The ecosystem has been seriously affected by sewage discharge and oil spill accidents. A series of issues (such as the continuous pollution of the ecological environment and the imminent exhaustion of freshwater resources) are becoming more and more unmanageable, resulting in a crisis of water quality and quantity. Therefore, studies on industrial wastewater purification and solar-driven seawater desalination based on wood composites have been widely considered as an important development direction. Generally, functional nanomaterials are loaded into the wood cell wall, from which lignin and hemicellulose are selectively removed. Alternatively, functional groups are modified on the basis of the molecular structure of the wood microchannels. Due to its three-dimensional (3D) pore structure and low thermal conductivity, wood is an ideal substrate material for industrial wastewater purification and solar-driven seawater desalination.

- wood composites

- polymers

- wastewater purification

- seawater desalination

1. Introduction

2. Application of Wood Composites in Water Purification

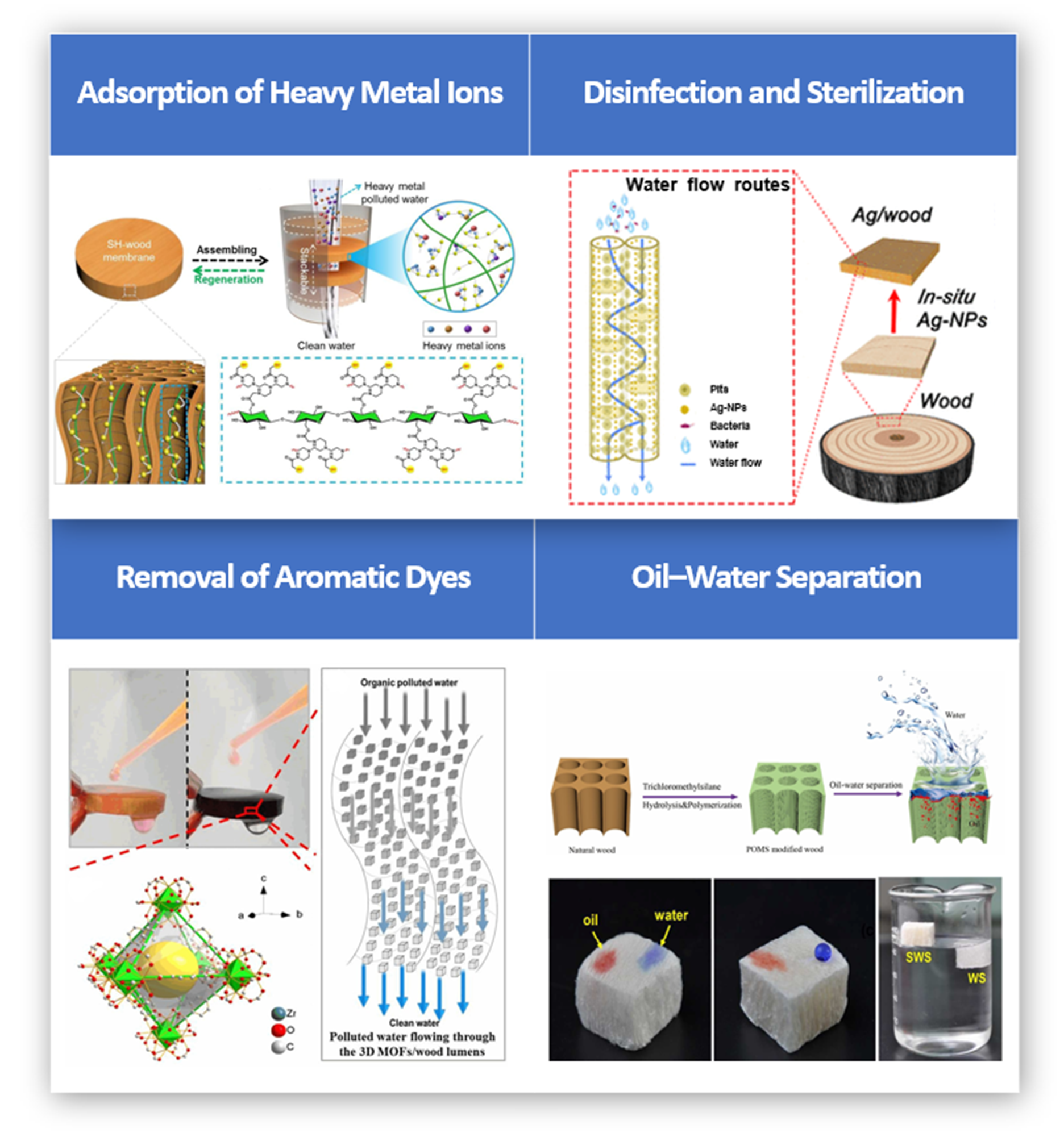

2.1. Adsorption of Heavy Metal Ions

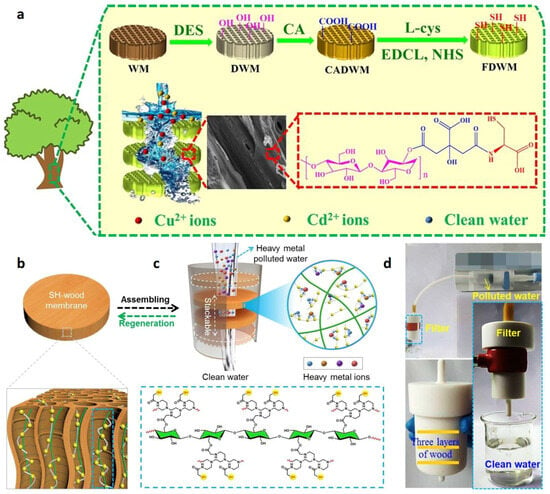

Because of their good solubility and stability, heavy metal ions in water exhibit the characteristics of high toxicity, non-degradation and biological enrichment in the ecosystem. If water containing heavy metal ions is discharged into the environment without treatment, it will cause serious harm to human health and the safety of other organisms [10]. Nowadays, the common methods to remove heavy metal ions from industrial wastewater include chemical precipitation, lime condensation, ion exchange, reverse osmosis and solvent extraction. However, they generally have problems such as complicated operations and high costs [11]. Therefore, an ideal choice is to treat heavy metal ions with adsorbents for the deep purification of water. Moreover, an adsorbent should meet the following standards: (1) low-cost and reusable; (2) effective and rapid; (3) selective and economically feasible [12]. The microstructure of wood contains a large number of hollow cells, which are interconnected and form interconnected channels, displaying a certain water flux. Moreover, wood is a typical multi-group ligand that can purify wastewater by adsorbing various heavy metal ions: (1) O– and COO– on the wood will react with heavy metal ions (Mn); (2) the negative polar bond in –OH, –NH, –OCH3 and –C=O in the wood will generate electrostatic attraction with heavy metal ions; (3) –OH and –COOH in the wood will exchange ions with heavy metal ions, and H will be released into the water. Sawdust is cheap and contains cellulose and lignin, which can absorb a variety of heavy metal ions. Therefore, it has a broad application prospect in the field of wastewater treatment. Ahmad et al. [13] ground sawdust into wood powder. Then, formaldehyde was used for the methylation reaction of wood powder to produce an adsorbent. The results show that the maximum removal rates for Cu2+ and Pb2+ are 99.39% and 94.61% when the adsorption material is in a solution with successive pH values of 7.0 and 6.6. Too high or too low a pH value will reduce the adsorption capacity of materials. This is because ion exchange and hydrogen bonding are the key to the efficiency of the removal of heavy metal ions by the adsorption material. In a water environment with a lower pH value, H competes with heavy metal cations for adsorption sites on adsorption materials. In a water environment with a higher pH value, OH− will form soluble hydroxyl complexes with heavy metal cations, and the electrostatic interaction between heavy metal cations and adsorption materials will be weakened. In order to improve the adsorption capacity, adsorption efficiency and selectivity of wood as adsorbent, other functional groups or inorganic nanomaterials can be further grafted or loaded in the wood channels. He et al. [14] prepared a 3D wood microfilter by modifying wood for the removal of heavy metal pollutants in wastewater. Specifically, a green deep eutectic solvent was used to remove lignin from beech wood. Then, carboxyl and sulfhydryl groups (-SH) were grafted on the surface of cellulose by sequentially using citric acid and l-cysteine. Finally, a 3D wood microfilter with an abundance of pores and adsorption sites was formed (Figure 1a). The adsorption kinetics and adsorption isotherms of heavy metal ions (Cu2+ and Cd2+) on the 3D wood microfilter were systematically investigated. The results showed that the 3D wood microfilter had a fast adsorption rate and high saturation capacity for both Cu2+ and Cd2+. Based on the advantages of easy multilayer assembly, a three-layer wood microfilter was designed to achieve the high flux rate (1.53 × 103 L·m−2·h−1) and high removal efficiency (>98%) for heavy metal ions in wastewater.

2.2. Disinfection and Sterilization

According to the statistics of the World Health Organization (WHO), approximately 1.6 million people die of diarrhea due to the lack of safe drinking water and basic sanitation facilities every year. Sterilization and disinfection of drinking water can effectively prevent diseases from being spread in water. The pore structure of wood has a natural barrier to larger colonies. After combination with antibacterial nanoparticles (NPs) (e.g., Ag NPs), a wood water filter with outstanding bacteria removal ability can be made. This is because Ag enters bacterial cells in the form of particles through endocytosis and is continuously released in the form of Ag. Specifically, Ag will cross-link or catalyze DNA molecules to form free radicals. Then, the proteins are denatured, the electron donors on DNA molecules are inhibited, and the DNA molecular chains break. In addition, Ag can combine with sulfhydryl and amino groups in cells, which will destroy the activity of cell synthetases. All the above procedures make bacteria and other microorganisms lose their ability to reproduce. When the bacteria die, Ag will be released and repeatedly perform the function of sterilization [16][17]. Electroporation sterilization technology applies a pulsed strong electric field to microorganisms and bacteria. It will destroy the cell membrane of bacteria and cause an osmotic imbalance inside and outside the cell membrane, eventually leading to the death of bacteria. There is no toxic by-product in the sterilization process. However, the high energy consumption and high risk of this technology limit its use in wastewater treatment [18]. Notably, researchers found that introducing 1D nanomaterials into conductive materials can solve the problems of energy consumption and safety [19]. Yang et al. [20] uniformly loaded Ag NPs into wood pores using the impregnation method, and the wood was further carbonized in a high-temperature tubular furnace. Then, Ag NP/carbonized wood membrane (3D Ag NP/WCM) composites with a three-dimensional mesoporous structure were obtained. The results show that the structure of nanofibers in carbonized wood is clearer. When a voltage is applied, the nanofibers will produce a peaking effect and greatly enhance the surrounding electric field, which can destroy the cell membrane of bacteria and lead to their inactivation. After electroporation, the damaged bacterial cells are more conducive to the invasion of Ag NPs in the carbonized wood and promote the sterilization process. The 3D Ag NP/WCM composite can be used in the condition of low voltage (4 V), low energy consumption (2 J·L−1) and high flux (3.8 × 103 L·h−1·m−2). It has a high bacteria removal rate (over 99.999%) and good stability (over 12 h). Compared with traditional electroporation sterilization technology, the wood composite not only avoids high energy consumption, but also reduces the safety risk of operation. It is a green, economical, fast, renewable and high-flux sterilization material for water treatment. Nowadays, traditional methods for sterilization are chlorination disinfection, ozone disinfection, heavy metal ion disinfection, etc. They work by decomposing the organic matter, bacteria and microorganisms in water through a hydroxide reaction or peroxidation. However, they usually have some issues such as cancer-causing by-products, high cost and difficult maintenance. Compared with these traditional sterilization and disinfection methods, wood composites have the characteristics of high efficiency, simplicity, stability, low cost, environmental protection and so on, and they are basically not affected by the surrounding temperature and pH. In addition, wood is green and rich in cellulose, hemicellulose and lignin, and it does not produce secondary pollution or toxic carcinogens. Moreover, the wood microstructure can be resistant to many species (e.g., Aspergillus Niger, E. coli, S. aureus and B. subtilis) and achieve a water flux of up to 3.8 × 103 L·h−1·m−2. Wood composites are capable of removing at least 75% or even up to 100% of bacteria from wastewater. Therefore, wood composites have considerable development prospects in the field of sterilization and disinfection.2.3. Removal of Aromatic Dyes

Printing and dyeing wastewater contains a lot of aromatic dyes, which are very difficult to remove. In addition, it also has the characteristics of dark color, high chemical oxygen demand (COD), high biological oxygen demand (BOD), complex and changeable composition, large discharge, wide distribution and difficult degradation. If the industrial wastewater is discharged without treatment, it will inevitably bring serious harm to the ecological environment due to its toxicity [21]. Therefore, removing these dye pollutants from water resources and wastewater is vital and important [22]. The natural pore structure of wood has a strong physical adsorption effect on aromatic dyes in wastewater. In addition, when the printing and dyeing wastewater flows through the pores of wood, its hydrodynamic effect is enhanced. In order to increase the time and opportunity of aromatic dye contact with active sites, functional nanomaterials or groups are loaded or grafted in the pore channels of wood. Chen et al. [23] synthesized Pd NPs in situ in basswood microchannels by using a hydrothermal method to prepare a Pd NP/wood membrane. Specifically, cellulose, with rich hydroxyl groups, can immobilize Pd NPs; thus, the wood changed from yellow to black at first. This is because the plasma effect produced by Pd NPs fixed on the surface of a wood microchannel absorbs a lot of light. When wastewater containing MB flowed through the wood microchannels, MB was degraded by Pd NPs. The color changed from blue to colorless, and the MB degradation efficiency was over 99.8%. The interaction between MOFs and aromatic dyes can be used to treat different aromatic dyes in wastewater [24]. Guo et al. [25] used ZrCl4, terephthalic acid and acetic acid as precursors for the in situ synthesis of UiO-66 MOF nanoparticles in three-dimensional mesoporous wood using the hydrothermal reaction method to obtain a UiO-66/wood membrane. Wood membrane filters for wastewater treatment can be obtained by changing the size and layers of this UiO-66/wood membrane according to actual needs. The results show that the flux of the filter assembled with three pieces of wood membrane is 1.0 × 103 L·m−2·h−1. The removal rates for cationic water-soluble aromatic dyes such as rhodamine 6G (Rh6G), propranolol and bisphenol A exceeded 96%, offering a rapid, multi-effect and recyclable method for removing aromatic dyes in this field. Wood has an abundance of nutrient transportation channels. However, the efficiency of the removal of high-concentration aromatic dyes by conduits in wastewater is generally low, which is the same for wood-based devices with tracheid channels [26]. In solvothermal conditions, Cui et al. [27] introduced polyoxometalate-based metal–organic frameworks (POMOFs) into natural wood (POMOF/wood) for effectively removing aromatic dyes and capturing iodine. Keggin-type POM anions with a highly negative charge were encapsulated to adjust the charge of the UiO-66 MOF, and the charge overcompensation in the POMOFs allowed them to efficiently adsorb cationic dyes. Benefiting from wood’'s unique microstructure, the removal efficiencies of POMOF/wood towards MB and gentian violet (GV) (with a permeance of 1.0 × ×104 L·m−2·h−1·bar−1) reach up to 94.07% and 95.23%, respectively.2.4. Oil–Water Separation

Oil pollution in wastewater mainly comes from petroleum exploitation, the chemical industry, steel factories, coking workshops, gas generating stations and other industrial departments. Its mass concentration is generally 5000~10,000 mg/L. Most of these oils float on the surface of rivers and oceans and form oil films, resulting in a lack of oxygen in water bodies. Eventually, this results in the death of a large number of aquatic organisms. When oil washes up on a beach, it will cause serious harm to the waterfowls, shrimps, crabs and other creatures on the beach [28]. Wood also has a good effect on oily wastewater separation; its pit structure is very beneficial to the demulsification of oil–water emulsions. In the filtration and separation of oil–water mixtures, the wettability of the solid material plays an important role and has become an accelerator in this field. The key points in preparing special wetting materials are (1) the biomimetic construction of a hierarchical micro–nanostructure on the surface of a substrate with low/high surface energy or (2) directly using low/high-surface-energy materials to biomimetically construct a hierarchical micro–nanostructure on the surface of a substrate. Superhydrophobic wood nanocomposites can be obtained by removing lignin from wood, further loading nanomaterials and then carrying out polymer backfilling and silanization treatment. Then, the expected goal for oil–water separation with high efficiency, high precision and high controllability can be achieved [23][26][29]. Zhao et al. [30] modified wood with polymethylsiloxane (POMS) to obtain superhydrophobic wood materials with a water contact angle (WCA) of 153°. POMS-modified wood has good oil absorption and oil–water separation performances. However, the accurate filtration efficiency and reusability of POMS-modified wood still need further discussion. Aside from cellulose, which is rich in hydroxyl groups, lignin and hemicellulose also exist in wood. They also contain -NH2 and -OH groups, resulting in the good hydrophilicity of wood. When wood is soaked in water, a hydrophilic and oil-repellent water film is formed on its surface. When an oil–water mixture is dripped on a wood surface, the water permeates into the wood, while the oil is excluded, showing a good superoleophobicity underwater. After selective removal of hemicellulose and lignin, the basic framework of cellulose with hierarchical high porosity and low density can be prepared easily [31][32]. Fu et al. [33] used a NaClO2 solution to remove the lignin of balsa wood. After freeze-drying, a porous delignified wood template with high hydrophilic and oleophobic properties was obtained. Then, it was impregnated with epoxy resin/amine/acetone solution. After curing, a hydrophobic and oleophilic wood composite with a unique pore structure was prepared. The product shows an outstanding compression strength (263 MPa) and oil absorption effect (15 g/g), and it can absorb oil pollution on and under the surface of water at the same time. Wang et al. [34] coated one side of delignified wood with a dodecyl mercaptan solution. After ultraviolet radiation induction, a Janus wood membrane with asymmetric wetting properties and unidirectional water transmission was prepared, and it was suitable for selectively separating the mixtures of light oil/water and heavy oil/water (the separation efficiency was higher than 99.3%). Blanco et al. [35] directly used spruce (thickness: 1 mm) for oil–water separation. Under gravity, its flux (3500 L·m−2·h−1) and efficiency (>99%) for separating oil–water mixtures were investigated. After the loading of Ag NPs in wood, superhydrophilic and underwater superoleophobic wood nanocomposites were prepared, the surface hydrophilicity of which could be further improved. After in situ auxiliary modification of photothermal materials (graphene) and transparent hydrophobic materials on delignified and hemicellulose wood, Chao et al. [36] prepared a compressible and resilient photothermal wood aerogel.

2. Application of Wood Composites in Solar Desalination

The wood composites discussed in the previous section can be applied to wastewater purification without the interference of external factors (e.g., solar energy). Thanks to their structural advantages, wood composites enable simple adsorption and filtration. However, when the salt content in brine is too high, it is difficult to desalinate seawater and obtain clean freshwater by simple adsorption or filtration of wood composites. The desalination of wood composites requires the input of external energy, for which clean and abundant solar energy is generally used. The specific process includes four steps: light absorption, photothermal conversion, interface evaporation and condensation collection. While wood itself has poor photothermal conversion performance, after modification with photothermal materials, wood composites can obtain good photothermal conversion and evaporation efficiency. Notably, water molecules are present in the liquid state in the process of wastewater purification using wood composites discussed in the previous section. This section discusses the application of wood composites in the solar interfacial evaporation of seawater with high salinity. Specifically, water molecules in seawater absorb heat from sunlight and then transform from the liquid state to the vapor state. Afterward, the desalting steam is condensed and collected as liquid freshwater. This process is the transformation of water molecules from the liquid state to the vapor state and then to the liquid state. This section focuses on the structural design of wood composites in solar desalination.

As a clean and renewable energy source, solar energy has a very broad application prospect in alleviating the shortages of energy and water resources. In solar desalination, sunlight is first captured by photothermal materials and then converted to heat. Further, the latent heat of the phase change (seawater from liquid to gas) can be overcome by the converted heat. Generally, the photothermal material is separated from the water body by a material with low thermal conductivity because the more converted heat is used to heat the fluid, the less heat is lost in this process. Meanwhile, the bottom water passes through the conduits in the substrate with low thermal conductivity and is further pumped to the top of the photothermal layer by its capillary force. Trees are the most extensive resources in the world [37,62,63], the conduits of which are beneficial to water transportation. Because of its outstanding transpiration capability, water can be pumped to a height of more than 100 m. Therefore, wood cut perpendicular to the growth direction is an ideal seawater desalination material. Moreover, the transpiration and sunlight absorption inside trees occur through xylem conduits and cavities [64]. Ninety percent of water absorbed by trees is emitted into the air through transpiration. The thermal conductivity of wood is very low and highly anisotropic along (0.35 W·m−1·K−1) and perpendicular (0.11 W·m−1·K−1) to its conduits, which is very beneficial for isolating unnecessary heat exchange between a photothermal layer and seawater, thus improving the heat management and evaporation performance.

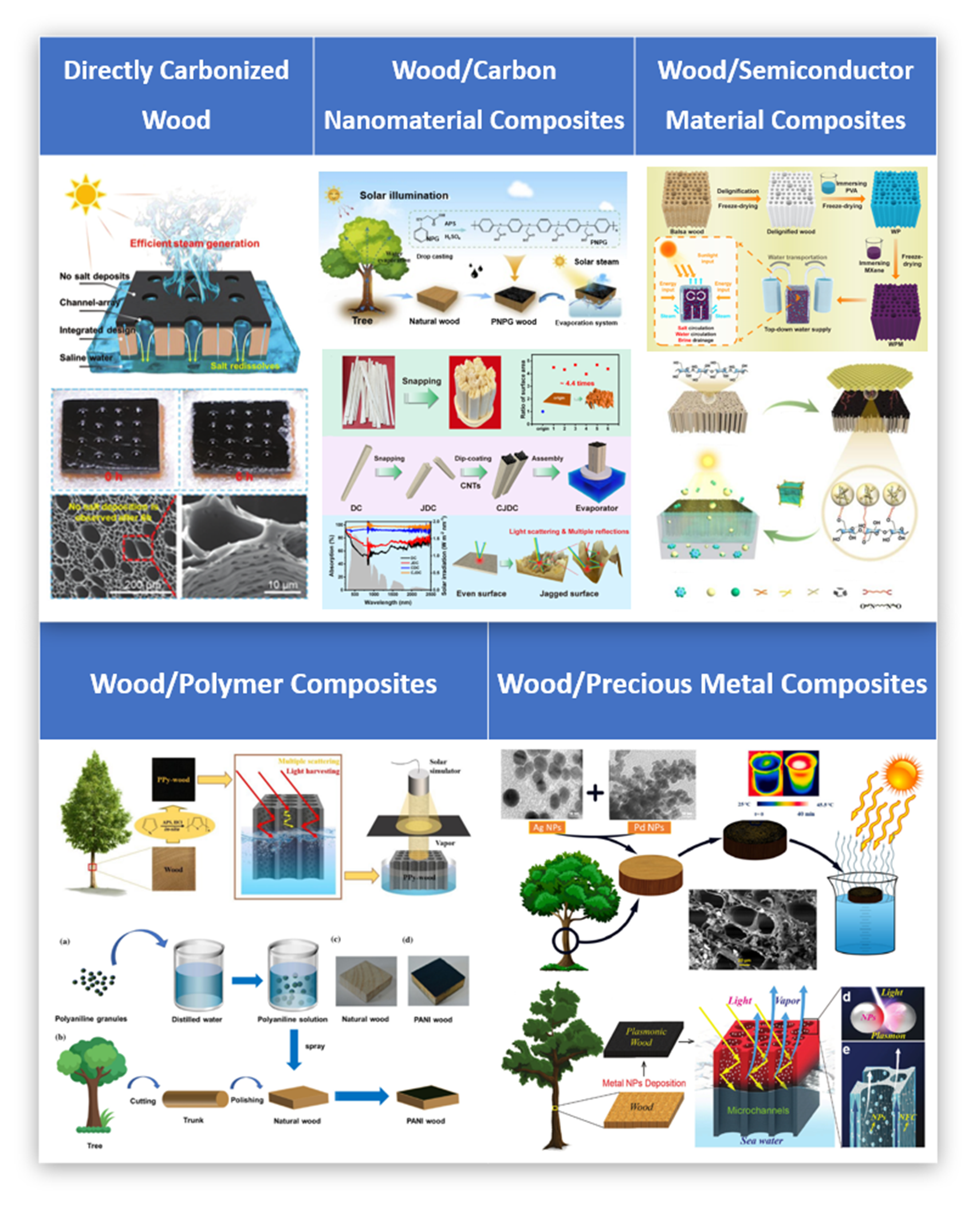

The traditional methods for seawater desalination include multi-stage flash evaporation (MSF) and multi-effect distillation (MED), as well as reverse osmosis (RO) technology. However, most of them have serious shortcomings including a high dependence on fossil resources; energy consumption; greenhouse gas emissions; high technical requirements; high costs for investment, equipment operation and maintenance; less actual return; and even secondary pollution caused by the large consumption of chemicals and detergents. Wood composites with good photothermal conversion properties with different structural designs such as directly carbonized wood, wood/carbon nanomaterial composites, wood/semiconductor composites, wood/polymer composites and wood/precious metal composites have been prepared. In addition, sunlight provides an almost infinite source of clean heat energy. With different structural designs, a high evaporation rate (1.351~4.31 kg·m−2·h−1) and photothermal conversion efficiency (87.4~122.2%) of wood composites have been achieved in solar desalination. Experimental data show that the photothermal layers on these wood composites after acid/alkaline and seawater immersion for 100 h and ultrasonic treatment for 2 h have no obvious changes. Apparently, these wood composites are extremely durable. Even after 100 cycles of freeze–thaw testing, the water evaporation rate of wood composites did not decrease significantly.

3.1. Directly Carbonized Wood

Wood emerges as a sustainable and promising precursor for carbon materials owing to its natural abundance and superb properties. The preparation of carbon materials with different morphologies (dots, spheres, nanowires, films and other 3D nanomaterials) and porous structures (disordered and ordered) is of great significance for various fields (e.g., adsorption, capacitors, catalysts, solar cells, sensors) [65]. Xue et al. [66] cut wood into cylinders and put them on an alcohol flame for carbonization. Then, they were immersed in cold water for rapid quenching. Finally, wooden cylinders with carbonized surfaces were obtained. Under 1 kW·m−2, their thermal conversion efficiency was as high as 72%. Also inspired by tree transpiration, Zhu et al. [19] designed a solar evaporation device with a double-layer structure. Firstly, wood was cut perpendicular to the wood growth direction and simply carbonized at 500 ℃ for 0.5 min. The thickness of the carbonized layer was only approximately 3 mm on the surface of the wood, which could be directly used for solar-driven seawater desalination. The results show the following: (1) The upper surface of carbonized wood can absorb 99% of light. (2) Under 10 kW·m−2, its photothermal conversion efficiency is 87%. (3) Under 10 kW·m−2, the amount of water evaporation increases linearly. (4) After 100 h of irradiation under 5 kW·m−2, the sample can still be used stably. (5) The sample can remain stable in seawater for a long time, and there is no salt accumulation on its surface. (6) Water can be directly extracted from the ground (sand and soil).

Kuang et al. [67] also used the above method to carbonize wood. The difference is that they used an electric drill to drill holes in the wood before carbonization . Then, the carbonized layer on the wood surface was polished with sandpaper and then placed in 20 wt% NaCl solution for 6 h under one solar irradiation. The surface of the sample without drilled holes was completely covered with precipitated salt. However, there was no obvious salt deposition on the surface of the sample with drilled holes, displaying an excellent selfdesalting ability. This is due to the rapid salt exchange among the pits on wood cell walls, wood microchannels and millimeter-sized drilling channels on wood. The increased salt concentration in the natural wood channel can be diluted at any time. Therefore, it will not block the steam discharge channel during the evaporating procedure of concentrated brine. It is always stable in long-term evaporation and has excellent performance under 1~5 solar irradiations. Its evaporation rate was 6.4 kg·m−2·h−1 when it was placed in high-salinity water (15 wt%) under six solar irradiations, showing excellent stability and durability. Chen et al. [68] developed a multifunctional solar evaporator composed of carbonized wood and biomass hydrogel modified by MXene. The evaporation rate and efficiency of the product were 3.71 kg·m−2·h−1 and 129.64%, respectively. Under two kinds of solar irradiation, the open circuit voltage is 1.8 mV. The high performance of the evaporator stems from (1) the high water transmission of natural wood structure, (2) the high solar absorption and heat conversion efficiency enhanced by carbonized wood and MXene, (3) the regulation of evaporation enthalpy and surface energy by MXene and (4) the temperature adjustment by the low-thermal-conductivity structural system.

Ghafurian et al. [69] utilized the natural water transport tissue of high-porosity wood (poplar) to maximize solar utilization for water vaporization. The inherent high porosity, low thermal conductivity and rapid capillary action of wood make it attractive in solar desalination. Natural wood cannot absorb broadband sunlight well. Therefore, these authors compared several innovative and potentially scalable technologies for wood surface modification, including laser carbonization, gold nanolayer deposition and their combination. The use of a high-power laser is a fast and accurate method for engraving, cutting and carbonizing wood, enabling groove patterns to be generated rapidly and controllably without destroying the wood samples. Under 3 kW/m2, the best performance of gold coating carbonized by a hot plate is 4.02 kg/m2·h, which is twice that of untreated sample (~2 kg/m2·h), and the best performance of gold nanocoating is 3.54 kg/m2·h. In addition, the performances of samples after 10 cycles of thermal treatment were investigated. The result showed that these samples could evaporate stably at the speed of 3.3 kg/m2·h. It can be concluded that surface modification provides wood with a scalable high performance. Therefore, fast-growing wood can be widely used in solar seawater desalination and/or low-temperature steam generation.

3.2. Wood/Carbon Nanomaterial Composites

Nanomaterials usually exhibit some unique electronic and optical properties. For instance, in the allotrope of a carbon nanotube, almost every band in the solar spectrum can excite electrons due to its large number of conjugated π bonds. This leads to various π-π* transitions inside and a dark appearance. Meanwhile, when the incident light energy matches the electron transition in the molecule, the electron will absorb the light and rise from the highest occupied molecular orbital (HOMO) to the lowest unoccupied molecular orbital (LUMO). After absorbing these energies, electrons relax through electron–phonon coupling. The carbon allotrope not only absorbs the light, but also transfers the energy of excited electrons to the atomic lattice in the vibration mode. Macroscopically, it will increase the temperature of the material [70]. In addition, other carbon photothermal nanomaterials (such as carbon nanotubes (CNTs) [71], carbon dots (CDs) [72], graphene [73], graphene oxide (GO) [74] and reduced graphene oxide (rGO) [75]) are also promising photothermal materials for interfacial water evaporation.

Taking advantage of the low curvature of the pore structure and the anisotropic thermal conductivity of wood, Chao et al. [54] used delignified wood as a substrate and carbon dots with a photothermal effect prepared using the removed lignin to realize a solar evaporation system with an all-wood composition. The results show that the evaporation rate and photothermal conversion efficiency of the solar evaporation system are 1.09 kg·m−2·h−1 and 79.5% under 1 kW·m−2. Liu et al. [74] obtained a woodGO double-layer composite by dropping graphene oxide on the cross-section of wood. Under 5 kW·m−2, the wood-GO composite and original wood were irradiated in dry and wet states. The results showed that wood-GO had a great temperature increase (∆dry = 43 ℃, ∆wet = 33 ℃), while the original wood changed little . A woodGO composite was placed in simulated seawater with a salinity of 3 wt%. Under 12 kW·m−2, its temperature reaches 67 ℃ in the first few seconds and remains constant. The generation of water vapor can be clearly seen on its surface. Compared with the original wood (10.08 kg·m−2·h−1 and 59.5%), its evaporation efficiency and photothermal conversion efficiency can reach 14.02 kg·m−2·h−1 and 82.8%, respectively. It not only realizes the effective utilization of renewable solar energy, but also realizes the full utilization of the internal circulation of wood-based materials.

To make use of the directional arrangement structure of natural wood fibers, Chao et al. [76] selectively removed lignin and hemicellulose and further modified the retained cellulose with photothermal coating (rGO) to prepare a wood-derived aerogel. Under 1 kW·m−2, the material was hung between seawater tanks to carry out a “connecting bridge” seawater desalination. The results show that the evaporation rate and photothermal conversion efficiency are 1.351 kg·m−2·h−1 and 90.89%, respectively. Compared with the traditional “close contact” solar evaporation, it avoids the heat loss and the decrease in light energy utilization rate caused by the close contact between photothermal materials and the water phase. It greatly improves its light energy utilization rate. Through the incomplete combustion of a paraffin candle flame, Hu et al. [77] constructed carbon nanoparticles on the surface of wood to prepare a novel double-layer solar evaporator. The results show that the carbon nanoparticle/wood composite with an interconnected porous structure has broadband and high light absorption (93~97%) and can convert solar energy into heat energy to heat the interface between water and air. Its principle is that water is effectively transported from the wood bottom to the surface of carbon nanoparticles by capillary force for sufficient evaporation water supply. Meanwhile, the abundant hydrophilic groups of wood form hydrogen bonds with water molecules, which weakens the hydrogen bonds between intermediate water molecules. Under 1 kW·m−2, the water evaporation enthalpy is reduced by approximately 26%, while the evaporation rate and conversion efficiency are 2.06 kg·m−2·h−1 and 90%, respectively, displaying good long-term stability, strong self-cleaning ability, and strong acid and alkali resistance.

Zhang et al. [78] used CNTs to decorate disposable hydrophilic wood chopsticks, which were assembled into a 3D array for efficient water evaporation and purification. Figure 6f shows the fabrication and solar absorption performance of CNT-functionalized disposable wood chopstick (CDC) and CNT-decorated jagged disposable wooden chopstick (CJDC) evaporators. Firstly, the chopsticks were broken into fragments with a 3D serrated top surface. Compared with a traditional flat surface, its surface area is significantly increased. In order to provide jagged disposable wood chopsticks (JDCs) with photothermal conversion capability, solar thermal CNTs were coated on the surface of JDCs using the impregnation method. Then, JDCs with high photothermal performance were obtained. To increase the top and side surface areas, a single CJDC unit was assembled into an integrated 3D evaporator for seawater desalination and water purification. As shown in Figure 6j, a CJDC has a higher absorption of sunlight than a CDC. The CJDC can capture the incident sunlight more effectively by multiple reflections and scattering on its surface. The exposure height of the disposable chopstick evaporator decorated with CNTs was 4 cm. The evaporation rate and energy efficiency of the wood composites were 3.70 kg m−2·h−1 and 122.2%, respectively. They have wide application prospects in solar-driven seawater desalination and industrial wastewater purification.

3.3. Wood/Semiconductor Material Composites

The band gap of a semiconductor material can determine its light absorption ability. When the light strikes the semiconductor surface, the concentration of carriers (electrons or holes) in the energy band will increase continuously. When the excited electrons jump back to the low-energy state, the energy will undergo a non-radiative relaxation process. Specifically, the photon energy will be converted into heat energy, thus affecting the photothermal conversion capability. Song et al. [79] coated Fe3O4/PVA on the surface of delignified basswood to obtain an Fe3O4/PVA/wood evaporator. The wood was treated with NaClO2 to remove hemicellulose and lignin for at least 10 h, while the cellulose content was basically preserved intact. Delignified wood has better ink transferability than original wood. In addition, delignified wood has better hydrophilicity than original wood. Polyvinyl alcohol (PVA) enhances the bonding force between a wood matrix and a semiconductor. Under 1 kW·m−2, the surface temperature of natural wood increased from 26 ℃ to 34 ℃ within 10 min, while the equilibrium temperature of Fe3O4/PVA/wood reached 63 ℃. Compared with the wood composite without delignification, Fe3O4/PVA/wood shows a higher temperature. Fan et al. [80] embedded a hydrogen evolution semiconductor material (CdS) and photothermal material (MoSe2) into porous delignified wood simultaneously to prepare a wood-mixed hydrogel. It can be used for water purification, hydrogen production and seawater desalination. By optimizing the structure and process design, the efficient pollutant removal, hydrogen production and steam generation of the product can be realized. Under one solar illumination, its hydrogen evolution rate, solar evaporation rate and energy conversion efficiency are 9.7 mmol g−1·h−1, 1.92 kg·m−2·h−1 and 90.7%, respectively. The hydrogel packages the photocatalytic system, which can effectively prevent the evaporation of toxic volatile organic compounds (VOCs) and retain the ability of continuous and efficient steam production.

He et al. [81] soaked various woods (such as beech, cedar, pine, ash, oak, poplar and cudgel) in a tannic acid (TA) solution to obtain wood-TA. Afterward, wood-TA was immersed in Fe2(SO4)3 solution to obtain wood-TA-Fe3+. However, a polypropylene (PP) porous membrane, polyester fabric and polyurethane (PU) sponge in the same condition are blue-gray rather than black. After comparing the SEM images of original poplar, wood-TA and wood-TA-Fe3+, it was found that many nanonodes appear in wood-TA-Fe3+ due to the coordination between the doped TA and Fe3+. The rough wood surface and abundant pore structure further reduce the energy loss caused by light reflection. The results show that the photothermal layer of the sample after acid/alkaline and seawater immersion for 100 h, ultrasonic treatment for 2 h and 100 cycles of freeze–thaw testing has no obvious change. For complex water quality, it can effectively prevent oil droplets from adhering to the material surface, which will avoid the blocking of its waterway and a decrease in evaporation performance. In addition, the researchers also cut many grooves on the wood surface to evaluate wood-TA-Fe3+ with an uneven surface. The results show that the water evaporation rate of wood-TA-Fe3+ with surface modification reaches 1.85 kg·m−2·h−1, which is 4 times that of wood-TA-Fe3+. Solar interfacial evaporation is considered as a promising strategy for solar-driven seawater desalination and industrial wastewater purification. Yan et al. [82] used delignified wood (DW) as a water transport substrate and lignosulfonate (LS)-modified nickel disulfide (NiS2) as a light absorber (LS-NiS2) to prepare an efficient LS-NiS2/DW evaporator. The results show that LS-NiS2 has a high absorption rate (>95%) and photothermal conversion efficiency in a wide wavelength range. Therefore, the evaporator has a higher solar energy utilization rate. On the other hand, the hydrophilicity of DW facilitates the activation of water. The evaporation enthalpy of LS-NiS2/DW (1274.4 kJ·kg−1) is lower than that of pure water. Under one solar irradiation, the evaporation rate of LS-NiS2/DW reaches up to 2.80 kg·m−2·h−1, and its evaporation efficiency reaches 87.4%. It is worth noting that LS-NiS2/DW shows a high evaporation rate (2.42~2.69 kg·m−2·h−1) in simulated seawater. Even after 24 h, no salt crystals are formed on its surface.

In order to realize high-yield, high-salinity and long-term seawater desalination, Hu et al. [83] enhanced the hydrophilicity of balsa wood by delignification. Vacuum-assisted impregnation of polyvinyl alcohol (PVA) and a special top-down water supply device were adopted. It illustrates the fabrication procedure for 3D PVA/MXene-decorated wood (WPM), which serves as a photothermal water evaporator with a top-down water supply design for solar-driven evaporation of seawater and high-salinity water. The presence of MXene nanosheets facilitates solar light absorption and solar–thermal conversion. Therefore, the evaporation rate of the PVA/MXene-decorated wood (WPM) solar evaporator under 1 kW·m−2 is as high as 4.31 kg·m−2·h−1. During the desalination of a 25 wt% NaCl solution for 8 h, its evaporation rate reached 3.83 kg·m−2·h−1. A sufficient down-top water supply dilutes the saline water with a high concentration on the surface of the WPM evaporator, thus avoiding salt deposition in the long-term solar-driven desalination process. The result shows that its average evaporation rate in 15 wt% NaCl solution under solar irradiation for more than 100 h is 4.24 kg·m−2·h−1. He et al. [84] reported a 3D wood membrane coated with MoS2 (WM-H, with S trap) for effective seawater desalination. The MoS2 was synthesized using thiourea and ammonium molybdate tetrahydrate. High-resolution SEM images show the structural changes. The pore size of NW is mainly distributed at approximately 10~25 µm. The specific surface area (SSA) increases from 0.22 m2·g−1 (NW) to 9.92 m2·g−1 (WM-H) and 10.45 m2·g−1 (WM-L). The adsorption/desorption capacity of WM-H and WM-L is much higher than that of NW. After treatment, the pore structure of the wood samples becomes regular. The pore diameters of WM-H and WM-L increased to approximately 10~40 µm and 10~50 µm, respectively. Therefore, the vertically arranged channels of wood can rapidly provide water for its heating surface, which could support the high rate of steam generation. This is due to rapid water diffusion and powerful capillary pumping. The excellent photothermal MoS2 provides enough heat for water evaporation. Under 1 kW·m−2, MoS2-coated wood with S defects has an excellent evaporation rate and heat conversion efficiency of 1.46 kg·m−2·h−1 and 82.5%, respectively. The adsorption peaks of Na+ on both sides of defective MoS2 are respectively 2.17 and 1.49 times higher than those for MoS2 without S defects.

3.4. Wood/Polymer Composites

Polydopamine (PDA) can be prepared by the self-polymerization of dopamine monomers under alkaline conditions. It has good adhesion and exhibits an absorption spectrum from ultraviolet light (UV) to near-infrared light (NIR). Therefore, it is an ideal photothermal coating material [85–87] that can evenly and stably adhere to the surface of a wood cavity on the basis of not blocking the pore channels. Polypyrrole (PPy) has good biocompatibility and environmental stability [14] and exhibits a high absorption rate of 90.8% in the whole solar spectrum [88,89]; it can be combined with the hydroxyl groups of cellulose through hydrogen bonds. The results show that PPy-wood shows almost full-spectrum light absorption and low incident angle sensitivity in the spectral range of 250~2500 nm. Zou et al. [90] mixed arginine and a dopamine solution to obtain a black precipitate (APDA), which was coated on the surface of camphor wood to prepare APDAwood. Compared with traditional PDA, APDA has a narrower band gap and stronger light absorption capacity, in accordance with density functional theory (DFT). In addition, APDA has no obvious luminescence under the excitation of 365 nm, 500 nm and 808 nm, which indicates that the non-radiative transition is dominant. That is, the light absorbed by APDA will be converted into heat more quickly and effectively. Under one solar irradiation, the surface temperature of APDA-wood rises faster than that of pure wood and water. The surface temperature of APDA-wood can reach 38 ℃ within 5 min and stabilize at 40 ℃, and the evaporation rate can reach 0.91 kg·m−2·h−1. In order to verify the actual seawater desalination, 3.5 wt% NaCl solution was used to simulate seawater. The results show that Na+ in simulated seawater decreased by approximately 4 orders of magnitude after APDA-wood desalination. The concentrations of Ca2+, Mg2+ and K+ also decreased by at least 2~3 orders of magnitude, meeting the standards of the US Environmental Protection Agency (EPA) and the WHO. Even after 100 cycles, the water evaporation rate of APDA-wood did not decrease obviously.

In addition, the physical characteristics of wood endow PPy-wood with excellent heat insulation and water transmission performance. After the absorption of a pyrrole solution and a mixed solution of APS (ammonium sulfate) and HCl, Huang et al. [91] prepared black PPy-wood. In the comparison of the optical characteristics of PPy-wood and original wood in the spectral range of 250~2500 nm, the light absorption rate of the original wood (44.9%) was much lower than that of PPy (90.8%). More importantly, under the synergistic effect of PPy and wood, the light absorption rate of PPy-wood in the whole spectral range is as high as 97.5%. Under 1, 3, 5, 7 and 10 solar irradiations, the evaporation rates of PPy-wood were 1.33, 3.47, 5.85, 8.38 and 11.77 kg·m−2·h−1, respectively. They are much higher than the evaporation rates of pure water (0.50, 0.78, 1.19, 1.66 and 2.31 kg·m−2·h−1) under the same conditions. After treatment with strong acid (pH = 2), strong alkali (pH = 10), high temperature (100 ◦C) and ultrasound washing, the coating of PPy-wood did not show obvious peeling, which verified its good structural stability. In addition, the multiple scattering of light can be reduced by wood’s rough surface. The light absorption efficiency of PPy-wood is over 93% at various angles (0~60◦). Wang et al. [92] prepared PPy-wood by loading the photothermal PPy on balsa wood by in situ polymerization. After one solar irradiation for 1 h, the surface temperatures of water, wood and PPy-wood were 28.2 ℃, 32.8 ℃ and 41.0 ℃, respectively. It should be noted that the surface temperature of PPywood can reach 39.6 ℃ within 5 min of illumination. However, the surface temperatures of pure water and wood only increased slightly (∆pure water ≈ 1.9 ℃, ∆virgin wood ≈ 6.5 ℃), further confirming that the PPy coating plays an important role in photothermal conversion. The evaporation rate (approximately 1.0 kg·m−2·h−1) and efficiency (over 70%) hardly changed in seven service cycles. After 45 days of long-term storage, the evaporation rate and efficiency of PPy-wood have no obvious variation.

Qu et al. [93] loaded polyaniline on the surface of natural wood using a spraying method. A low-cost, easily manufactured and high-performance wood evaporator was successfully assembled. Because of the hydrogen bond between polyaniline and the wood surface, the solar absorption and photothermal conversion efficiency of the evaporator are greatly enhanced. The capillary effect of wood and the hydrophilicity of cellulose facilitate the continuous upward flow of water. Meanwhile, wood’s low thermal conductivity causes the conversion of solar energy to heat at the interface of the wood block. In addition, the porosity and layering of wood blocks decrease the hydrogen bond density of water passing through. Under one solar irradiation, the high temperature of 68.3 ℃ can be reached within 30 min, verifying the good photothermal conversion effect of a PANI-wood block. In the same condition, the surface temperature of natural wood is relatively stable at 46.2 ℃ . The temperature of the evaporator and natural wood tends to be stable after 30 min. This is because the PANI remarkably increases the solar energy absorption of the wood evaporator after modification. The evaporation efficiency of the polyaniline-wood evaporator is 1.66 kg·m−2·h−1 under one solar irradiation. In addition, the concentration of main ions in purified water obtained by the evaporator fully meets the WHO requirements for drinking water.

Poly (N-phenylglycine) (PNPG) is a conjugated polymer with good light absorption, which can greatly make up for the weak light absorption of wood. In addition, PNPG can effectively improve the photothermal conversion efficiency of wood evaporators. Inspired by the transpiration of trees, Lin et al. [94] developed a PNPG-wood solar evaporator with low thermal conductivity and a special microstructure. Under one solar irradiation, its evaporation rate and conversion efficiency can reach 1.64 kg·m−2·h−1 and 90.4%, respectively, which are higher than those of most reported wood solar evaporators. This system has the potential to solve the practical issues of seawater desalination and water purification. Li et al. [95] successfully constructed a polyelectrolyte hydrogel (SCPH) with rapid pumping, enhanced salt discharge, and improved mechanical strength and thermal insulation performance. The wood sponge skeleton of SCPH has a series of characteristics such as high mechanical strength, low thermal conductivity, excellent compressibility and high porosity. In addition, the polyelectrolyte hydrogel has weak mechanical strength, high thermal conductivity, and good pumping properties and salt rejection performance. Therefore, a novel SCPH material was developed by making full use of the advantages of polyelectrolyte hydrogel and balsa sponge. The material has a very low thermal conductivity (0.109 W·m−1·K−1), while its mechanical strength is significantly improved. In addition, it is worth noting that its salt rejection rate reached 88.7% even in a 10% salinity solution. The evaporation rate of the SCPH evaporator reached 2.13 kg m−2·h−1, which greatly exceeded that of a reported polyelectrolyte hydrogel evaporator. It is exciting that the proposed evaporator can run in 20% salt water for 30 days. There is no salt accumulation on its surface, representing an improvement over most reported single-hydrogel evaporators. Sheng et al. [96] used a chemically stable coordination polymer (Ni-DTA) as a hydrophilic photothermal nanomaterial to produce a robust wood-based evaporator (Balsa-NiDTA) with better molecular design performance. Ni-DTA synthesized in situ on the cell wall of balsa wood provides enough light and heat fields, which make the converted energy localize to promote interfacial evaporation. Reasonably controlling the ratio of methanol to dimethylformamide allows 1D nanofibers and 0D nanoparticles to coexist. Therefore, its evaporation rate and energy efficiency under one solar illumination can reach up to 2.75 kg·m−2·h−1 and 82%, respectively. The results show that the Ni-DTA polymer with strong hydration ability will reduce the equivalent evaporation enthalpy, which is attributed to the decrease in the H bond density of water molecules near the evaporation interface. The evaporator shows a high chemical stability, which is mainly attributed to the firm Ni-S/Ni-N bond and the excellent cellulose affinity of Ni-DTA. In addition, the evaporator has excellent antibacterial activity and low oil pollution tendency, which are helpful in realizing the efficient and sustainable solar desalination of Balsa-NiDTA under various harsh conditions.

3.5. Wood/Precious Metal Composites

When light is incident on a photothermal conversion layer composed of precious metal nanoparticles, if the incident photon frequency matches the total vibration frequency of precious metal nanoparticles or metal conduction electrons, it will have a strong absorption effect on photon energy and produce the local surface plasmon resonance (LSPR) effect [97]. Due to the LSPR effect, precious metal nanoparticles can show a stronger absorption spectrum in the ultraviolet–visible band. In addition, the LSPR effect also causes nearfield enhancement, hot electron generation and photothermal conversion [98]. This is because the electrons are excited from an occupied state to an unoccupied state, forming hot electrons [99], the energy of which is redistributed through electron scattering, thus rapidly increasing the temperature of metal particles [100]. The shape and position of LSPR are closely related to the composition, size, shape, dielectric property and dielectric environment of nanoparticles [101]. In general, reducing the shape symmetry or creating a hollow structure can broaden the spectral LSPR band. However, a variation in particle size or the surrounding media will mainly cause a shift in the LSPR band and broaden the absorption band [102]. Silver is widely known for its high plasma resonance effect and low plasma loss. Gold is famous for its visible–near-infrared plasma resonance effect and chemical stability. Therefore, Au NPs and Ag NPs are the most widely used plasmon metals and photothermal materials for solar evaporation [103]. Goharshadi et al. [104] coated layered porous wood with Ag and Pd nanoparticles (NPs) as a double layer. Then, the coated wood could be used as an effective light absorber in interface solar steam generation (ISSG). The results showed that the plasmon resonance effect of Ag and Pd NPs could increase the photothermal conversion efficiency of the wood composite when Ag and Pd NPs were used as the bottom layer and upper layer, respectively. The wood composite’s highest evaporation rate was 4.82 kg·m2·h−1 under three solar irradiations. Initially, the salinity, conductivity and pH of seawater were 3138.19 mg·L−1, 6000 µS·cm−1 and 8.1, respectively. After treatment, the salinity, conductivity and pH of seawater were reduced to 6.76 mg·L−1, 20.5 µS·cm−1 and 6.7, respectively. In addition, the wood composite also presented a stable water generation capability during long-term cycles.

Zhu et al. [105] designed a novel plasmonic wood for efficient steam generation. First, basswood was cut perpendicular to the direction of the tree’s growth. Plasma metal nanoparticles were then deposited in the wood microchannels to form plasma wood. Black plasmonic wood can float on water without additional assistance. The plasma palladium nanoparticles on the surfaces of microchannels convert incident light into heat due to the plasma effect. Therefore, plasmonic wood has a high solar absorptivity (≈99%) in the wide wavelength range of 200~2500 nm. Due to the thin decorative layer, metal nanoparticles will not block the water microchannels, ensuring continuous water transportation. Due to the low thermal conductivity of plasmonic wood, the heat is concentrated on the evaporation surface, resulting in an effective solar steam generator. The hydrophilicity and capillary effect of plasmonic wood can effectively transport water upward to maintain a continuous water supply for steam generation. The low thermal conductivity of wood microchannels contributes to thermal localization, which can effectively inhibit heat dissipation to bulk water. Therefore, the plasmonic wood has a unique 3D mesoporous arrangement structure. The solar energy conversion efficiency can reach 85% under 10 solar irradiations. The as-obtained plasmonic wood also showed strong stability (over 144 h) and self-cleaning ability. Thanks to the above advantages, plasmonic wood can be applied to many fields such as water sterilization and seawater desalination.

References

- Chen, C.J.; Kuang, Y.D.; Zhu, S.Z.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.; Hu, L. Structure-property-function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666.

- Boutilier, M.; Lee, J.; Chambers, V. Water filtration using plant xylem. PLoS ONE 2014, 9, e89934.

- Wang, M.Z.; Fang, Y.; Li, Q.; Bai, L.; Liu, S.; Li, J.; Chen, W. Nanostructures of plant cell walls and individualization methodology of nanofibrillated cellulose. Acta Polym. Sin. 2020, 51, 586–597.

- Zhang, M.; Zhou, N.; Shi, Y.; Ma, Y.; An, C.; Li, J.; Jiang, W.; Wang, C.; Shi, J. Construction of antibacterial, superwetting, catalytic, and porous lignocellulosic nanofibril composites for wastewater purification. Adv. Mater. Interfaces 2022, 9, 2201388.

- Li, Z.; Zhang, M. Progress in the Preparation of Stimulus-Responsive Cellulose Hydrogels and Their Application in Slow-Release Fertilizers. Polymers 2023, 15, 3643.

- Tang, Y.; Chen, L.; Wei, X. Removal of lead ions from aqueous solution by the dried aquatic plant, Lemna perpusilla Torr. J. Hazard. Mater. 2013, 244–245, 603–612.

- Liu, C.; Luan, P.C.; Li, Q.; Cheng, Z.; Xiang, P.; Liu, D.; Hou, Y.; Yang, Y.; Zhu, H. Biopolymers derived from trees as sustainable multifunctional materials: A review. Adv. Mater. 2020, 33, 1654.

- Lars, A.B.I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 2018, 30, 1–15.

- Li, J.; Sun, Q.F. Inspirations from nature preliminary discussion of wood bionics. China Eng. Sci. 2014, 16, 4–12.

- An, C.C.; Zhang, M.; Xiao, Z.H.; Yang, Q.; Feng, L.; Li, S.; Shi, M. Lignocellulose/chitosan hybrid aerogel composited with fluorescence molecular probe for simultaneous adsorption and detection of heavy metal pollutants. J. Environ. Chem. Eng. 2023, 11, 111205.

- Tripathi, A.; Ranjanm, R. Heavy metal removal from wastewater using low cost adsorbents. J. Bioremediat. Biodegrad. 2015, 6, 315.

- Zhu, M.W.; Li, Y.J.; Chen, G.; Jiang, F.; Yang, Z.; Luo, X.; Wang, Y.; Lacey, S.D.; Dai, J.; Wang, C.; et al. Tree-inspired design for high-efficiency water extraction. Adv. Mater. 2017, 29, 1704107.

- Ahmad, A.; Rafatullah, M.; Sulaiman, O.; Ibrahim, M.H.; Chii, Y.Y.; Siddique, B.M. Removal of Cu (II) and Pb (II) ions from aqueous solutions by adsorption on sawdust of meranti wood. Desalination 2009, 247, 636–646.

- He, L.; Zhao, L.; Sun, W.; Fang, J.; Liu, X.; Qi, J.; Qian, Y.; Li, H. 3D Wood Microfilter for Fast and Efficient Removal of Heavy Metal Ions from Water. Langmuir 2023, 39, 15319–15327.

- Yang, Z.; Liu, H.; Li, J.; Yang, K.; Zhang, Z.; Chen, F.; Wang, B. High-throughput metal trap: Sulfhydryl-functionalized wood membrane stacks for rapid and highly efficient heavy metal ion removal. ACS Appl. Mater. Interfaces 2020, 12, 15002–15011.

- Guo, Q.; Qiu, Y.Q. Research progress in application of nano-silver in water treatment. Synth. Mater. Aging Appl. 2019, 48, 125–129.

- Zhang, M.; Shi, Y.; Wang, R.; Chen, K.; Zhou, N.; Yang, Q.; Shi, J. Triple-functional lignocellulose/chitosan/Ag@TiO2 nanocomposite membrane for simultaneous sterilization, oil/water emulsion separation, and organic pollutant removal. J. Environ. Chem. Eng. 2021, 9, 106728.

- Wen, J.J.; Tan, X.J.; Hu, Y.Y.; Guo, Q.; Hong, X. Filtration and electrochemical disinfection performance of PAN/PANI/AgNWs-CC composite nanofiber membrane. Environ. Sci. Technol. 2017, 51, 6395–6403.

- Huo, Z.Y.; Luo, Y.F.; Xie, X.; Feng, C.; Jiang, K.; Wang, J.; Hu, H. Carbon-nanotube sponges enabling high-efficiency and reliable cell inactivation by low-voltage electroporation. Environ. Sci. Nano 2017, 4, 2010–2017.

- Yang, Z.; Ni, H.; Liu, P.; Liu, H.; Yang, K.; Zhang, Z.; Wang, B.; Li, X.; Chen, F. Nanofibrils in 3D aligned channel arrays with synergistic effect of Ag/NPs for rapid and highly efficient electric field disinfection. Chin. Chem. Lett. 2021, 32, 3143–3148.

- Cheng, Z.; Guan, H.; Meng, J.; Wang, X. Dual-functional porous wood filter for simultaneous oil/water separation and organic pollutant removal. ACS Omega 2020, 5, 14096–14103.

- Adam, A.M.A.; Saad, H.A.; Atta, A.A.; Alsawat, M.; Hegab, M.S.; Refatm, M.S.; Altalhim, T.A.; Alosaimi, E.H.; Younes, A. Preparation and characterization of new CrFeO3-carbon composite using environmentally friendly methods to remove organic dye pollutants from aqueous solutions. Crystals 2021, 11, 960.

- Chen, F.J.; Gong, A.S.; Zhu, M.W.; Chen, G.; Lacey, S.D.; Jiang, F.; Li, Y.; Wang, Y.; Dai, J.; Yao, Y.; et al. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment. ACS Nano 2017, 11, 4275–4282.

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500.

- Guo, R.X.; Cai, X.H.; Liu, H.W.; Yang, Z.; Meng, Y.; Chen, F.; Li, Y.; Wang, B. In situ growth of metal-organic frameworks in three-dimensional aligned lumen arrays of wood for rapid and highly efficient organic pollutant removal. Environ. Sci. Technol. 2019, 53, 2705–2712.

- Sens, M.L.; Emmendoerfer, M.L.; Mueller, L.C. Water filtration through wood with helical cross-flow. Desalination Water Treat. 2015, 53, 15–26.

- Cui, Z.; Wu, J.; Xu, Y.; Wu, T.; Li, H.; Li, J.; Kang, L.; Cai, Y.; Li, J.; Tian, D. In-situ growth of polyoxometalate-based metal-organic frameworks on wood as a promising dual-function filter for effective hazardous dye and iodine capture. Chem. Eng. J. 2023, 451, 138371.

- Li, J.; Zhang, M.; Qiang, T. Research progress in modified PVDF membrane with inorganic particles for oil bearing wastewater treatment in oilfields. J. For. Environ. 2016, 36, 257–265.

- Wang, C.Y.; Wang, X.; Yu, Q. New research progress of functional wood. J. For. Eng. 2019, 4, 10–18.

- Zhao, M.; Tao, Y.; Wang, J.; He, Y. Facile preparation of superhydrophobic porous wood for continuous oil-water separation. J. Water Process Eng. 2020, 36, 101279.

- Song, J.W.; Chen, C.J.; Wang, C.W.; Kuang, Y.; Li, Y.; Jiang, F.; Li, Y.; Hitz, E.; Zhang, Y.; Liu, B.; et al. Super flexible wood. ACS Appl. Mater. Interfaces 2017, 9, 23520–23527.

- Chao, W.; Sun, X.; Li, Y.; Cao, G.; Wang, R.; Wang, C.; Ho, S. Enhanced directional seawater desalination using a structure-guided wood aerogel. ACS Appl. Mater. Interfaces 2020, 12, 22387–22397.

- Fu, Q.L.; Ansari, F.; Zhou, Q.; Berglund, L.A. Wood nanotechnology for strong, mesoporous, and hydrophobic biocomposites for selective separation of oil/water mixtures. ACS Nano 2018, 12, 2222–2230.

- Wang, K.; Liu, X.; Tan, Y.; Zhang, W.; Zhang, S.; Li, J.; Huang, A. Highly fluorinated and hierarchical HNTs/SiO2 Chemical hybrid particles for substrate-independent superamphiphobic coatings. Chem. Eng. J. 2019, 359, 626–640.

- Blanco, M.V.D.; Fscher, E.J.; Cabane, E. Underwater superoleophobic wood cross sections for efficient oil/water separation. Adv. Mater. Interfaces 2017, 4, 1700584.

- Chao, W.X.; Wang, S.B.; Li, Y.D.; Cao, G.; Zhao, Y.; Sun, X.; Wang, C.; Ho, S. Natural sponge-like wood-derived aerogel for solar-assisted adsorption and recovery of high-viscous crude oil. Chem. Eng. J. 2020, 400, 125865.