Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Zhijun Xu and Version 2 by Rita Xu.

Insufficient stability of the top plate at the corner of an easily combustible coal seam comprehensive mining face may lead to a natural fire within the goaf. While corner sealing is crucial for minimizing air leakage, current sealing methods struggle to effectively prevent such leakage. Additionally, the distribution characteristics of the oxidation zone in the goaf after sealing are unclear, making it difficult to control the extent of the oxidation zone.易燃煤层综合采掘工作面拐角处顶板稳定性不足,可能导致采空区内发生自然火灾。虽然角落密封对于最大限度地减少空气泄漏至关重要,但目前的密封方法难以有效防止此类泄漏。此外,密封后采空区氧化区的分布特征不明确,难以控制氧化区的程度。

- air leakage at the corner of the working face

- inorganic paste filling material

- filling and sealing

1. Introduction

China possesses substantial coal reserves and has traditionally relied on coal as its main energy source. The progress of the coal industry is crucial for the nation’s economic growth [1][2]. Nevertheless, the coal industry faces a range of obstacles, including water, fire, gas, and roof collapses during mining, limiting its development. Among these challenges, the spontaneous combustion of residual coal in the goaf, triggered by air leakage at the working face corners, is a major issue that impacts the safety of coal production in mines [3][4][5]. The occurrence of spontaneous combustion disasters in goaf areas is often attributed to the self-ignition of residual coal upon exposure to oxygen [6]. Through the collapse pattern of the goaf roof [7][8][9], a suspended structure forms at the corner of the working face due to the support provided by the coal wall and hydraulic supports. This region exhibits a high void ratio, designating the two corners as the primary pathways for air leakage within the goaf. Effectively addressing air leakage at the corners of the working face has consistently posed a significant challenge in mitigating spontaneous combustion and fires originating from residual coal in goaf areas [10][11]. Understanding the relationship between internal airflow and resistance within the goaf area indicates that increasing resistance can fundamentally diminish air leakage [12]. Filling and sealing the corners of the working face constitute reliable methods for enhancing resistance. Safely and efficiently sealing the pathways of air leakage at the corners of the working face to reduce air infiltration into the goaf has become a critical aspect of ensuring the secure extraction of coal in mining operations. The currently prevalent methods for corner sealing mainly consist of building cement walls and applying high-molecular-weight materials. However, these sealing techniques face problems, such as an insufficient sealing efficacy, an extensive construction effort, and high-molecular-weight materials being prone to self-ignition. In this context, the potential use of inorganic paste materials with proper fluidity, strong self-supporting properties, and appropriate strength for filling corners in the working area and sealing the main air leak passages in the goaf should be evaluated. Research into inorganic paste materials for use as coal mine filling materials was initiated by scholars in the引言

中国拥有大量的煤炭储量,传统上依赖煤炭作为其主要能源。煤炭工业的进步对国家的经济增长至关重要[1,2]。然而,煤炭行业面临着一系列障碍,包括水、火、煤气和采矿过程中的顶板坍塌,限制了其发展。在这些挑战中,由工作面拐角处的漏气引发的采空区残余煤的自燃是影响矿井煤炭生产安全的主要问题[3,4,5]。

采空区自燃灾害的发生通常归因于残余煤在暴露于氧气时自燃[6]。采空区顶板[7,8,9]的坍塌模式,由于煤壁和水力支架的支撑作用,在工作面拐角处形成了悬浮结构。该区域表现出较高的空隙率,将两个角指定为采空区内空气泄漏的主要路径。有效解决工作面角落的漏气问题一直是减轻采空区残煤引起的自燃和火灾的重大挑战[10,11]。了解采空区内部气流与阻力之间的关系表明,增加阻力可以从根本上减少空气泄漏[12]。填充和密封工作面的角落是提高阻力的可靠方法。安全有效地密封工作面角落的漏气通道,以减少空气渗入采空区,已成为确保采矿作业中安全开采煤炭的关键方面。

目前流行的边角密封方法主要包括建造水泥墙和应用高分子量材料。然而,这些密封技术面临着密封效果不足、施工工作量大、高分子量材料容易自燃等问题。在这种情况下,应评估具有适当流动性、强自支撑性能和适当强度的无机糊状材料的潜在用途,用于填充工作区的角落和密封采空区的主要漏气通道。

学者们在1950s [13][14]. Different types of inorganic filling materials, including fly ash paste, high-sand filling materials, foam cement, inorganic-cured foam materials, and ultra-high-water materials, were studied and provided a solid foundation for practical applications [15][16]. 年代开始研究用作煤矿充填材料的无机糊状材料[13\u14]。研究了粉煤灰糊状物、高砂填充材料、泡沫水泥、无机固化泡沫材料、超高水位材料等不同类型的无机填充材料,为实际应用提供了坚实的基础[15\u16]。Huang Xingli and colleagues [17] utilized inorganic foaming filling materials to seal ventilation channels in the goaf, using mobile grouting technology. This refined inorganic filling material significantly reduced the initial setting time, effectively addressing the issues of spontaneous combustion and fires in coal seams. Feng Guangming [18] developed ultra-high-water filling materials and successfully applied them to fill mining working faces, tackling the challenge of high filling costs. Liu Yong [19] conducted experiments on high-sand filling materials, using water, cement, fly ash, and wind-blown sand as inorganic filling aggregates, and determined the optimal concentration ratio suitable for water-preserving mining, significantly impacting water-preserving mining practices in western mining areas. Zhao Xuefei [20] utilized various fine-tail grains of sand as filling aggregates, examining the filling performance of cemented paste materials under different aggregates and additives, and found that substituting cement with high-alumina clay resulted in minimal changes in the compressive strength of the filling body while gradually enhancing stability in later stages. Zheng Juanrong [21] and collaborators introduced different types of early-strength agents to tailings cemented paste filling materials and discovered that 及其同事[17]利用无机发泡填充材料,使用移动灌浆技术密封采空区的通风通道。这种精制的无机填充材料大大缩短了初凝时间,有效地解决了煤层自燃和火灾问题。冯光明[18]开发了超高水位充填材料,并成功应用于采矿工作面充填,解决了充填成本高的挑战。刘勇[19]以水、水泥、粉煤灰、风吹砂为无机充填骨料,对高砂充填材料进行了试验,确定了适合保水开采的最佳浓度比,对西部矿区的保水开采实践产生了重大影响。赵雪飞[20]利用各种细尾砂粒作为填充骨料,研究了不同骨料和添加剂下胶结浆体材料的充填性能,发现用高铝粘土代替水泥后,填土抗压强度变化最小,后期稳定性逐渐增强。郑娟荣[21]及其合作者将不同类型的早强剂引入尾矿胶结膏体充填材料中,发现Na2SO所以4 and NaOH early-strength agents had superior effects. Zhang Xuebo [22] used advanced 早强剂效果优越。张学波[22]利用先进的Fluent numerical simulation software to conduct research on air leakage in the goaf. The simulation results led to the application of a custom test scheme using tracer gas 数值模拟软件对采空区漏气问题进行了研究。仿真结果导致在全机械化采掘工作面上应用示踪气SF6 on the fully mechanized mining face, revealing the air leakage patterns of the working face.

Inorganic paste filling materials have become the preferred choice for mining operations and the sealing of working faces. However, practical challenges arise when using these materials to seal corner leakage paths at working faces, mainly due to their high cost and low recovery rate. Therefore, there is a continuous need to develop new types of inorganic paste filling materials that consider the geological conditions of mines and the storage conditions of surrounding materials. The objective of this development is to provide an efficient and reliable sealing solution for corner leakage paths at working faces [23]. The sealing of corner leakage paths can significantly impact the pressure field within the goaf. The effects of filling at different corners and intervals can vary greatly, affecting ventilation patterns and gas distribution in the goaf, as well as directly influencing the cost of filling and normal mining operations at the working face [24][25][26]. Currently, the distribution characteristics of the oxidation zone in the goaf under different filled corners and intervals between two corners are not well understood, posing a challenge in establishing rational and effective corner-filling strategies for working faces.

的定制测试方案,揭示了工作面的漏气模式。

无机膏体填充材料已成为采矿作业和工作面密封的首选。然而,当使用这些材料密封工作面的角泄漏路径时,出现了实际挑战,主要是因为它们成本高,回收率低。因此,不断需要开发兼顾矿山地质条件和周围材料储存条件的新型无机膏体填充材料。这一开发的目标是为工作面的角泄漏路径提供高效可靠的密封解决方案[23]。角泄漏路径的密封会显着影响采空区内的压力场。不同角落和间隔的充填效果可能会有很大差异,影响采空区的通风模式和气体分布,并直接影响工作面的充填成本和正常采矿作业[24,25,26]。目前,采空区氧化区在不同填充角和两个角间间隔下的分布特征尚不清楚,对建立合理有效的工作面角填充策略提出了挑战。

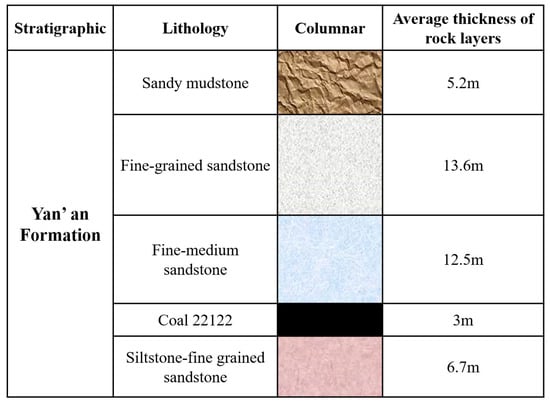

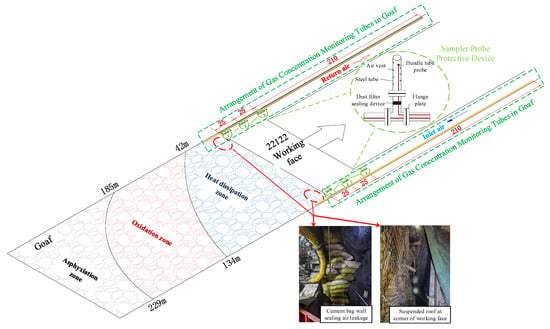

2. Mitigating Risks in Coal Mining降低煤矿开采风险

The Cuncaota 村草塔二矿位于内蒙古自治区鄂尔多斯市一金火落旗。从该矿井中提取的煤层为II Mine is located in the Yijinhuoluo Banner, Ordos City, within the Inner Mongolia Autonomous Region. The coal seams extracted from this mine are Type I, which makes them prone to spontaneous combustion. They have a significant mining height and long working faces, with relatively fewer collapses in the upper and lower triangular areas. However, there is a considerable amount of residual coal near the two roadways in the goaf, posing a significant risk of spontaneous combustion. Classified as a low-gas mine, the risk of surpassing gas pressure limits is relatively low. The main safety concern affecting mine production is the spontaneous combustion of residual coal in the goaf due to air leakage. Therefore, immediate measures are necessary to mitigate the likelihood of spontaneous combustion in the goaf and ensure the safety of mine production.型,因此容易自燃。它们具有显着的采矿高度和较长的工作面,上三角形区域的坍塌相对较少。然而,采空区两条巷道附近有相当多的残煤,存在自燃的重大风险。被归类为低瓦斯矿,超过瓦斯压力限值的风险相对较低。影响矿山生产的主要安全问题是采空区残煤因漏气而自燃。因此,必须立即采取措施,以减轻采空区自燃的可能性,并确保矿山生产的安全。 The 22,122 working face is located in the No. 1 mining area, spanning 工作面位于1号矿区,长835.5 m in length and ,宽340.9 m in width, covering a total area of ,总面积284,821.95 m2. The coal seam varies in thickness from 煤层厚度从2.14 m to 4.81 m, with an average thickness of 2.93 m. The roof of the working face consists mainly of sandy mudstone and siltstone, followed by mudstone and medium-grained sandstone, with localized occurrences of fine-grained sandstone and coarse-grained sandstone. The floor primarily consists of siltstone and fine-grained sandstone. The stratigraphic column of the working face is shown in Figure 米到4.81米不等,平均厚度为2.93米。工作面顶板主要由砂质泥岩和粉砂岩组成,其次为泥岩和中粒砂岩,局部出现细粒砂岩和粗粒砂岩。底板主要由粉砂岩和细粒砂岩组成。工作面的地层柱如图1. In the auxiliary haulage roadway of the 所示。在22,122 area, the roof consists mainly of continuous medium-grained sandstone, with good rock layer integrity and reduced susceptibility to collapse during mining operations. However, there is a significant issue of air leakage at the two corners of the working face. Currently, measures such as wind curtains and cement bag walls are primarily used to mitigate air leakage. The 22 coal seam is characterized by its overall black coloration with black-brown streaks. The primary constituents of the coal rock include dark coal, bright coal, and some occurrences of cannel coal and vitrinite. The coal exhibits an asphalt luster, featuring a uniform and banded structure, blocky texture, extensive crack development, semi-hardness, and a propensity for spontaneous combustion. The coal seam has a natural ignition period of 42 days, with flame lengths exceeding 400 mm, and the coal dust within the seam possesses explosive properties.区域的辅助运输巷道中,顶板主要由连续的中粒砂岩组成,岩层完整性好,采矿作业时坍塌的易碎性降低。然而,工作面的两个角存在严重的漏气问题。目前,风幕和水泥袋墙等措施主要用于缓解漏气。22煤层的特点是整体呈黑色,带有黑褐色条纹。煤岩的主要成分包括暗煤、亮煤以及一些煤和玻璃矿。煤呈沥青光泽,结构均匀,呈条状结构,质地块状,裂纹广泛,半硬度,易自燃。煤层的自然着火期为42天,火焰长度超过400毫米,煤层内的煤尘具有爆炸性。

Figure图 1. Stratigraphic column of the 22,122 working face.工作面的地层柱。

Figure 图2. Conditions of 22,122 working face and distribution diagram of goaf oxidation zone 3 experimental analysis of mountain sand paste filling material.

22工作面条件及采空区分布图 122 山砂浆填充材料实验分析。