66, 501–509.

- Yari, A.; Madramootoo, C.; Woods, S.; Adamchuk, V.; Huang, H.-H. Assessment of Field Spatial and Temporal Variabilities to Delineate Site-Specific Management Zones for Variable-Rate Irrigation. J. Irrig. Drain. Eng. 2017, 143, 04017037.

- Szabó, A.; Tamás, J.; Kövesdi, Á.; Nagy, A. Evaluation of New Pivoting Linear-move Precision Irrigation Machine. Irrig. Drain. 2023, 72, 922–933.

- Deng, X.; Dou, Y.; Hu, D. Robust Closed-Loop Control of Vegetable Production in Plant Factory. Comput. Electron. Agric. 2018, 155, 244–250.

- Adeyemi, O.; Grove, I.; Peets, S.; Norton, T. Advanced Monitoring and Management Systems for Improving Sustainability in Precision Irrigation. Sustainability 2017, 9, 353.

- Klein, L.J.; Hamann, H.F.; Hinds, N.; Guha, S.; Sanchez, L.; Sams, B.; Dokoozlian, N. Closed Loop Controlled Precision Irrigation Sensor Network. IEEE Internet Things J. 2018, 5, 4580–4588.

- Patil, P.; Desai, B.L. Intelligent Irrigation Control System by Employing Wireless Sensor Networks. Int. J. Comput. Appl. 2013, 79, 33–40.

- Gauri, M.; Kulkarni, N.R. Design and optimization of pid controller using genetic algorithm. Int. J. Res. Eng. Technol. 2013, 2, 926–930.

- Fuentes, S.; Tongson, E. Advances and Requirements for Machine Learning and Artificial Intelligence Applications in Viticulture. Wine Vitic. J. 2018, 33, 47–52.

- Dimitriadis, S.; Goumopoulos, C. Applying Machine Learning to Extract New Knowledge in Precision Agriculture Applications. In Proceedings of the 2008 Panhellenic Conference on Informatics, Samos Island, Greece, 28–30 August 2008; pp. 100–104.

- Goldstein, A.; Fink, L.; Meitin, A.; Bohadana, S.; Lutenberg, O.; Ravid, G. Applying Machine Learning on Sensor Data for Irrigation Recommendations: Revealing the Agronomist’s Tacit Knowledge. Precis. Agric. 2018, 19, 421–444.

- Singh, S.N.; Jha, R.; Nandwana, M.K. Optimal Design of Solar Powered Fuzzy Control Irrigation System for Cultivation of Green Vegetable Plants in Rural India. In Proceedings of the 2012 1st International Conference on Recent Advances in Information Technology (RAIT), Dhanbad, India, 15–18 March 2012; pp. 877–882.

- Wong, W.; Chee, E.; Li, J.; Wang, X. Recurrent Neural Network-Based Model Predictive Control for Continuous Pharmaceutical Manufacturing. Mathematics 2018, 6, 242.

- Lee, J.B.; Gondhalekar, R.; Dassau, E.; Doyle, F.J. Shaping the MPC Cost Function for Superior Automated Glucose Control. IFAC-PapersOnLine 2016, 49, 779–784.

- Bosschaerts, W.; Van Renterghem, T.; Hasan, O.A.; Limam, K. Development of a Model Based Predictive Control System for Heating Buildings. Energy Procedia 2017, 112, 519–528.

- MacDermott, A.; Shi, Q.; Merabti, M.; Kifiyat, K. Considering an Elastic Scaling Model for Cloud Security. In Proceedings of the 2013 IEEE Third International Conference on Information Science and Technology (ICIST), Yangzhou, China, 23–25 March 2013; pp. 150–155.

- Ding, Y.; Wang, L.; Li, Y.; Li, D. Model Predictive Control and Its Application in Agriculture: A Review. Comput. Electron. Agric. 2018, 151, 104–117.

- Morato, M.M.; Normey-Rico, J.E.; Sename, O. Model Predictive Control Design for Linear Parameter Varying Systems: A Survey. Annu. Rev. Control 2020, 49, 64–80.

More