Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Sirius Huang and Version 1 by Igor Shufrin.

Modern economic, social and environmental challenges require a new type of construction that ensures resilience, low construction costs and ease of maintenance. Material production, manufacturing of structural elements and final assembly should minimise the environmental impacts, such as greenhouse emissions and waste production.

- construction innovation

- sustainable building

- modular construction

- mortarless construction

- environmental impact

1. Introduction

The construction industry is rapidly evolving with continuously growing project complexity and speeding up demands. Modern economic, social and environmental challenges require a new type of construction that ensures resilience, low construction costs and ease of maintenance. Material production, off-site prefabrication of structural elements and final assembly should minimise the environmental impacts, such as greenhouse emissions, waste production and, where possible, utilise/recycle the waste. In order to satisfy these requirements, new building material and new construction, monitoring and planning methods are needed.

2. Modern Challenges of Construction

The main challenges the construction industry faces today are as follows [1]:- -

-

Reduction in environmental impact through reduction in CO2 production, use of renewable materials and recycling [2,3][2][3];

- -

-

Energy efficiency of buildings through improved thermal insulation and energy retrofit [4,5][4][5];

- -

-

Reduction in labour costs and improvement of workplace productivity through automation of construction [6] and reduction in safety risks [7,8][7][8];

- -

-

Building sustainability—enhanced resilience and improved structural longevity [9];

- -

-

Minimising the demolition waste and waste utilisation as a step towards achieving circular economy (e.g., [10,11][10][11]).

3. Current Strategies

3.1. Targeting the Environmental Impacts

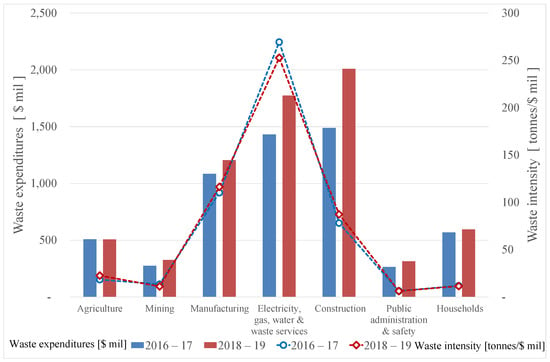

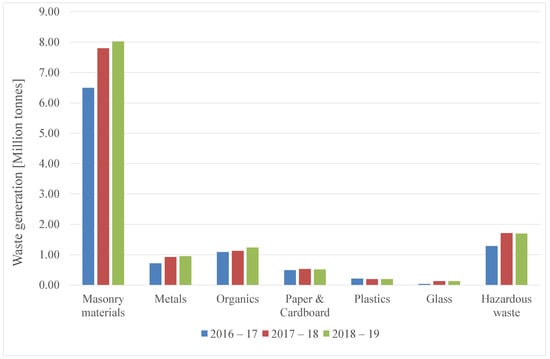

Construction activities make significant impacts on the environment. These impacts are ranging from the direct impacts relating to a use of land and energy and production of waste and greenhouse gas emission to the indirect impacts of building maintenance and a use of transport and urbanisation [12]. Manufacturing of construction materials contributes towards the environmental impacts of construction the most. For instance, in the 2010–2020 decade, every year, Australia produced on average 25,000,000 m3 of pre-mixed concrete, 9 million tons of cement, 1300 million clay bricks, 2 million tons of concrete bricks, blocks and pavers and 13 million roofing tiles [13,14,15][13][14][15]. The level of impact of the material production is greatly dependent on the source of raw materials and the way they are processed. The material life span, life cycle energy consumption of all components, recycling potential and transportation aspects are among the factors influencing the environmental impact of construction materials. Continuous growth in the number and size of buildings [14] leads to the increase in the use of land, changes in the surface conditions and pollution of water resources. Energy consumption at the construction stage and throughout the whole lifespan of the buildings is also increasing with the rise in the number of buildings. This accelerates the depletion of non-renewable energy resources and intensifies the emission of greenhouse gases [3]. Another consequence of growing construction activity is the production of waste. During the last decade, Australians generated over one ton of solid waste per person per year. In the 2018–2019 financial year, the construction activities were responsible for 16.8% of the total waste. The construction industry expenditures on the waste services increased by 35% since the 2016–2017 period and reached AUD 2 billion [16]. The waste intensity, an indicator that quantifies the amount of waste generated per million dollars of added value, also increased within construction during this period (see Figure 1).The main types of the waste the construction discarded are soil rubble, concrete-based masonry and clay-based masonry (Figure 2) [16]. These data show that over 90% of the waste generated by the Australian construction industry accounts for the masonry waste. It is also seen that the generation of masonry, metal and organic wastes is growing, while the amount of paper, plastics and glass wastes, which in general are deemed recyclable, does not change. The second most prevalent waste is the hazardous waste, which is particularly alarming as some types of the construction waste can be detrimental to the environment, for example, gypsum disposed of in landfill creates poisons (hydrogen sulphide) [12]. Figure 1. Expenditure on waste collection, treatment and disposal services (waste services) and waste intensity by industry in Australia in 2016–2017 and 2018–2019 financial years [16].

Figure 1. Expenditure on waste collection, treatment and disposal services (waste services) and waste intensity by industry in Australia in 2016–2017 and 2018–2019 financial years [16]. Figure 2. Generation of waste materials by Australian construction industry in 2016–2017 to 2018–2019 financial years. Hazardous waste includes tyres [16].

Figure 2. Generation of waste materials by Australian construction industry in 2016–2017 to 2018–2019 financial years. Hazardous waste includes tyres [16].3.1.1. Assessment of the Environmental Impacts

The environmental impacts of construction are commonly assessed using the Life Cycle Assessment methods (LCA) and Material Flow Analysis (MFA) by the levels of the embodied energy and CO2 and other greenhouse gas emission [17]. LCA is the most popular tool used to estimate the environmental impacts of construction at different levels ranging from assessment of construction materials and building components [18,19,20,21,22][18][19][20][21][22] to whole buildings and infrastructure systems [23,24][23][24]. LCA is able to assist with selection of building materials, environmental assessment of building products and choice of contractors. On the other hand, there are a number of challenges in building LCA, e.g., the common LCA procedures require weightings to obtain a single score, which demands expertise and leads to a subjective judgement. The specification of service life for building LCA still remains a challenge. In particular, the Australian construction industry has a need of simplified methods of assessment that will combine LCA with LCC (life cycle costing) [25]. A Material Flow Analysis (MFA) is a procedure evaluating the flow and stocks of materials within the system, which is based on the law of conservation of mass [26,27][26][27]. MFA is used to evaluate the balance of inputs (construction materials, energy), outputs (gas emission, solid waste, sewage, etc.) and stocks—the materials and products that remain in place such as buildings and long-life structures. In construction, the MFA is applied at the different scales ranging from a single building to an entire city and can be used both as an independent analysis or as a part of LCA. Recent MFA studies show that the addition of building stocks through urbanized areas is significant. The considerable amount of materials are stocked in buildings and infrastructure, for example, in Japan, this level was over 69% by 2010 [27]. The MFA research also demonstrated that the material intensity and emission intensity are the main factors defining the construction environmental impacts [28]. Historically, the energy consumption during the exploitation of buildings and other civil engineering structures was responsible for the major emissions of CO2 and other greenhouse gases (GHGs) associated with the construction activity [29]. Nowadays, the construction stage of modern zero-emission buildings with improved energy efficiency may produce more than 60% of total GHG emissions over building lifetime. This requires the full assessment of embodied GHG emissions during the production, construction, operation and decommission stages of the life cycle of buildings [29,30,31][29][30][31]. The environmental impacts at the decommission phase are critical for the efficient recycling and reuse of materials and waste disposal. Applying the principle of resource recovery for the construction waste at all stages can significantly save initial resources [32].3.1.2. What Are the Greatest Environmental Impacts?

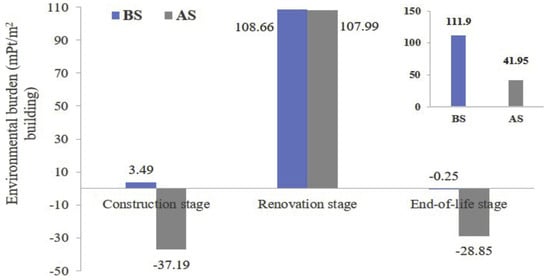

The material embodied energy and emissions constitute the greatest environmental impact of construction [25,33,34][25][33][34]. The material efficiency strategies that would lead to a reduction in the material environmental impacts include improved utilization of materials through more efficient design of buildings and structures and optimization of material selection, extension of service life through repairs, remanufacturing and recycling and improved yield in production and waste processing. The optimal strategy must take into consideration the whole span of building lifetime. The improvement in the energy efficiency implies trade-offs between the material utilization and energy efficiency of a building, such as better thermal insulation, smart ventilation systems or more windows with an additional glass pane, that incur the increase in the embodied energy and greenhouse gas emission during the construction stage [34,35,36][34][35][36]. Several studies were dedicated to the evaluation of environmental impacts of different construction materials. Heeren and Hellweg (2019) used dynamic MFA combined with a geospatial data analysis to investigate the environmental impacts of construction materials. Their findings identify a significant increase in the use of thermal insulation materials and their environmental impacts. In particular, the disposal and recycling of insulation foams and polymers are problematic due to the presence of flame retardants [15,33,37][15][33][37]. The embodied emission in five main structural systems, namely brick masonry, hollow block masonry, reinforced masonry, a reinforced concrete frame and reinforced concrete walls, was compared in [38]. It was demonstrated that the hollow block masonry generates the lowest emission levels, while the reinforced concrete walls generate the highest. Robati et al. adapted the principles of Value Engineering to evaluate the pathways for simultaneous optimization of capital costs and embodied carbon in multistorey buildings. They showed that a choice of the building structural system is the most critical factor for the reduction in embodied carbon and cost. A shift from a reinforced concrete building to post-tensioned concrete structures reduces the embodied carbon levels by 8%, while the use of a full timber structure returns up to 26% of reduction [39]. A comprehensive literature review of the studies dealing with assessment of the environmental impacts of building was published by the authors of [30]. This paper presented a comparative LCA study on the embodied energy and carbon of construction materials and structural systems. It demonstrated the superiority of timber structures over concrete and steel ones in terms of the embodied carbon as well. In terms of the embodied energy, however, concrete structures require less energy to build than timber or steel structures. Similar conclusions were drawn in [40], which surveyed the studies on the embodied carbon assessment of buildings published between 2000 and 2020. They processed and normalised the cradle-to-gate results obtained for 131 cases of different building structures and showed that on average the embodied carbon levels vary between 281 kgCO2e/m2 for timber and 320 kgCO2e/m2 for masonry buildings to 435 kgCO2e/m2 for steel and 443 kgCO2e/m2 for concretes ones. A state-of-the-art review on utilization of low-carbon concretes was given in [3]. This paper analysed various methods for the reduction in embodied carbon (EC) in concrete materials proposed during the past two decades and identified that adoption of alternative cementitious binders, such as fly ash and ground blast-furnace slag, can reduce the EC levels by 64.9% on average. It was also concluded that the use of recycled concrete aggregates and high-strength concretes does not always lead to the reduction in the EC levels in concretes. Reusing the building materials is still a challenge. Building materials are disposed at the end of their life; subsequently, significant environmental impacts occur at the end-of-life stage through generation of waste [11,41,42][11][41][42]. At the same time, recovery of materials at various construction stages and associated waste management may reduce the environmental burden. As demonstrated in [32], the recovery of secondary materials at the construction and end-of-life stages reduces the environmental impacts, while the renovation works that include material replacement would increase the impact indicators (see Figure 3). It was also shown that on-site sorting of construction waste with further reuse reduces up to 63% of total environmental impacts. Figure 3. Comparison of construction environmental burden at various building life stages and waste management scenarios: Base Scenario (BS)—construction waste is sorted off-site for all building life stages, Alternative Scenario (AS)—construction waste is sorted on-site during construction and renovation stages, while demolition waste management combines the on- and off-site sorting [32].

Figure 3. Comparison of construction environmental burden at various building life stages and waste management scenarios: Base Scenario (BS)—construction waste is sorted off-site for all building life stages, Alternative Scenario (AS)—construction waste is sorted on-site during construction and renovation stages, while demolition waste management combines the on- and off-site sorting [32].3.1.3. Strategies for Reduction in the Environmental Impacts

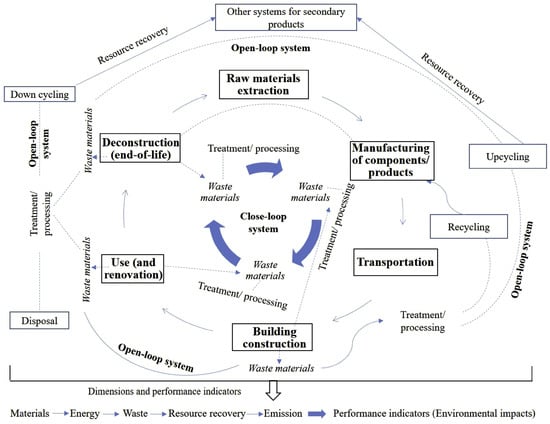

The circular economy (CE) approach makes it possible to reduce the use of primary materials and the associated environmental impacts [19,42,43,44,45][19][42][43][44][45]. The CE approach capitalizes on recycling of materials and utilization of byproducts [46]. The CE turns the wastes into a source of raw materials and includes them into a continuous life cycle [11,43,47][11][43][47]. The CE framework for a building life cycle is illustrated in Figure 4. It involves managing waste materials at various building stages through closed-loop and open-loop systems. The closed-loop systems are implemented for recycling and reusing materials within the building process, while the open-loop systems involve utilizing recycled materials from external sources.In line with the CE principles, the reduction in GHG emission can be achieved by material recycling and upcycling, which calls for the design of buildings that include the solutions for the disassembly of materials [29,48][29][48]. A recent review on Australian research into the CE in construction demonstrated that the design and planning are the most important stages for efficient waste utilisation and recycling [49]. Design out of waste, for reverse logistics and for disassembly; standardised and front-end engineering designs; and enhanced longevity are among the highlighted strategies that lead to the reduction in the waste. Most of these concepts also apply at the manufacturing stage that calls for reuse of structures and adoption of recycled materials [49]. Prefabrication and standardisation of modular elements present another avenue for reduction in the environmental impacts in construction [50,51][50][51]. An increase in the building lifetime reduces the embodied material GHG emissions as well; however, this prolonged building life will require additional rounds of renovations and maintenance [29]. The optimal solution would require improving the building resilience. During the last two decades, many research efforts have been dedicated to utilisation of landfill wastes and byproducts from other industrial activities, e.g., oil and gas processing, mining and metallurgy. Supplementary cementitious materials, such as fly ash, ground furnace, steel slug and rice husk were proposed to be used in combination with or instead of Portland cement [45,52,53,54][45][52][53][54]. Ceramics from construction and mining waste, e.g., glass powder, brick and tile ceramics, kaolin and clay tailings, were investigated as a replacement for fine and coarse aggregates in concretes [45,55,56][45][55][56]. Aggregates from plastic and polymeric wastes present opportunities for lightweight concretes [45,54,55][45][54][55]. Applications of the end-of-life tyres in pavements and concretes became a subject of intensive research [55,57,58,59,60,61][55][57][58][59][60][61]. Concrete with rubber particles recycled from end-of-life tyres was dubbed rubberised concrete. These rubber particles generally degrade physical and mechanical properties of concrete, yet the opportunity to utilise the large amount of waste tyres is too appealing and thus has to be considered.

3.2. Improving Energy Efficiency

Globally, buildings are responsible for nearly a half of energy consumption. The total life cycle energy of buildings consists of the embodied and operational energy. Targeting the zero net GHG emission requires optimizing both types of the energy consumption [5,62,63][5][62][63].3.2.1. Energy Consumption at Various Life Cycle Stages and Its Assessment

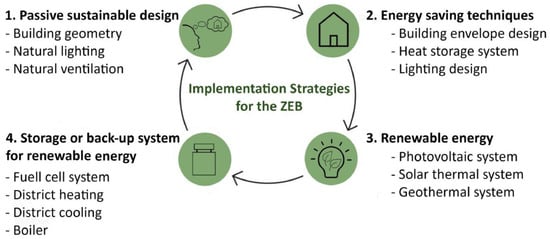

The current construction practice consumes 10–20% of total energy as the embodied energy and 80–90% as the operational part [63,64][63][64]. The embodied energy constitutes the total energy consumed throughout the building process including the acquisition of raw materials, off- and on-site manufacturing, transportation and equipment. This part is also referred to as the initial embodied energy [63]. The operational energy is the energy embodied in the building services, maintenance and repairs; it is also referred to as recurrent embodied energy. Since the operational energy constitutes a major part of energy consumption, the majority of research efforts so far have been focusing on reducing this part of energy consumption. At the same time, due to the recent advances in the construction materials and energy-efficient building envelopes capable of reducing the operational energy, the focus on the reduction in the embodied energy is becoming more significant and receiving more attention [62,63,65][62][63][65]. This section is focusing on the building energy assessment methods and strategies for operational energy savings. The assessment of the total energy life cycle is usually conducted using either the Process-based, the Input–Output (IO)-based or the Hybrid methods; each of these methods has different limitations. The Process-based analysis considers the specific processes involved in the production. The energy inputs are estimated based on the manufacturing data for materials and components directly or indirectly used for the construction. These calculations are often incomplete due to the lack of data or omission of some processes not directly associated with the production. The Input–Output analysis aggregates the national data and uses the energy intensities associated with the appropriate construction sector. The Hybrid methods are based on the process analysis and take into account the national data for the completeness of the assessment. Several variations of these methods have been recently developed. It is commonly believed that the hybridization of Process and IO databases is the prospective direction for the accurate assessment of the total building energy [62,63,66,67,68][62][63][66][67][68]. Due to the limitations of the assessment methods, the assessment of the operating energy part is easier and more accurate, while the review of the methods for the embodied energy calculation revealed high inconsistency in the results [63]. The operating energy consists of direct consumption by building services and indirect inputs associated with maintenance and repairs. The maintenance and repairs are conducted periodically (preventive maintenance) or condition-based when the repairs are scheduled as a result of a fault or near fault state [63]. The indirect operating energy savings are achieved by implementing advanced monitoring systems [69]. Buildings often undergo the replacement of its systems due to changes in technology. For example, the existing windows, lighting features and HVAC systems can be replaced with novel and more energy-efficient options. The strategies for the direct operating energy savings pertain to a relatively new concept of zero-energy buildings, which was introduced in the early 2000s [70,71][70][71]. The zero-energy building goal can be achieved through two means: by reducing the energy demand of a building and by recovery of some consumed energy by using the renewable energy sources (see Figure 5). The active strategies to achieve this balance include utilization of renewable energy systems and integration of an energy storage solution. The passive approaches for the reduction in the building energy consumption in new buildings include the energy optimisation of building architecture, the enhancement of building envelopes and effective management of building services (water, HVAC, lighting, etc.) [5,70,72,73,74][5][70][72][73][74].

3.2.2. Existing Approaches for Energy Saving

Building Envelopes

The most direct approach to energy saving is to improve the building envelope—a system of structural and non-structural elements that separates the building from the outside environment to provide better thermal isolation. Examples of the methods realising the direct approach include increasing thermal mass of the walls, development and application of hybrid materials ensuring low thermal conductivity, use of heat insulation glasses, development of smart walls, etc. The conventional insulation foams, mineral and sheep wool, gypsum, natural fibres and their combinations are replaced by new thermal building insulation, such as closed-cell foam, vacuum insulation panels, gas-filled panels, aerogels and phase-change materials (PCMs) [75]. Composite materials are extensively used to enhance the thermal insulation. The basic types of composites used are polymer-based, metal-based and ceramic-based composites with various types of filler fibres. Many commercially available insulation materials make use of the natural fillers, such as jute, hemp, rise husk, etc. [76]. The thermal conductivity of the insulation material mainly depends upon the density and microstructure of the composite. However, the operational environment can considerably alter its performance. High operational temperature and moisture content considerably increase the thermal conductivity (lowers the thermal insulation). Other factors that influence the insulation ability of materials include ambient pressure, air-surface velocity and aging. The fibrous and foam materials exhibit lower thermal conductivity under lower pressure. This property is utilised in the vacuum insulation panels, in which a low vacuum pressure at the panel core reduces its thermal conductivity and boosts the effective insulation. Higher rates of air movement enhance heat transfer and worsen the insulation performance. Mechanical and thermal properties of materials deteriorate over their life. The air infusion in foams is particularly harmful for the thermal insulations as it increases the moisture absorption [77]. The main difficulty in designing composites for thermal insulation is the trade-off between the good mechanical properties and low thermal conductivity.Adaptive Building Insulation

Changes in external conditions during a day and throughout a year cause the change in the comfort demands of building users, which in turn calls for a building envelope capable to respond to these changing conditions. Recent research works demonstrated that such a dynamic active insulation would be able to reduce the energy consumption by up to 40% in comparison to the conventional (static) one [78]. As proposed in the literature, adaptive building envelopes can be divided into passive systems that use the natural power sources, active systems that require external power supply and hybrid systems that require a certain level of automation to alternate between the suppression of heat flux in the insulation regime to the enhancement of heat transfer in the conductive regime [78,79,80,81,82][78][79][80][81][82]. Another approach is the use of smart materials, for instance, phase changing materials (PCMs) offering the smart controls of building thermal insulation. PCMs are the latent heat storage materials that allow absorption of the excess energy in buildings and reduce the internal temperature fluctuations [83,84,85][83][84][85]. At the same time, the embodied environmental impacts of PCM are higher than the conventional isolation materials. The additional embodied energy is accrued at the construction and operation stages as the PCM and\or its containers require regular replacements [21]. Recent reviews on the application of PCM to building insulation were presented in [21,86][21][86]. The consideration of regional climate conditions is essential for the selection of the building envelope and optimisation of the dynamic active isolation. A review on the climate adaptive façade systems can be found in [87,88][87][88].Architectural and Design Solutions

Another approach to the energy savings is to reduce the space heating and cooling energy through the appropriate architectural and design solutions. The concepts of bioclimatic, solar and sustainable bioclimatic architecture that aim at human comfort with optimised energy consumption have become common in building design [89,90][89][90]. Conceptually, bioclimatic architecture aims to maximise the use of passive strategies, in particular, passive heating and cooling. These methods involve optimisation of heat dissipation and exclusion for the passive cooling and heat retention and admission for the passive heating [91]. Bioclimatic design includes considerations of (1) the building orientation with respect to sun angles and wind directions, (2) the building layout accounting for space zoning, (3) the shape of the building or “building massing”, (4) thermal mass and thermal isolation, (5) solar gains, shading and glazing, (6) natural ventilation and (7) various forms of heat exchange [91]. The integration of the energy design into the structural design stage provides additional pathways for energy savings. The advantages of such a simultaneous approach over the design methods, which are based on the predefined specification of the thermal mass, thermal insulation and window-to-floor ratio, were demonstrated in [92]. Special considerations are to be given to the energy design of high-rise buildings, where heating and cooling loads depend on the building height and its use. The contribution of the heating energy towards the total energy in residential skyscrapers substantially increases with the increase in the height of the building, which calls for revaluation of current practices of wall design in high-rise buildings [93,94][93][94].Nature-Based Solutions for Energy Saving

The rising recognition of nature-based solutions for energy saving in recent decades has led to development of green façades. The green façade is a type of vertical green system, which consists of climbing plants grown against or on support structures attached to external building walls. Green façades contribute to cooling indoor spaces by providing shade and reducing the impact of direct sunlight on building surfaces. By acting as a natural insulator, green façades reduce the heating and cooling loads. Beyond their functional benefits, the green façades contribute to biophilic design philosophy of connecting people with nature and enhance the visual appeal of buildings and urban landscapes [70,95,96,97][70][95][96][97]. Vertical green systems are commonly classified into green façades and living walls. In green facades, climbing plants are rooted in the ground and directly supported by the building structure, while living walls use modular panels consisting of the plants, growing medium and irrigation system [95,98][95][98]. Convection, conduction, radiation and evapotranspiration are the means of energy flow in vertical green façades. The performance of vertical green systems is defined by their impact on the building heat transfer. The design parameters of green façades are interdependent as the leaf area and composition of the greenery are related to types of plants used. The living requirements of the plants will dictate design of a support structure and a type of irrigation. Any deterioration in plant conditions or growing condition will affect the energy efficiency of the whole building [99,100][99][100]. The main advantages of vertical green systems can be summarised as follows:- -

-

Green façades demonstrated capacity to reduce the temperature of externals walls by 3.5 °C on average during hot periods and increase the temperature by an average of 2.8 °C during cold periods [99];

- -

-

Green façades exhibited ability to reduce an annual HVAC energy use by up to 20% [99];

- -

-

Green façades demonstrated stable thermal performance in extreme weather conditions [100];

- -

-

Green façades showed better cooling performance on a building façade subjected to the solar radiation at the highest and steepest angles [100].

Energy Retrofit

Energy retrofit of existing buildings primarily targets the energy efficiency through savings in the energy demands. The energy retrofit is able to reduce the total energy for the remaining life cycle up to 80% [68,102][68][102]. The retrofit of existing buildings causes less environmental impacts than new constructions, while the building refurbishment extends its lifetime, improves the intensity of use and reduces the environmental impacts [35,68,103,104][35][68][103][104]. The retrofit strategies, however, should also account for the shifts towards more sustainable energy sources that will become relevant in the long-term scenarios. The balance between the additional impacts from retrofitting materials and the operational energy savings will change in the future upon implementation of energy sources with a lesser environmental footprint. The energy retrofit of existing buildings should include upgrades of Heating, Ventilation and Air Conditioning (HVAC) systems and electricity and heat means [35].3.3. Enhancing Resilience

The concept of civil engineering system resilience is commonly applied to the design of earthquake- and blast-resistance structures [9,105,106,107,108][9][105][106][107][108]. The resilience is defined as the ability of a structure to moderate the effects of extreme loads, to contain failures and to minimise the time to restore functionality. This definition applies to multiple scales, ranging from a single structure or structural component to building networks and entire communities.Design Strategies for Resilience

The essential features of a resilient building system are as follows: (1) it is a robust structural system that limits failure propagation during the extreme loading events; (2) it possesses a redundancy of structural components that allows for a redistribution of the bearing capacity in the event of degradation; and (3) it has rapidity as an ability to adapt to rapidly changing conditions and to quickly recover functionality [105,107,109][105][107][109]. These general features have been considered in various research studies on earthquake- and blast-resilient structures. The elevated seismic resilience is achieved by introducing the base isolation at the ground level [109] with supplemental damping [110]. The latter is achieved by incorporating special joint connections that adequately dissipate energy [111[111][112][113][114][115],112,113,114,115], shear links that were designed to localise the damage [116] and self-centred connections that effectively recover the shape of the joint [117,118,119,120][117][118][119][120]. In general, blast-resistant design procedures adopt the traditional seismic-resistant ductile design approach [121]. However, research into resilience demonstrated that the functionality factor of resilience in ductile structures is below the acceptable limits since repairing and restoring these structures after damage are unfeasible [122]. Moreover, the current blast-resistant design standards do not include provisions for discontinuous (rocking) connections [123]. Since the explosive loads are typically 1000 times faster than earthquake-induced loads, the energy dissipation concepts used in seismic-resistant structures cannot be directly applied to the blast resilience design. Moreover, evaluations of the response of earthquake-resistant buildings subjected to blast loading showed that, for higher explosive charges and closer stand-off distances (i.e., the distance between the explosion and the structure), the seismic design alone may not provide a sufficient level of resilience [124,125][124][125]. The existing approaches to the design of blast- and seismic-resilient structures can be summarised as follows: a resilient structural system should be designed to (1) incorporate a nonlinear deformation mechanism that features modest strength and discontinuities to provide a sufficient level of energy dissipation; (2) incorporate durable or easily replaceable energy dissipation devices that reduce forces and displacements in structural and non-structural elements, which are not associated with the nonlinear deformation mechanism; (3) exhibit self-centring performance that reduces the lateral and vertical displacements of the structure; and (4) be able to localise damage or provide an alternative load path to prevent progressive structural collapse.

References

- Hampson, K.; Bfandon, P. Construction 2020—A Vision for Australia’s Property and Construction Industry; CRC Construction Innovation: Brisbane, Australia, 2004.

- Chen, L.; Chan, A.P.C.; Owusu, E.K.; Darko, A.; Gao, X. Critical success factors for green building promotion: A systematic review and meta-analysis. Build. Environ. 2022, 207, 108452.

- Chen, S.; Teng, Y.; Zhang, Y.; Leung, C.K.Y.; Pan, W. Reducing embodied carbon in concrete materials: A state-of-the-art review. Resour. Conserv. Recycl. 2023, 188, 106653.

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86.

- Satola, D.; Wiberg, A.H.; Singh, M.; Babu, S.; James, B.; Dixit, M.; Sharston, R.; Grynberg, Y.; Gustavsen, A. Comparative review of international approaches to net-zero buildings: Knowledge-sharing initiative to develop design strategies for greenhouse gas emissions reduction. Energy Sustain. Dev. 2022, 71, 291–306.

- Xiao, B.; Chen, C.; Yin, X. Recent advancements of robotics in construction. Autom. Constr. 2022, 144, 104591.

- Xu, M.; Nie, X.; Li, H.; Cheng, J.C.P.; Mei, Z. Smart construction sites: A promising approach to improving on-site HSE management performance. J. Build. Eng. 2022, 49, 104007.

- Zielinski Nguyen Ajslev, J.; Elisabeth Ejstrup Nimb, I. Virtual design and construction for occupational safety and health purposes—A review on current gaps and directions for research and practice. Saf. Sci. 2022, 155, 105876.

- Menna, C.; Felicioni, L.; Negro, P.; Lupíšek, A.; Romano, E.; Prota, A.; Hájek, P. Review of methods for the combined assessment of seismic resilience and energy efficiency towards sustainable retrofitting of existing European buildings. Sustain. Cities Soc. 2022, 77, 103556.

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768.

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046.

- Trewin, D. Construction and the environment. In Year Book Australia; Australian Bureau of Statistics: Canberra, Australia, 2003; Volume 85, p. 640.

- Australian Bureau of Statistics (ABS). Production of Selected Construction Material; Australian Bureau of Statistics: Canberra, Australia, 2014.

- Australian Bureau of Statistics (ABS). Engineering Construction Activity, Australia; Australian Bureau of Statistics: Canberra, Australia, 2022.

- Macedo, K.R.M.; Cestari, S.P.; Mendes, L.C.; Albitres, G.A.V.; Rodrigues, D.C. Sustainable hybrid composites of recycled polypropylene and construction debris. J. Compos. Mater. 2018, 52, 2949–2959.

- Australian Bureau of Statistics (ABS). Waste Account, Australia, Experimental Estimates 2018–2019; Australian Bureau of Statistics: Canberra, Australia, 2020.

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107.

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416.

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780.

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290.

- Struhala, K.; Ostrý, M. Life-Cycle Assessment of phase-change materials in buildings: A review. J. Clean. Prod. 2022, 336, 130359.

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905.

- Andersen, S.C.; Birgisdottir, H.; Birkved, M. Life Cycle Assessments of Circular Economy in the Built Environment—A Scoping Review. Sustainability 2022, 14, 6887.

- Cheng, B.; Lu, K.; Li, J.; Chen, H.; Luo, X.; Shafique, M. Comprehensive assessment of embodied environmental impacts of buildings using normalized environmental impact factors. J. Clean. Prod. 2022, 334, 130083.

- Zuo, J.; Pullen, S.; Rameezdeen, R.; Bennetts, H.; Wang, Y.; Mao, G.; Zhou, Z.; Du, H.; Duan, H. Green building evaluation from a life-cycle perspective in Australia: A critical review. Renew. Sustain. Energy Rev. 2017, 70, 358–368.

- Kaufman, S.M. 3—Quantifying sustainability: Industrial ecology, materials flow and life cycle analysis. In Metropolitan Sustainability; Zeman, F., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 40–54.

- Augiseau, V.; Barles, S. Studying construction materials flows and stock: A review. Resour. Conserv. Recycl. 2017, 123, 153–164.

- Göswein, V.; Silvestre, J.D.; Habert, G.; Freire, F. Dynamic Assessment of Construction Materials in Urban Building Stocks: A Critical Review. Environ. Sci. Technol. 2019, 53, 9992–10006.

- Lausselet, C.; Urrego, J.P.F.; Resch, E.; Brattebø, H. Temporal analysis of the material flows and embodied greenhouse gas emissions of a neighborhood building stock. J. Ind. Ecol. 2020, 25, 419–434.

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-analysis of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935.

- Roh, S.; Tae, S. An integrated assessment system for managing life cycle CO2 emissions of a building. Renew. Sustain. Energy Rev. 2017, 73, 265–275.

- Hossain, M.U.; Ng, S.T. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23.

- Heeren, N.; Hellweg, S. Tracking Construction Material over Space and Time: Prospective and Geo-referenced Modeling of Building Stocks and Construction Material Flows. J. Ind. Ecol. 2019, 23, 253–267.

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 2019, 14, 043004.

- de Oliveira Fernandes, M.A.; Keijzer, E.; van Leeuwen, S.; Kuindersma, P.; Melo, L.; Hinkema, M.; Gonçalves Gutierrez, K. Material-versus energy-related impacts: Analysing environmental trade-offs in building retrofit scenarios in The Netherlands. Energy Build. 2021, 231, 110650.

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Inés Fernández, A. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542.

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A framework for sustainable and circular system design: Development and application on thermal insulation materials. Resour. Conserv. Recycl. 2020, 154, 104631.

- Zhang, X.; Zheng, R. Reducing building embodied emissions in the design phase: A comparative study on structural alternatives. J. Clean. Prod. 2020, 243, 118656.

- Robati, M.; Oldfield, P.; Nezhad, A.A.; Carmichael, D.G.; Kuru, A. Carbon value engineering: A framework for integrating embodied carbon and cost reduction strategies in building design. Build. Environ. 2021, 192, 107620.

- Pan, W.; Teng, Y. A systematic investigation into the methodological variables of embodied carbon assessment of buildings. Renew. Sustain. Energy Rev. 2021, 141, 110840.

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular Economy of Construction and Demolition Waste: A Literature Review on Lessons, Challenges, and Benefits. Materials 2021, 15, 76.

- Zhang, N.; Xi, B.; Li, J.; Liu, L.; Song, G. Utilization of CO2 into recycled construction materials: A systematic literature review. J. Mater. Cycles Waste Manag. 2022, 24, 2108–2125.

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 18, 93–113.

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250.

- Nodehi, M.; Taghvaee, V.M. Applying Circular Economy to Construction Industry through Use of Waste Materials: A Review of Supplementary Cementitious Materials, Plastics, and Ceramics. Circ. Econ. Sustain. 2022, 2, 987–1020.

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718.

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643.

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life cycle assessment of a Danish office building designed for disassembly. Build. Res. Inf. 2018, 47, 666–680.

- Shooshtarian, S.; Maqsood, T.; Caldera, S.; Ryley, T. Transformation towards a circular economy in the Australian construction and demolition waste management system. Sustain. Prod. Consum. 2022, 30, 89–106.

- Gunawardena, T.; Mendis, P. Prefabricated Building Systems—Design and Construction. Encyclopedia 2022, 2, 70–95.

- Nguyen, T.D.H.N.; Moon, H.; Ahn, Y. Critical Review of Trends in Modular Integrated Construction Research with a Focus on Sustainability. Sustainability 2022, 14, 12282.

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104.

- Luhar, I.; Luhar, S. A Comprehensive Review on Fly Ash-Based Geopolymer. J. Compos. Sci. 2022, 6, 219.

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Yang, J.; Ling, T.-C. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resour. Conserv. Recycl. 2021, 164, 105103.

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745.

- Cobirzan, N.; Muntean, R.; Thalmaier, G.; Felseghi, R.A. Recycling of Mining Waste in the Production of Masonry Units. Materials 2022, 15, 594.

- Zhang, P.; Wang, X.; Wang, J.; Zhang, T. Workability and Durability of Concrete Incorporating Waste Tire Rubber: A Review. J. Renew. Mater. 2023, 11, 745–776.

- Qaidi, S.M.A.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Althoey, F.; Zaid, O.; Sor, N.H. Rubberized geopolymer composites: A comprehensive review. Ceram. Int. 2022, 48, 24234–24259.

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Xiao, J.; Youssf, O. Dynamic performance of rubberised concrete and its structural applications—An overview. Eng. Struct. 2021, 234, 111990.

- Pham, T.M.; Chen, W.; Khan, A.M.; Hao, H.; Elchalakani, M.; Tran, T.M. Dynamic compressive properties of lightweight rubberized concrete. Constr. Build. Mater. 2020, 238, 117705.

- Dong, M.; Elchalakani, M.; Karrech, A.; Fawzia, S.; Mohamed Ali, M.S.; Yang, B.; Xu, S.-Q. Circular steel tubes filled with rubberised concrete under combined loading. J. Constr. Steel Res. 2019, 162, 105613.

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413.

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754.

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using bibliometric analysis. Energy Build. 2017, 155, 172–184.

- Ajayi, S.O.; Oyedele, L.O.; Ilori, O.M. Changing significance of embodied energy: A comparative study of material specifications and building energy sources. J. Build. Eng. 2019, 23, 324–333.

- Crawford, R.H. Validation of a hybrid life-cycle inventory analysis method. J. Environ. Manag. 2008, 88, 496–506.

- Crawford, R.H.; Bontinck, P.-A.; Stephan, A.; Wiedmann, T.; Yu, M. Hybrid life cycle inventory methods—A review. J. Clean. Prod. 2018, 172, 1273–1288.

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301.

- Dyskin, A.V.; Basarir, H.; Doherty, J.; Elchalakani, M.; Joldes, G.R.; Karrech, A.; Lehane, B.; Miller, K.; Pasternak, E.; Shufrin, I.; et al. Computational monitoring in real time: Review of methods and applications. Geomech. Geophys. Geo-Energy Geo-Resour. 2018, 4, 235–271.

- Cabeza, L.F.; Chàfer, M. Technological options and strategies towards zero energy buildings contributing to climate change mitigation: A systematic review. Energy Build. 2020, 219, 110009.

- Belussi, L.; Barozzi, B.; Bellazzi, A.; Danza, L.; Devitofrancesco, A.; Fanciulli, C.; Ghellere, M.; Guazzi, G.; Meroni, I.; Salamone, F.; et al. A review of performance of zero energy buildings and energy efficiency solutions. J. Build. Eng. 2019, 25, 100772.

- Fu, S.C.; Zhong, X.L.; Zhang, Y.; Lai, T.W.; Chan, K.C.; Lee, K.Y.; Chao, C.Y.H. Bio-inspired cooling technologies and the applications in buildings. Energy Build. 2020, 225, 110313.

- Omrany, H.; Chang, R.; Soebarto, V.; Zhang, Y.; Ghaffarianhoseini, A.; Zuo, J. A bibliometric review of net zero energy building research 1995–2022. Energy Build. 2022, 262, 111996.

- Moran, P.; Goggins, J.; Hajdukiewicz, M. Super-insulate or use renewable technology? Life cycle cost, energy and global warming potential analysis of nearly zero energy buildings (NZEB) in a temperate oceanic climate. Energy Build. 2017, 139, 590–607.

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365.

- Ambli, K.G.; Dodamani, B.M.; Jagadeesh, A.; Vanarotti, M.B. Heterogeneous composites for low and medium temperature thermal insulation: A review. Energy Build. 2019, 199, 455–460.

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604.

- Fawaier, M.; Bokor, B. Dynamic insulation systems of building envelopes: A review. Energy Build. 2022, 270, 112268.

- Cui, H.; Overend, M. A review of heat transfer characteristics of switchable insulation technologies for thermally adaptive building envelopes. Energy Build. 2019, 199, 427–444.

- Rupp, S.; Krarti, M. Analysis of multi-step control strategies for dynamic insulation systems. Energy Build. 2019, 204, 109459.

- van Roosmalen, M.; Herrmann, A.; Kumar, A. A review of prefabricated self-sufficient facades with integrated decentralised HVAC and renewable energy generation and storage. Energy Build. 2021, 248, 111107.

- Karanafti, A.; Theodosiou, T.; Tsikaloudaki, K. Assessment of buildings’ dynamic thermal insulation technologies-A review. Appl. Energy 2022, 326, 119985.

- Navarro, L.; de Garcia, A.; Solé, C.; Castell, A.; Cabeza, L.F. Thermal loads inside buildings with phase change materials: Experimental results. Energy Procedia 2012, 30, 342–349.

- Abden, M.J.; Tao, Z.; Alim, M.A.; Pan, Z.; George, L.; Wuhrer, R. Combined use of phase change material and thermal insulation to improve energy efficiency of residential buildings. J. Energy Storage 2022, 56, 105880.

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2020, 33, 101913.

- Lamrani, B.; Johannes, K.; Kuznik, F. Phase change materials integrated into building walls: An updated review. Renew. Sustain. Energy Rev. 2021, 140, 110751.

- Bekler, C.; Ayçam, İ.; Gökşen, F. Evaluation of Climate Adaptive Building Skins in the Last Decade. Period. Polytech. Archit. 2022, 53, 82–94.

- Loonen, R.C.G.M.; Trčka, M.; Cóstola, D.; Hensen, J.L.M. Climate adaptive building shells: State-of-the-art and future challenges. Renew. Sustain. Energy Rev. 2013, 25, 483–493.

- Bajcinovci, B.; Jerliu, F. Achieving Energy Efficiency in Accordance with Bioclimatic Architecture Principles. Environ. Clim. Technol. 2016, 18, 54–63.

- Nguyen, A.T.; Reiter, S. Bioclimatism in architecture: An evolutionary perspective. Int. J. Des. Nat. Ecodyn. 2017, 12, 16–29.

- Bugenings, L.A.; Kamari, A. Bioclimatic Architecture Strategies in Denmark: A Review of Current and Future Directions. Buildings 2022, 12, 224.

- Zilberberg, E.; Trapper, P.; Meir, I.A.; Isaac, S. The impact of thermal mass and insulation of building structure on energy efficiency. Energy Build. 2021, 241, 110954.

- Saroglou, T.; Meir, I.A.; Theodosiou, T.; Givoni, B. Towards energy efficient skyscrapers. Energy Build. 2017, 149, 437–449.

- Saroglou, T.; Theodosiou, T.; Givoni, B.; Meir, I.A. A study of different envelope scenarios towards low carbon high-rise buildings in the Mediterranean climate—Can DSF be part of the solution? Renew. Sustain. Energy Rev. 2019, 113, 109237.

- Pérez, G.; Rincón, L.; Vila, A.; González, J.M.; Cabeza, L.F. Green vertical systems for buildings as passive systems for energy savings. Appl. Energy 2011, 88, 4854–4859.

- Al-Kodmany, K. Greenery-Covered Tall Buildings: A Review. Buildings 2023, 13, 2362.

- Koch, K.; Ysebaert, T.; Denys, S.; Samson, R. Urban heat stress mitigation potential of green walls: A review. Urban For. Urban Green. 2020, 55, 126843.

- Pérez, G.; Coma, J.; Martorell, I.; Cabeza, L.F. Vertical Greenery Systems (VGS) for energy saving in buildings: A review. Renew. Sustain. Energy Rev. 2014, 39, 139–165.

- Bakhshoodeh, R.; Ocampo, C.; Oldham, C. Thermal performance of green façades: Review and analysis of published data. Renew. Sustain. Energy Rev. 2022, 155, 111744.

- Seyrek Şık, C.I.; Woźniczka, A.; Widera, B. A Conceptual Framework for the Design of Energy-Efficient Vertical Green Façades. Energies 2022, 15, 8069.

- Nagdeve, S.S.; Manchanda, S.; Dewan, A. Thermal performance of indirect green façade in composite climate of India. Build. Environ. 2023, 230, 109998.

- Mastouri, H.; Bahi, H.; Radoine, H.; Benhamou, B. Improving energy efficiency in buildings: Review and compiling. Mater. Today Proc. 2020, 27, 2999–3003.

- Mourão, J.; Gomes, R.; Matias, L.; Niza, S. Combining embodied and operational energy in buildings refurbishment assessment. Energy Build. 2019, 197, 34–46.

- Ongpeng, J.M.C.; Rabe, B.I.B.; Razon, L.F.; Aviso, K.B.; Tan, R.R. A multi-criterion decision analysis framework for sustainable energy retrofit in buildings. Energy 2022, 239, 122315.

- Bruneau, M.; Reinhorn, A.M. Overview of the resilience concept. In Proceedings of the 8th U.S. National Conference on Earthquake Engineering, San Francisco, CA, USA, 18–22 April 2006; Earthquake Engineering Research Institute: Oakland, CA, USA.

- Wang, J.; Zhao, H. High Performance Damage-Resistant Seismic Resistant Structural Systems for Sustainable and Resilient City: A Review. Shock. Vib. 2018, 2018, 8703697.

- Hassler, U.; Kohler, N. Resilience in the built environment. Build. Res. Inf. 2014, 42, 119–129.

- Bruneau, M.; Reinhorn, A.M. Exploring the Concept of Seismic Resilience for Acute Care Facilities. Earthq. Spectra 2007, 23, 41–62.

- Cimellaro, G.P.; Nagarajaiah, S.; Kunnath, S.K. (Eds.) Computational Methods, Seismic Protection, Hybrid Testing and Resilience in Earthquake Engineering. A Tribute to the Research Contributions of Prof. Andrei Reinhorn; Springler: Cham, Switzerland; Berlin/Heidelberg, Germany, 2015; Volume 33.

- De Domenico, D.; Ricciardi, G. Earthquake Protection of Existing Structures with Limited Seismic Joint: Base Isolation with Supplemental Damping versus Rotational Inertia. Adv. Civ. Eng. 2018, 2018, 6019495.

- Nuzzo, I.; Losanno, D.; Caterino, N.; Serino, G.; Bozzo Rotondo, L.M. Experimental and analytical characterization of steel shear links for seismic energy dissipation. Eng. Struct. 2018, 172, 405–418.

- Priestley, M.J.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the presss five-story precast concrete test building. PCI J. 1999, 44, 42–67.

- Soong, T.T.; Spencer, B.F., Jr. Supplemental energy dissipation: State-of-the-art and state-of-the-practice. Eng. Struct. 2002, 24, 243–259.

- Rodgers, G.W.; Mander, J.B.; Chase, J.G.; Dhakal, R.P. Beyond Ductility: Parametric Testing of a Jointed Rocking Beam-Column Connection Designed for Damage Avoidance. J. Struct. Eng. 2016, 142, C4015006.

- Nuzzo, I.; Losanno, D.; Cilento, F.; Caterino, N. Analytical and numerical modelling of shear-link device for seismic energy dissipation in frame structures. Eng. Struct. 2020, 214, 110630.

- Ji, X.; Wang, Y.; Ma, Q.; Okazaki, T. Cyclic Behavior of Replaceable Steel Coupling Beams. J. Struct. Eng. 2017, 143, 04016169.

- Garlock Maria, M.; Sause, R.; Ricles James, M. Behavior and Design of Posttensioned Steel Frame Systems. J. Struct. Eng. 2007, 133, 389–399.

- Eatherton, M.R.; Hajjar, J.F. Hybrid simulation testing of a self-centering rocking steel braced frame system. Earthq. Eng. Struct. Dyn. 2014, 43, 1725–1742.

- Kim, H.-J.; Christopoulos, C. Seismic design procedure and seismic response of post-tensioned self-centering steel frames. Earthq. Eng. Struct. Dyn. 2009, 38, 355–376.

- Wang, H.; Marino, E.M.; Pan, P.; Liu, H.; Nie, X. Experimental study of a novel precast prestressed reinforced concrete beam-to-column joint. Eng. Struct. 2018, 156, 68–81.

- Krauthammer, T. Modern Protective Structures; CRC Press: Boca Raton, FL, USA, 2008.

- Draganić, H.; Gazić, G.; Varevac, D. Experimental investigation of design and retrofit methods for blast load mitigation—A state-of-the-art review. Eng. Struct. 2019, 190, 189–209.

- UFC 3-340-02; Structures to Resist the Effects of Accidental Explosions. U.S. Department of Defense: Washington, DC, USA, 2014.

- Elsayed, M.; El-Dakhakhni, W.; Tait, M. Resilience Evaluation of Seismically Detailed Reinforced Concrete-Block Shear Walls for Blast-Risk Assessment. J. Perform. Constr. Facil. 2016, 30, 04015087.

- Li, B.; Pan, T.C.; Nair, A. A case study of the structural responses of a tall building in Singapore subjected to close-in detonations. Struct. Des. Tall Spec. Build. 2011, 20, 223–246.

More