TIn recent years, the ecosystem has been seriously affected by sewage discharge and oil spill accidents. A series of issues (such as the continuous pollution of the ecological environment and the imminent exhaustion of freshwater resources) are becoming more and more unmanageable, resulting in a crisis of water quality and quantity. Therefore, studies on industrial wastewater purification and solar-driven seawater desalination based on wood composites have been widely considered as an important development direction. This paper comprehensively analyzes and summarizes the applications of wood composites in the fields of solar-driven seawater desalination and polluted water purification. In particular, the present situation of industrial wastewater containing heavy metal ions, microorganisms, aromatic dyes and oil stains and related problems of solar-driven seawater desalination are comprehensively analyzed and summarized. Generally, functional nanomaterials are loaded into the wood cell wall, from which lignin and hemicellulose are selectively removed. Alternatively, functional groups are modified on the basis of the molecular structure of the wood microchannels. Due to its three-dimensional (3D) pore structure and low thermal conductivity, wood is an ideal substrate material for industrial wastewater purification and solar-driven seawater desalination. Based on the study of objective conditions such as the preparation process, modification method and selection of photothermal conversion materials, the performances of the wood composites in filtration, adsorption and seawater desalination are analyzed in detail. In addition, this work points out the problems and possible solutions in applying wood composites to industrial wastewater purification and solar-driven seawater desalination.

- wood composites

- polymers

- wastewater purification

- seawater desalination

1. Introduction

2. Application of Wood Composites in Water Purification

2.1. Adsorption of Heavy Metal Ions

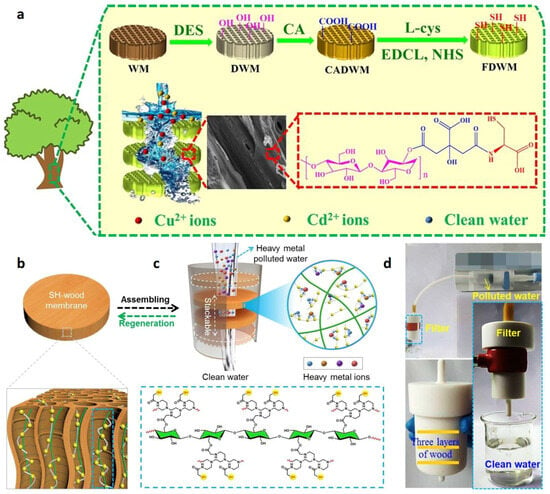

Because of their good solubility and stability, heavy metal ions in water exhibit the characteristics of high toxicity, non-degradation and biological enrichment in the ecosystem. If water containing heavy metal ions is discharged into the environment without treatment, it will cause serious harm to human health and the safety of other organisms [10][17]. Nowadays, the common methods to remove heavy metal ions from industrial wastewater include chemical precipitation, lime condensation, ion exchange, reverse osmosis and solvent extraction. However, they generally have problems such as complicated operations and high costs [11][18]. Therefore, an ideal choice is to treat heavy metal ions with adsorbents for the deep purification of water. Moreover, an adsorbent should meet the following standards: (1) low-cost and reusable; (2) effective and rapid; (3) selective and economically feasible [12][19]. The microstructure of wood contains a large number of hollow cells, which are interconnected and form interconnected channels, displaying a certain water flux. Moreover, wood is a typical multi-group ligand that can purify wastewater by adsorbing various heavy metal ions: (1) O– and COO– on the wood will react with heavy metal ions (Mn); (2) the negative polar bond in –OH, –NH, –OCH3 and –C=O in the wood will generate electrostatic attraction with heavy metal ions; (3) –OH and –COOH in the wood will exchange ions with heavy metal ions, and H will be released into the water. Sawdust is cheap and contains cellulose and lignin, which can absorb a variety of heavy metal ions. Therefore, it has a broad application prospect in the field of wastewater treatment. Ahmad et al. [13][20] ground sawdust into wood powder. Then, formaldehyde was used for the methylation reaction of wood powder to produce an adsorbent. The results show that the maximum removal rates for Cu2+ and Pb2+ are 99.39% and 94.61% when the adsorption material is in a solution with successive pH values of 7.0 and 6.6. Too high or too low a pH value will reduce the adsorption capacity of materials. This is because ion exchange and hydrogen bonding are the key to the efficiency of the removal of heavy metal ions by the adsorption material. In a water environment with a lower pH value, H competes with heavy metal cations for adsorption sites on adsorption materials. In a water environment with a higher pH value, OH− will form soluble hydroxyl complexes with heavy metal cations, and the electrostatic interaction between heavy metal cations and adsorption materials will be weakened. In order to improve the adsorption capacity, adsorption efficiency and selectivity of wood as adsorbent, other functional groups or inorganic nanomaterials can be further grafted or loaded in the wood channels. He et al. [14][21] prepared a 3D wood microfilter by modifying wood for the removal of heavy metal pollutants in wastewater. Specifically, a green deep eutectic solvent was used to remove lignin from beech wood. Then, carboxyl and sulfhydryl groups (-SH) were grafted on the surface of cellulose by sequentially using citric acid and l-cysteine. Finally, a 3D wood microfilter with an abundance of pores and adsorption sites was formed (Figure 1a). The adsorption kinetics and adsorption isotherms of heavy metal ions (Cu2+ and Cd2+) on the 3D wood microfilter were systematically investigated. The results showed that the 3D wood microfilter had a fast adsorption rate and high saturation capacity for both Cu2+ and Cd2+. Based on the advantages of easy multilayer assembly, a three-layer wood microfilter was designed to achieve the high flux rate (1.53 × 103 L·m−2·h−1) and high removal efficiency (>98%) for heavy metal ions in wastewater.

2.2. Disinfection and Sterilization

According to the statistics of the World Health Organization (WHO), approximately 1.6 million people die of diarrhea due to the lack of safe drinking water and basic sanitation facilities every year. Sterilization and disinfection of drinking water can effectively prevent diseases from being spread in water. The pore structure of wood has a natural barrier to larger colonies. After combination with antibacterial nanoparticles (NPs) (e.g., Ag NPs), a wood water filter with outstanding bacteria removal ability can be made. This is because Ag enters bacterial cells in the form of particles through endocytosis and is continuously released in the form of Ag. Specifically, Ag will cross-link or catalyze DNA molecules to form free radicals. Then, the proteins are denatured, the electron donors on DNA molecules are inhibited, and the DNA molecular chains break. In addition, Ag can combine with sulfhydryl and amino groups in cells, which will destroy the activity of cell synthetases. All the above procedures make bacteria and other microorganisms lose their ability to reproduce. When the bacteria die, Ag will be released and repeatedly perform the function of sterilization [16][17][29,30]. Electroporation sterilization technology applies a pulsed strong electric field to microorganisms and bacteria. It will destroy the cell membrane of bacteria and cause an osmotic imbalance inside and outside the cell membrane, eventually leading to the death of bacteria. There is no toxic by-product in the sterilization process. However, the high energy consumption and high risk of this technology limit its use in wastewater treatment [18][34]. Notably, researchers found that introducing 1D nanomaterials into conductive materials can solve the problems of energy consumption and safety [19][35]. Yang et al. [20][36] uniformly loaded Ag NPs into wood pores using the impregnation method, and the wood was further carbonized in a high-temperature tubular furnace. Then, Ag NP/carbonized wood membrane (3D Ag NP/WCM) composites with a three-dimensional mesoporous structure were obtained. The results show that the structure of nanofibers in carbonized wood is clearer. When a voltage is applied, the nanofibers will produce a peaking effect and greatly enhance the surrounding electric field, which can destroy the cell membrane of bacteria and lead to their inactivation. After electroporation, the damaged bacterial cells are more conducive to the invasion of Ag NPs in the carbonized wood and promote the sterilization process. The 3D Ag NP/WCM composite can be used in the condition of low voltage (4 V), low energy consumption (2 J·L−1) and high flux (3.8 × 103 L·h−1·m−2). It has a high bacteria removal rate (over 99.999%) and good stability (over 12 h). Compared with traditional electroporation sterilization technology, the wood composite not only avoids high energy consumption, but also reduces the safety risk of operation. It is a green, economical, fast, renewable and high-flux sterilization material for water treatment. Nowadays, traditional methods for sterilization are chlorination disinfection, ozone disinfection, heavy metal ion disinfection, etc. They work by decomposing the organic matter, bacteria and microorganisms in water through a hydroxide reaction or peroxidation. However, they usually have some issues such as cancer-causing by-products, high cost and difficult maintenance. Compared with these traditional sterilization and disinfection methods, wood composites have the characteristics of high efficiency, simplicity, stability, low cost, environmental protection and so on, and they are basically not affected by the surrounding temperature and pH. In addition, wood is green and rich in cellulose, hemicellulose and lignin, and it does not produce secondary pollution or toxic carcinogens. Moreover, the wood microstructure can be resistant to many species (e.g., Aspergillus Niger, E. coli, S. aureus and B. subtilis) and achieve a water flux of up to 3.8 × 103 L·h−1·m−2. Wood composites are capable of removing at least 75% or even up to 100% of bacteria from wastewater. Therefore, wood composites have considerable development prospects in the field of sterilization and disinfection.2.3. Removal of Aromatic Dyes

Printing and dyeing wastewater contains a lot of aromatic dyes, which are very difficult to remove. In addition, it also has the characteristics of dark color, high chemical oxygen demand (COD), high biological oxygen demand (BOD), complex and changeable composition, large discharge, wide distribution and difficult degradation. If the industrial wastewater is discharged without treatment, it will inevitably bring serious harm to the ecological environment due to its toxicity [21][38]. Therefore, removing these dye pollutants from water resources and wastewater is vital and important [22][39]. The natural pore structure of wood has a strong physical adsorption effect on aromatic dyes in wastewater. In addition, when the printing and dyeing wastewater flows through the pores of wood, its hydrodynamic effect is enhanced. In order to increase the time and opportunity of aromatic dye contact with active sites, functional nanomaterials or groups are loaded or grafted in the pore channels of wood. Chen et al. [23][16] synthesized Pd NPs in situ in basswood microchannels by using a hydrothermal method to prepare a Pd NP/wood membrane. Specifically, cellulose, with rich hydroxyl groups, can immobilize Pd NPs; thus, the wood changed from yellow to black at first. This is because the plasma effect produced by Pd NPs fixed on the surface of a wood microchannel absorbs a lot of light. When wastewater containing MB flowed through the wood microchannels, MB was degraded by Pd NPs. The color changed from blue to colorless, and the MB degradation efficiency was over 99.8%. The interaction between MOFs and aromatic dyes can be used to treat different aromatic dyes in wastewater [24][40]. Guo et al. [25][41] used ZrCl4, terephthalic acid and acetic acid as precursors for the in situ synthesis of UiO-66 MOF nanoparticles in three-dimensional mesoporous wood using the hydrothermal reaction method to obtain a UiO-66/wood membrane. Wood membrane filters for wastewater treatment can be obtained by changing the size and layers of this UiO-66/wood membrane according to actual needs. The results show that the flux of the filter assembled with three pieces of wood membrane is 1.0 × 103 L·m−2·h−1. The removal rates for cationic water-soluble aromatic dyes such as rhodamine 6G (Rh6G), propranolol and bisphenol A exceeded 96%, offering a rapid, multi-effect and recyclable method for removing aromatic dyes in this field. Wood has an abundance of nutrient transportation channels. However, the efficiency of the removal of high-concentration aromatic dyes by conduits in wastewater is generally low, which is the same for wood-based devices with tracheid channels [26][44]. In solvothermal conditions, Cui et al. [27][45] introduced polyoxometalate-based metal–organic frameworks (POMOFs) into natural wood (POMOF/wood) for effectively removing aromatic dyes and capturing iodine. Keggin-type POM anions with a highly negative charge were encapsulated to adjust the charge of the UiO-66 MOF, and the charge overcompensation in the POMOFs allowed them to efficiently adsorb cationic dyes. Benefiting from wood’s unique microstructure, the removal efficiencies of POMOF/wood towards MB and gentian violet (GV) (with a permeance of 1.0 × 104 L·m−2·h−1·bar−1) reach up to 94.07% and 95.23%, respectively.2.4. Oil–Water Separation

Oil pollution in wastewater mainly comes from petroleum exploitation, the chemical industry, steel factories, coking workshops, gas generating stations and other industrial departments. Its mass concentration is generally 5000~10,000 mg/L. Most of these oils float on the surface of rivers and oceans and form oil films, resulting in a lack of oxygen in water bodies. Eventually, this results in the death of a large number of aquatic organisms. When oil washes up on a beach, it will cause serious harm to the waterfowls, shrimps, crabs and other creatures on the beach [28][48]. Wood also has a good effect on oily wastewater separation; its pit structure is very beneficial to the demulsification of oil–water emulsions. In the filtration and separation of oil–water mixtures, the wettability of the solid material plays an important role and has become an accelerator in this field. The key points in preparing special wetting materials are (1) the biomimetic construction of a hierarchical micro–nanostructure on the surface of a substrate with low/high surface energy or (2) directly using low/high-surface-energy materials to biomimetically construct a hierarchical micro–nanostructure on the surface of a substrate. Superhydrophobic wood nanocomposites can be obtained by removing lignin from wood, further loading nanomaterials and then carrying out polymer backfilling and silanization treatment. Then, the expected goal for oil–water separation with high efficiency, high precision and high controllability can be achieved [23][26][29][16,44,49]. Zhao et al. [30][50] modified wood with polymethylsiloxane (POMS) to obtain superhydrophobic wood materials with a water contact angle (WCA) of 153°. POMS-modified wood has good oil absorption and oil–water separation performances. However, the accurate filtration efficiency and reusability of POMS-modified wood still need further discussion. Aside from cellulose, which is rich in hydroxyl groups, lignin and hemicellulose also exist in wood. They also contain -NH2 and -OH groups, resulting in the good hydrophilicity of wood. When wood is soaked in water, a hydrophilic and oil-repellent water film is formed on its surface. When an oil–water mixture is dripped on a wood surface, the water permeates into the wood, while the oil is excluded, showing a good superoleophobicity underwater. After selective removal of hemicellulose and lignin, the basic framework of cellulose with hierarchical high porosity and low density can be prepared easily [31][32][53,54]. Fu et al. [33][55] used a NaClO2 solution to remove the lignin of balsa wood. After freeze-drying, a porous delignified wood template with high hydrophilic and oleophobic properties was obtained. Then, it was impregnated with epoxy resin/amine/acetone solution. After curing, a hydrophobic and oleophilic wood composite with a unique pore structure was prepared. The product shows an outstanding compression strength (263 MPa) and oil absorption effect (15 g/g), and it can absorb oil pollution on and under the surface of water at the same time. Wang et al. [34][56] coated one side of delignified wood with a dodecyl mercaptan solution. After ultraviolet radiation induction, a Janus wood membrane with asymmetric wetting properties and unidirectional water transmission was prepared, and it was suitable for selectively separating the mixtures of light oil/water and heavy oil/water (the separation efficiency was higher than 99.3%). Blanco et al. [35][57] directly used spruce (thickness: 1 mm) for oil–water separation. Under gravity, its flux (3500 L·m−2·h−1) and efficiency (>99%) for separating oil–water mixtures were investigated. After the loading of Ag NPs in wood, superhydrophilic and underwater superoleophobic wood nanocomposites were prepared, the surface hydrophilicity of which could be further improved. After in situ auxiliary modification of photothermal materials (graphene) and transparent hydrophobic materials on delignified and hemicellulose wood, Chao et al. [36][58] prepared a compressible and resilient photothermal wood aerogel.3. Summary and Prospects

Wood has a unique natural pore structure and low thermal conductivity. In addition, it has wide sources, large volume, light weight, good toughness, impact resistance, good biocompatibility, reproducibility and biodegradability. These characteristics lay a solid foundation for its application in water pollution purification and solar-driven seawater desalination. The modification of wood is very beneficial for the full contact and interaction of heavy metal ions, aromatic dyes and bacteria with functional groups and nanomaterials in wood nano/micropores. Apparently, such modified wood composites with a high flux and large adsorption capacity are very suitable for industrial wastewater purification. In addition, wood composites combined with precious metals, semiconductors, polymers and carbon nanomaterials and directly carbonized wood exhibit a unique 3D pore structure, low thermal conductivity, good transpiration characteristics, etc. These merits greatly improve the solar-driven seawater desalination rate and efficiency of wood composites.

3.1. Existing Issues

Wood composites are used as photothermal evaporators, filter membranes and adsorbents in the field of water treatment. Many efforts and great breakthroughs have been made in the purification of industrial wastewater containing heavy metal ions, bacteria, aromatic dyes, oil stains, etc. Meanwhile, the catalytic and photothermal properties of nanomaterials and the low thermal conductivity and unique pore structure of wood allow wood composite evaporators to better utilize the full spectrum of sunlight. These outstanding performances accelerate the development of wood composite evaporators in solar-driven seawater desalination. However, there are still many challenges on the road to commercialization; these challenges are listed as follows:

- The types of pollutants in actual industrial wastewater are complex. In most reported works, the types of pollutants treated by wood composites are relatively single. The influencing factors and changing rules of industrial wastewater treatment are not investigated deeply enough, and the application scope is still limited.

- There are many kinds of woods. Therefore, their pore structures and chemical compositions are quite different. This means that the controllability is relatively low (e.g., uneven distribution of functional groups and nanomaterials and insufficient stability) in the modification of wood (cell walls).

- As effective photothermal materials, carbon nanomaterials generally have a high cost, low hydrophilicity, complex production process, etc. These drawbacks cause the uneconomical and poor binding between biomass matrices and carbon nanomaterials.

3.2. Further Research

Wood composites with excellent performances in the fields of industrial wastewater purification and solar-driven seawater desalination should be further studied in the following aspects:

- Multi-directional improvements and multifunctionalization of wood should be enhanced. The 3D nano/micropore structure of wood (conduits or tracheids along the direction of wood growth and wood rays, pits and nanoholes perpendicular to the direction of wood growth) should be made full use of. With reasonable and optimized structure design, suitable nanomaterial loading and functional group modifications on cell walls and surfaces, wood can be endowed with greater value and more functions. This can greatly enrich the types of pollutant treatments and improve the evaporation performance of wood composites with more flexibility in applied environments in wastewater purification and seawater desalination.

- Aside from exploring more effective technologies, more simple, feasible and green technical methods should be studied scientifically for fabricating wood composites. The movement path of fluid in wood microchannels should be explored in greater depth. In addition, the effects of hemicellulose/lignin removal technologies and drying methods on wood’s porous structure and its drying shrinkage anisotropy should be studied in depth. The relationship between the hemicellulose and lignin removal and the variation in wood’s porous structure should be investigated carefully. The purpose is to optimize the structure of wood with the appropriate technologies, which should be simple and controllable, green and feasible, low in energy and consumption, and suitable for large-scale production.

- The inherent physical and chemical properties of wood have great advantages in the field of polluted water purification and solar-driven seawater desalination, which has built a solid foundation for large-scale and commercial applications. However, research on the application of wood composites in this field is still in the exploratory stage. There is an urgent need to systematically evaluate the multifunctional performance of different woods. The accumulation of data on the practical application and economic effectiveness of wood composites should be enhanced, and a complete development system of wood composites in wastewater purification and seawater desalination should be established.

- The advantages and disadvantages of photothermal materials and loading nanomaterials or functional groups should be carefully studied and reasonably combined. The wetting and photothermal properties of a wood composite interface have a great influence on its evaporation performance under solar irradiation. Considering the respective advantages of any raw materials, the development strategy of functional and robust wood composites should be updated and optimized. Wood-based filters and evaporators with low cost, good recombination, high water flux, high photothermal rate, low light reflection, good catalysis, long service life, and simple and feasible characteristics should be prepared more controllably. In addition, it is of great significance to develop wood composites with stimulation response to improve their selectivity and intelligence.

- Although the evaporation efficiency of wood composites is high, their solar evaporation is affected by the steam pressure in the limited space. The evaporation result is not ideal in actual seawater desalination applications. Compared with a traditional solar distiller with volume heating, the freshwater productivity of functional wood composites has been improved. However, the service life of wood composites will be reduced in a complex ecological environment with high humidity and high salinity. A similar situation also occurs in the wastewater purification of wood composites. Therefore, future research should not only focus on increasing fresh and clean water production, but also pay more attention to improving wood durability (such as salt resistance, acid and alkali resistance, oil resistance and bacteriostasis).

In summary, there are still many challenges in the fields of industrial wastewater purification and solar-driven seawater desalination. The use of wood composites gives full play to the advantages of renewable resource utilization and effectively solves a series of problems such as the continuous pollution of the ecological environment and the imminent exhaustion of freshwater resources, thus being able to avoid the crisis of water quality and quantity. In addition, it is also a green and sustainable method that provides fresh and clean water for residents’ production and life. Therefore, this review provides a favorable solution for the water shortage issue in remote areas and offers a new idea for alleviating energy consumption and environmental pollution.